Method of segment prefabricated bridge long and short line method combined bidirectional matching prefabrication

A technology of two-way matching and short-line method, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems that long-term and short-line methods cannot be carried out at the same time, long construction time on site, and poor concrete quality, so as to improve prefabrication efficiency and construction The effect of small footprint and controllable prefabrication precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as figure 1 As shown, it schematically shows the prefabrication sequence of linear bridge segments. In this embodiment, 10 prefabricated segments are taken as an example, which are marked as #1-#10 segments from left to right.

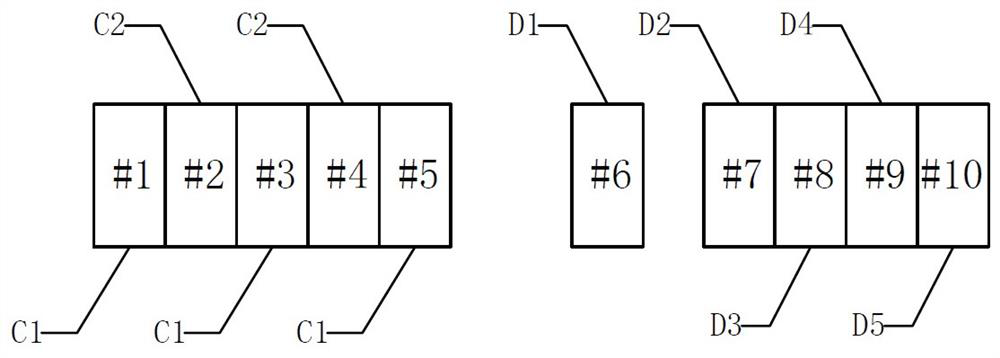

[0026] Step S1, allocate the prefabricated box girder segment C1 required by the long-line method and the prefabricated box girder segment D2-Dn required by the short-line method in the same prefabricated sequence according to the bridge type, and reserve one in the middle of the prefabricated sequence for the long The stub joins the matching poured box girder segment D1.

[0027] In this embodiment, the long and short line prefabrication distribution of the 10 prefabricated segments is as follows: figure 2 As shown, the long-line method can prefabricate three box girder segments C1 at the same time, and the box girder segment C2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com