A New Process for Microstructure and Performance Optimization of Low Rhenium Single Crystal Castings

A new process and casting technology, which is applied in the microstructure and performance optimization of low-rhenium nickel-based single crystal alloys, can solve the problems of reducing the volume fraction of γ' phase, slow diffusion of refractory elements, and uneven initial structure of the alloy. , achieve the effect of improving strength and durability, eliminating microporosity and shrinkage cavity, and uniform distribution of strengthening phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail according to a specific embodiment below:

[0034] This example is a performance optimization method for low-rhenium nickel-based single crystal castings. The specific alloy composition is (wt%): Cr: 3%, Co: 10%, W: 8.5%, Mo: 1%, Re: 3.5 %, Ta: 5%, Al: 6%, Ti: 0.2%, Nb: 0.2%, Hf: 0.1%, and the rest is Ni.

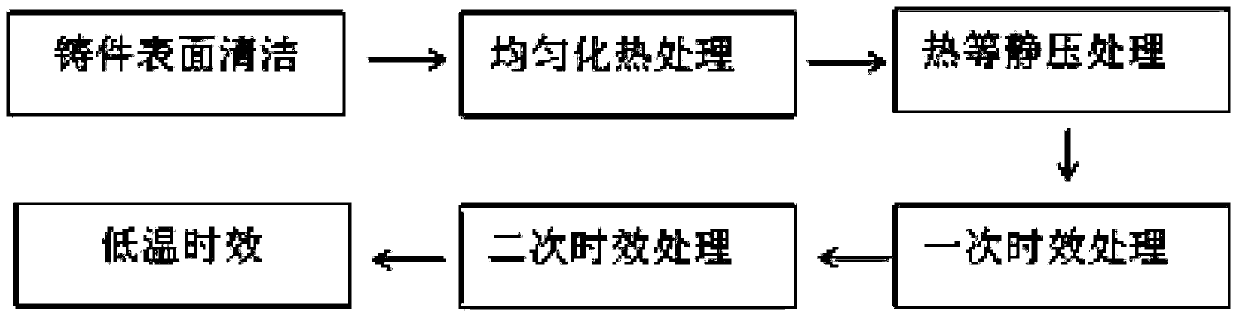

[0035] Step one, clean the casting surface. Use a high-pressure sandblasting machine to blow off the mold shell residue on the surface of the casting, and use a hard brush and sandpaper to clean the parts that are not easy to clean such as the corners, grooves, and variable cross-sections of the casting. Prepare a NaOH solution with a concentration of 20%-30%, heat the cleaning solution to 50°C, pour it into the water tank, then soak the cleaned casting in the cleaning solution for 15 minutes, take it out and soak it in clean water for 5 minutes and rinse it off.

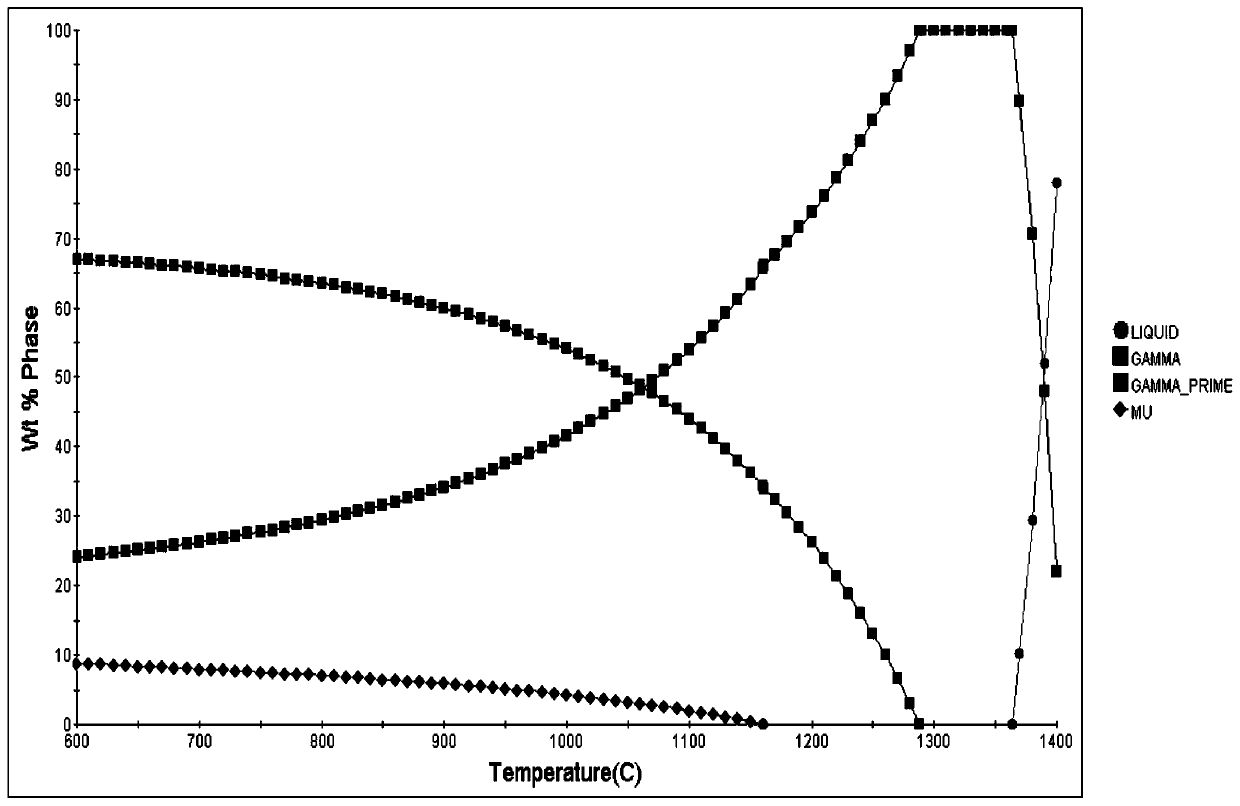

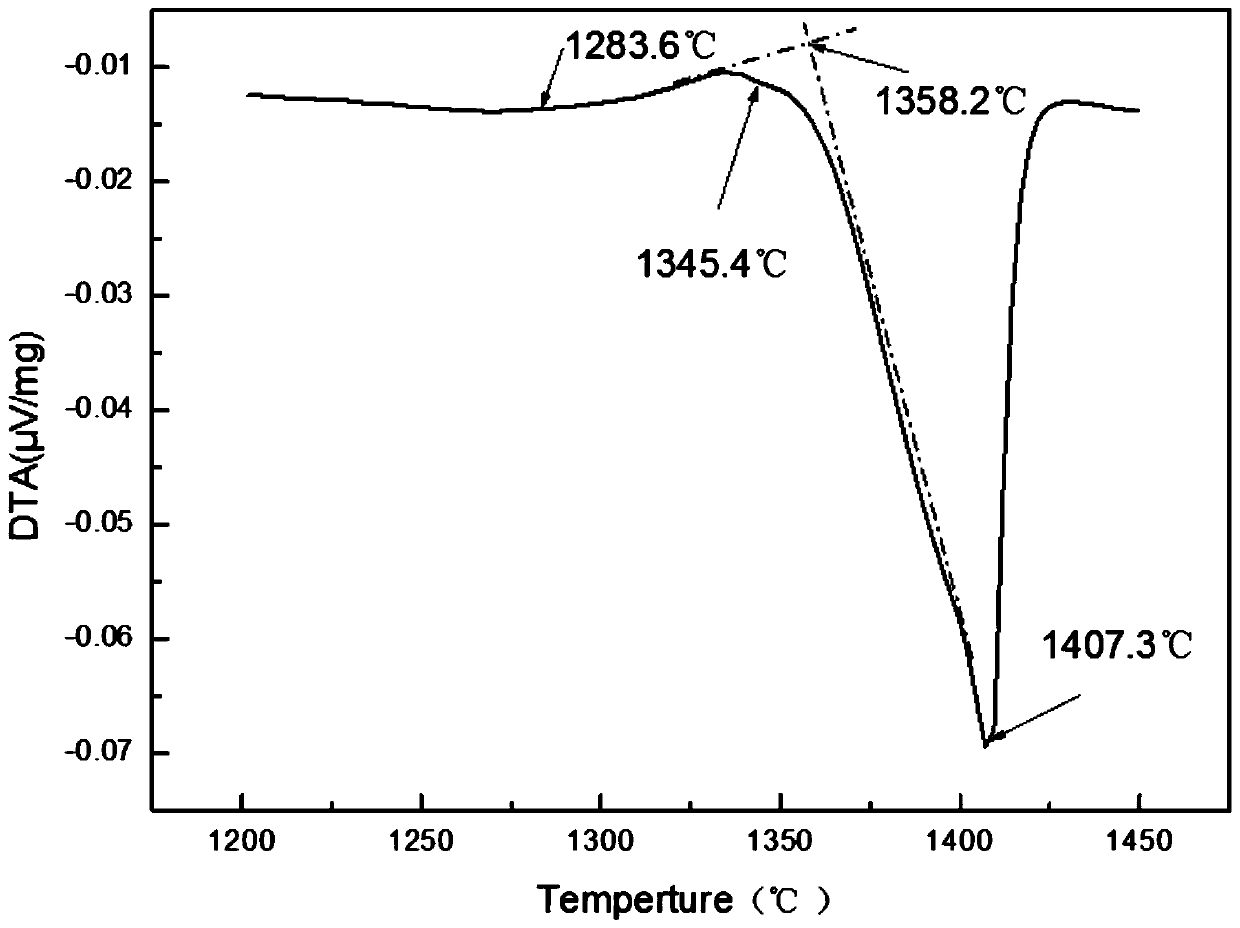

[0036] Step two, preliminarily determine the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solidus temperature | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com