Air energy heat pump outdoor unit facilitating rapid heat dissipation and method

An air-energy heat pump and outdoor unit technology, applied in heat pumps, refrigerators, fluid heaters, etc., can solve the problems of no rapid heat dissipation, difficult air discharge, and difficult air discharge, so as to achieve high safety and avoid energy waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

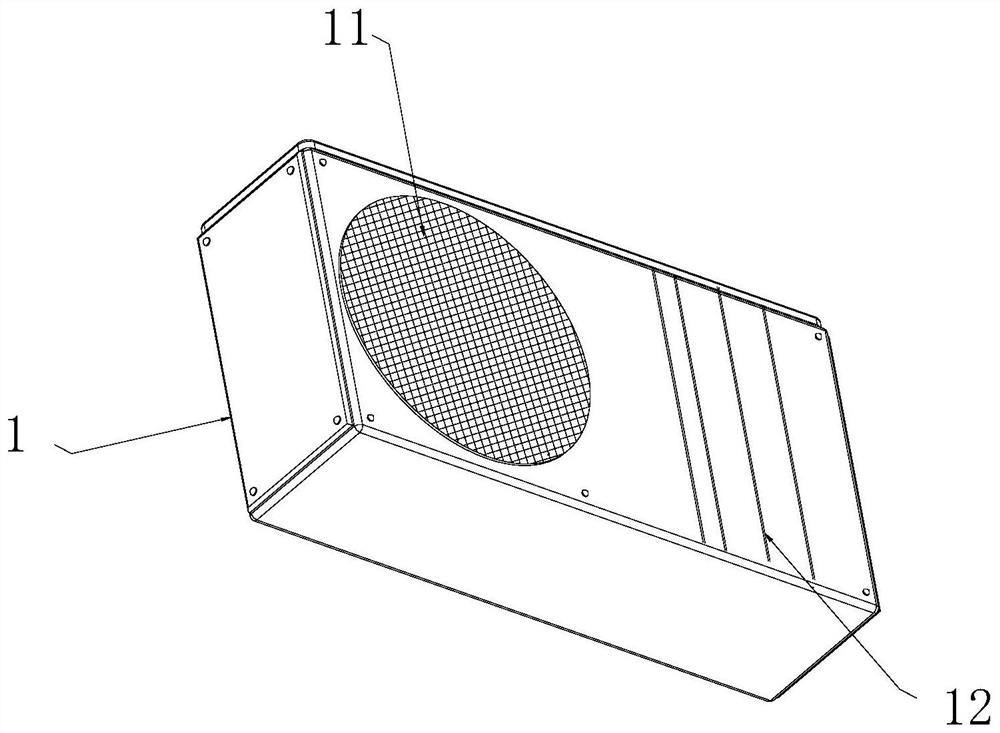

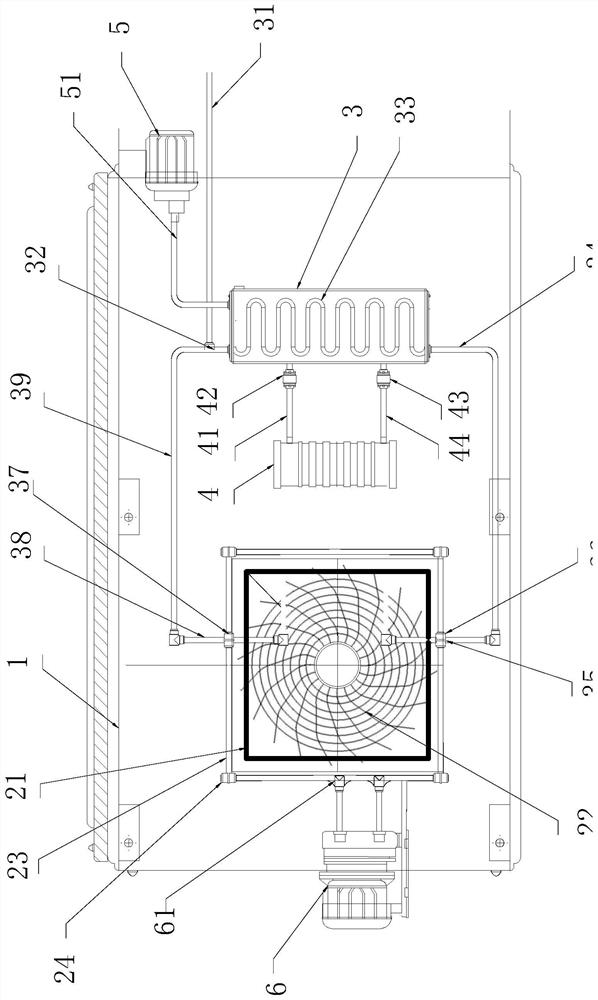

[0032] see figure 1 and image 3 , an air source heat pump outdoor unit that facilitates rapid heat dissipation, comprising a chassis 1, the chassis 1 is built with a heat pump installation area 11 and a cooling area 12, the heat pump installation area 11 is built with a thermal contact plate 21, and the thermal contact plate 21 is provided with an annular heat conducting frame 22, the edge of the thermal contact plate 21 is provided with an annular conduit 23, and the circular conduit 23 is provided with a circulation pump 24, and the cooling zone 12 is respectively provided with a low-pressure chamber 3 and a high-pressure chamber 4 , the cooling zone 12 is externally connected to a cooling water pipeline 31, the water delivery end of the cooling water pipeline 31 is provided with a three-way switch valve 32, and the low-pressure chamber 3 is built with a heat energy medium pipe 33, and the heat energy medium pipe 33 is in the shape of "S "Curve bending and folding design, ...

Embodiment 2

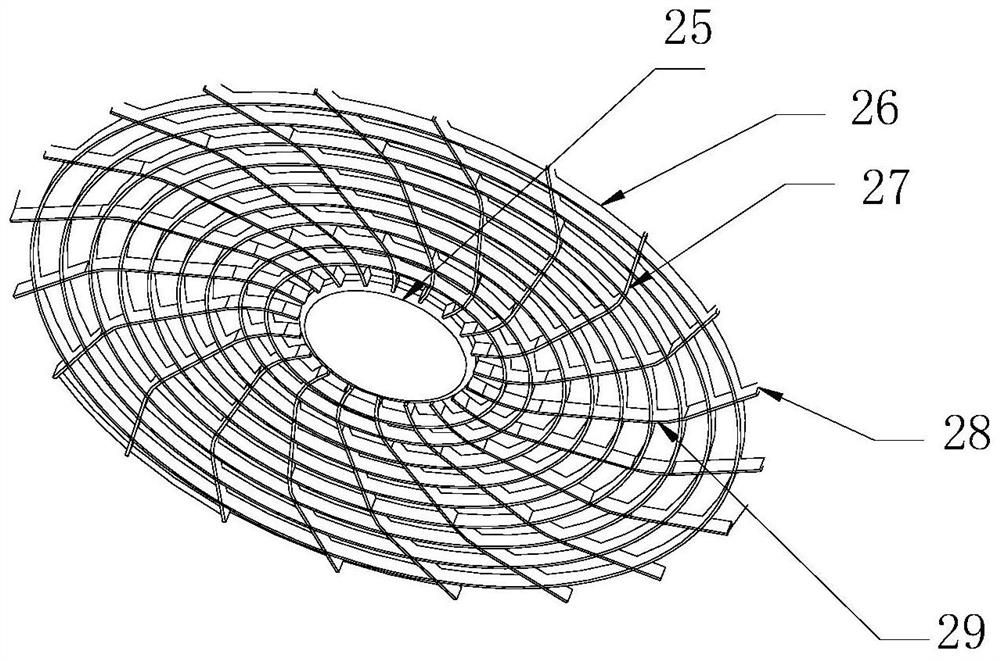

[0037] see image 3 , this embodiment is a further optimization of Embodiment 1. On the basis of it, a heat pump heat conduction substrate 25 is arranged in the middle of the annular heat conduction frame 22, and an annular outer diffusion frame 26 and a vertical The staggered frame 27 , the bottom of the annular outer diffusion frame 26 is provided with a thermal pad 29 fixed to the thermal contact plate 21 , and the vertical staggered frame 27 is in contact with the annular conduit 23 through the outer heat conduction sheet 28 . The heat pump heat conduction substrate 25, the annular outer diffusion frame 26 and the vertical interlaced frame 27 are all made of good heat conduction metal. The outer edge heat conducting sheet 28 is wound on the annular conduit 23 with a soft metal strip.

[0038] For the annular heat conduction frame 22, the heat pump heat conduction substrate 25 of this application is designed to perform close heat conduction with the heat pump, and then spr...

Embodiment 3

[0040] see figure 2 , this embodiment is a further optimization of Embodiment 1. On the basis of it, the other side of the thermal contact plate 21 is provided with a secondary cooling pump 6, and the secondary cooling pump 6 passes through the drainage branch pipe 61 and the annular conduit 23 connected. The annular conduit 23 forms a circulation loop with the secondary cooling pump 6 through the drainage branch pipe 61, which is used to reduce the temperature of the cooling water and play an auxiliary cooling effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com