Full-prefabricated concrete shear wall and construction method thereof

A technology of prefabricated concrete and prefabricated shear, applied to walls, building materials, building components, etc., can solve the problems of reducing prefabrication efficiency, affecting structural performance, and requiring high quality workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

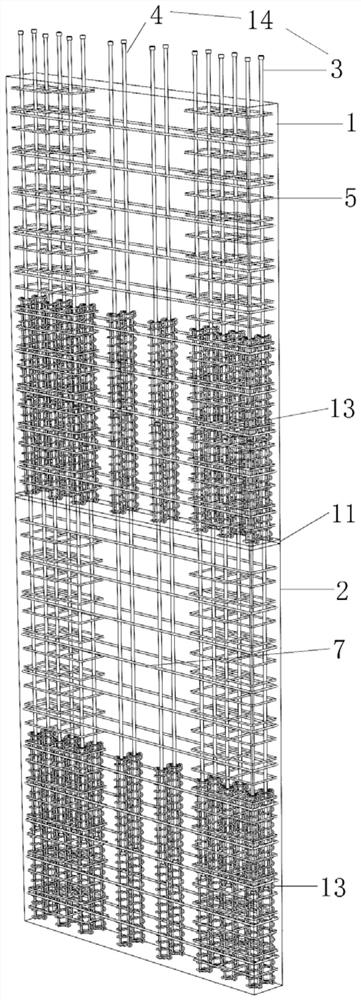

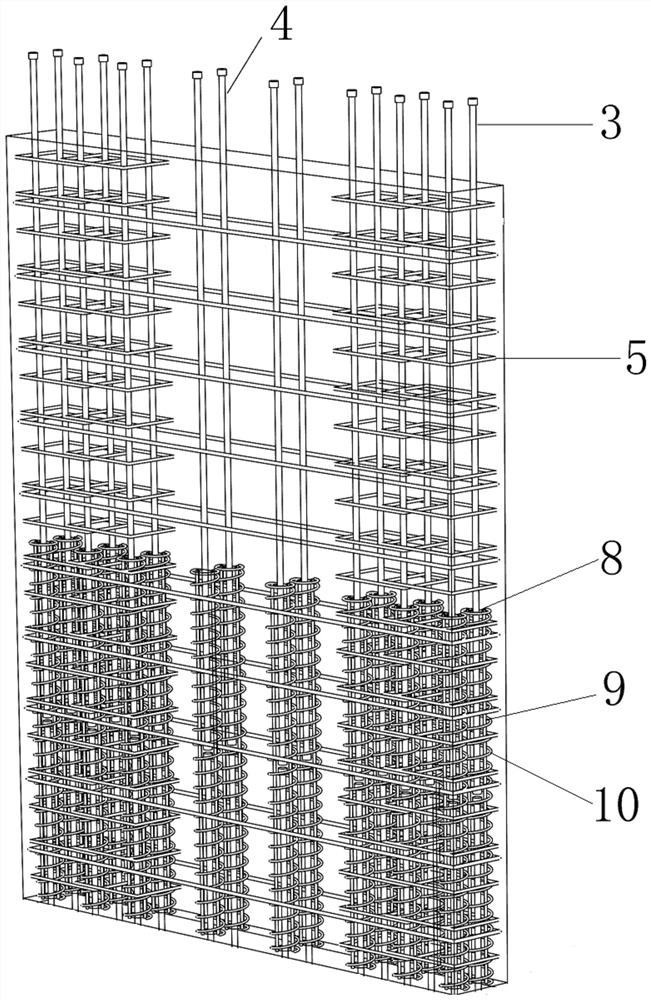

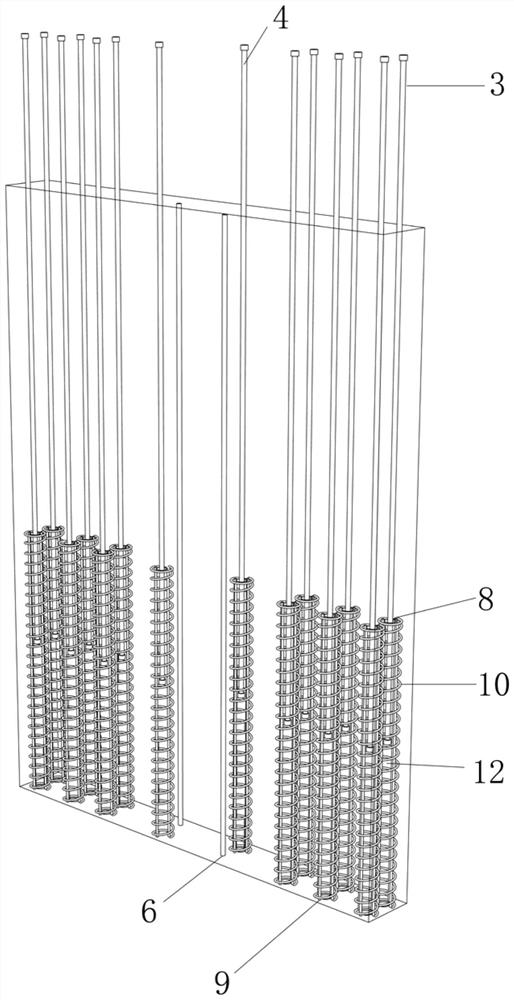

[0036] Such as figure 1 As shown, a fully prefabricated concrete shear wall includes several layers of fully prefabricated shear wall panels that are docked and fixed; the fully prefabricated shear wall panels include a prefabricated concrete body and several vertical butt joint steel bars 14 distributed through the prefabricated concrete body, There is a steel bar docking assembly 13 under the interior of the precast concrete body. The top of the vertical docking steel bar 14 protrudes from the upper surface of the precast concrete body, and the bottom end is inserted into the steel bar docking assembly 13; the upper fully prefabricated shear wall panel 1 and the lower fully prefabricated shear There is a slurry layer 11 between the force wall panels 2, and when the upper fully prefabricated shear wall panel 1 and the lower fully prefabricated shear wall panel 2 are butted and fixed to each other, the top of the vertical butt joint reinforcement bar of the lower floor is inser...

Embodiment 2

[0047] Such as figure 1 As shown, a fully prefabricated concrete shear wall includes several layers of fully prefabricated shear wall panels that are docked and fixed; the fully prefabricated shear wall panels include a prefabricated concrete body and several vertical butt joint steel bars 14 distributed through the prefabricated concrete body, There is a steel bar docking assembly 13 under the interior of the precast concrete body. The top of the vertical docking steel bar 14 protrudes from the upper surface of the precast concrete body, and the bottom end is inserted into the steel bar docking assembly 13; the upper fully prefabricated shear wall panel 1 and the lower fully prefabricated shear There is a slurry layer 11 between the force wall panels 2, and when the upper fully prefabricated shear wall panel 1 and the lower fully prefabricated shear wall panel 2 are butted and fixed to each other, the top of the vertical butt joint reinforcement bar of the lower floor is inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com