Preparation method for mobile communication equipment outer shell

A technology for mobile communication equipment and shells, which is applied in branch office equipment, telephone communication, manufacturing tools, etc., can solve the problems of low processing efficiency, easy deformation, and low yield rate, and achieve improved yield rate, avoiding the risk of deformation, and good performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

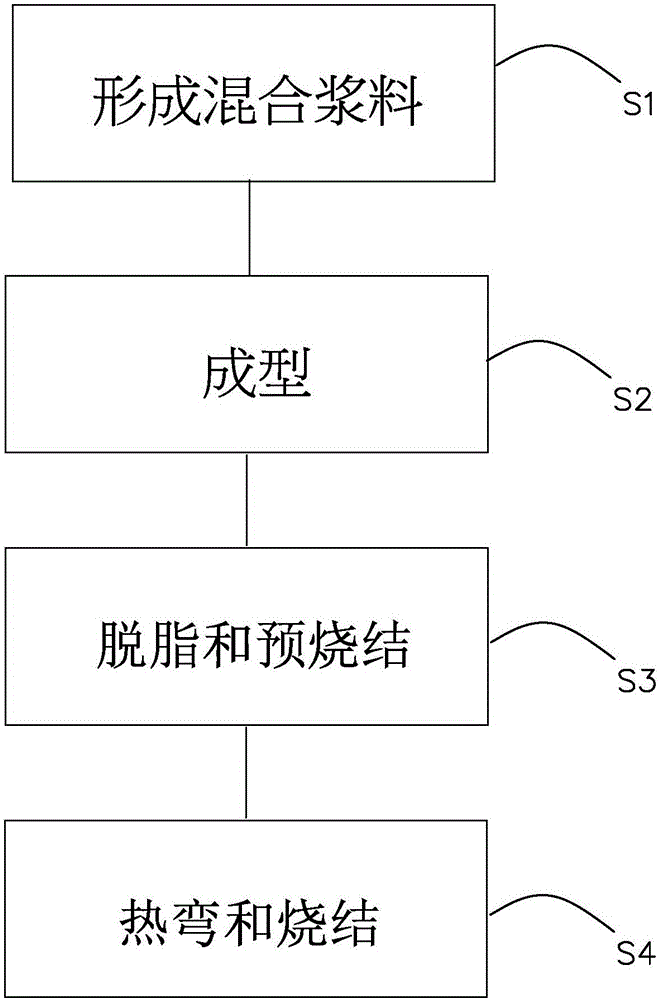

[0023] refer to figure 1 As shown, the present invention provides a method for preparing a communication device shell, which has a high product yield, thereby reducing production costs, and has beneficial effects such as product density, fracture toughness, and bending strength.

[0024] Specifically include the following steps:

[0025] Step S1, slurry mixing: mixing zirconia ceramic powder with a solvent and a binder to form a mixed slurry;

[0026] Wherein the zirconia ceramic powder is added with any one or more powders of yttrium oxide, titanium oxide and silicon oxide; the solvent is alcohol or toluene; the adhesive is any one of PVB1 or PVB2.

[0027] Step S2, forming: mixing the slurry to obtain a single-layer base film tape with a thickness of 0-1 mm by tape casting, and preparing superimposed film tapes of different thicknesses on the base f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com