Shield method contact channel starting tunnel portal steel sleeve adapting structure and mounting method thereof

A technology for connecting passages and supporting structures, applied in tunnels, shaft equipment, shaft linings, etc., can solve the problems of device deformation, affecting the progress of the project, low installation success rate, etc., achieving the effect of light weight, ensuring installation quality, and smooth lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

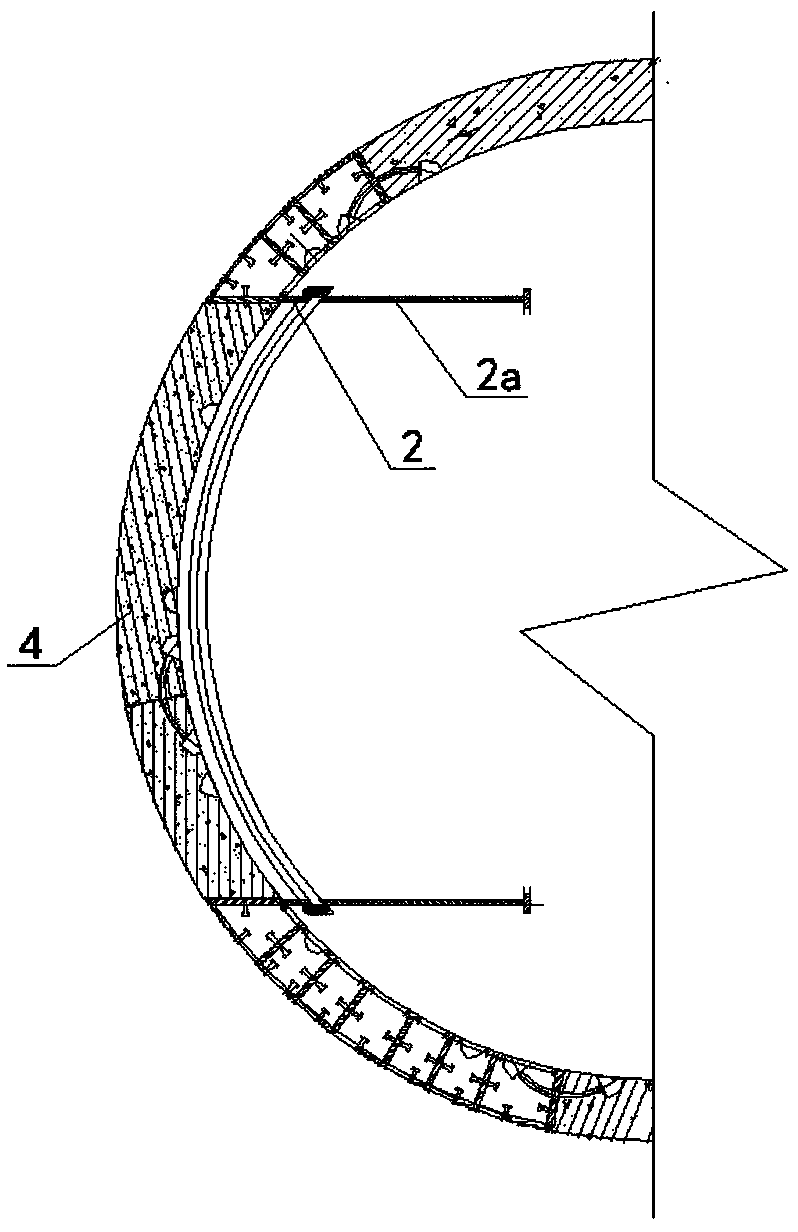

[0035] see Figure 4 and Figure 5 In this embodiment, a "T"-shaped interface is formed between the main line tunnel 7 and the communication channel 8. For the subway shield tunnel with an inner diameter of φ5500mm, the opening diameter of the communication channel of the shield method is φ3400mm. Therefore, the steel sleeve 1 and The interface between the starting portals 4 of the communication passage is a hyperboloid shape formed by the intersection of the large-diameter subway shield tunnel and the opening of the small-diameter communication passage.

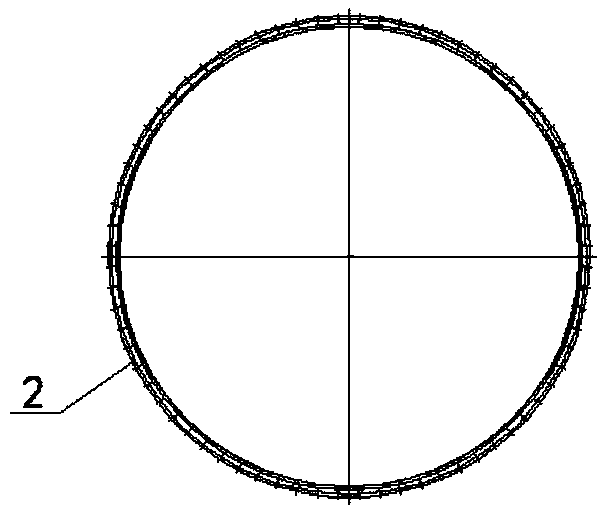

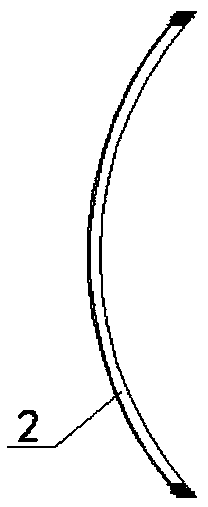

[0036] see figure 1 , figure 2 and Figure 2a In this embodiment, the steel sleeve receiving structure of the originating portal of the shield method communication channel is: the steel sleeve 1 used in the construction of the shield method connecting channel originating portal is separately set as the sleeve body 2a and located at A ring of receiving tube 2 at the front end of the sleeve body 2a, the front port of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com