High-strength and high-toughness nylon composite material used for railway fasteners, and preparation method thereof

A nylon composite material, high-strength and high-toughness technology, applied in the field of nylon composite material and its preparation, can solve problems such as mechanical properties decline, achieve high toughness, excellent mechanical properties, and solve the effect of reducing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate the understanding of the present invention, the following will describe the present invention more fully and in detail in combination with preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

[0036] Unless otherwise defined, all technical terms used hereinafter have the same meanings as commonly understood by those skilled in the art. The terminology used herein is only for the purpose of describing specific embodiments, and is not intended to limit the protection scope of the present invention.

[0037] Unless otherwise specified, the various reagents and raw materials used in the present invention are commercially available products or products that can be prepared by known methods.

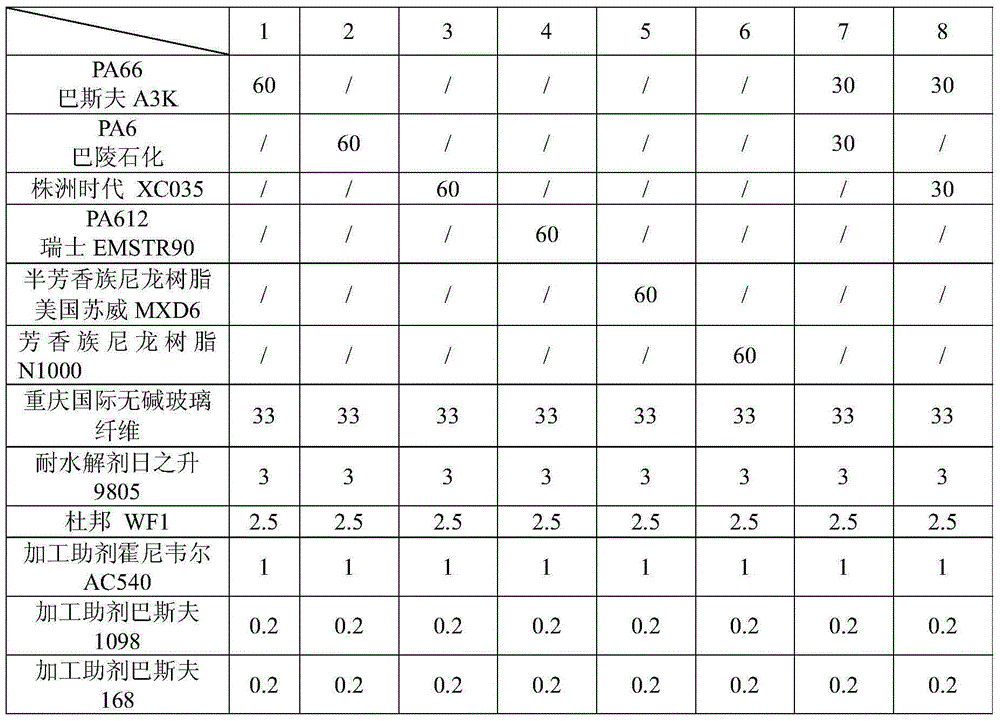

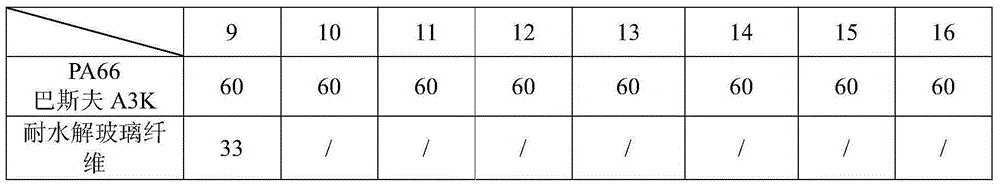

[0038] The preparation methods of the following specific examples are the same, all are to pre-mix the matrix resin, inorganic minerals, compatibilizer and processing aid in the mixer accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com