Connecting structure for jointly prefabricating assembly type shear wall and heat-preservation partition wall

A technology for connecting structures and shear walls, applied in thermal insulation, walls, building components, etc., can solve problems such as low construction efficiency and environmental pollution, and achieve the effect of improving prefabrication efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

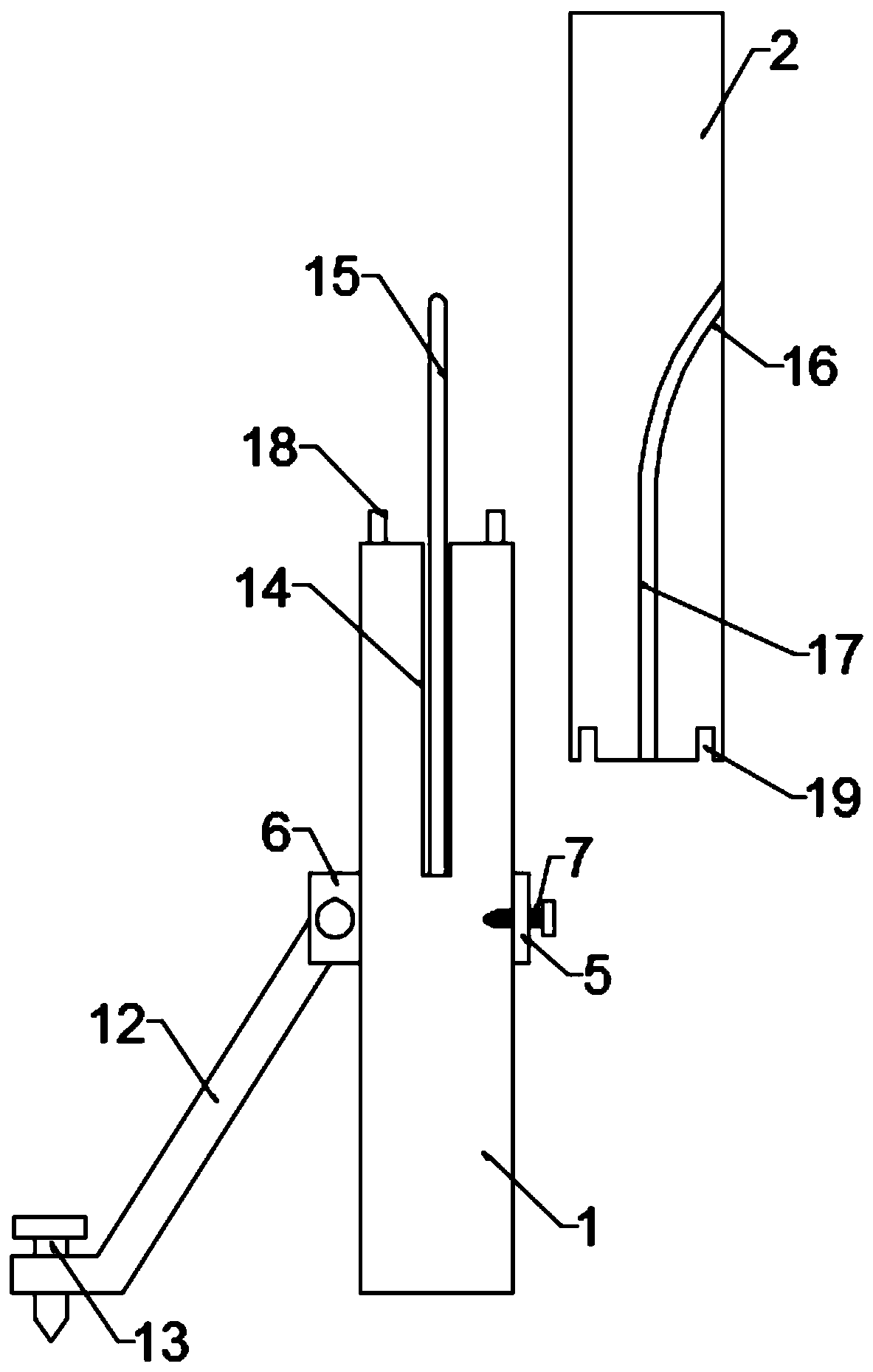

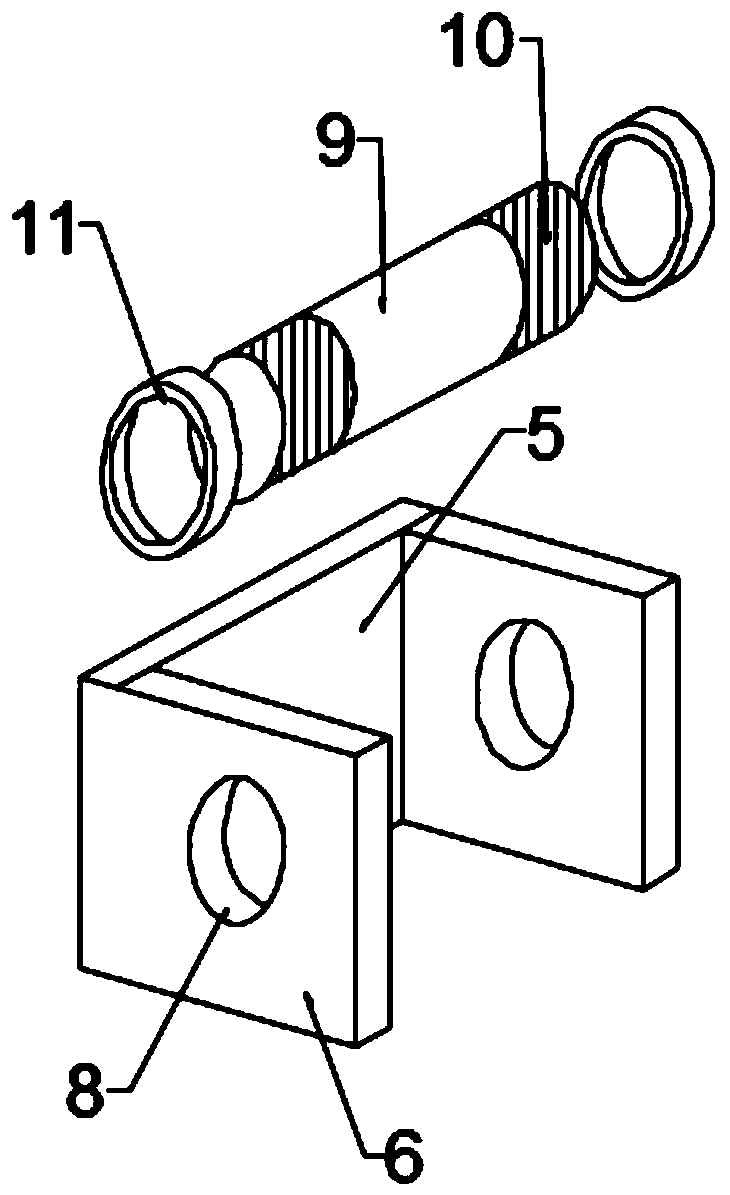

[0034] see Figure 1-5 , in the embodiment of the present invention, a prefabricated connection structure of a prefabricated shear wall and a thermal insulation partition wall, including a shear wall body 1, the top of the shear wall body 1 is connected with an upper wall 2 through an upper connection structure, so The left and right sides of the shear wall body 1 are connected with side walls 3 through the side connection structure, and the outer side wall of the shear wall body 1 is connected with the insulation partition wall 4 through the external connection structure; the surface of the shear wall body 1 A detachable support mechanism is installed; the side wall 3 is installed on the upper surface of the auxiliary connection mechanism.

[0035] The prefabricated connection structure of the prefabricated shear wall and the insulation partition wall avoids the installation of insulation boards at the construction site, and the prefabricated prefabrication of the upper conne...

Embodiment 2

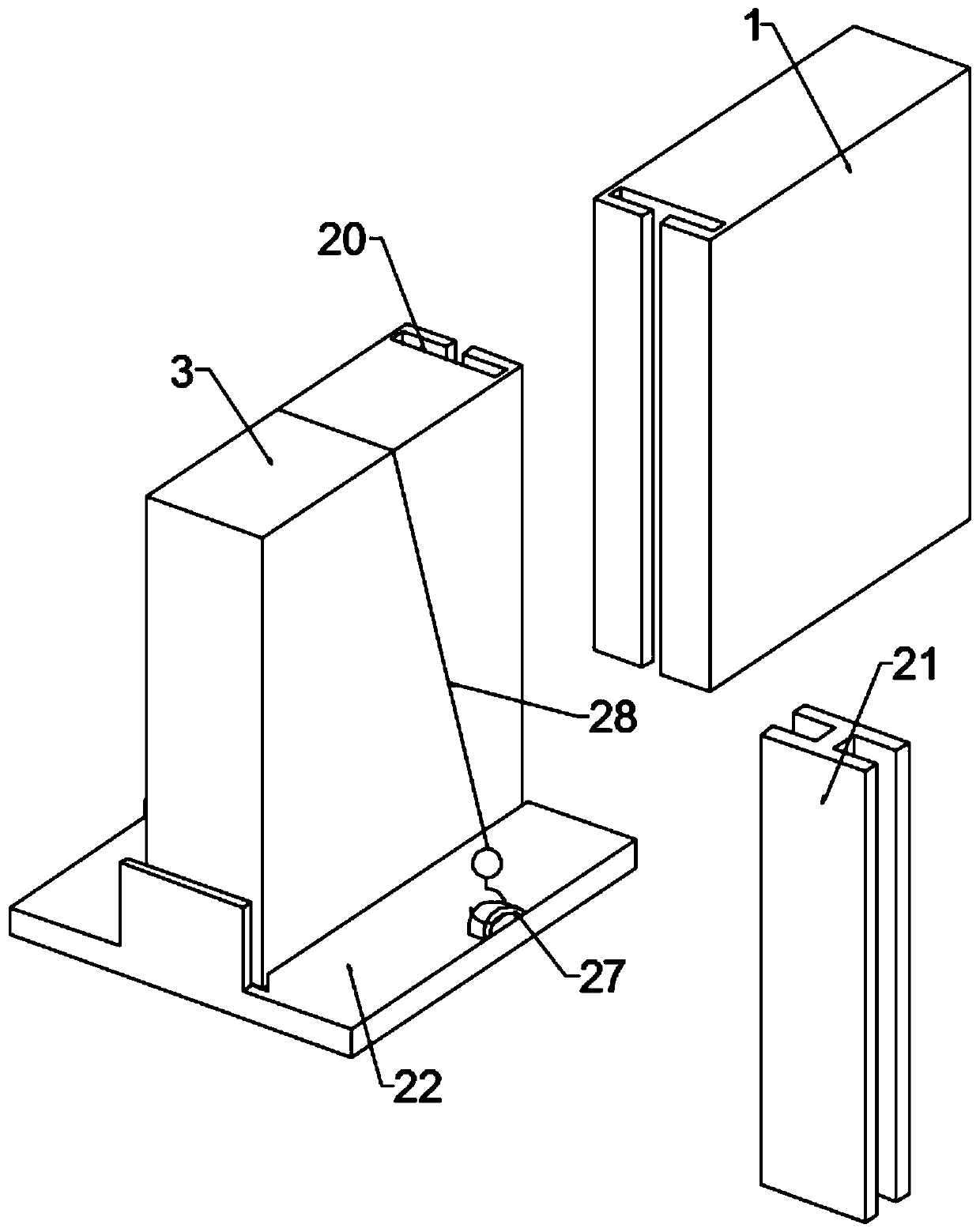

[0047] see Figure 3-4 , in the embodiment of the present invention, the auxiliary connection mechanism includes an auxiliary plate 22, the rear side of the auxiliary plate 22 is fixed with a fixed plate 24, and the front side of the auxiliary plate 22 is connected with a buffer section 23; the fixed plate 24 Hydraulic telescopic oil cylinder 25 is installed on it, and push plate 26 is fixed on the top of described hydraulic telescopic oil cylinder 25;

[0048] Further, hooks 27 are fixed on the front side and the back side of the auxiliary board 22 , and a binding rope 28 is hooked and connected to the two hooks 27 .

[0049] First the side wall 3 is moved to the upper surface of the auxiliary plate 22 by the buffer section 23, one end of the binding rope 28 is hooked in the hook 27, and the other end of the binding rope 28 is hooked around the side wall 3 and hung in another hook 27, Then the auxiliary plate 22 is slid through the I-shaped groove 20 and the pulley 31 at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com