Replacing method for hydraulic oil cylinder of stacker-reclaimer

A technology of hydraulic cylinders and replacement methods, applied in the field of stackers and reclaimers, to achieve the effects of reducing maintenance risks, avoiding deformation, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0052] This implementation mode also provides another implementation mode, which is as follows:

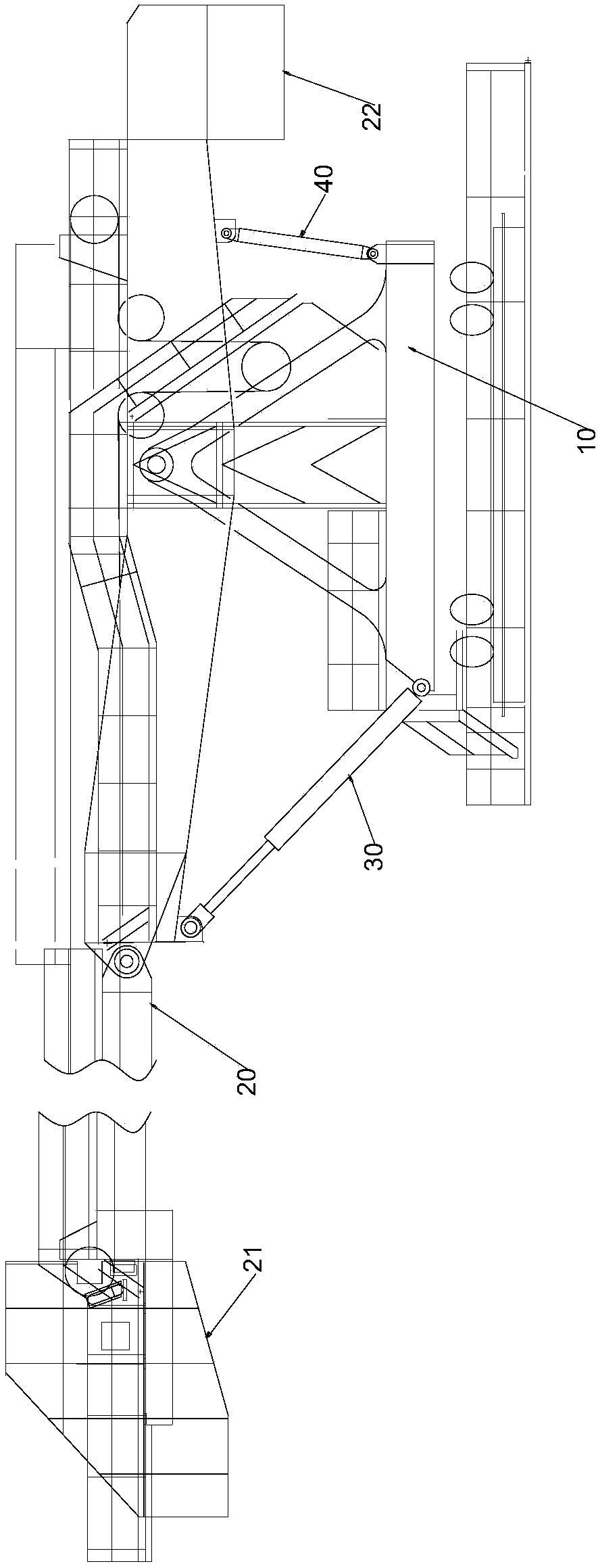

[0053] One end of the boom 20 has a bucket wheel mechanism 21, and the other end has a boom counterweight 22, and the hinge point between the boom 20 and the installation base 10 is located at the bucket wheel mechanism 21 and the boom counterweight. Between 22;

[0054] The stabilizing part 40 is used for pulling the boom 20, and the stabilizing part 40 is pulled between the hinge point and the boom counterweight 22 (such as figure 1shown). Wherein, the stabilizing component 40 may be one or more pull rods. Preferably, the stabilizing component 40 uses two pull rods symmetrical to the boom 20 to pull the boom 20, so that the boom is relatively fixed. Specifically, notify the operator of the stacker-reclaimer to stop the large machine at the designated location (generally next to the empty yard), use a crane to hoist the two tie rods to the installation position, and arrange the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com