Hoisting technology for turning over of tower

A tower and hoisting technology, which is applied in the field of offshore oil engineering, can solve the problem that all tower accessories cannot be carried and hoisted, and achieve the effects of reducing the workload of final assembly, improving efficiency, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

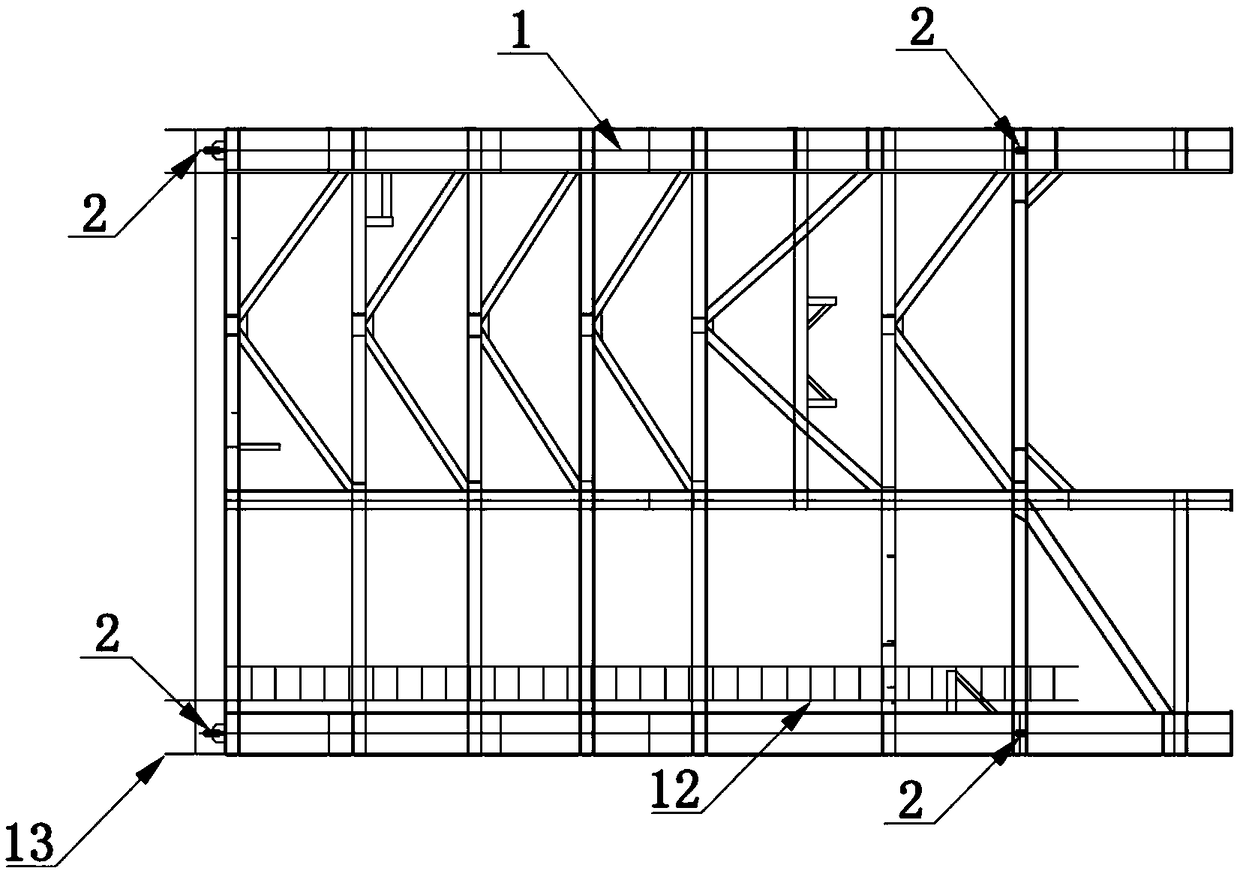

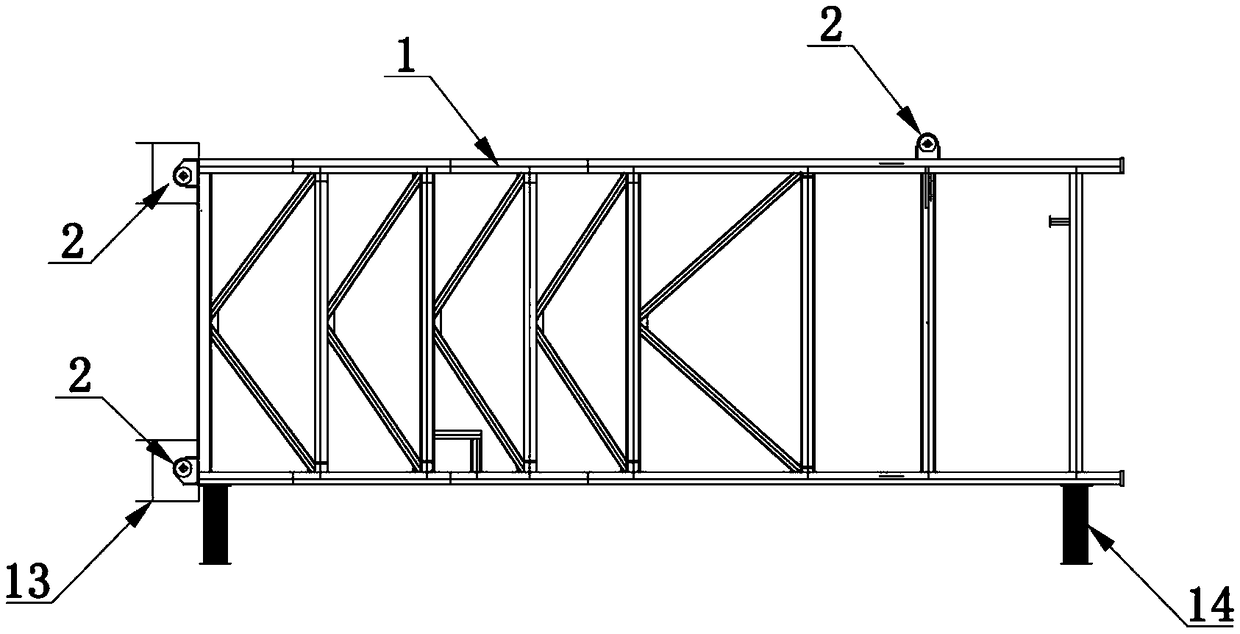

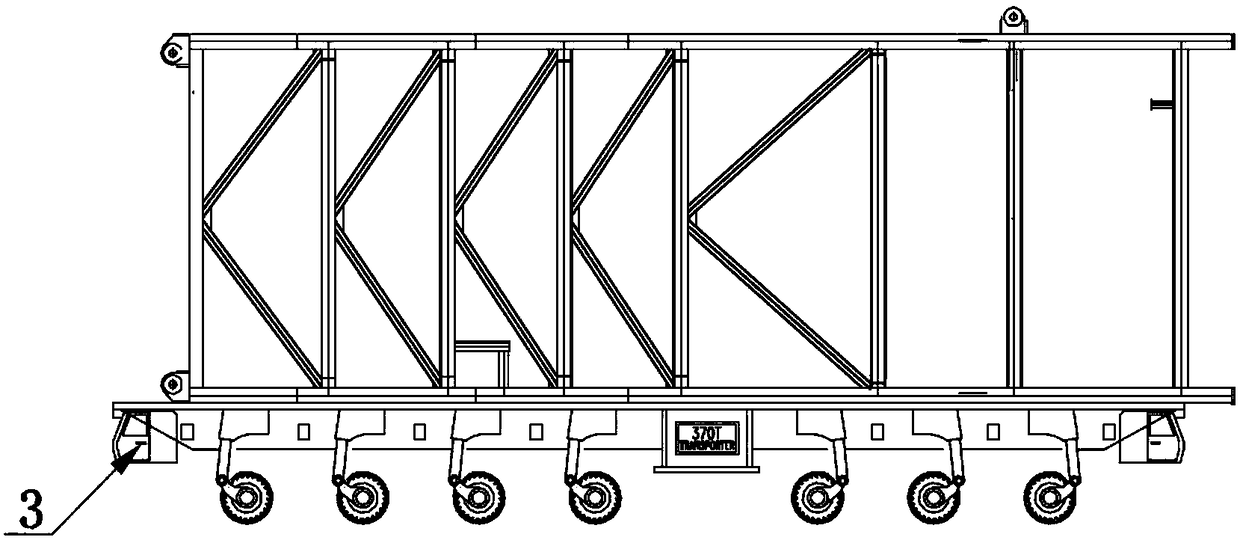

[0034] Such as Figure 1 to Figure 9 Shown, the present invention adopts following implementation steps:

[0035] The first step: arrange several pier 14 in the prefabricated site, and then, adopt the horizontal construction method to carry out the overall prefabrication of the tower 1;

[0036] The above-mentioned tower building 1 is a steel structure.

[0037] The overall prefabrication steps of Tower 1 are as follows:

[0038] ① On the upper surface of the prefabricated position of the tower 1 and the positions of the vertical legs on both sides, install a plate type lifting point 2 by welding;

[0039] ② On the side of the prefabricated position of the tower 1, that is, when standing upright, the four corners of the top floor of the tower 1 are installed with plate-type lifting points 2 by welding;

[0040] ③ When the plate type lifting points 2 at the four corners of the top floor are installed by welding, it is necessary to ensure that the two plate type lifting point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com