Preparation method of wound trapezoidal cell and trapezoidal cell

A cell and trapezoidal technology, which is applied in the field of polymer lithium-ion battery manufacturing, can solve the problems of short standby time of equipment, high stress at the step transition of step cells, and potential safety hazards, so as to improve storage space utilization and continuous appearance Smooth down, improve the effect of standby time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above and other objects, features and advantages of the present invention more apparent, the following specifically cites the embodiments of the present invention, together with the accompanying drawings, for a detailed description as follows.

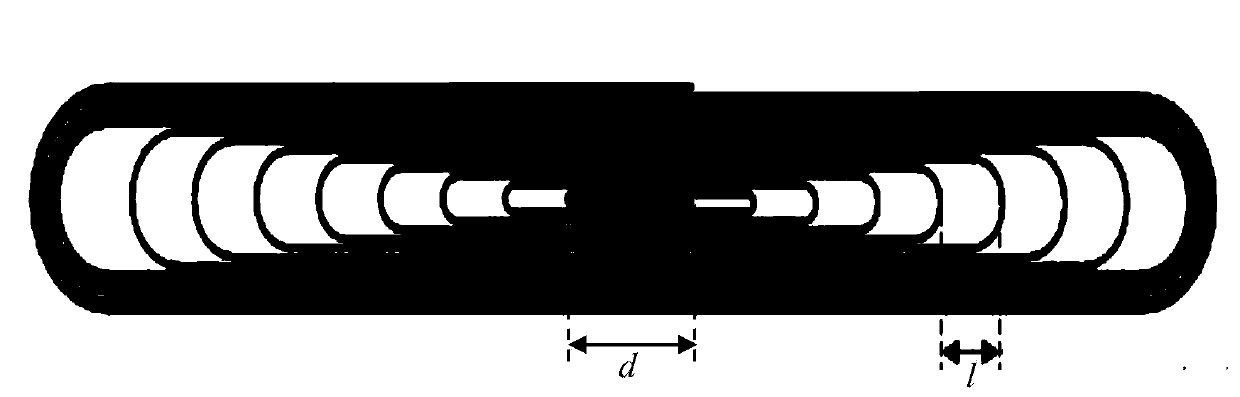

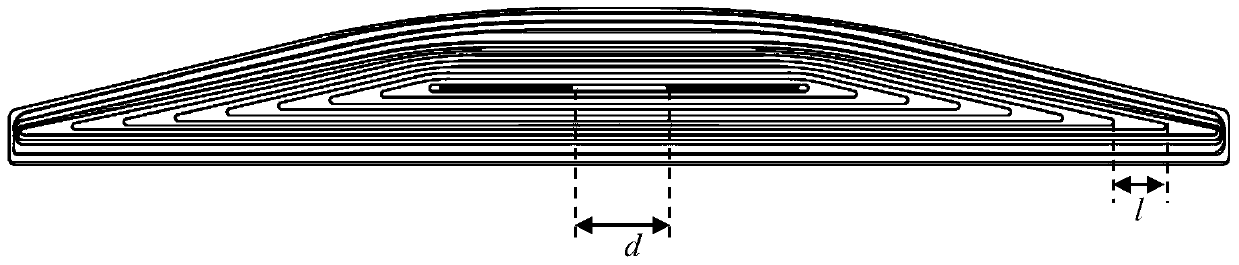

[0020] The purpose of the present invention is to prepare a cell with a trapezoidal cross section, so that the lithium battery made from the cell can be placed in a product with a reserved storage space of a special shape, so as to make full use of the reserved space of the product , to maximize the cell design capacity. The preparation method of the winding type trapezoidal electric core of the present invention is as follows:

[0021] Coating active material on one side of the negative electrode collector to make a negative electrode sheet, and coating active material on both sides of the positive electrode collector to make a positive electrode sheet; the negative electrode collector can be made of copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com