Manufacturing method of a valve

A technology for manufacturing valves and shells, which is applied to valve details, valve devices, valve shell structures, etc., and can solve problems such as deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

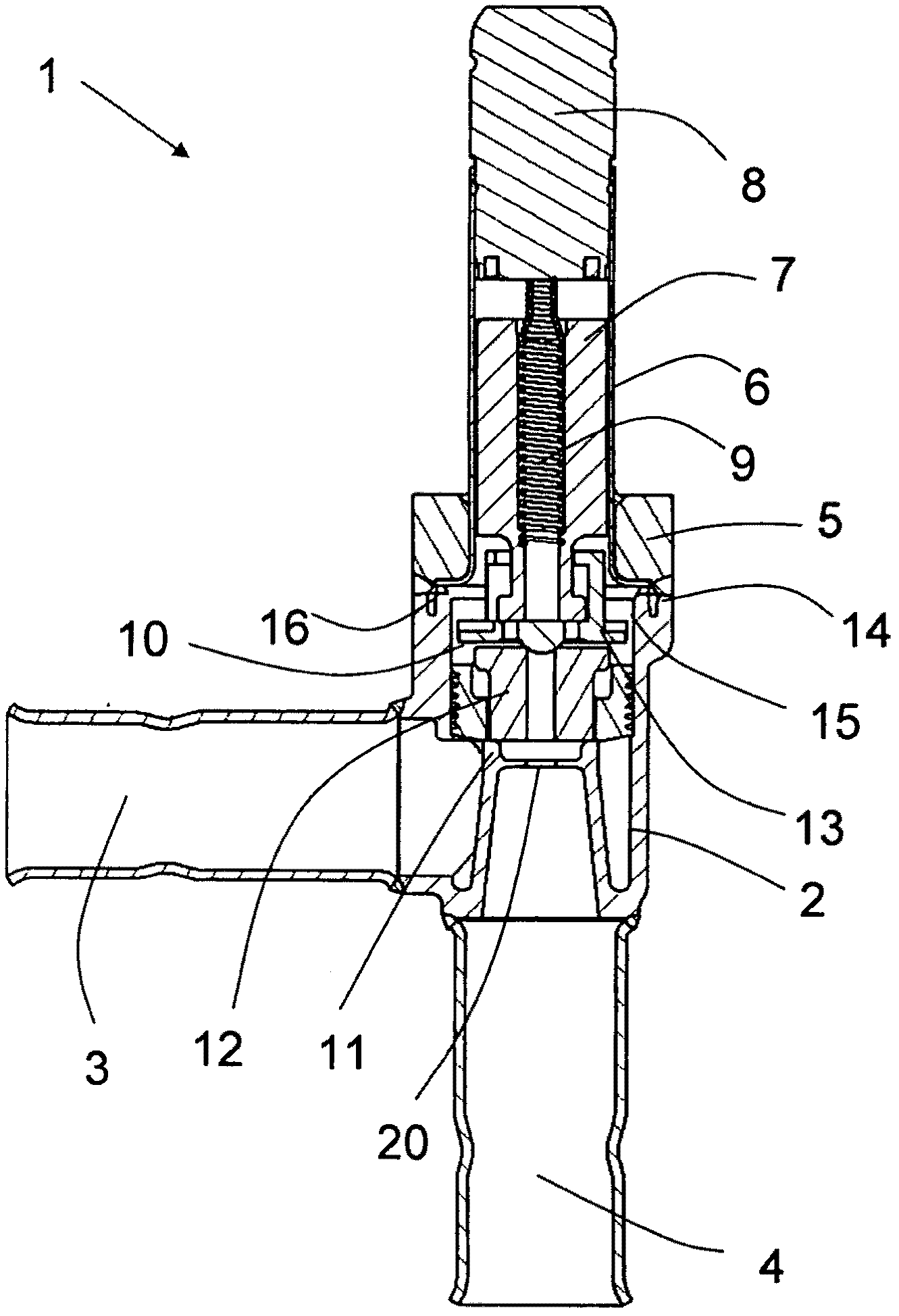

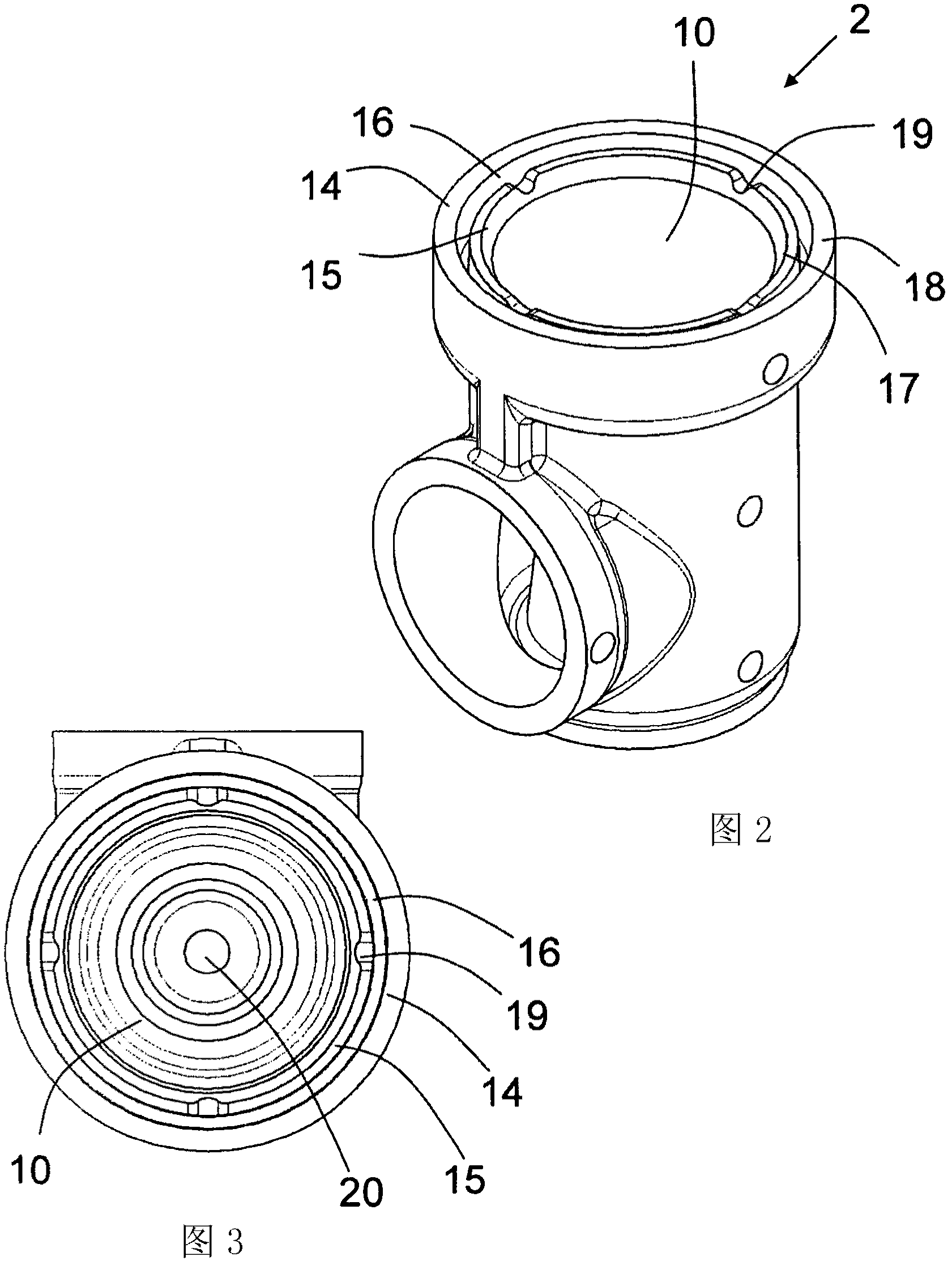

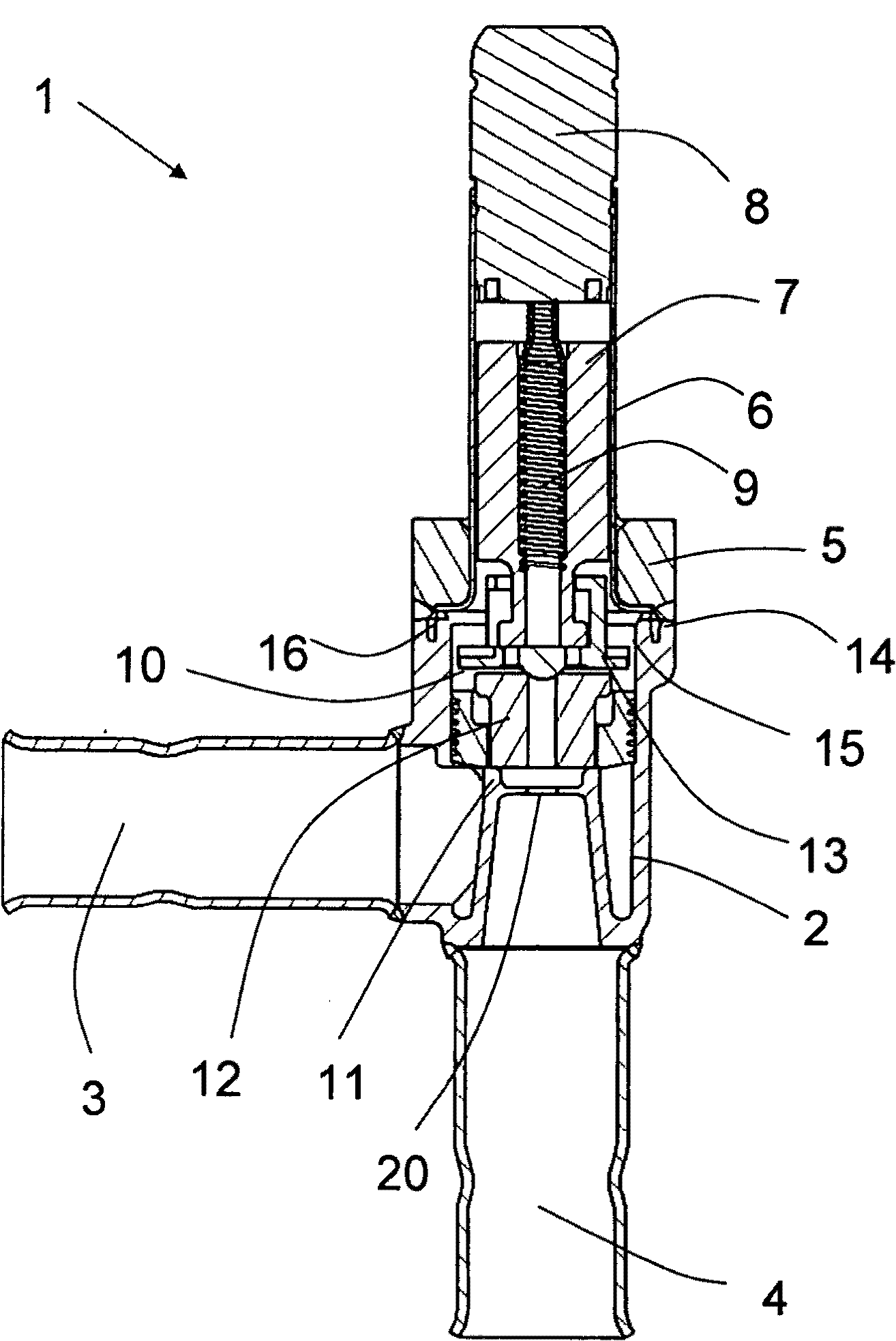

[0021] figure 1 Preferred embodiments of the present invention are shown. The valve 1 comprises a housing 2 , an inlet 3 , an outlet 4 and an upper part 5 . Fastened to the upper part 5 is a guide tube 6 around which the valve comprises a solenoid, but it is not shown in the figure. Inside the guide tube 6 is an armature 7 and an armature top 8 . The spring 9 keeps the valve closed when the armature 7 is not activated by the solenoid. The housing 2 comprises an inner chamber 10 and a valve seat 11 and a nozzle 20 , inside the inner chamber 10 are internal components including a servo piston 12 and a servo closing member 13 . The housing also includes a welding cover 14 , an inner liner 15 and a groove 16 , and the groove 16 is arranged between the welding cover 14 and the inner liner 15 .

[0022] The servo closing member 13 moves up and down inside the inner chamber 10 . The servo-close member 13 moves along the liner 15, so it is very important that the liner 15 is rest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com