Heat-resisting casting Al-Cu alloy and preparation method

A technology of casting aluminum and copper alloys, which is applied in the field of metal materials, can solve problems such as exceeding 250 ° C or even higher, and can not meet the requirements, and achieve the effects of reducing segregation of alloy elements, improving strength and elongation, and reducing microporosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

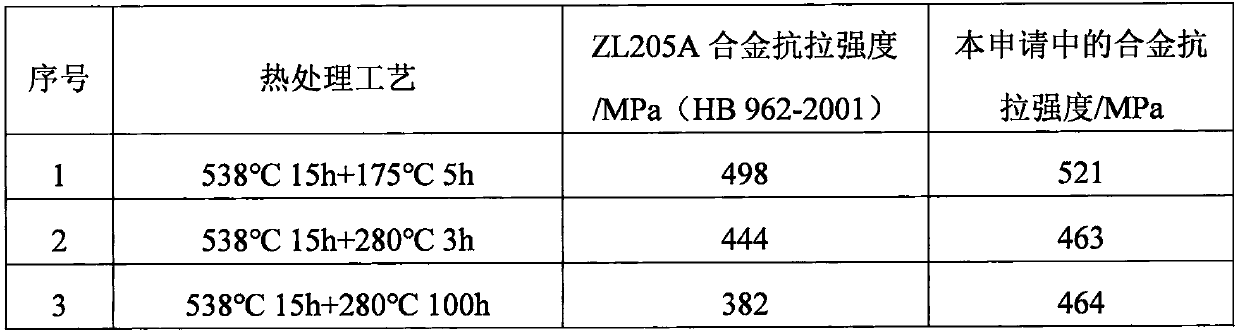

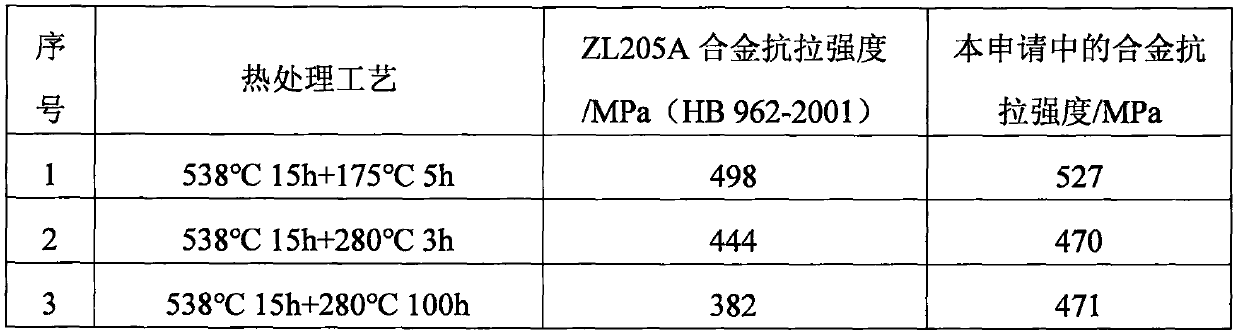

Embodiment 1

[0029] A heat-resistant cast aluminum-copper alloy disclosed in Example 1 has the following mass percentages of its components: Cu: 2.9%, Mn: 0.61%, Ti: 0.32%, Sc: 0.35%, Zr: 0.17%, Cd: 0.21 %, B: 0.003%, impurity is not more than 0.08%, and the balance is aluminum.

[0030] The preparation method of the heat-resistant cast aluminum-copper alloy containing the above-mentioned components is as follows:

[0031] Step 1: First heat the furnace to 300-400°C and keep it warm for 25 minutes, then add pure aluminum, AlCu50, AlTi4, AlSc2, AlZr4, AlMn10 (the content of elements in the master alloy meets the requirements of GB / T 27677-2011) in the middle The alloy is smelted so that the component contents of Cu, Ti, Sc, Zr, and Mn meet the aforementioned percentages. Raise the temperature of the furnace to 825°C and keep it warm for 1.5h. After the aluminum ingot and other components are completely melted into an aluminum alloy solution, add a part of Al5TiB1A master alloy (the element...

Embodiment 2

[0041] A heat-resistant cast aluminum-copper alloy disclosed in Example 2, the mass percentages of its components are as follows: Cu: 3.3%, Mn: 0.67%, Ti: 0.42%, Sc: 0.41%, Zr: 0.18%, Cd: 0.25% %, B: 0.01%, impurity is not more than 0.05%, and the balance is aluminum.

[0042] The heat-resistant casting aluminum-copper alloy of the component content described in embodiment 2, its preparation method is as follows:

[0043]The first step: first raise the temperature of the furnace to 350 ° C for 30 minutes, and then add pure aluminum, AlCu50, AlTi4, AlSc2, AlZr4, AlMn10 (the element content requirements in the master alloy meet the requirements of GB / T 27677-2011) master alloy Smelting, so that the content of components such as Cu, Ti, Sc, Zr, Mn meets the percentage of Example 2, the furnace is heated to 835 ° C, kept for 1.5 h, after the aluminum-copper alloy is completely melted, add a part of Al5TiB1A master alloy (according to Mass percentage, the content of adding B accou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com