A new efficient installation method for ballast groove slabs of steel truss bridges

An installation method and channel plate technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as the inability to use large mechanical equipment, the heavy weight of a single ballast channel plate, and the limited working space of steel truss girders, etc., to achieve large Promote value, improve efficiency, and technically feasible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

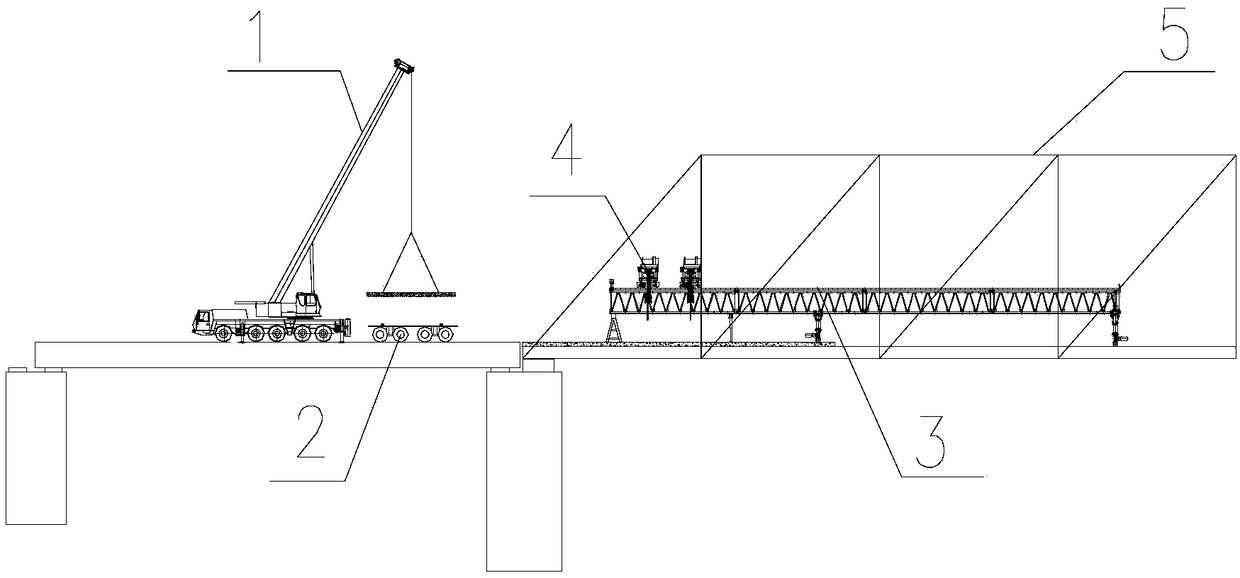

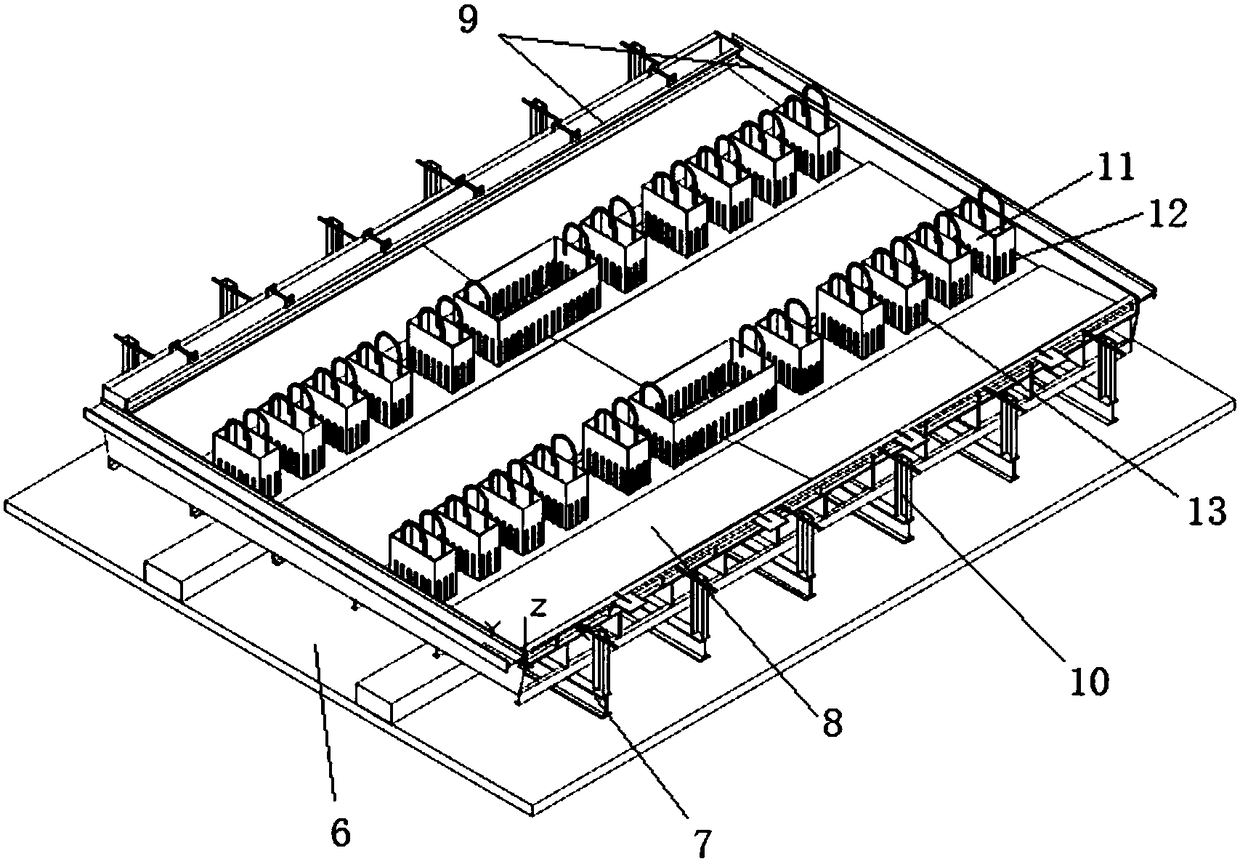

[0029] See attached picture.

[0030] A new type of efficient installation method for ballast slabs of steel truss bridges, based on the steel truss bridge deck adopting longitudinal and beam structure systems, prefabricated ballast slabs are installed in sections on the longitudinal and transverse beams, prefabricated ballast slabs When the shear nail groove is reserved at the corresponding position, the shear nail groove and the longitudinal beam are combined with the principle of joint stress after pouring concrete through the cylindrical head flexible shear nail arranged on the top surface of the longitudinal beam at the shear nail groove; it is characterized in that: Specific steps are as follows:

[0031] 1) First, design and process the corresponding ballast slab prefabricated formwork according to the section form of the ballast slab. During the prefabrication process of the ballast slab, ensure the accuracy of the position of the steel bars and the quality of concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com