Compound lithium iron phosphate material and preparing method thereof, positive electrode piece and lithium ion battery

A technology for compounding lithium iron phosphate and lithium iron phosphate, which is applied in the field of lithium ion batteries, can solve the problems of time-consuming secondary treatment, affecting the performance of positive electrode materials, doping, etc., and achieves elimination of micropores and surface defects, excellent safety performance, The effect of increasing material capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

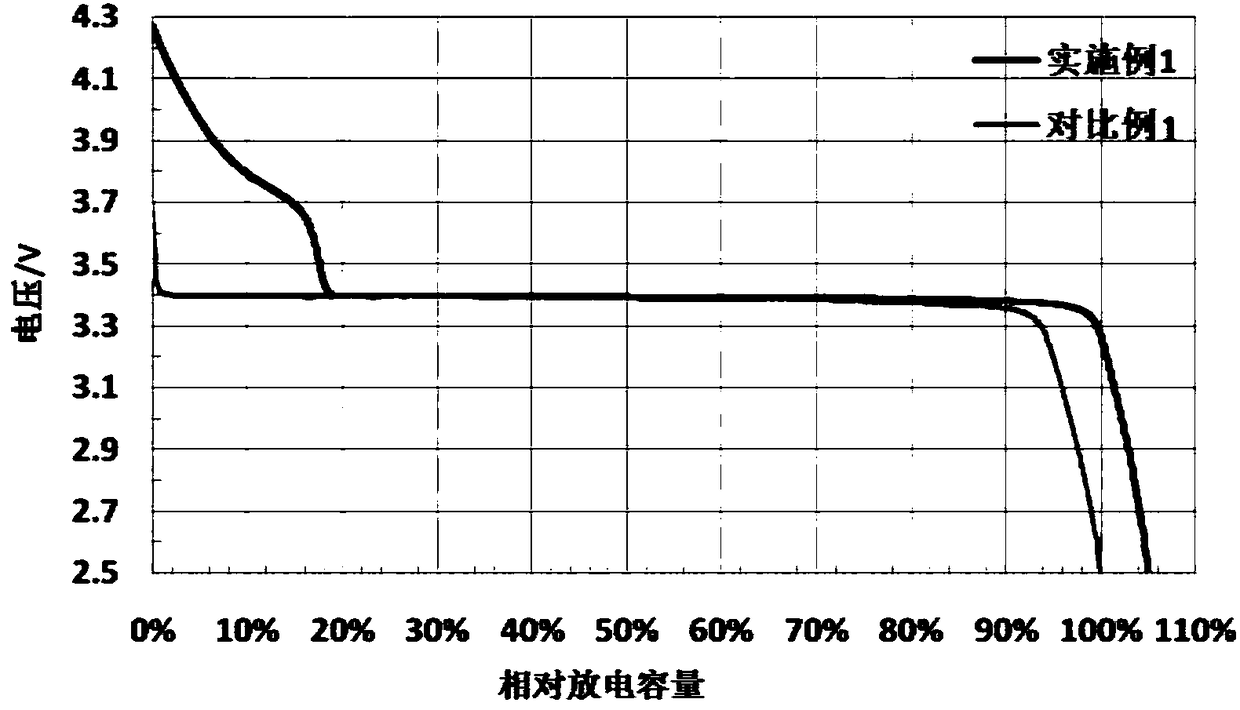

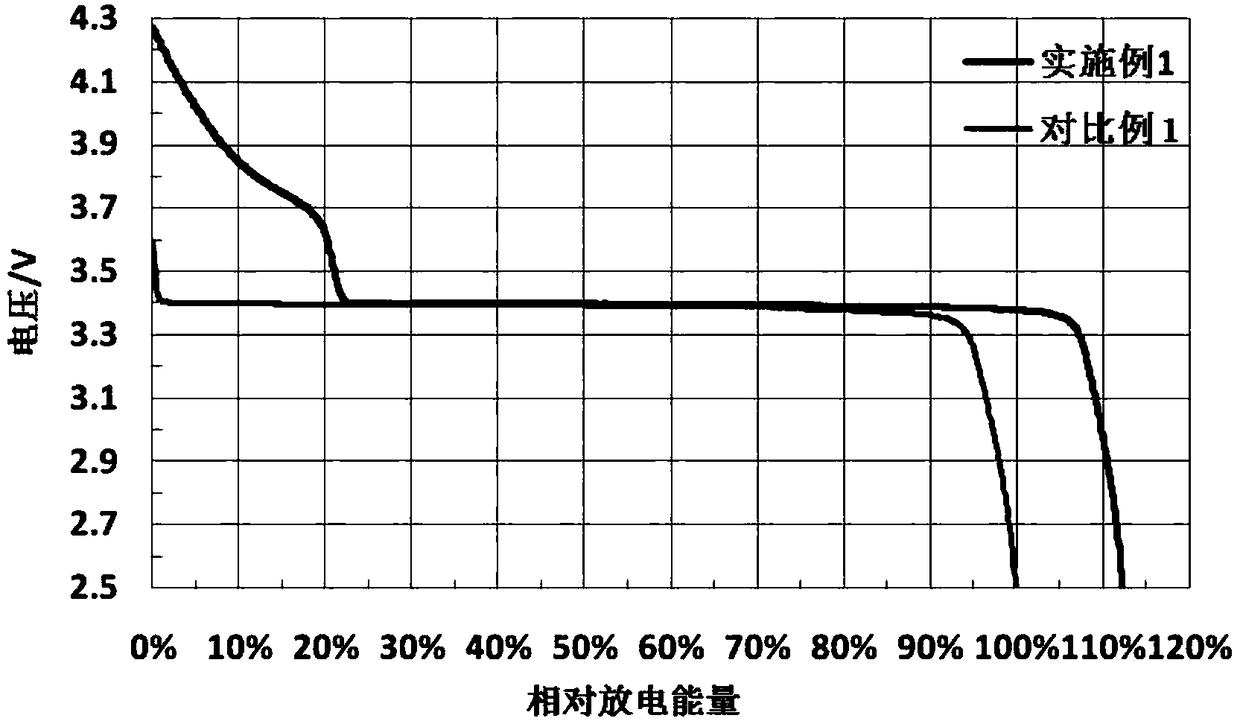

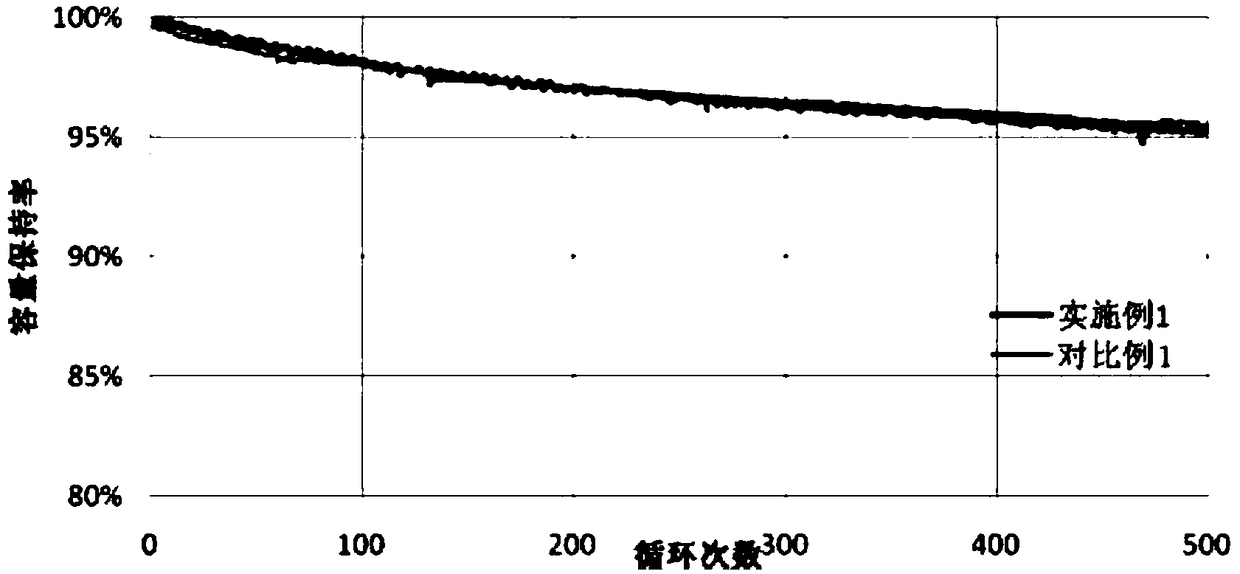

Embodiment 1

[0048] The composite lithium iron phosphate material of this embodiment is composed of the following components by mass percentage: 80% of lithium iron phosphate, 17% of NCM 622, 1% of carbon nanotubes, and 2% of conductive carbon black, wherein the particle size of lithium iron phosphate is D50=1 μm, the particle size of NCM622 is D50=4 μm.

[0049] The preparation method of the composite lithium iron phosphate material of the present embodiment comprises the following steps:

[0050] Take lithium iron phosphate, NCM622, carbon nanotubes, and conductive carbon black according to the above mass percentages, and set aside; mix lithium iron phosphate, NCM622, carbon nanotubes, and conductive carbon black evenly, and then keep warm at 500°C under the protection of high-purity nitrogen atmosphere 2h, namely; wherein the purity of high-purity nitrogen ≥ 99.999%.

[0051] The positive electrode sheet of this embodiment includes a positive electrode current collector and a positive ...

Embodiment 2

[0059] The composite lithium iron phosphate material of the present embodiment is composed of the following components by mass percentage: 80% of lithium iron phosphate, 17% of NCM 523, 1% of carbon nanotubes, and 2% of conductive carbon black, wherein the particle size of lithium iron phosphate is D50=1 μm, the particle size of NCM523 is D50=3.8 μm.

[0060] The preparation method of the composite lithium iron phosphate material of the present embodiment comprises the following steps:

[0061] Take lithium iron phosphate, NCM523, carbon nanotubes, and conductive carbon black according to the above mass percentages, and set aside; mix lithium iron phosphate, NCM523, carbon nanotubes, and conductive carbon black evenly, and then keep warm at 550°C under the protection of a high-purity nitrogen atmosphere 2h, namely; wherein the purity of high-purity nitrogen ≥ 99.999%.

[0062] The positive electrode sheet of this embodiment includes a positive electrode current collector and ...

Embodiment 3

[0070] The composite lithium iron phosphate material of this embodiment is composed of the following components by mass percentage: 77% of lithium iron phosphate, 20% of NCM 622, 1% of carbon nanotubes, and 2% of conductive carbon black, wherein the particle size of lithium iron phosphate is D50=1 μm, the particle size of NCM622 is D50=4 μm.

[0071] The preparation method of the composite lithium iron phosphate material of the present embodiment comprises the following steps:

[0072] Take lithium iron phosphate, NCM622, carbon nanotubes, and conductive carbon black according to the above mass percentages, and set aside; mix lithium iron phosphate, NCM622, carbon nanotubes, and conductive carbon black evenly, and then keep warm at 580°C under the protection of a high-purity nitrogen atmosphere 2.5h, namely; wherein the purity of high-purity nitrogen ≥ 99.999%.

[0073] The positive electrode sheet of this embodiment includes a positive electrode current collector and a posit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com