Reflector of improved design and its manufacturing process, for the field of solar energy

A technology of reflectors and mirrors, applied in the field of solar energy and specular reflectors, to achieve the effect of simplified assembly, easy assembly, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

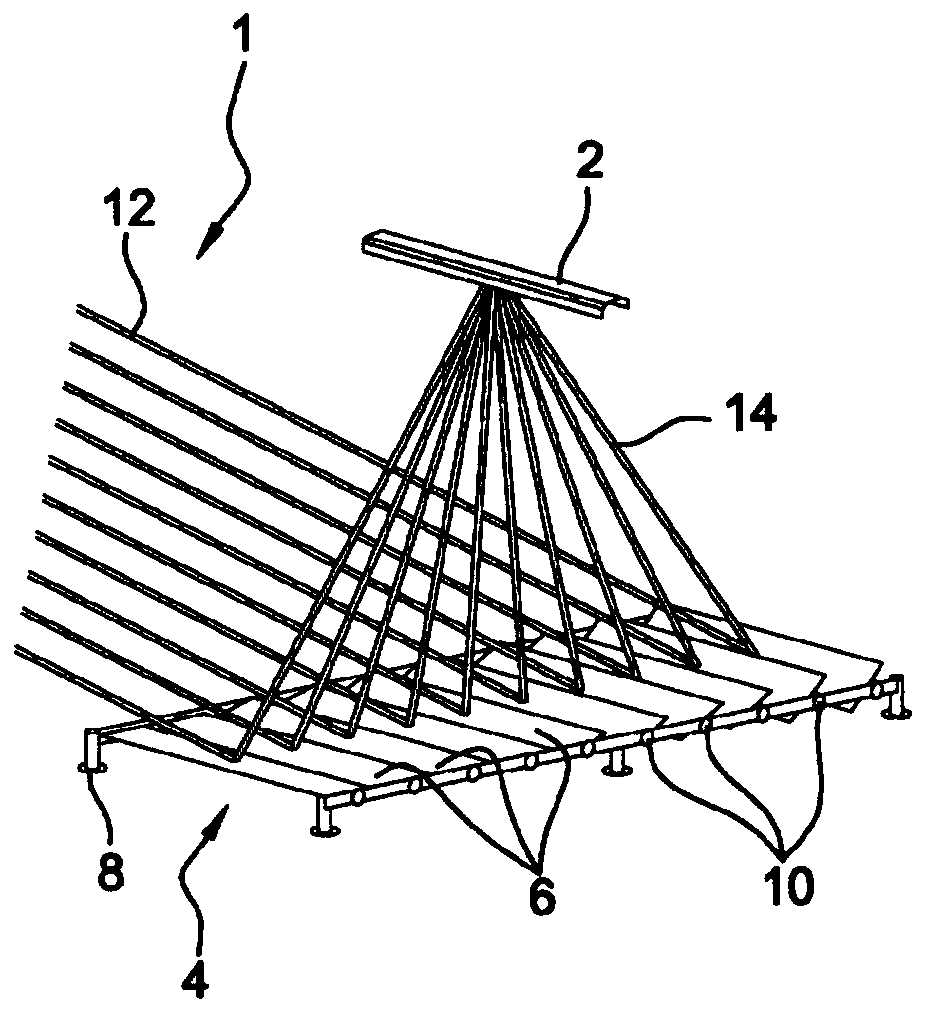

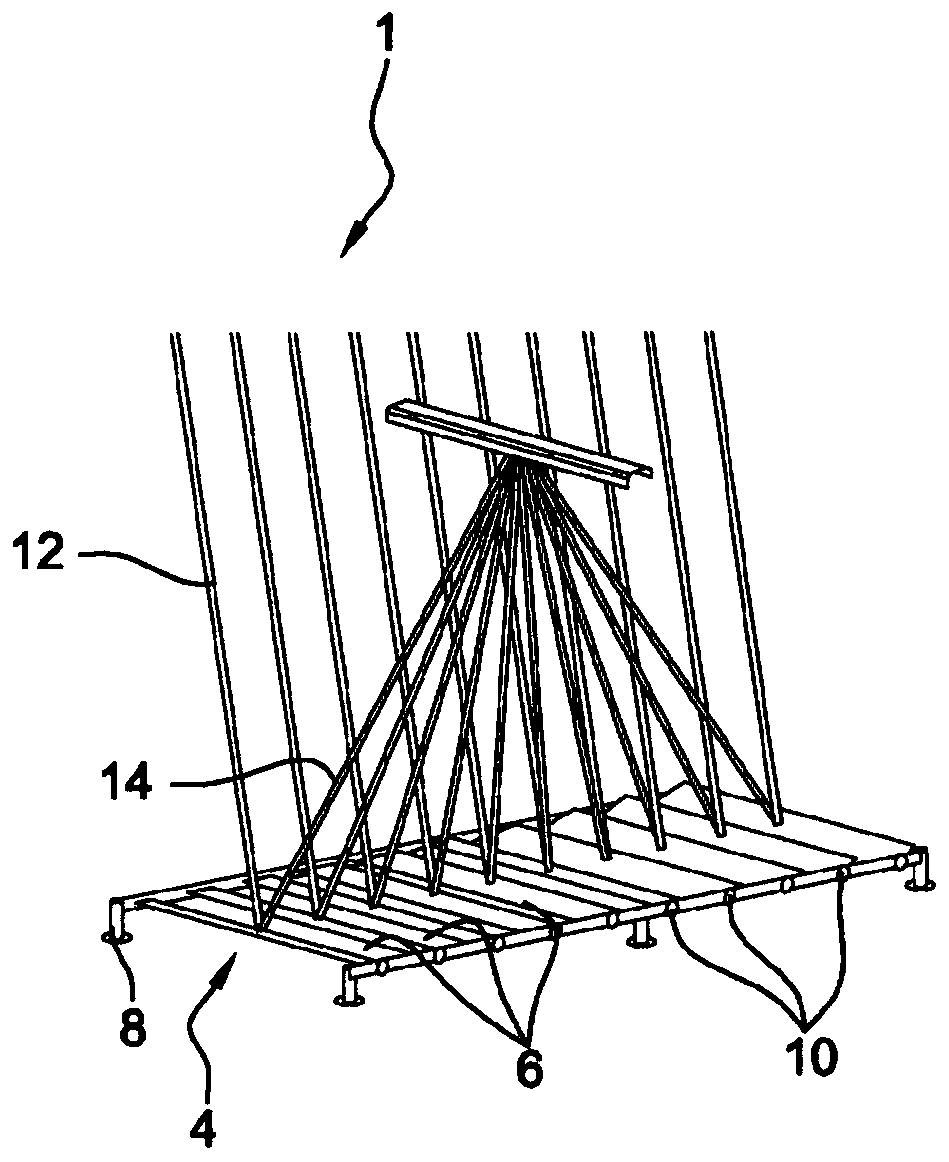

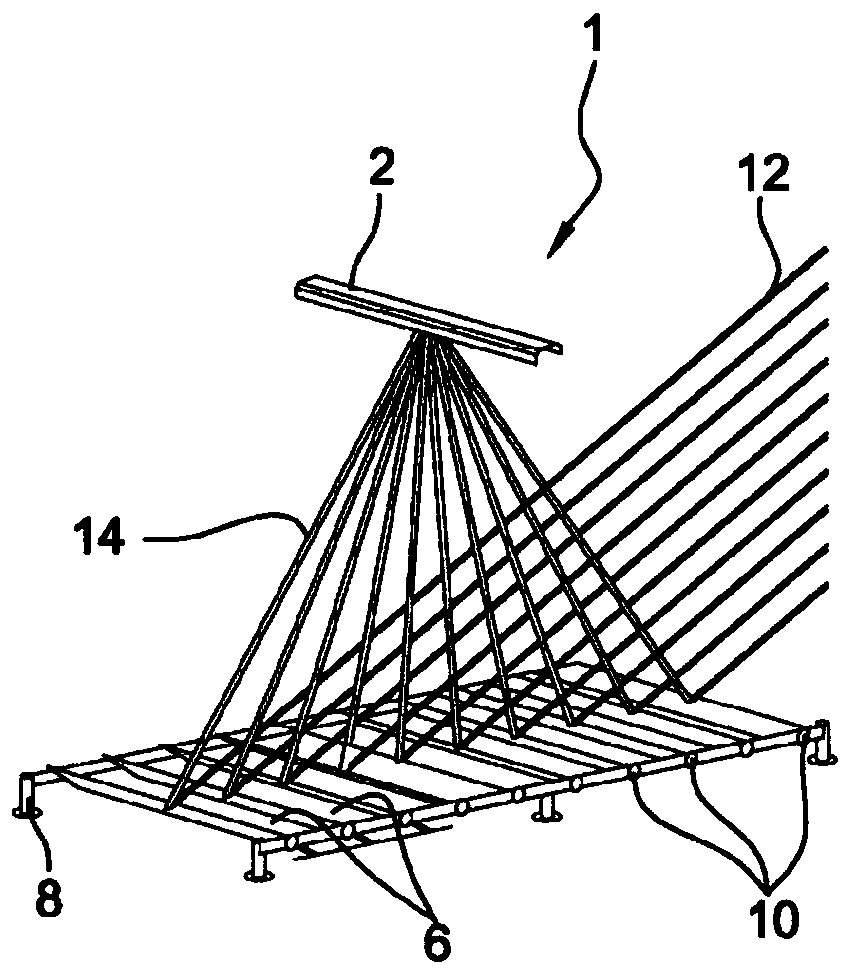

[0056] Reference is first made to Figures 1a to 1c, which illustrate a concentrated solar thermal power plant. Such a power plant 1 comprises a solar collector 2 and a reflector field 4 that concentrates solar radiation on the collector 2 . In this example the power station is a linear Fresnel type mirror, but alternatively it could also be a cylindrical parabolic type mirror, or in the case of a double curvature mirror it has a "solar tower" type Heliostats ("solar tower" type heliostats) or "dish" type parabolic mirrors.

[0057] The field 4 comprises a row of reflectors 6 arranged side by side. As will be described below, each reflector 6 comprises a mirror made of several individual mirror elements each assembled together on a structure via a frame dedicated to the invention. Furthermore, the support structure is freely mounted for rotation on the frame 8 along a preferably parallel pivot axis 10 . The rotation control can be independent or dependent and is controlled i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com