Wear-resisting low-carbon steel shot, preparation method thereof and centrifugal atomizing device

A centrifugal atomization, carbon steel shot technology, applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problems of reducing production costs, poor molten steel fluidity, and many surface cracks, achieving high cleaning efficiency, low cost, The effect of reducing cavities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

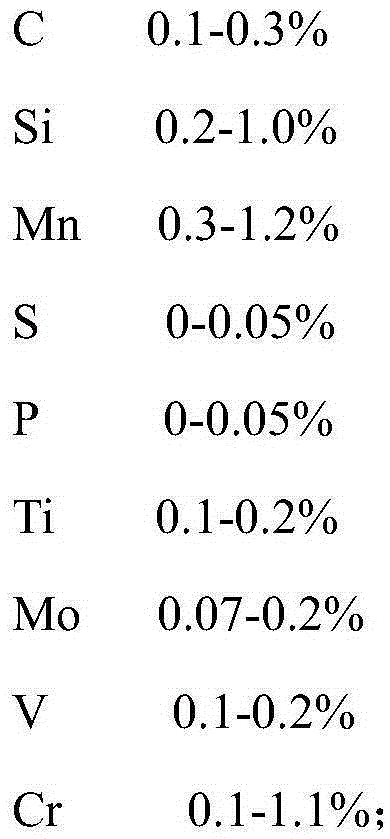

[0037] The wear-resistant low-carbon steel shot is expressed in mass percentage, and its chemical composition is as follows:

[0038]

[0039] The rest is Fe.

[0040] Its preparation method is as follows:

[0041] putting a steel plate with a carbon content of 0.15wt% into an intermediate frequency induction furnace, melting it at 1650°C, and then adding proportioned amounts of silicon, manganese, titanium, molybdenum, vanadium and chromium to obtain molten steel;

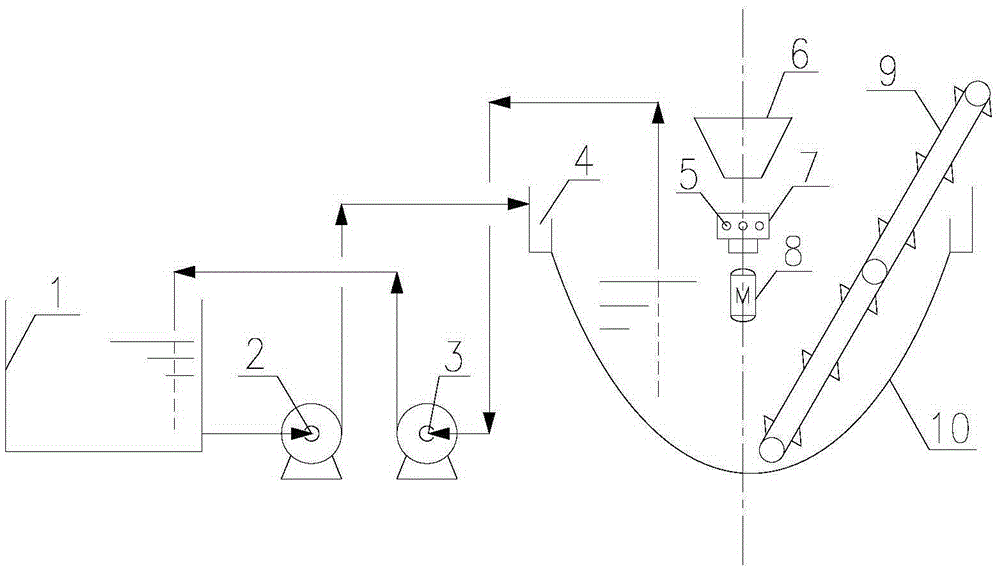

[0042] (2) Centrifugal atomization forming:

[0043] After the molten steel is shaped by a centrifugal atomization device, steel shots are obtained;

[0044] (3) Drying and coarse sieving:

[0045] Put the steel shot into the drying furnace for flow drying, the drying temperature is 35°C, and then sieve the dried steel shot to obtain the semi-finished product;

[0046] (4) Quenching and tempering:

[0047] Heat the semi-finished product to 920°C, hold it for 20 minutes, then water-cool and quench it, then ...

Embodiment 2

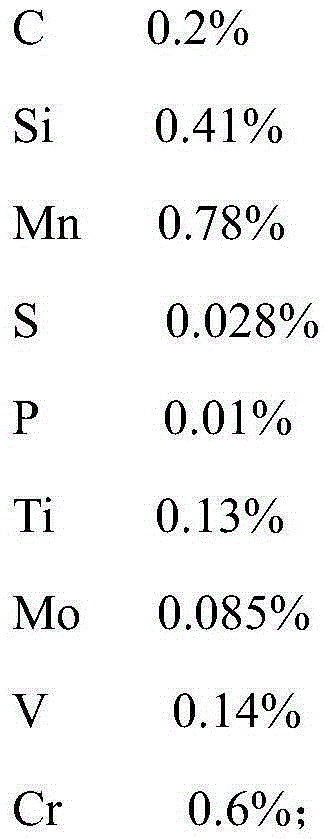

[0052] The wear-resistant low-carbon steel shot is expressed in mass percentage, and its chemical composition is as follows:

[0053]

[0054] The rest is Fe.

[0055] Its preparation method is as follows:

[0056] putting a steel plate with a carbon content of 0.15wt% into an intermediate frequency induction furnace, melting it at 1700°C, and then adding proportioned amounts of silicon, manganese, titanium, molybdenum, vanadium and chromium to obtain molten steel;

[0057] (2) Centrifugal atomization forming:

[0058] After the molten steel is shaped by a centrifugal atomization device, steel shots are obtained;

[0059] (3) Drying and coarse sieving:

[0060] Put the steel shot into the drying furnace for flow drying, the drying temperature is 40°C, and then sieve the dried steel shot to obtain the semi-finished product;

[0061] (4) Quenching and tempering:

[0062] Heat the semi-finished product to 890°C, hold it for 30 minutes, then water-cool and quench it, then ...

Embodiment 3

[0066] The wear-resistant low-carbon steel shot is expressed in mass percentage, and its chemical composition is as follows:

[0067]

[0068] The rest is Fe.

[0069] Its preparation method is as follows:

[0070] Putting the steel plate with a carbon content of 0.15wt% into an intermediate frequency induction furnace, melting it at 1750°C, and then adding proportioned amounts of silicon, manganese, titanium, molybdenum, vanadium and chromium to obtain molten steel;

[0071] (2) Centrifugal atomization forming:

[0072] After the molten steel is shaped by a centrifugal atomization device, steel shots are obtained;

[0073] (3) Drying and coarse sieving:

[0074] Put the steel shot into the drying furnace for flow drying, the drying temperature is 45°C, and then sieve the dried steel shot to obtain the semi-finished product;

[0075] (4) Quenching and tempering:

[0076] Heat the semi-finished product to 910°C, hold it for 40 minutes, then water-cool and quench it, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com