Manufacturing method of fabricated building construction platform

A construction and assembly technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of overall bulkiness, lack of good maintenance devices, inconvenient transportation and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

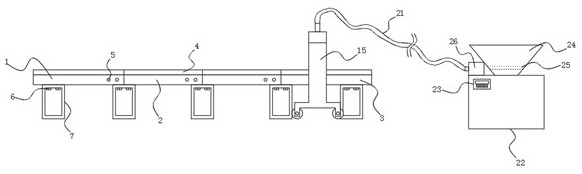

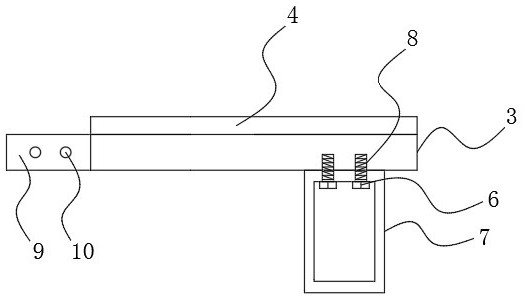

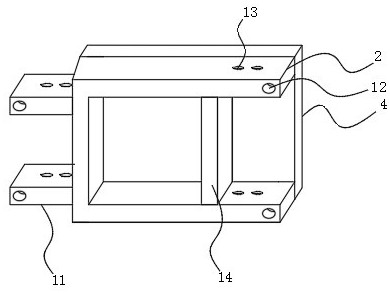

[0021] Attached below Figure 1-4 The specific implementation manner of the present invention will be described in further detail.

[0022] Example, by Figure 1-4 Given, the present invention provides a prefabricated building construction platform, including a first end frame 1, a middle frame 2, a second end frame 3, a platform steel plate 4, a first fixing bolt 5, a second fixing bolt 6, and a leg 7 , the first threaded hole 8, the first connecting block 9, the second threaded hole 10, the second connecting block 11, the third threaded hole 12, the fourth threaded hole 13, the auxiliary steel block 14, the moving frame 15, the beam 16, the installation Block 17, shunt pipe 18, shower nozzle 19, connecting pipe 20, infusion pipe 21, liquid storage tank 22, control panel 23, liquid receiving bucket 24, filter screen 25 and water pump 26, one side of the first end frame 1 passes through the first Fixing bolt 5 is equipped with several middle frames 2, and one end of middle f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com