Sea sand recycled mixed concrete member

A concrete and sea sand technology, applied in the direction of supply devices, ceramic molding machines, molds, etc., can solve the problems of inability to meet the large-scale prefabrication requirements of sea sand concrete, low efficiency of anti-rust film, deterioration of concrete structure, etc., and achieve high prefabrication efficiency , Improve the strength and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

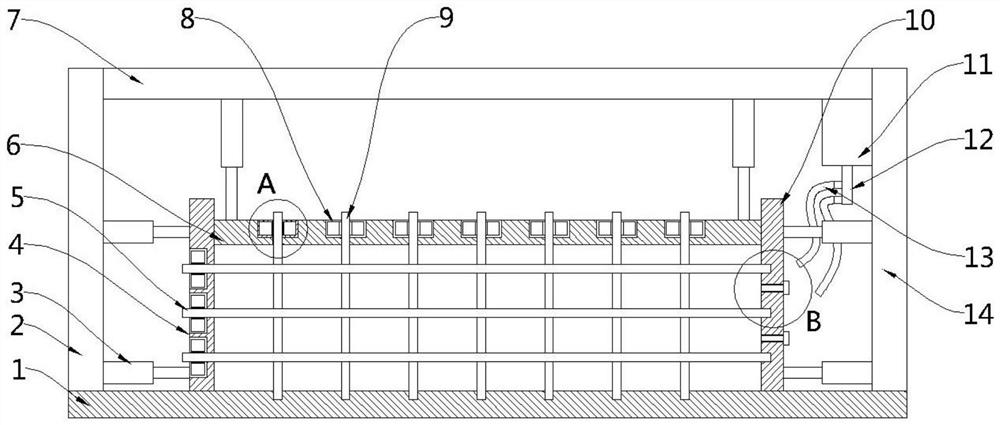

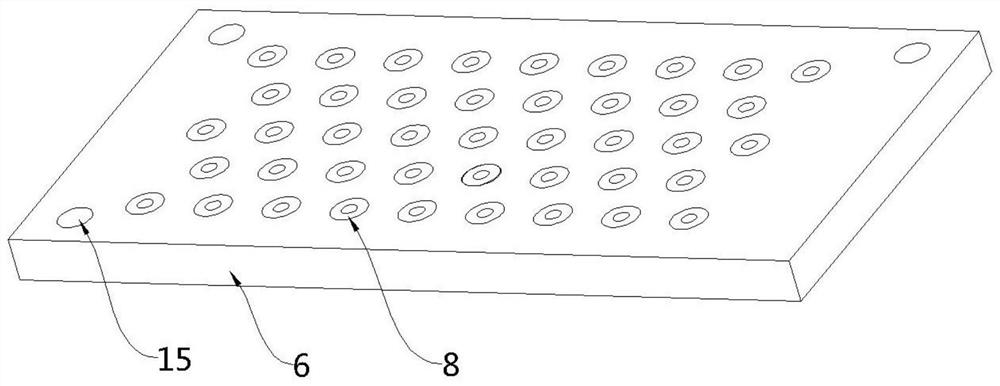

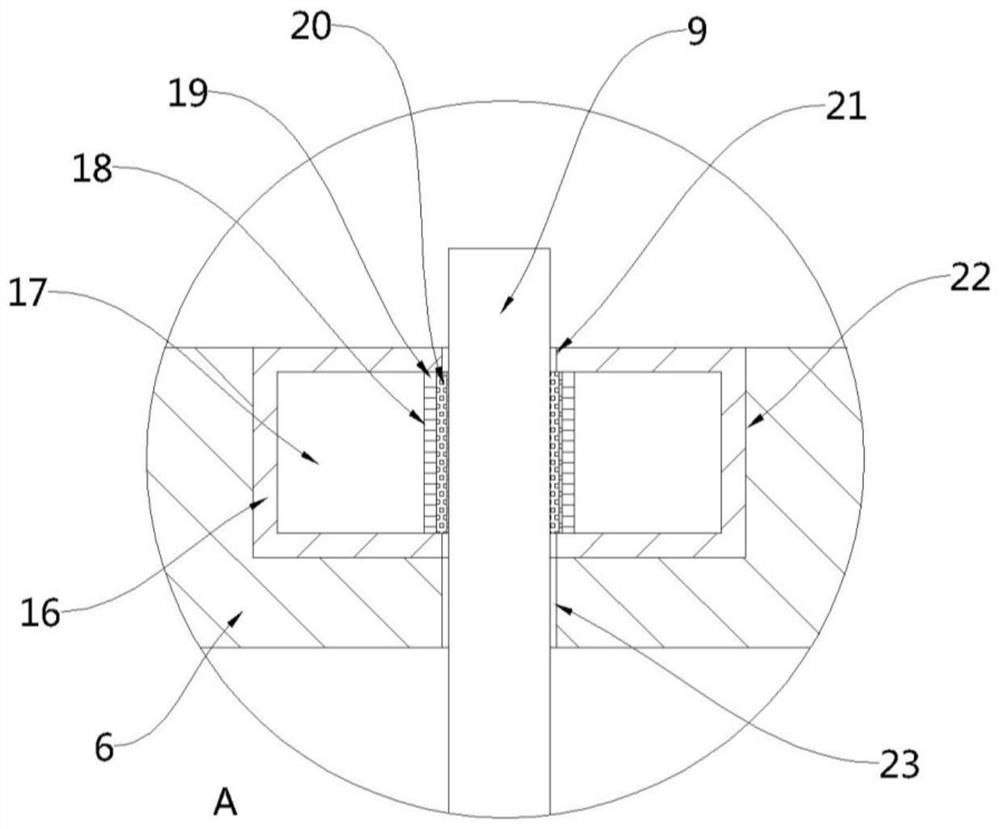

[0025] see Figure 1-4 , this embodiment provides a sea sand recycled mixed concrete component, including a base 1 and a top plate 7 arranged above the base 1, the upper edge of the base 1 is connected with the first side plate 1 and the second side plate 14 The top plate 7 is connected, and the upper part of the base 1 is provided with two groups of first baffles 4 and two groups of second baffles 10, and the two groups of first baffles 4 and two groups of second baffles 10 form a rectangular pouring cavity, so A cover plate 6 is arranged above the pouring cavity, and a plurality of recessed holes 22 are provided on the upper part of the cover plate 6 and the outer side of the first baffle plate 4, and an anti-rust liquid storage part 8 is arranged inside the recessed holes 22, and the recessed holes 22 is provided with a second channel 23 extending to the other side of the cover plate 6 and the first baffle plate 4. Specifically, the anti-rust liquid storage part 8 includes ...

Embodiment 2

[0033] see figure 1 , a sea sand recycled mixed concrete component. Compared with Embodiment 1, the second baffle 10 is provided with a number of first sockets corresponding to the transverse ribs 5 on the side facing the first baffle 4 in this embodiment. The upper part of the base 1 is provided with a plurality of second insertion holes corresponding to the longitudinal ribs 9 .

[0034] Through the setting of the first socket and the second socket, it is convenient to fix the transverse reinforcement 5 and the longitudinal reinforcement 9, so as to ensure that the horizontal reinforcement 5 and the longitudinal reinforcement 9 shake in the pouring cavity during the pouring process of the sea sand concrete, so that its position Changes will affect the strength of concrete members.

[0035]The embodiment of the present invention has the advantage of high prefabrication efficiency of sea sand concrete. By setting the anti-rust liquid storage part 8 on the outside of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com