A multi-cable assembly device for power transmission and its use method

A technology for assembling devices and cables, applied to cable laying equipment, insulators, etc., can solve the problems of fire, fire, and high production costs, and achieve the effects of solving the skin effect, improving performance, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

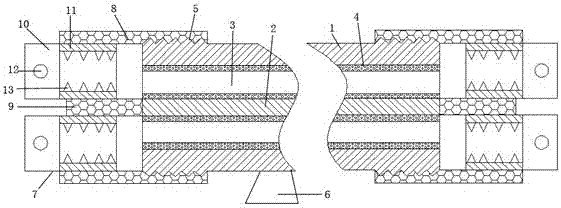

[0019] Embodiment 1: Assuming that the effective cross-sectional area of a certain type of cable conductor is 3000mm², and a copper conductor is used, the method of use is as follows:

[0020] The first step is to determine the total diameter. First, according to the power supply load, the effective diameter of the required power cable conductor is calculated to be 3000mm²;

[0021] The second step is to differentiate the cables. According to the effective diameter of 3000mm², the combination is based on the existing thinner power cables, which can be realized by parallel connection of six 500 mm² power cables;

[0022] The third step is assembly. According to the actual needs of the six 500 mm² power cables, select the corresponding sheath tube, and pass the 500 mm² power cables through the wire cavity respectively, and only one power cable passes through the wire cavity. Cables, and connect the power cable conductors in each wire-passing cavity to the corresponding wiring ...

Embodiment 2

[0024] Embodiment 2: Assuming that the effective cross-sectional area of a certain type of cable conductor is 3500mm², and copper conductors are used, the production process is as follows:

[0025] The first step is to determine the total diameter. First, according to the power supply load, the effective diameter of the required power cable conductor is calculated to be 3500mm²;

[0026] The second step is to differentiate the cables. According to the effective diameter of 3500mm², the combination is based on the existing thinner power cables, which can be realized by connecting seven 500 mm² power cables in parallel;

[0027] The third step is assembly. According to the actual needs of the seven 500 mm² power cables, select the corresponding sheath tube, and pass the 500 mm² power cables through the wire cavity respectively, and only one power cable passes through the wire cavity. Cables, and connect the power cable conductors in each wire-passing cavity to the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com