Prefabrication method of pre-embedded steel plate type UHPC small box girder end diaphragm

A pre-embedded steel plate and small box girder technology, which is applied to bridges, manufacturing tools, bridge materials, etc., can solve the problems of large amount of on-site construction work, self-heavy prestressed reinforced concrete structures, and large amount of on-site pouring, which is beneficial to Structural stress, improving prefabrication efficiency, and improving the effect of integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

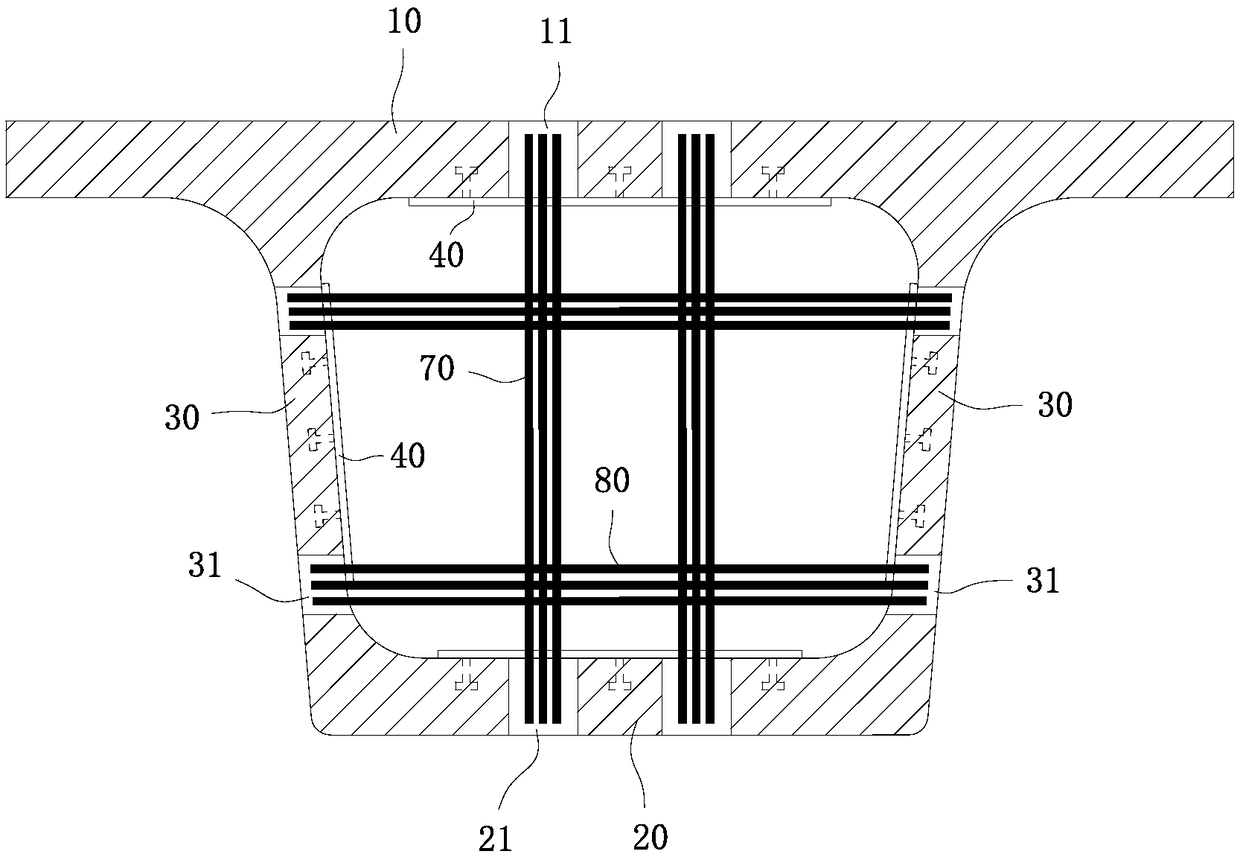

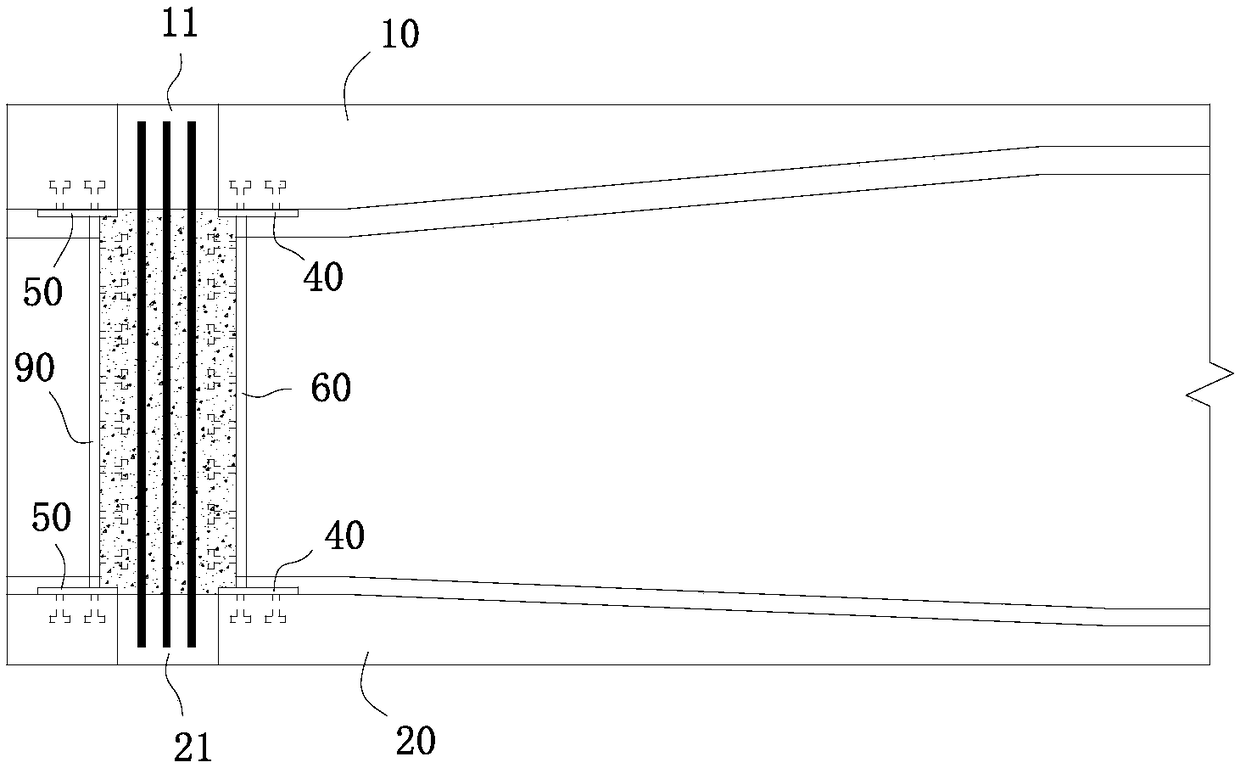

[0025] refer to Figure 1 to Figure 2 , the prefabrication method of the prefabricated steel plate type UHPC small box girder end diaphragm of the present invention comprises the following steps:

[0026] S1. Prefabricate the box girder body consisting of top plate 10, bottom plate 20 and web 30 by pouring ultra-high performance concrete through the outer formwork and inner formwork, and the top plate 10, bottom plate 20 and web plate at the same cross-sectional position at the end of the box girder body 30 are respectively reserved with a top plate reserved hole 11, a bottom plate reserved hole 21 and a web reserved hole 31. The alignment between the top plate reserved hole 11 and the bottom plate reserved hole 21 is in the same vertical direction. The plate reserved holes 31 are also aligned in the same horizontal direction. The bottom plate 20 and the web plate 30 of the box girder body are pre-embedded with slow bonding prestressed tendons along the longitudinal direction....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com