Patents

Literature

33 results about "Masonry arch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

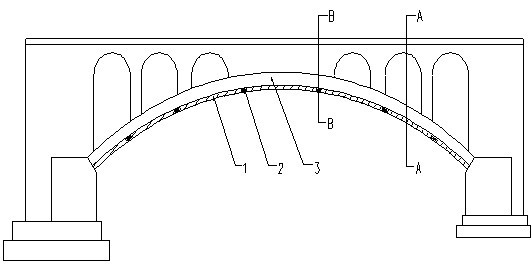

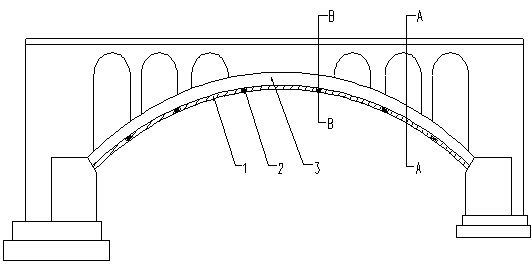

Reinforcing method of masonry arch bridge

InactiveCN102322026AReduce dosageImprove bearing capacityBridge erection/assemblyBridge strengtheningReinforced concreteEngineering

The invention discloses a reinforcing method of a masonry arch bridge, which comprises the following steps of: a, planting ribs on an arch ring of the arch bridge along the cambered surface direction of the arch bridge; b, planting ribs at the position close to the two sides, on the circular arc surface of the arch ring along the cambered surface direction of the arch bridge; and c, forming symmetrically distributed reinforced concrete ribs along the distribution direction of the planted ribs in the step a and the step b in a way of casting molding, wherein the cross section of the reinforcedconcrete ribs is L-shaped. The reinforced concrete ribs which are of integral structures are formed along the two sides of the arch ring in the way of planting the ribs and casting concrete, then load can be directly transferred to an arch base through the symmetrically distributed reinforced concrete ribs of which the cross section is L-shaped, and the stress to the reinforced concrete ribs is equal to that to a ribbed arch bridge. When the method is compared with the method of singly increasing the area of the arch ring, the dependence on the primary arch ring is smaller, even the primary arch ring can be supported, the damage to the primary arch ring is small, the requirement of increasing the loading capacity of the masonry arch bridge is met, and the damage to the primary old arch ring is avoided to the maximal degree.

Owner:CHONGQING JIAOTONG UNIVERSITY

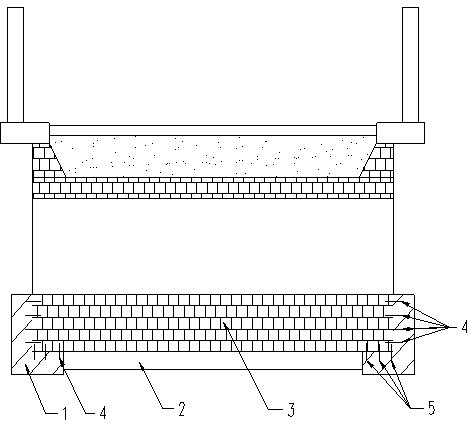

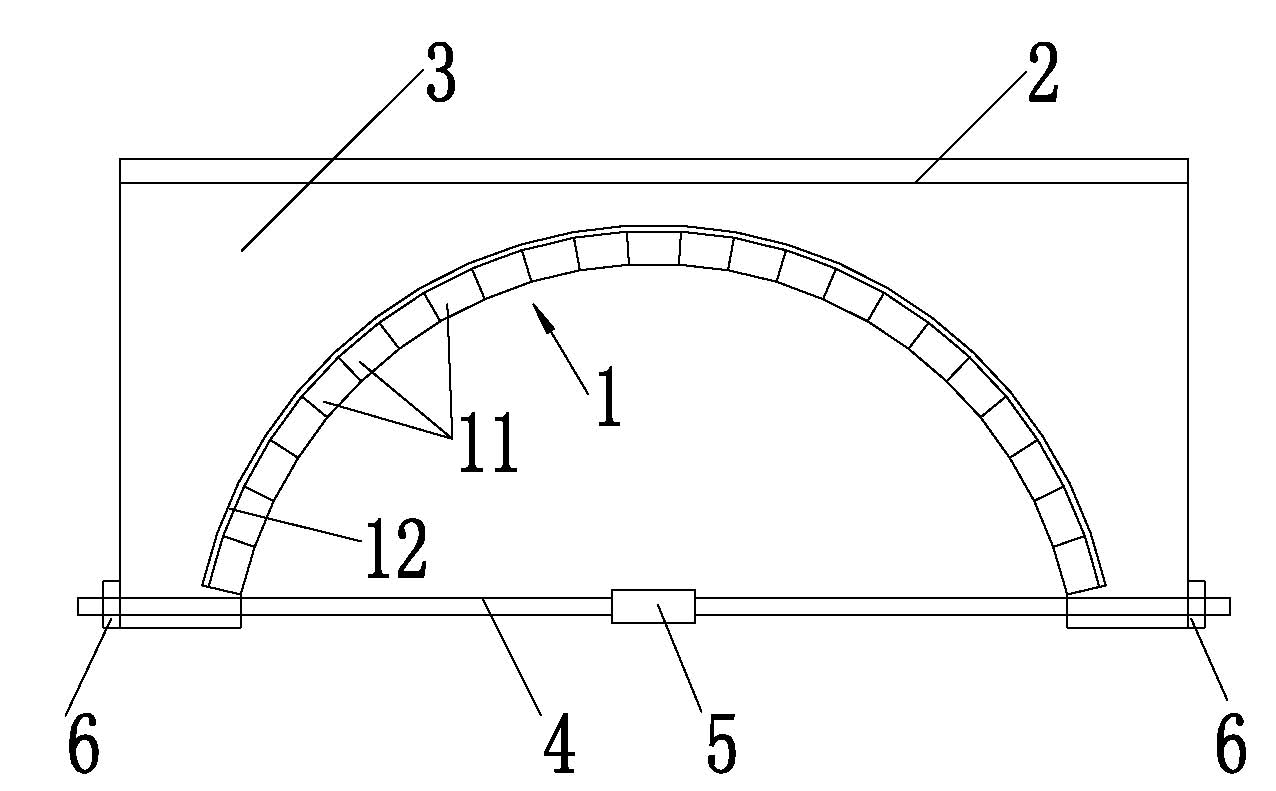

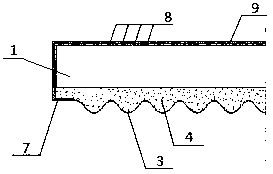

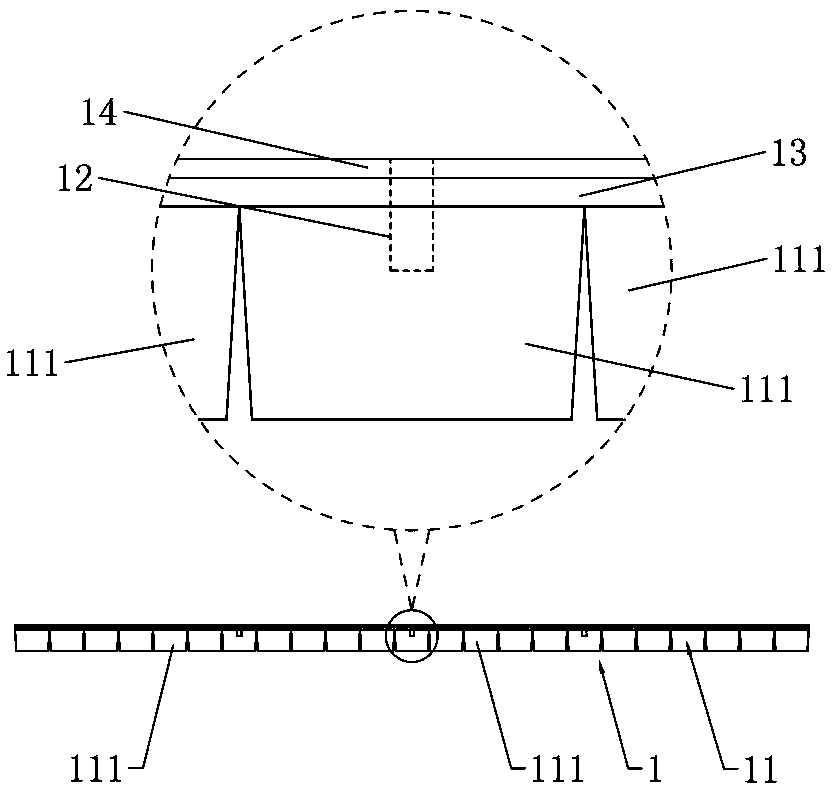

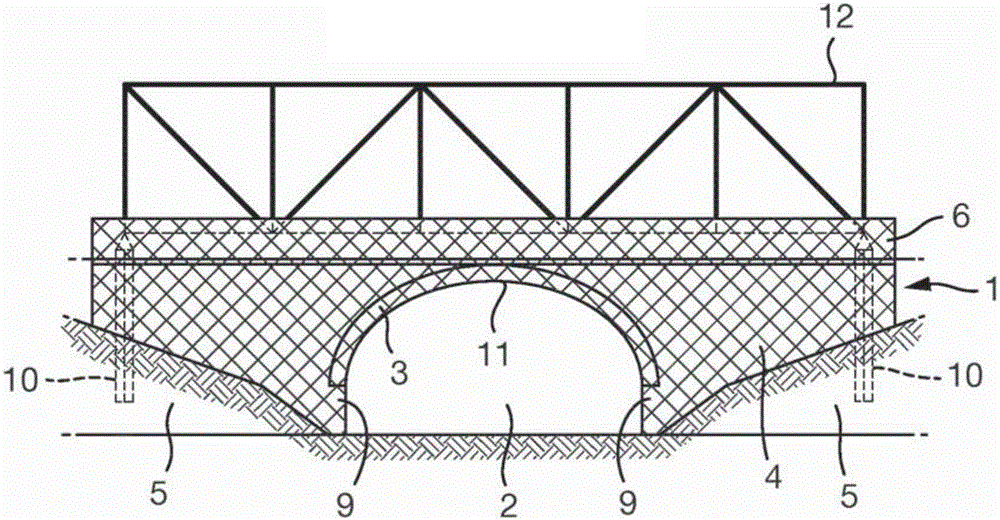

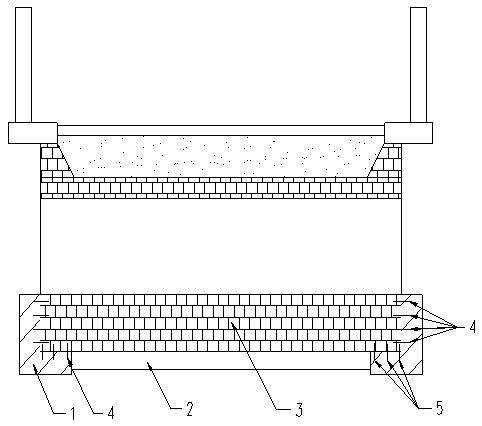

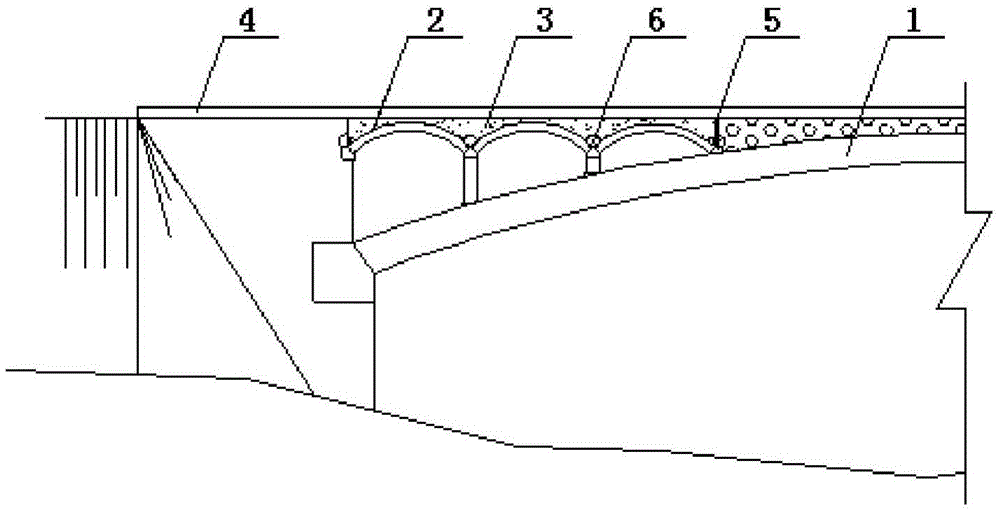

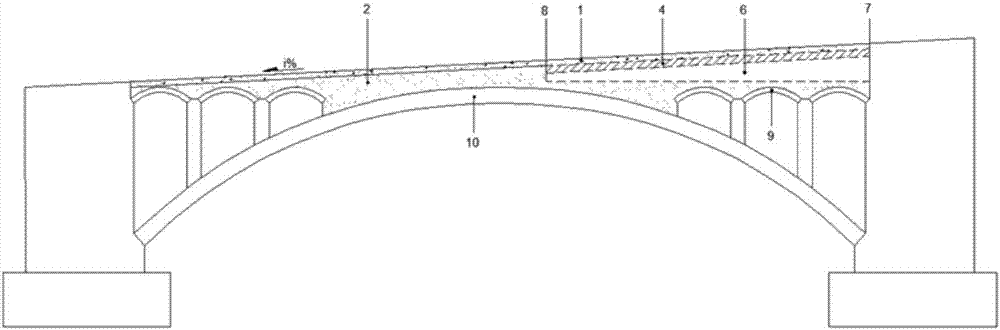

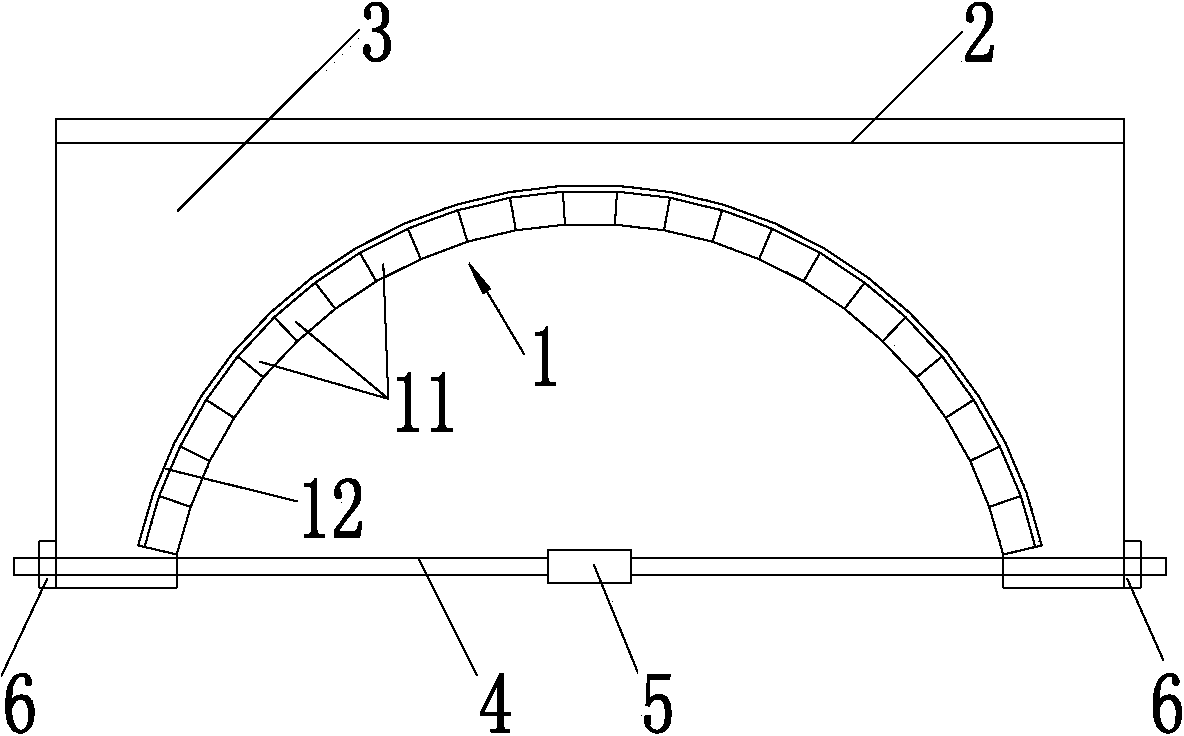

Masonry arch bridge using lightweight concrete as arch filler

ActiveCN102587268AImprove carrying capacityLose weightBridge structural detailsBridge erection/assemblyApparent densityCarrying capacity

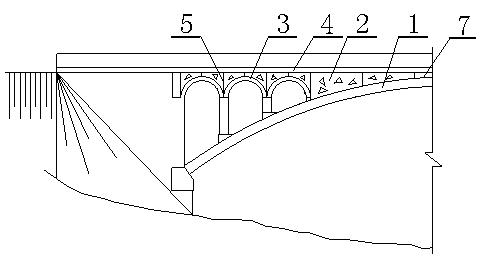

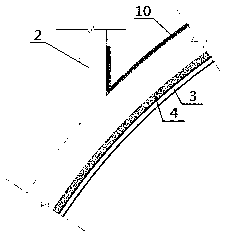

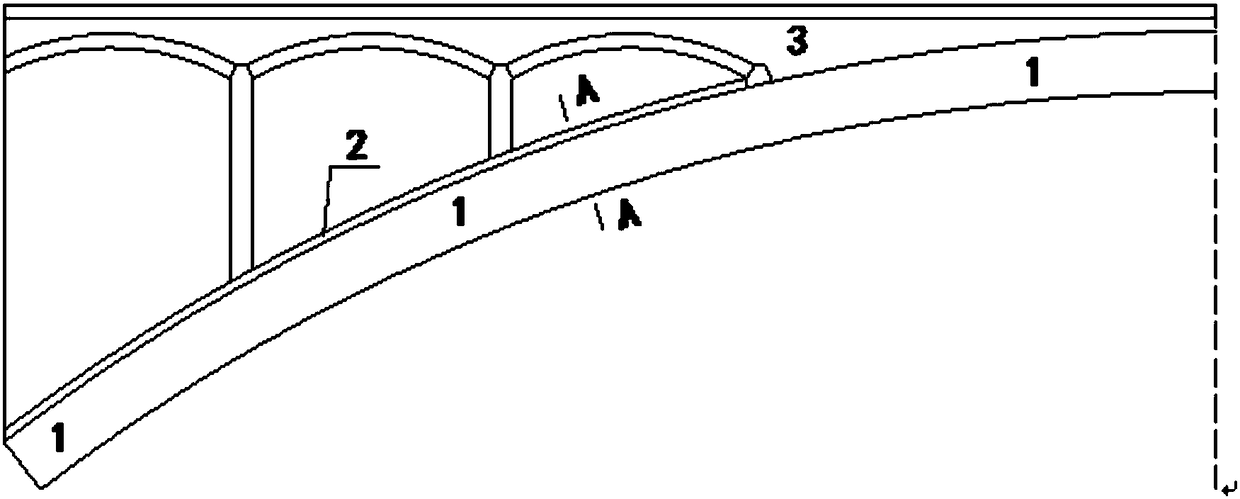

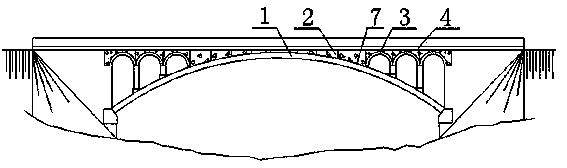

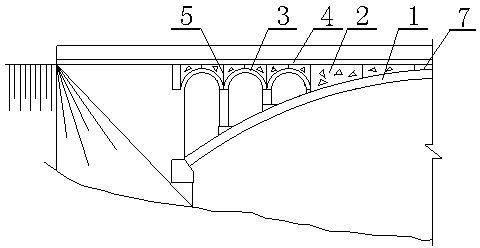

The invention discloses a masonry arch bridge using lightweight concrete as arch filler. The masonry arch bridge comprises a main arch ring (1), a spandrel arch (3) and an arch filler layer (2) and is characterized in that the arch filler layer (2) is a lightweight concrete filler layer, and the apparent density of the lightweight concrete filler layer is 800kg / m<3>-1950kg / m<3>; a leveling layer (4) is arranged on the top surface of the arch filler layer (2); a waterproof layer (7) is arranged between the main arch ring (1) and the arch filler layer (2); and saw joints (5) are arranged along the transverse direction of the bridge; and water permeating pipes (6) are arranged in the lowest position of each filler formed by the pairwise saw joints (5) and at two sides of a side wall. The waterproof layer (7) is formed by laying a permanent condensate or asphalt. The masonry arch bridge has the advantages that the stress of the arch can be effectively improved, the internal force of a dead load is reduced, and the carrying capacity of a bearing live load of the masonry arch bridge is increased.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

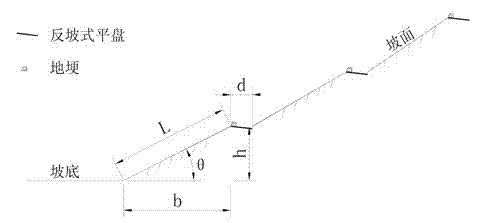

Technique for safe improvement as well as ecological repair and reconstruction of mine soil discharge yard

InactiveCN102392455AEnsure safetyImprove the environmentExcavationsHorticultureFruit treeWater discharge

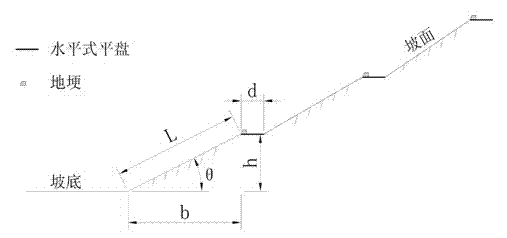

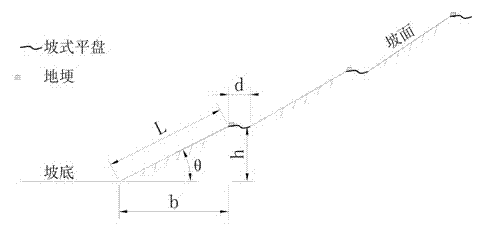

The invention discloses a technique for safe improvement as well as ecological repair and reconstruction of a mine soil discharge yard. The technique is implemented according to the following processes and steps: carrying out comprehensive optimization according to experience, calculation and land use properties to determine slope, slope length and flat pan width of the soil discharge yard, and designing slope cutting grade of an accumulation side slope of the soil discharge yard into three grades, wherein the height of each grade of slope is 9-11 m, the flat pan width of the side slope is 4-8 m, and the slope ratio is as follows: the first grade is 1:(2.0-2.1), the second grade is 1:(1.7-1.8) and the third grade is 1:(1.45-1.60); preparing the flat pan into a horizontal, slope or reverse slope type; and constructing the first-grade and second-grade side slopes by adopting grass planting in stone masonry arch rack, slope bottom apron protection, and designing mortar flag stone side slope flat pan and water discharge channel of the flat pan as well as slope edging, constructing the third-grade side slope by a vetiver grass slope protection greening technique, firstly sowing Bahia grass in the flat pan of the soil discharge yard with the seed amount of 15-25 g / m<2>, after sowing, maintaining and managing in time, checking seedlings and supplementing deficient seedlings, harvesting 1-2 times every year and maintaining seedling height of 20-30 cm when most stem tillers enter fringe-bearing flourishing growth stage, and planting fruit trees or crops in the flat pan after 1-2 years. In the technique disclosed by the invention, engineering measure and biological measure are comprehensively adopted to ensure the safety of the mine soil discharge yard and achieve good ecological repair effect and landscape effect; and plants adaptable to local conditions are planted and the cost is lower.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

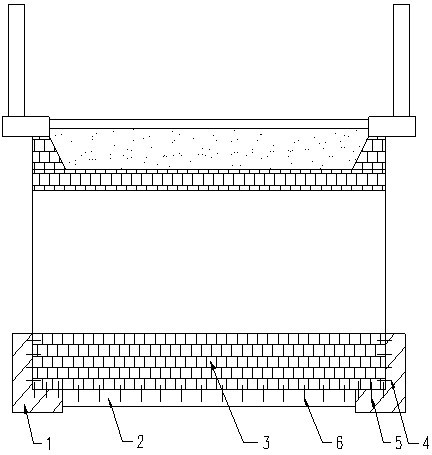

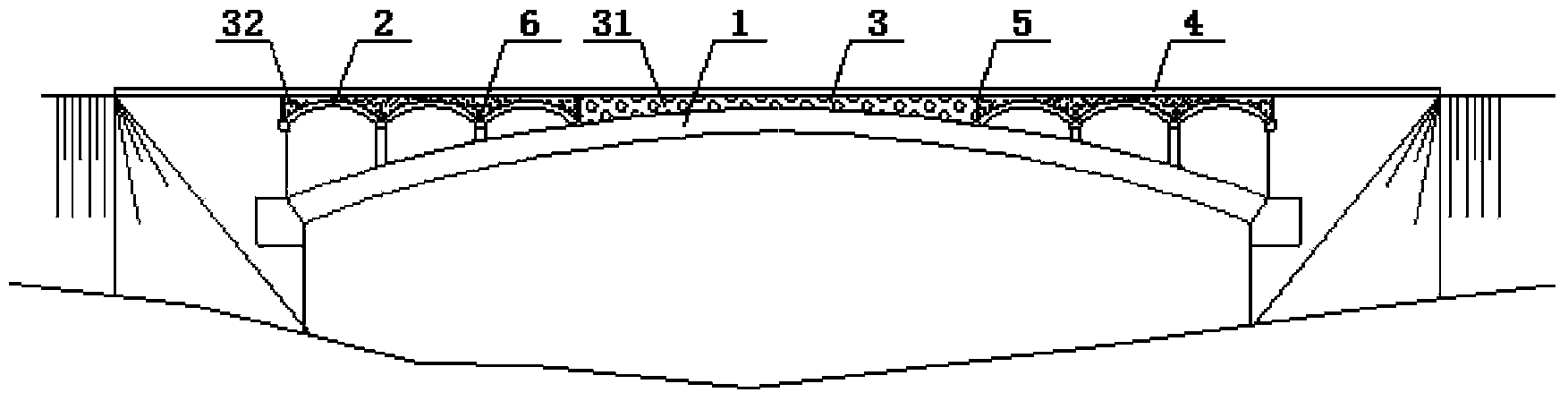

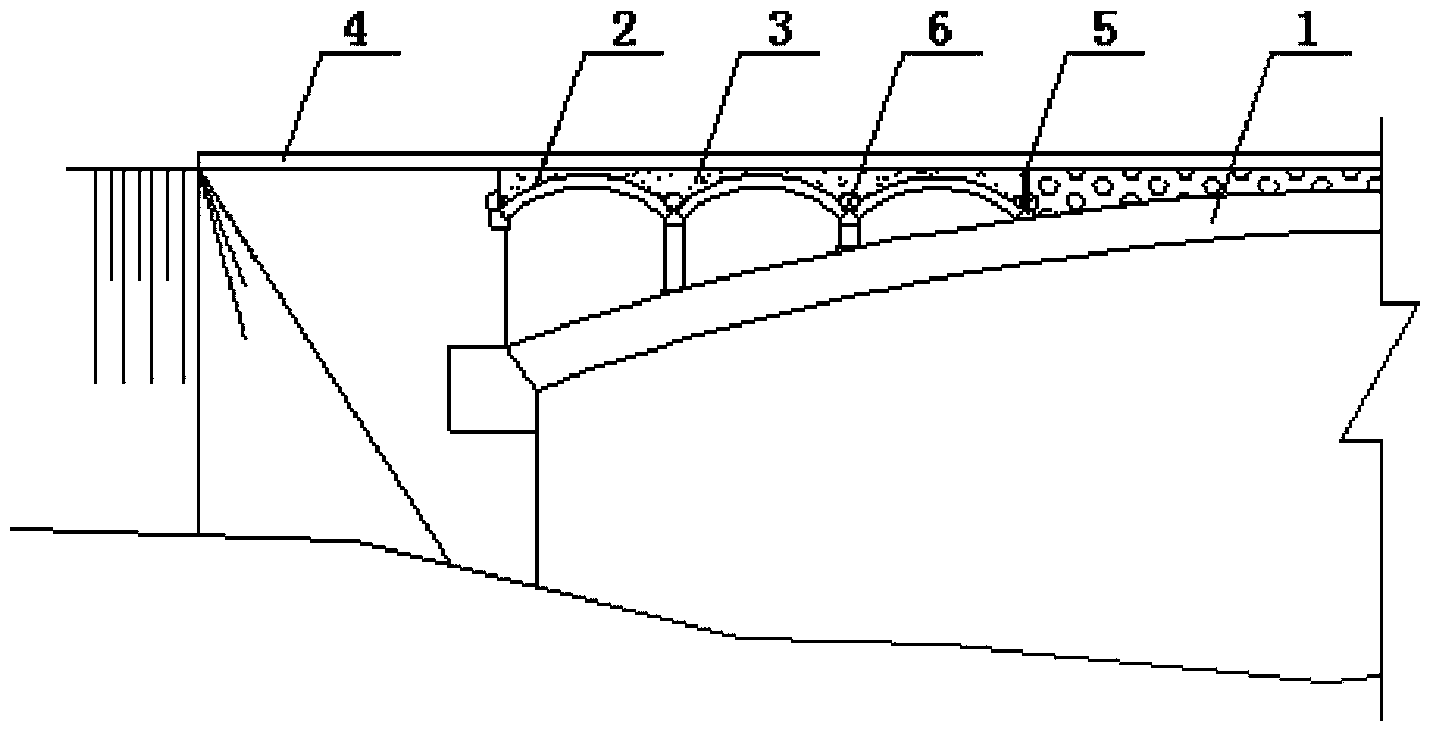

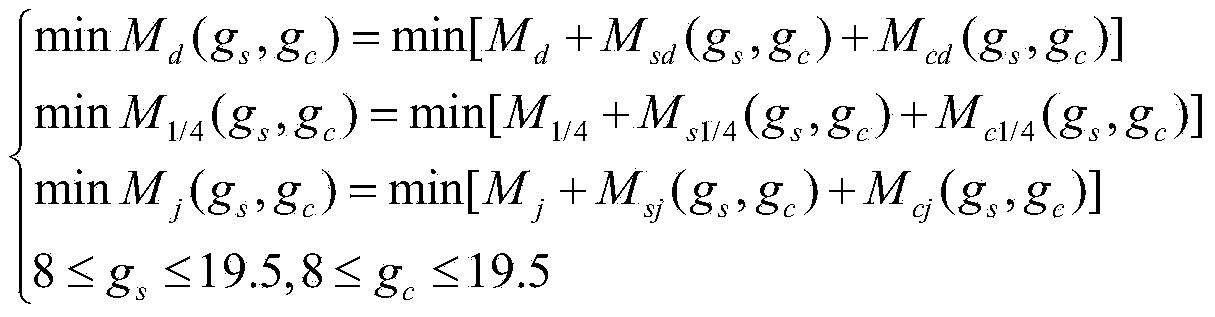

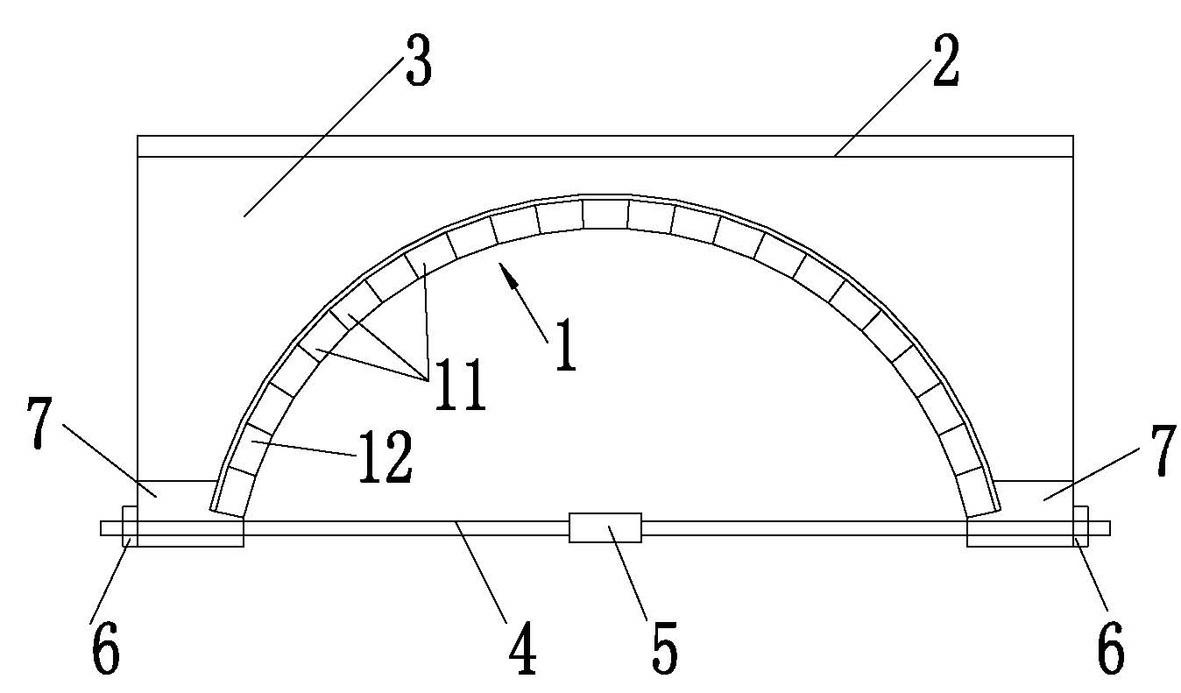

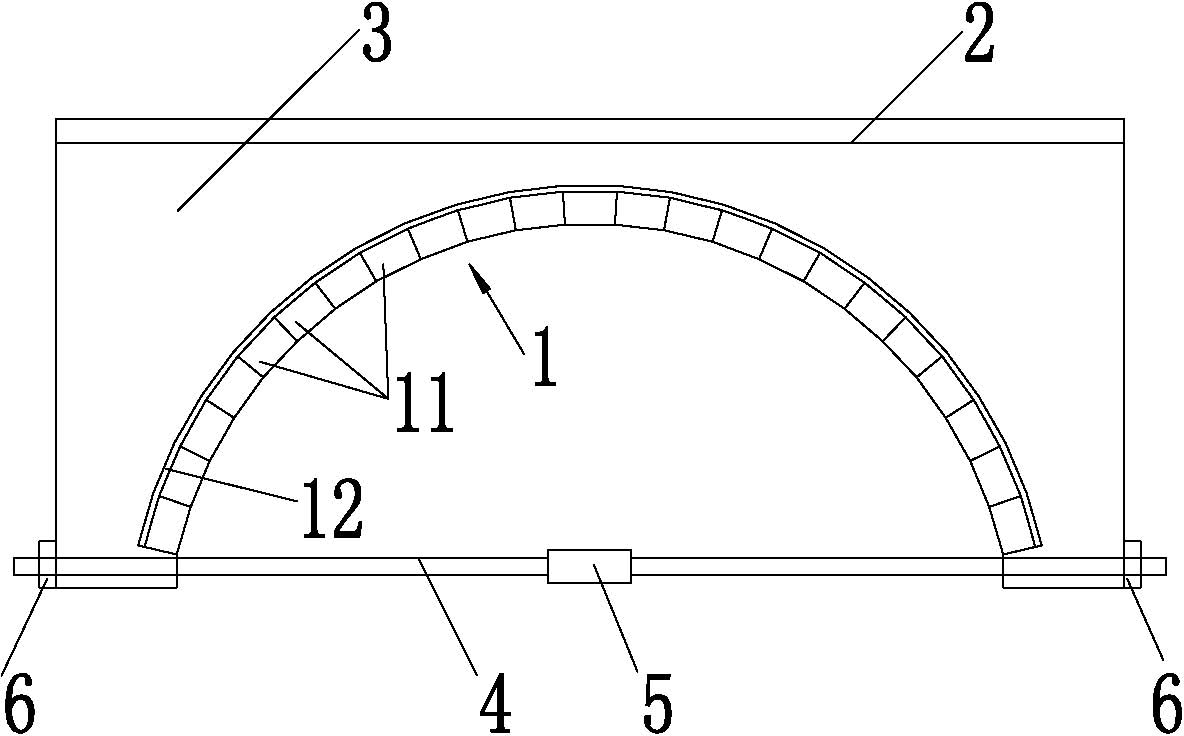

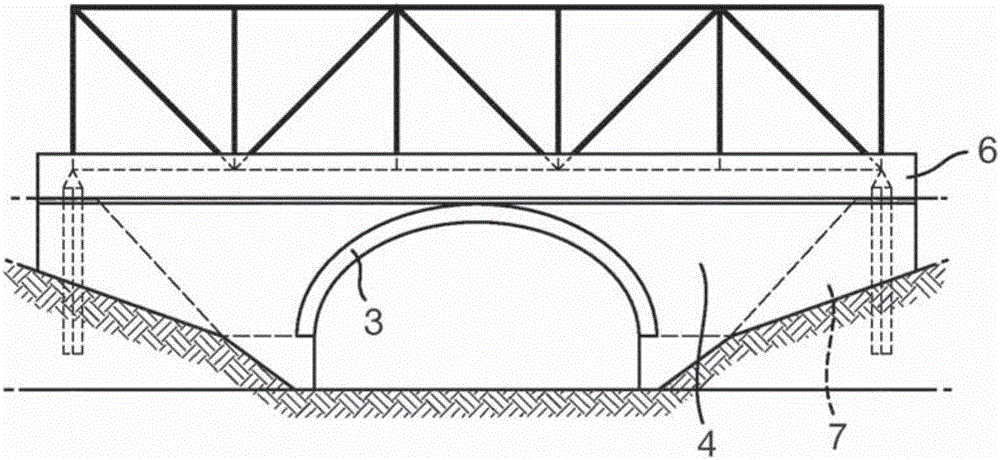

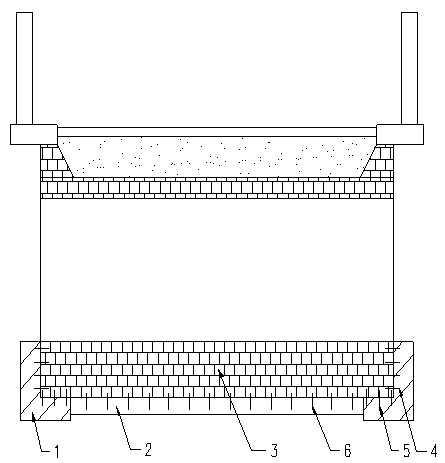

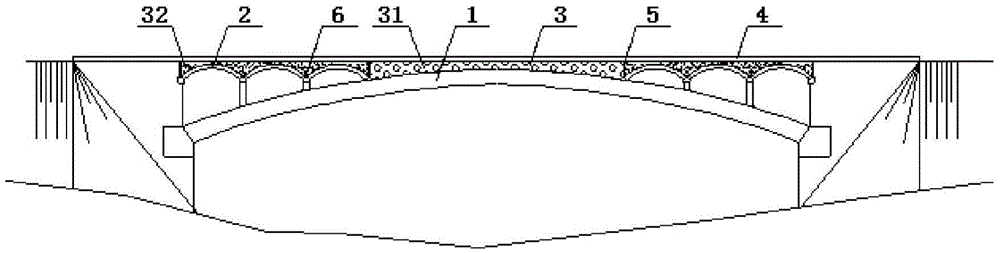

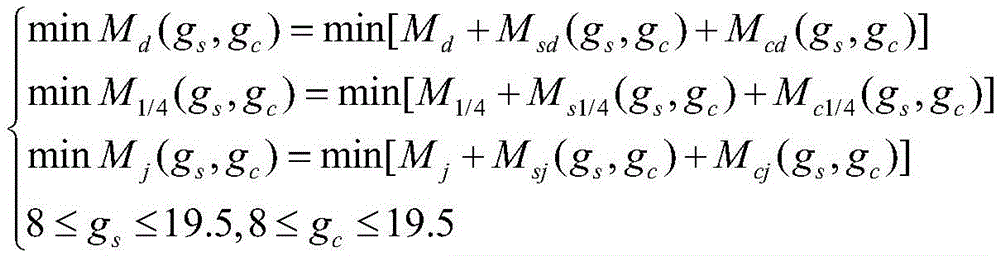

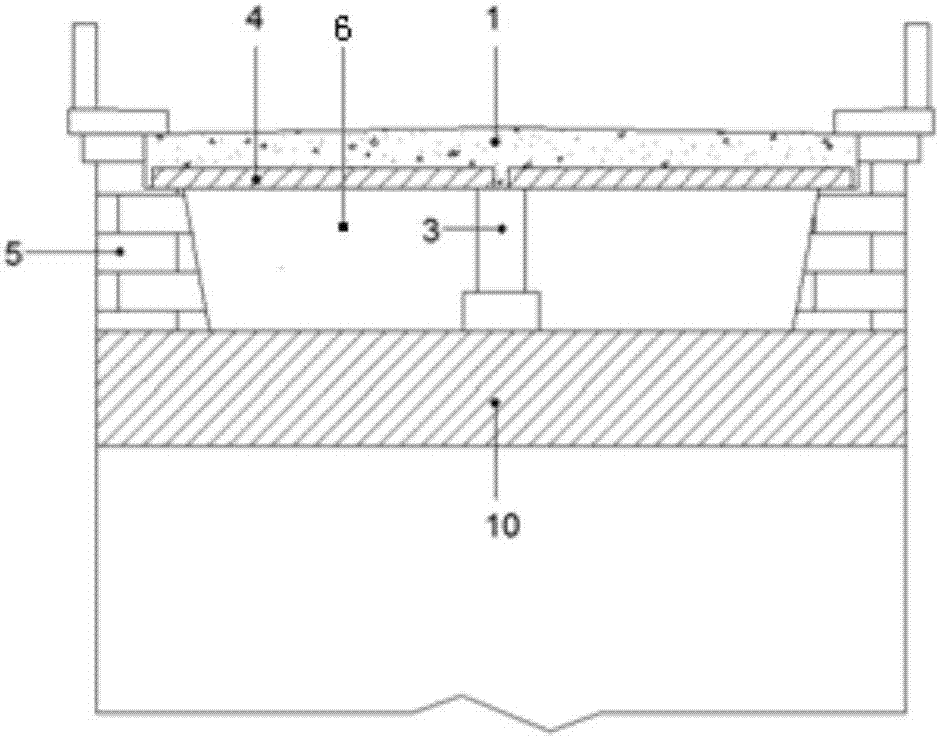

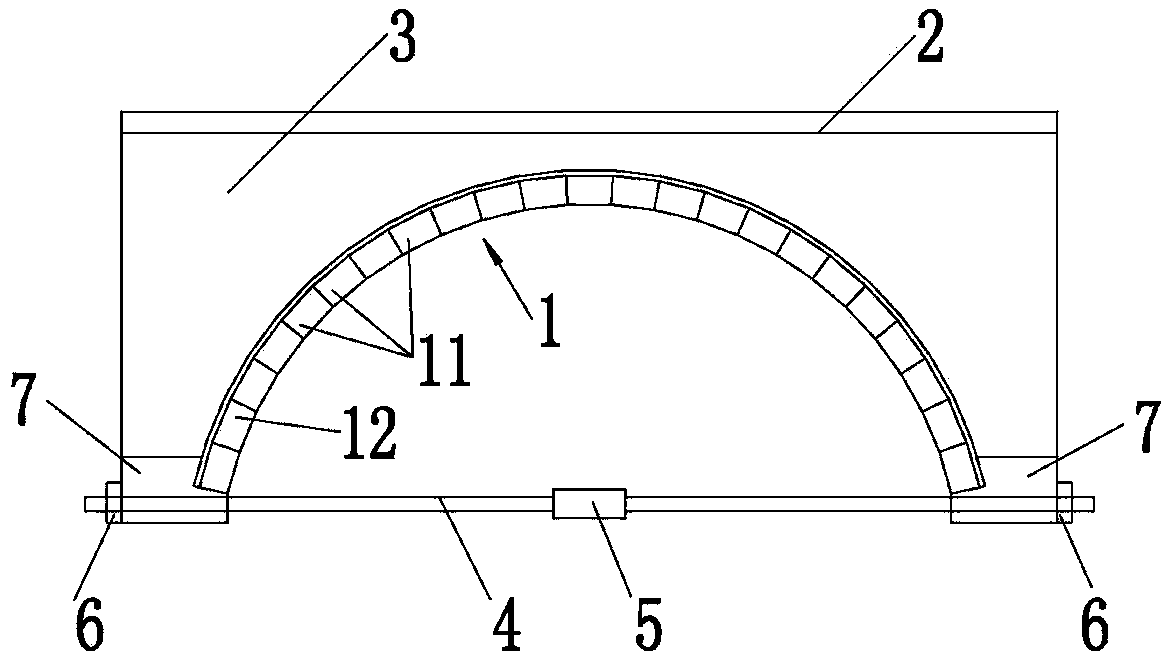

Method for adjusting weight of fillers on masonry arch bridge in partitioning manner

ActiveCN104074139AReduce bending momentUniform moment distributionBridge erection/assemblyBridge strengtheningApparent densityCarrying capacity

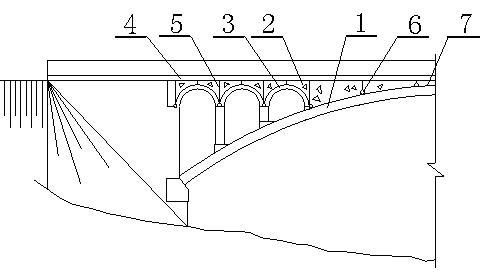

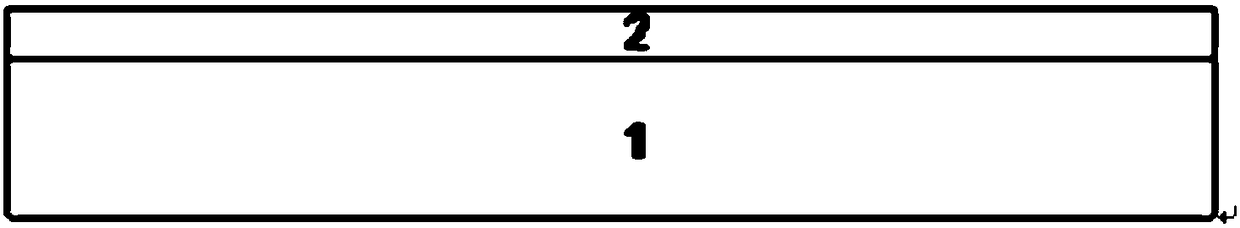

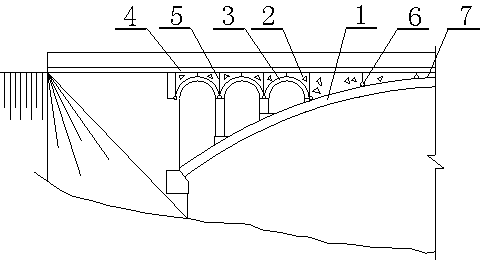

The invention discloses a method for adjusting the weight of fillers on a masonry arch bridge in a partitioning manner. The masonry arch bridge comprises a main arch ring (1), spandrel arch rings (2), a filler layer (3) on arches, and a bridge panel (4). The method comprises the steps: the filler layer (3) on the arches is divided into an arch top area (31) and spandrel arch areas (32), wherein the arch top area (31) is formed between the main arch ring (1) and the bridge panel (4), and the spandrel arch areas (32) are formed between the spandrel arch rings (2) and the bridge panel (4); lightweight concrete fillers with the apparent density from 800kg / m3 to 1200 kg / m3 are filled into the arch top area (31), and lightweight concrete fillers or ordinary soil quality fillers with the apparent density from 1200kg / m3 to 1950 kg / m3 are filled into the spandrel arch areas (32); and the weight of the filler layer (3) on the arches is adjusted by calculating three objective functions, i.e. bending moments Md, M1 / 4 and Mj generated by the main arch ring on the arch top, the one quarter of an arch span, and arch feet, and the like. The method has the advantages that the utilization efficiency of arch ring materials can be improved, the distribution of the internal force of the main arch ring is improved, and the carrying capacity of the arch bridge is improved.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

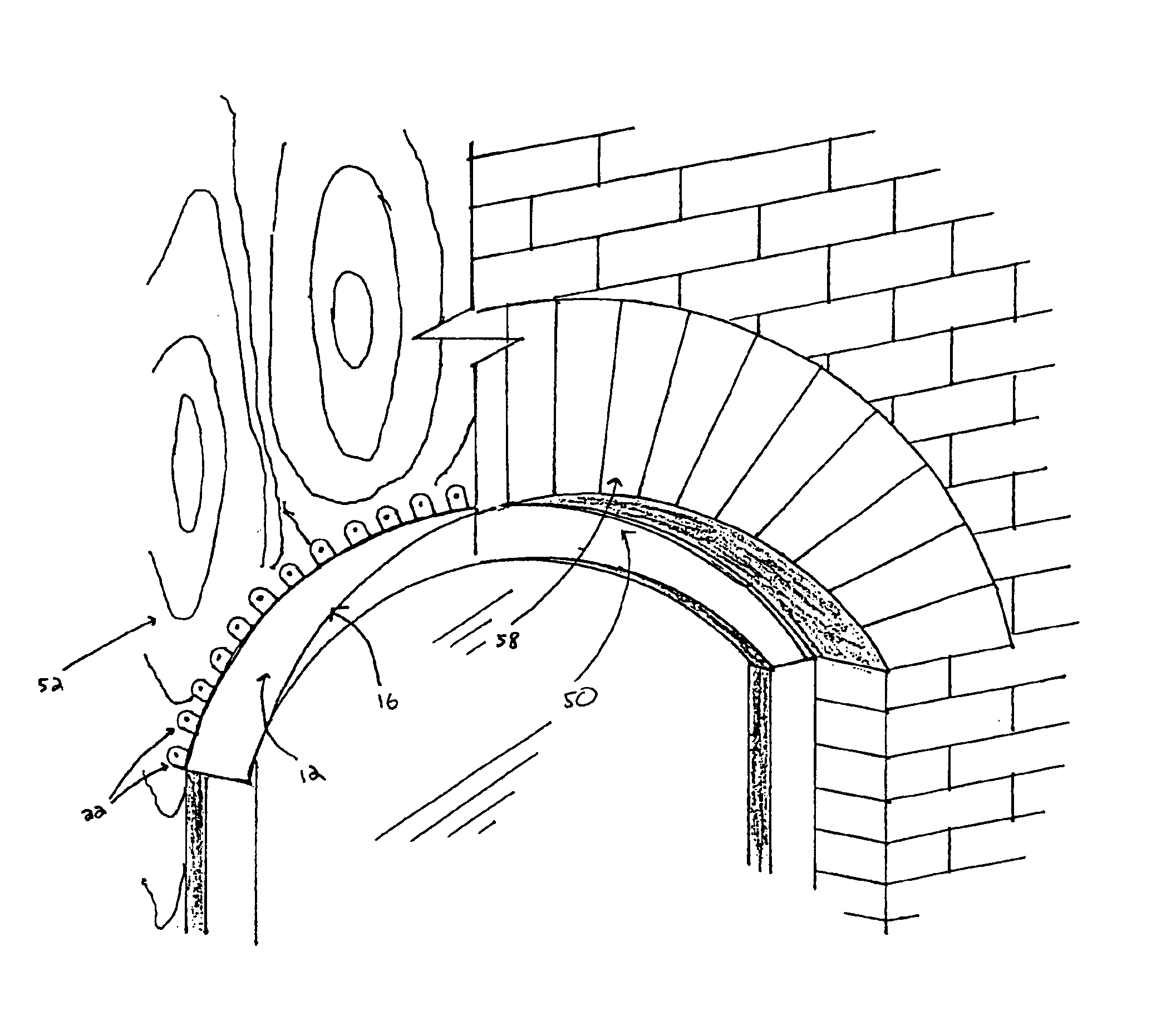

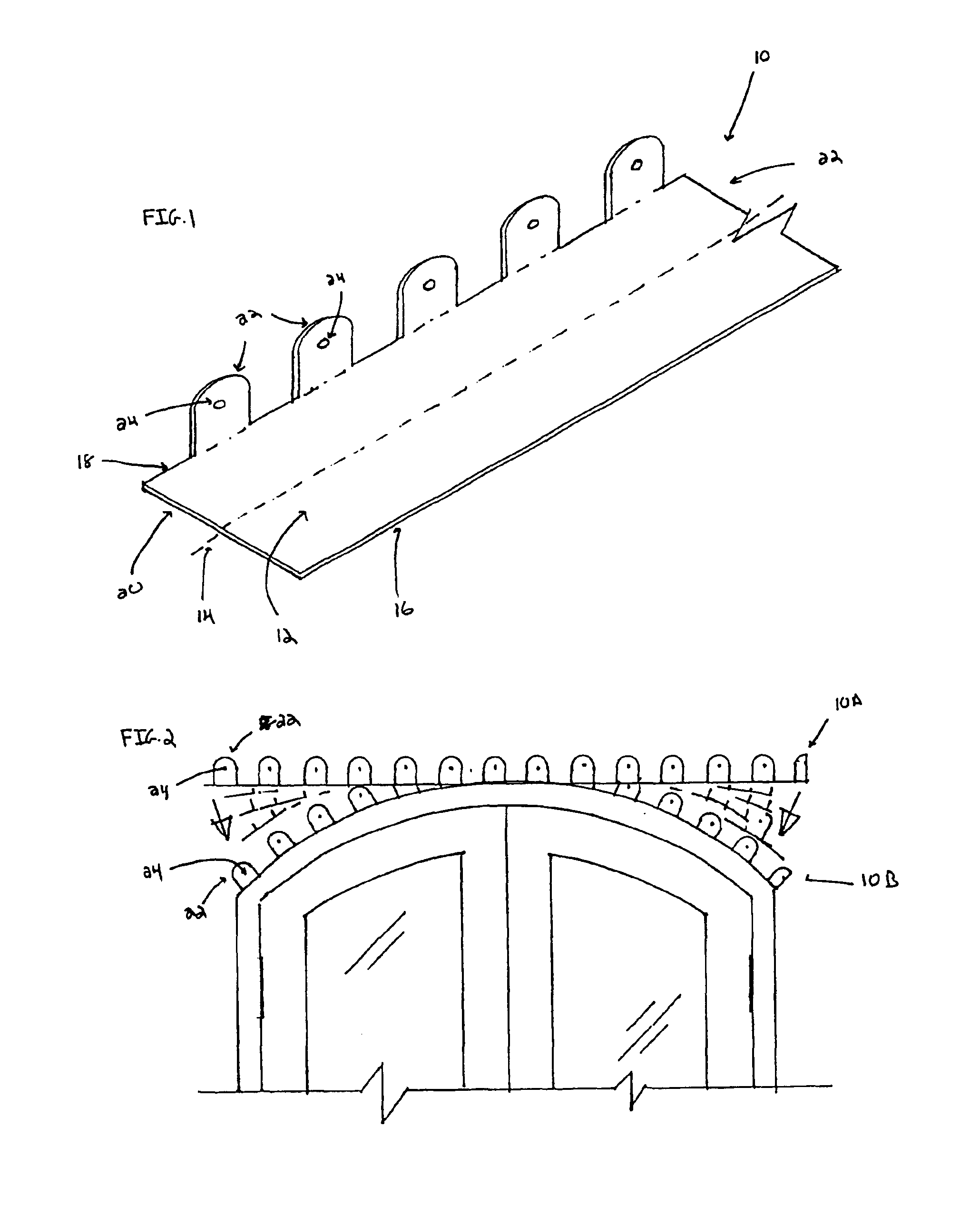

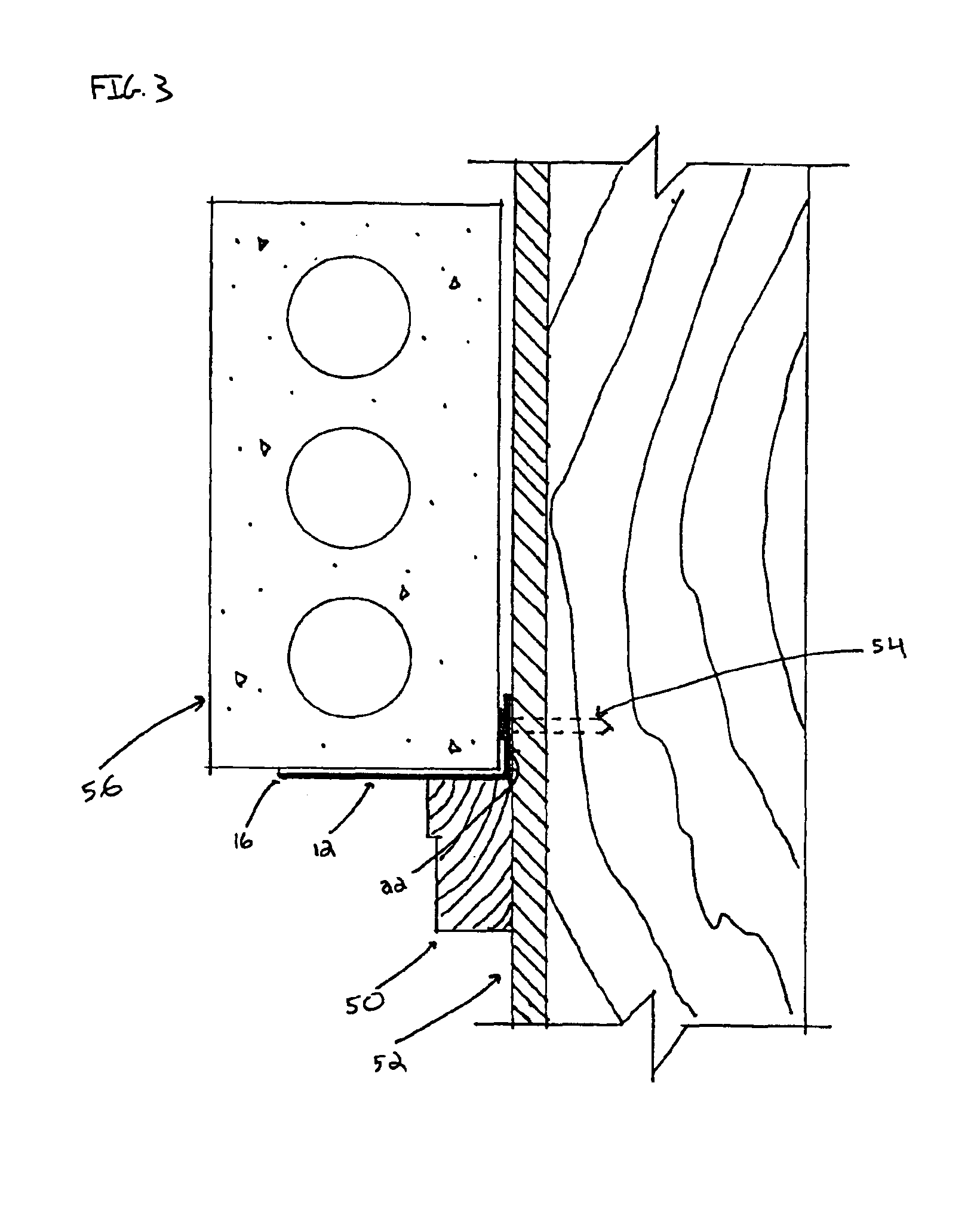

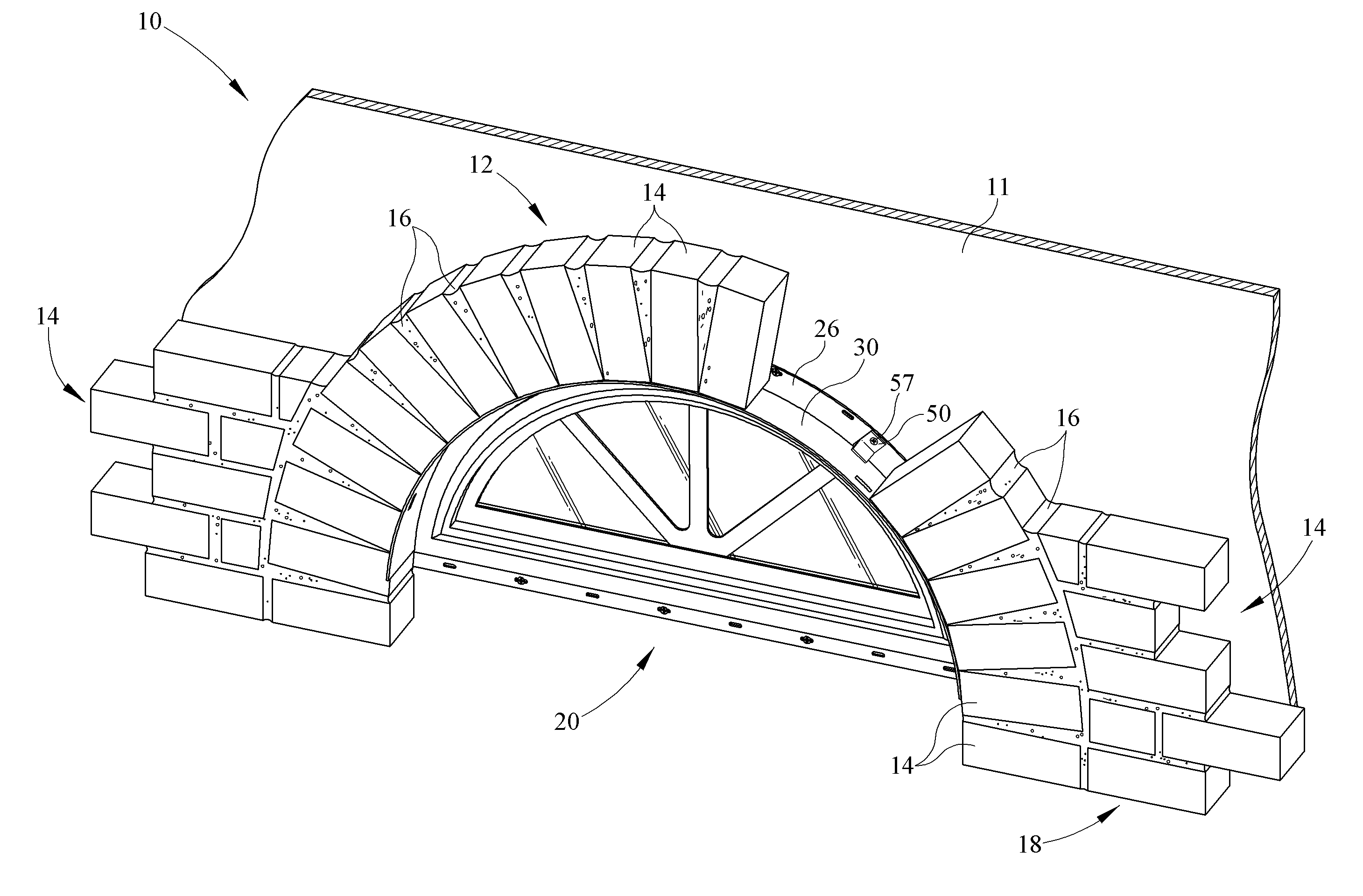

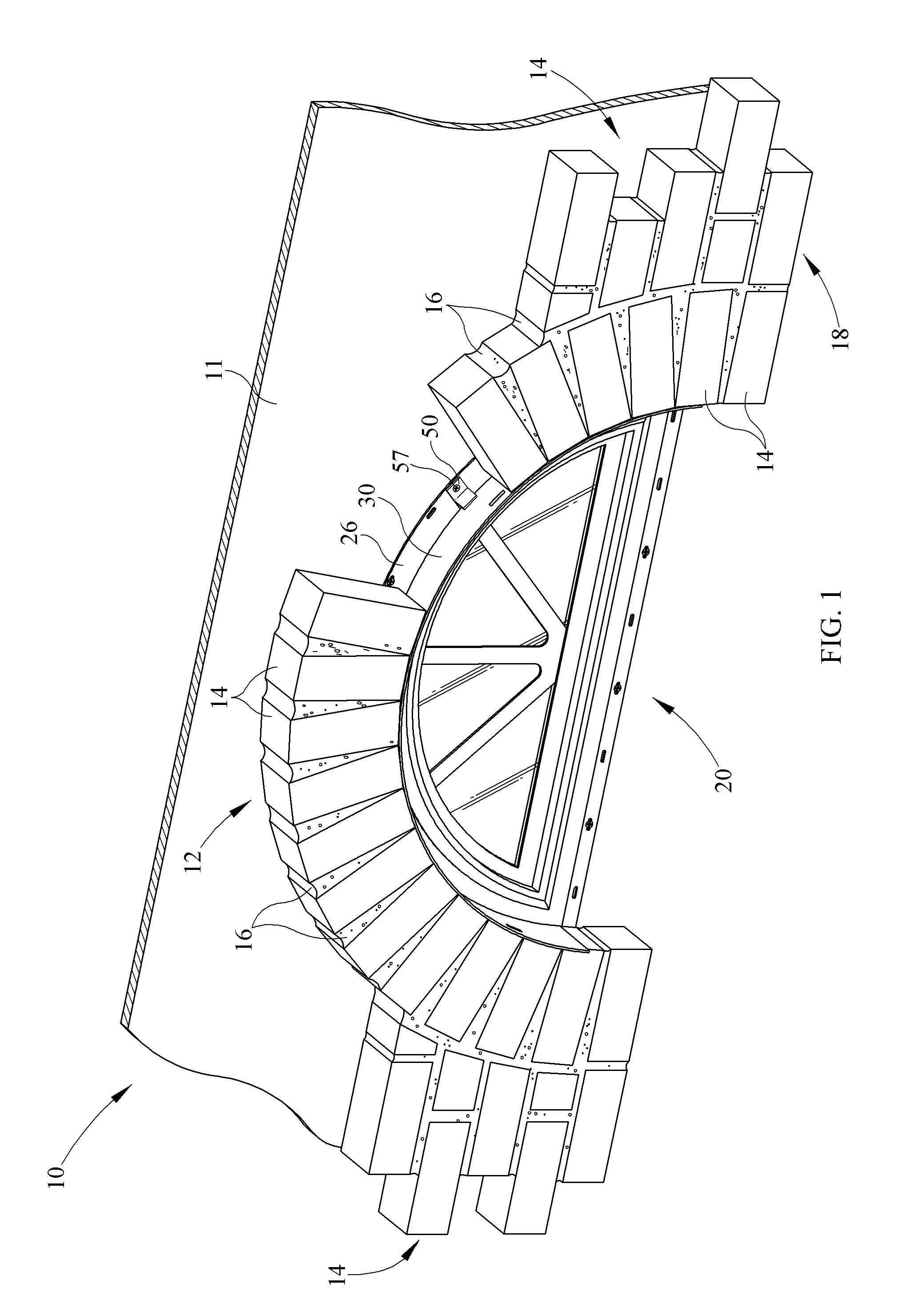

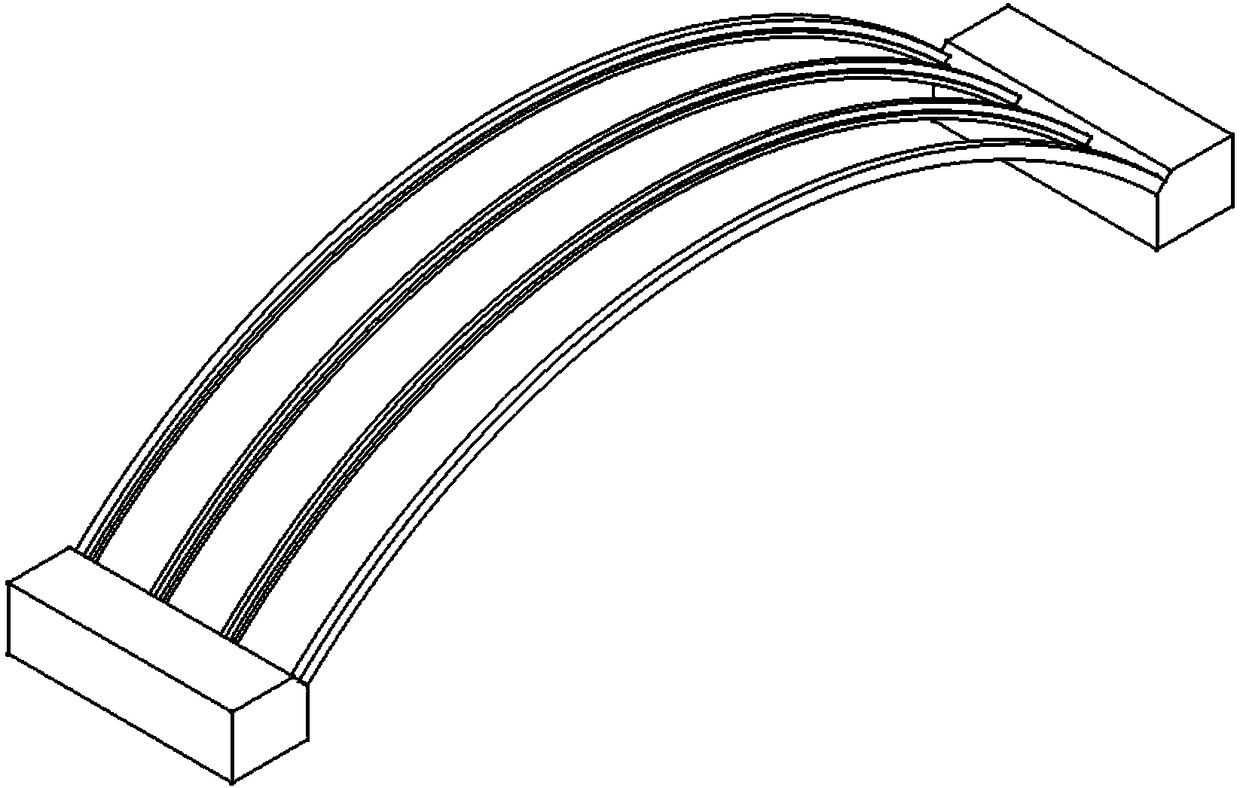

Adjustable masonry arch form

An adjustable masonry arch form is disclosed. The adjustable masonry arch form has a planar base section to support the masonry elements which will form the masonry arch, and a plurality of attachment elements secured to the planar base for securing the form to a structure. The adjustable masonry arch form is constructed from material rigid enough to support the masonry elements, but flexible enough to be bent to conform to any given arched construction without unwanted buckling of the form. The masonry elements which form the masonry arch are placed directly on the planar base of the form in the desired configuration and secured in the masonry arch by mortar. The form is left in position permanently, obviating the need to build a temporary arch support saving time and expense and obviating waste of materials.

Owner:BAILEY MICHAEL EUGENE

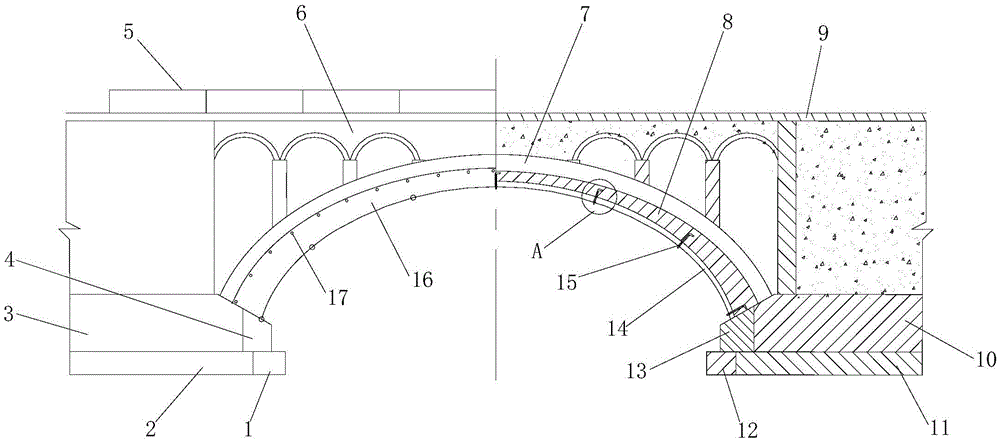

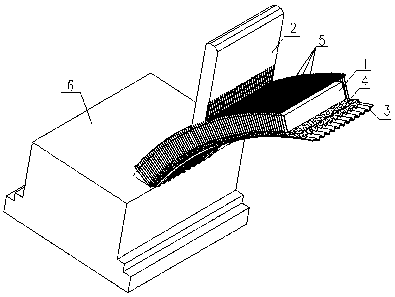

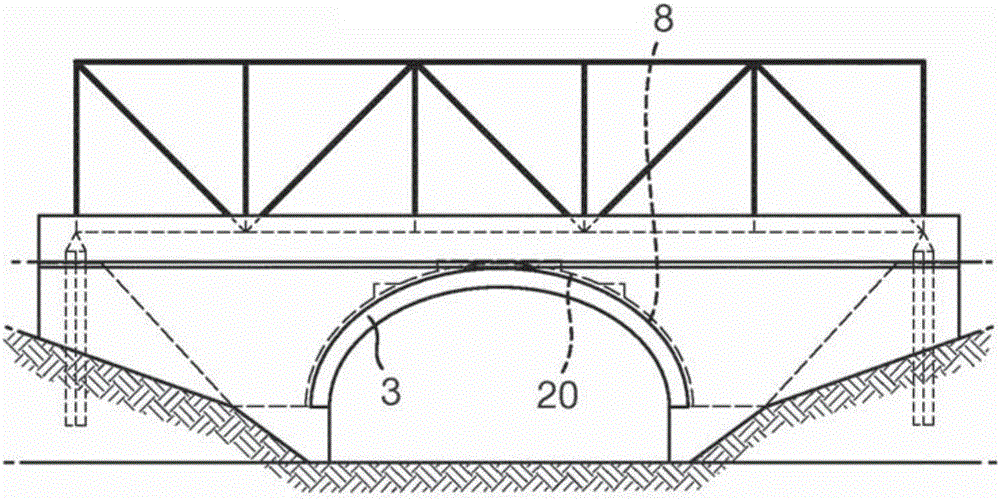

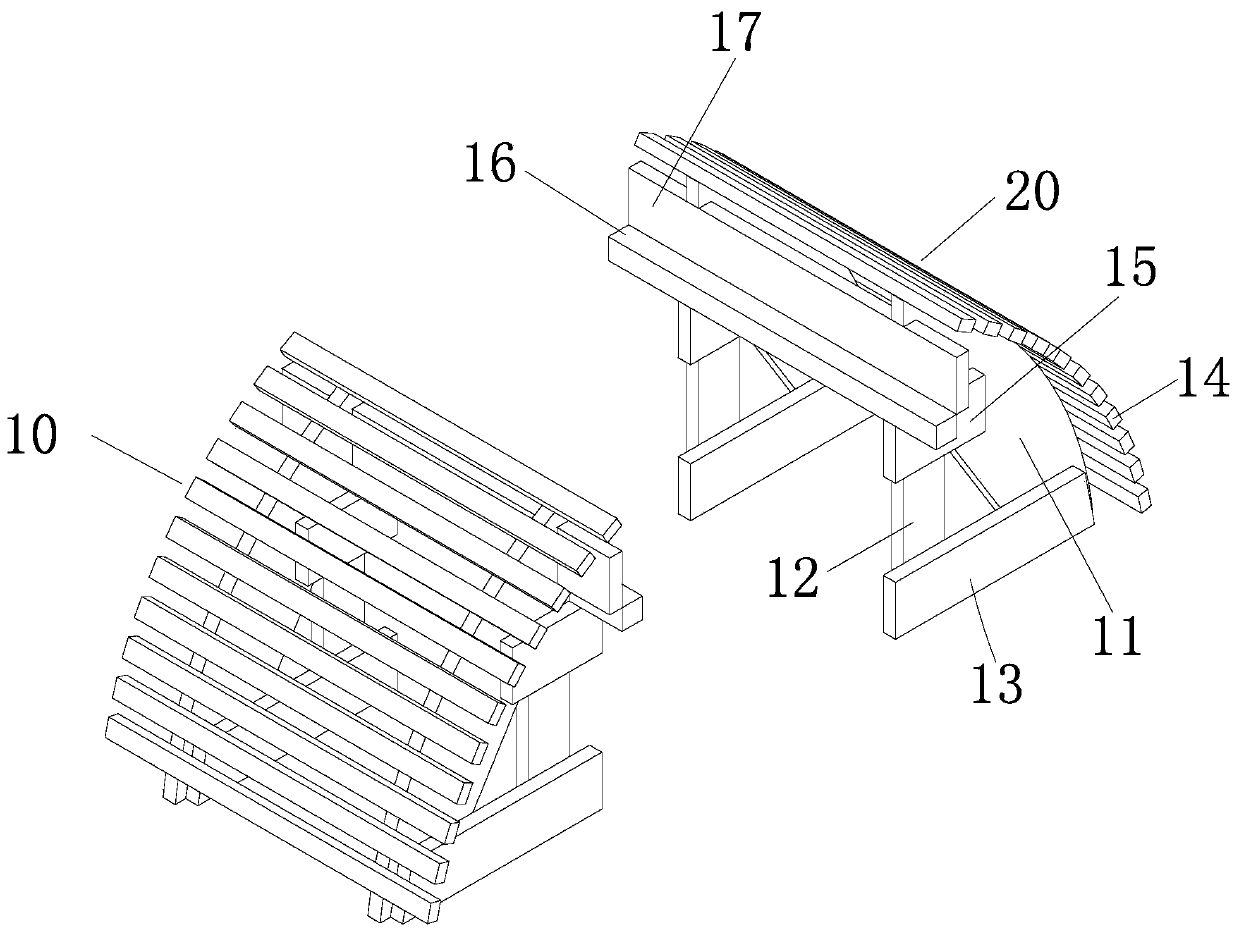

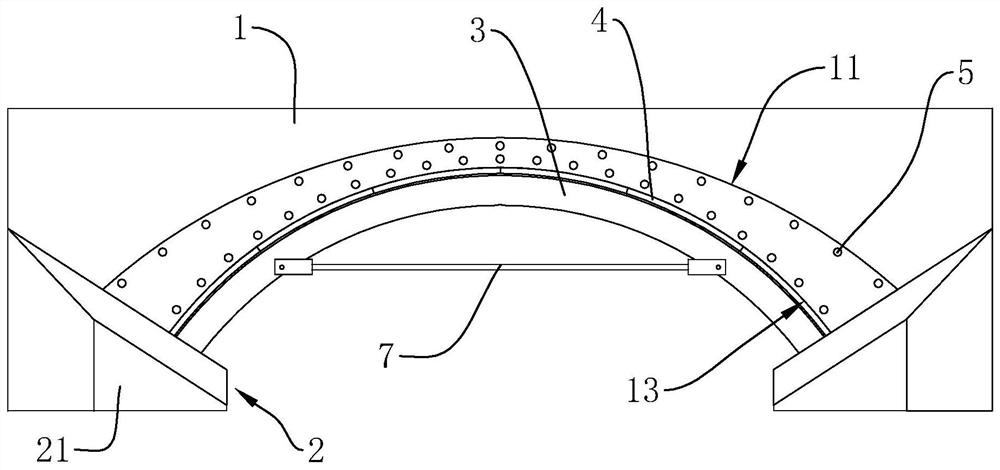

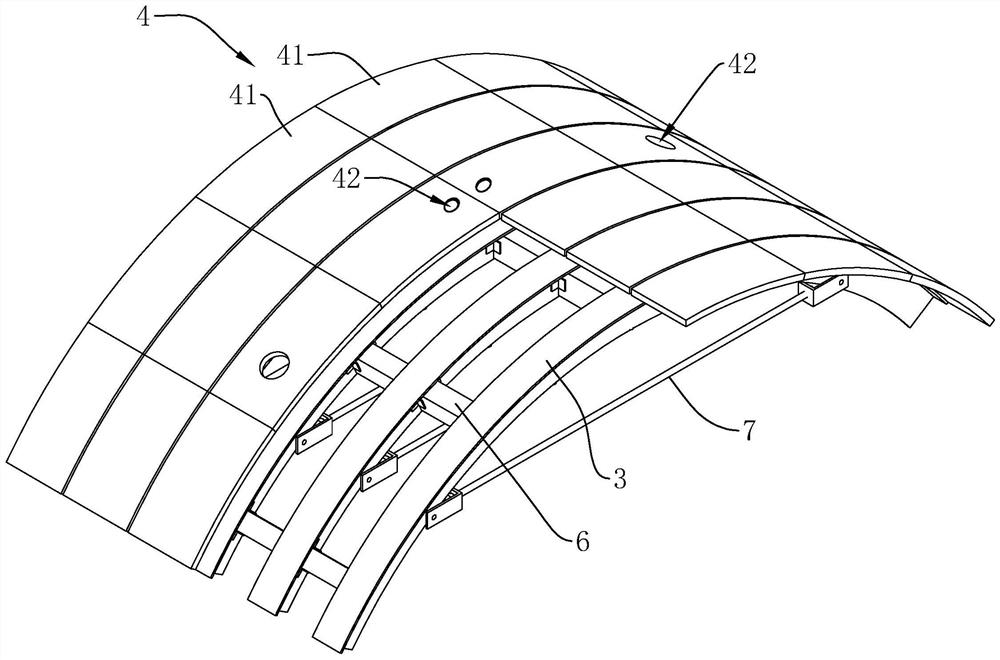

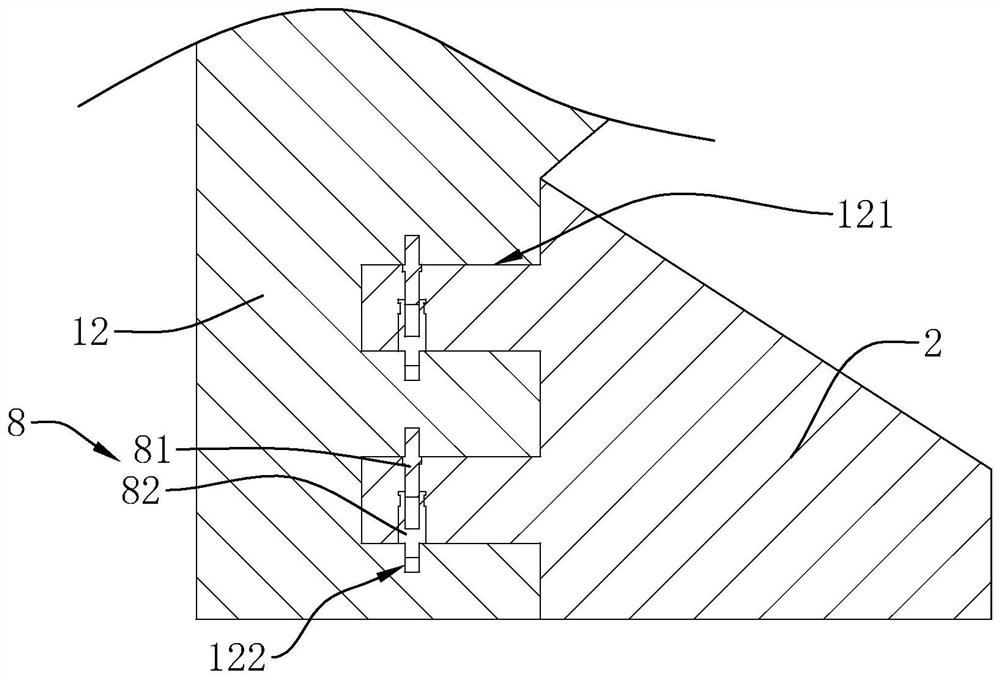

Masonry arch bridge reinforced structure and construction method thereof

ActiveCN105464006ARealize the reinforcement effectImprove bearing capacityBridge erection/assemblyBridge strengtheningFalseworkEngineering

The invention discloses a masonry arch bridge reinforced structure which comprises two side widened foundations, two side widened arch supports and a reinforced arch ring composed of self-compacting concrete and a corrugated steel arch shell. The reinforced structure can greatly enhance the bearing force of a damaged arch bridge, and the reinforcing operation has relatively small influence on mechanical properties of the existing arch ring. The invention also discloses a construction method of the masonry arch bridge reinforced structure, comprising the following steps: constructing the widened foundations; constructing the widened arch supports; constructing the corrugated steel arch shell; constructing sealing end plates; and constructing concrete filler. According to the construction method, by splicing the corrugated steel arch shell on an arch falsework and an extended arch support in a grouping mode, the construction of the masonry arch bridge reinforced structure can be quickly and effectively realized through traction movement and gradual positioning.

Owner:CHANGAN UNIV

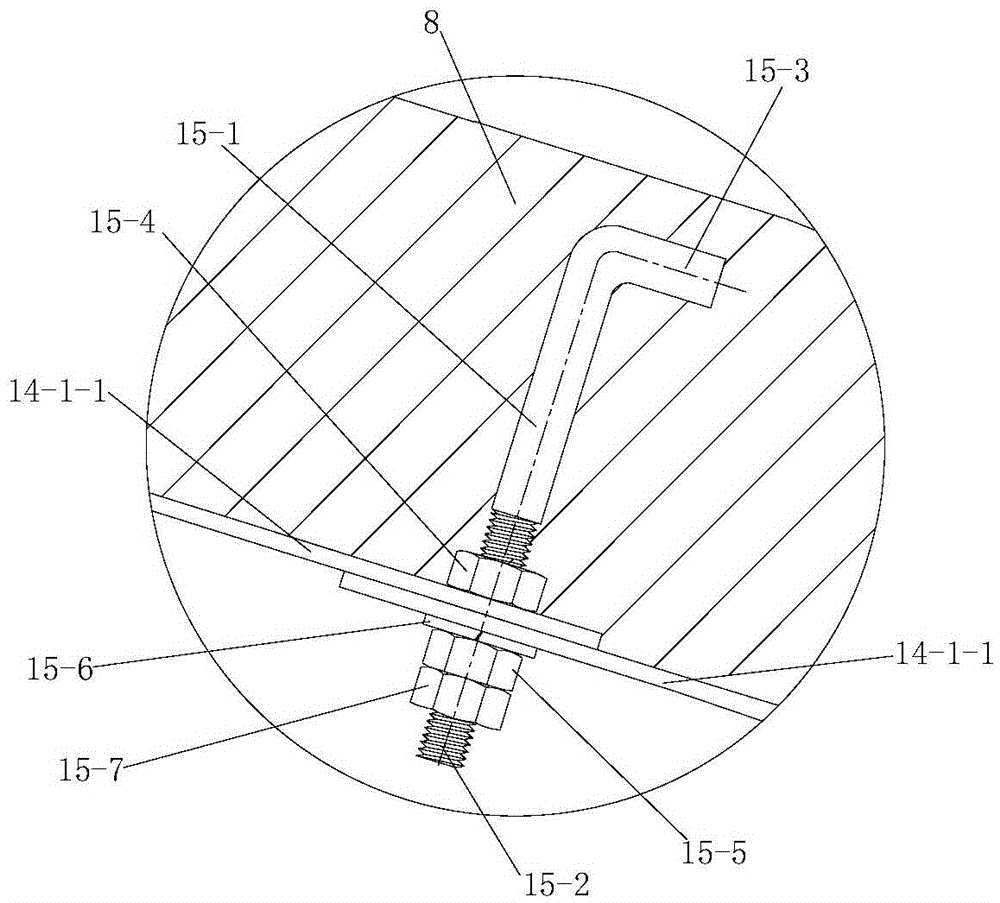

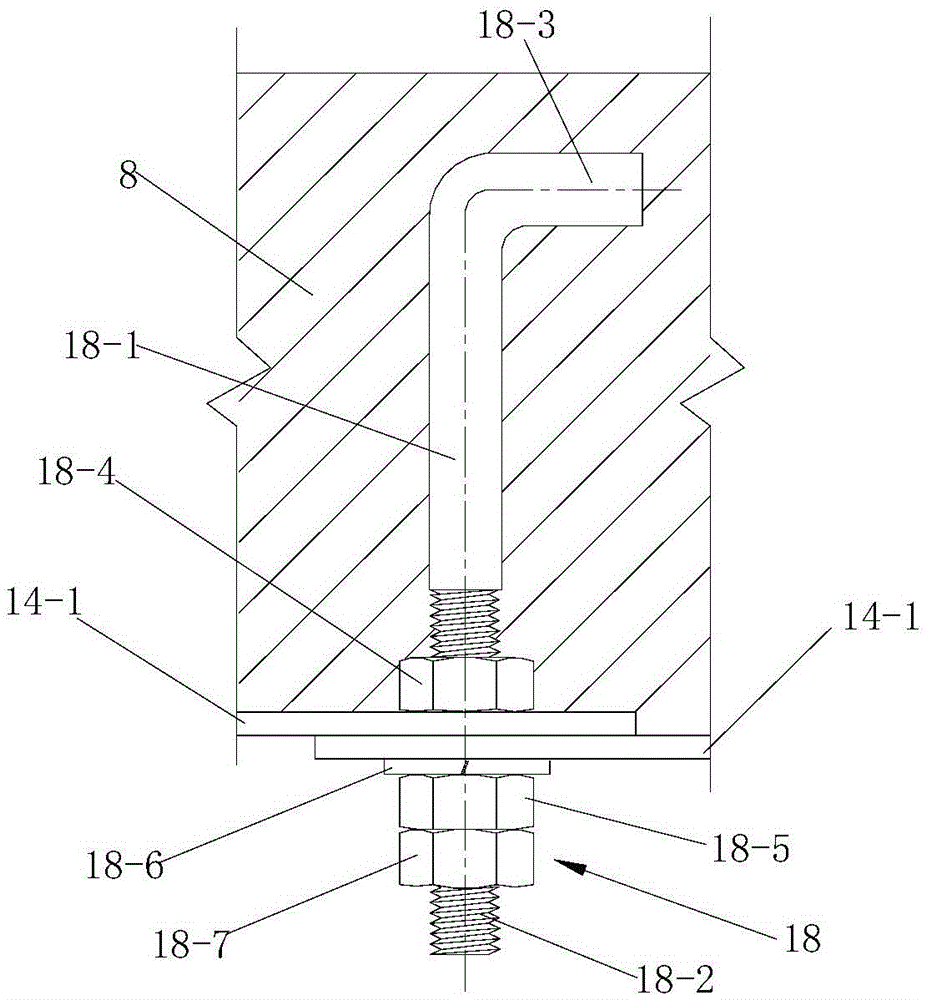

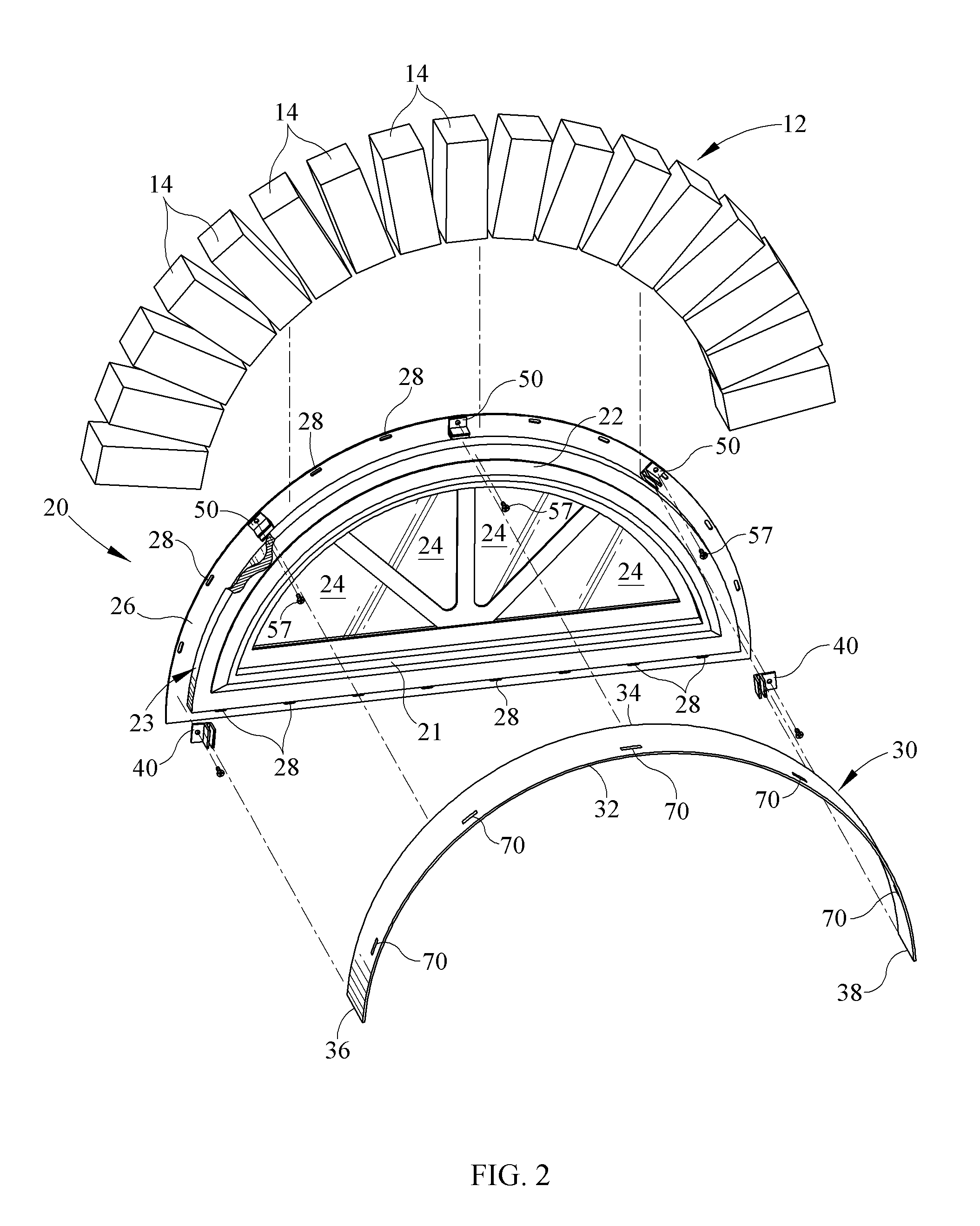

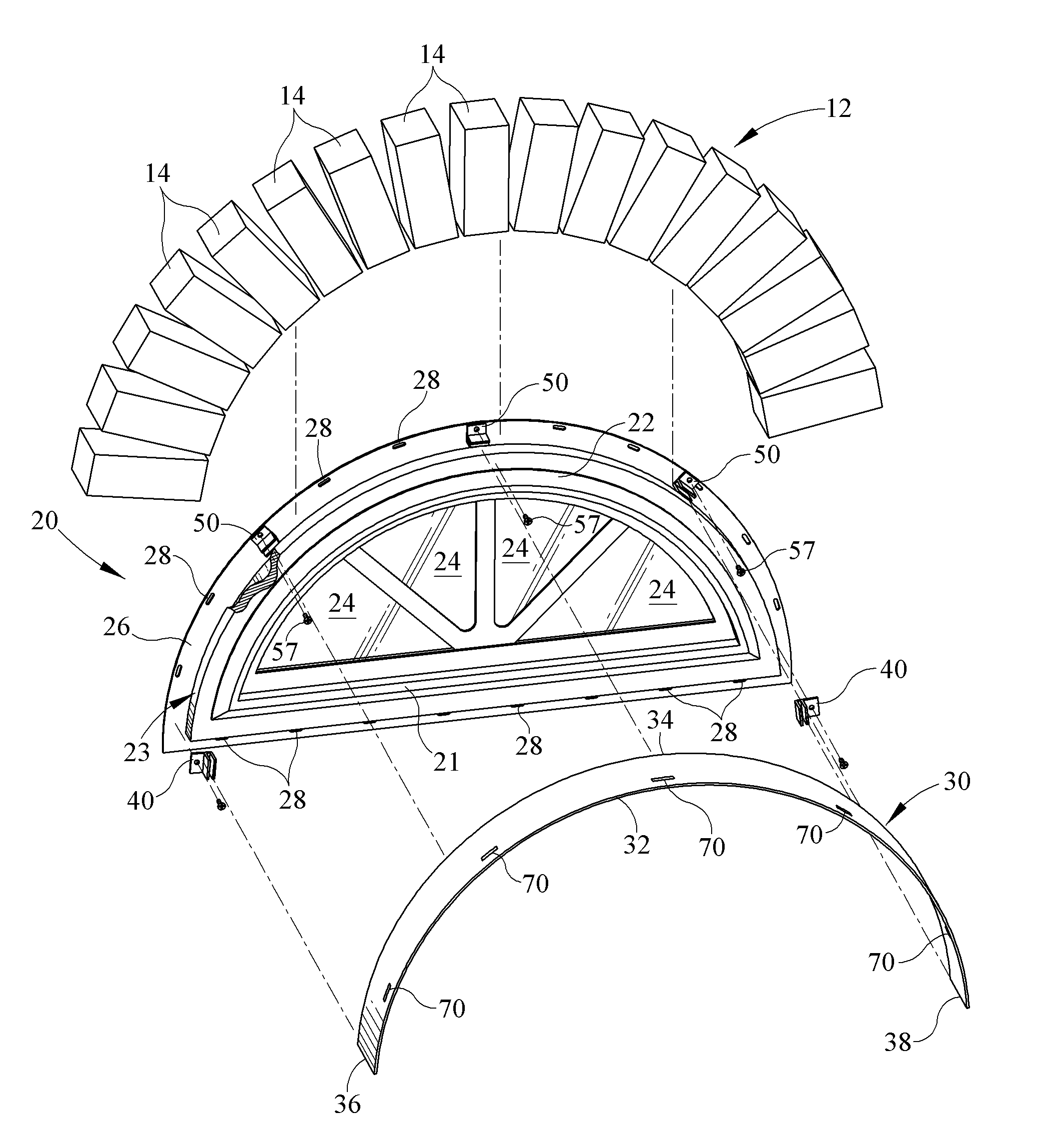

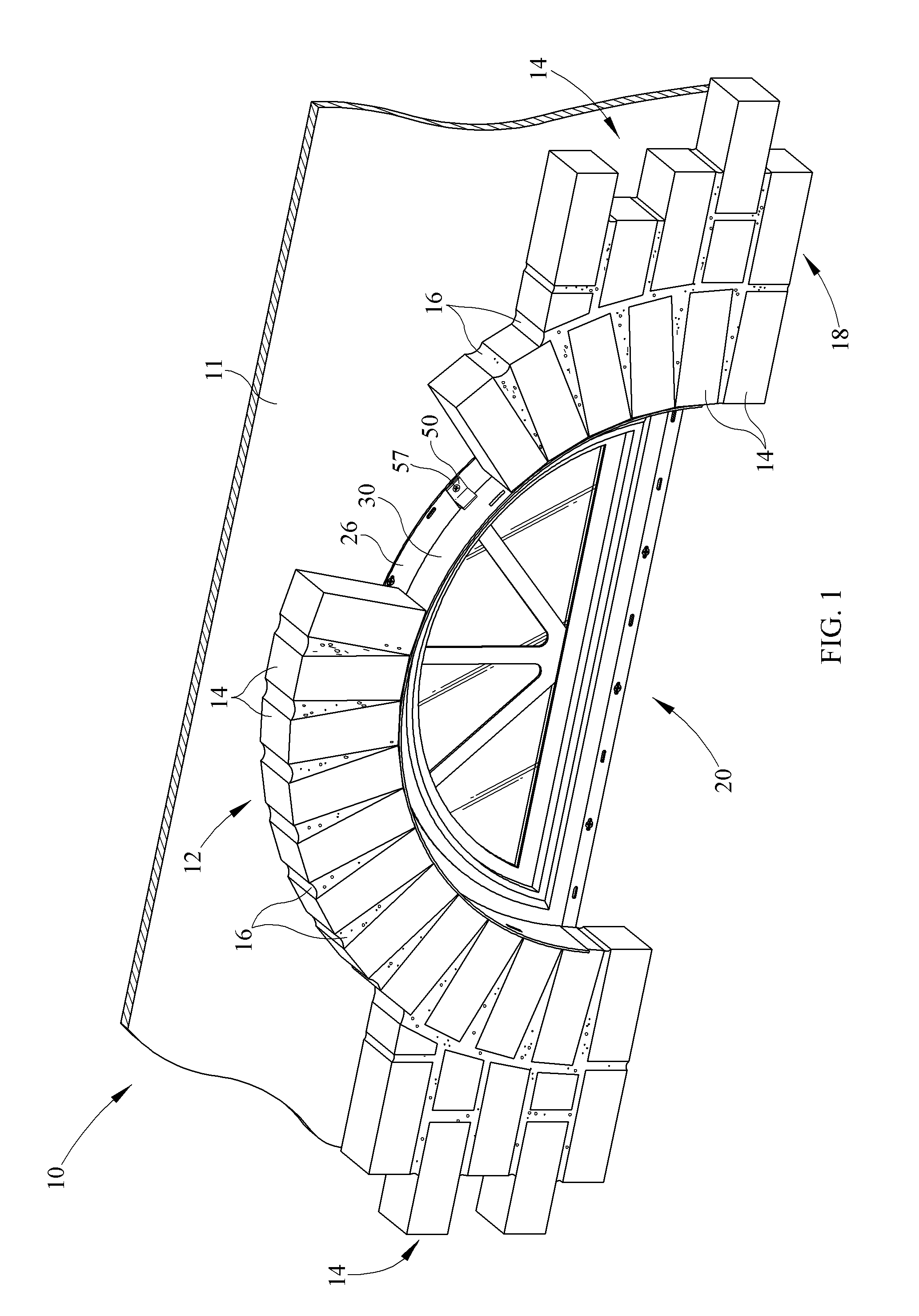

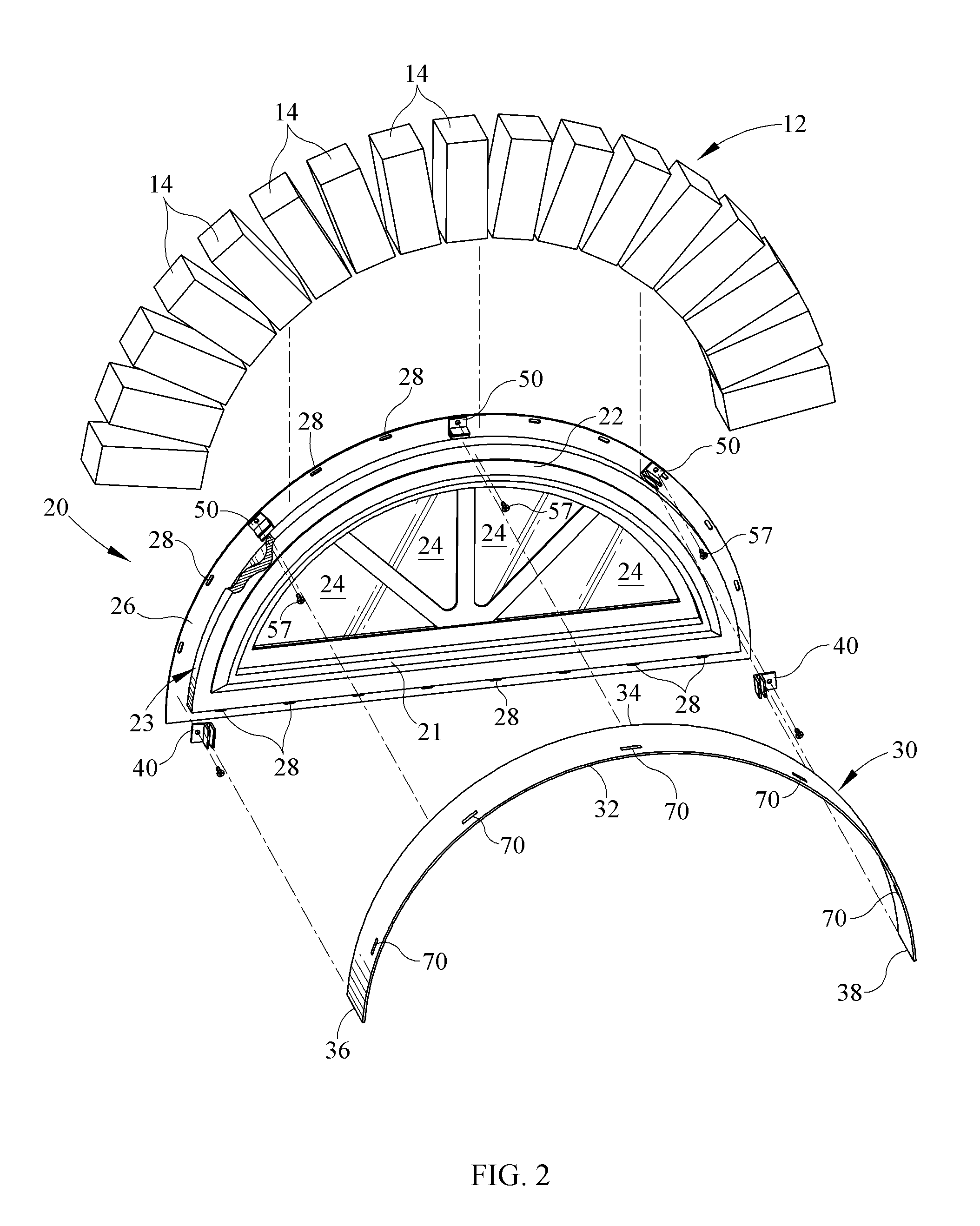

Removable arch form assembly and method of installing

A removable arch form assembly for use in forming a masonry arch of a plurality of masonry elements on a substructure comprises a flexible arch form having a substantially rectangular shape, first and second end clips engaging an arched structure about which the masonry arch is to be formed, at least one intermediate clip positioned on the arched structure between the end clips and at an elevation differing from the end clips, the end clips and the at least one intermediate clip removably receiving the flexible arch form and retaining the form in an arched orientation.

Owner:SCANLAN TOM

Reinforced portable integral prefabricated masonry arch bridge

ActiveCN102493327AImprove bearing capacityImprove stabilityArch-type bridgeArchitectural engineeringBridge deck

The invention relates to the technical field of arch bridges, in particular to a reinforced portable integral prefabricated masonry arch bridge, which comprises a bridge body and a bridge deck, wherein the inner side of the bridge body is provided with an arch ring; the arch ring comprises a main body consisting of a plurality of prefabricated arch blocks arranged in turn, and a fiber reinforced composite material connecting layer fixedly attached to the upper surface of the main body; side faces of every two adjacent prefabricated arch blocks are attached to each other; lower surfaces of all prefabricated arch blocks form a lower surface of the arch ring; the fiber reinforced composite material connecting layer is fixedly connected with the upper surface of each prefabricated arch block; a transverse pull rod is arranged between arch feet of the bridge body; and two ends of the transverse pull rod are fixedly connected with the bridge body through bolts. Compared with the prior art, the transverse pull rod is arranged between the arch feet of the bridge body and is used for providing self lateral restriction for an arch body, so that the bearing capacity and stability of the arch bridge structure are improved and the arch bridge can be applied to soft foundations.

Owner:DONGGUAN UNIV OF TECH

Removable arch form assembly and method of installing

Owner:SCANLAN TOM

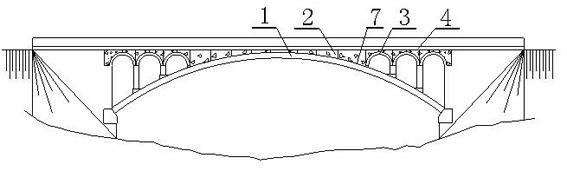

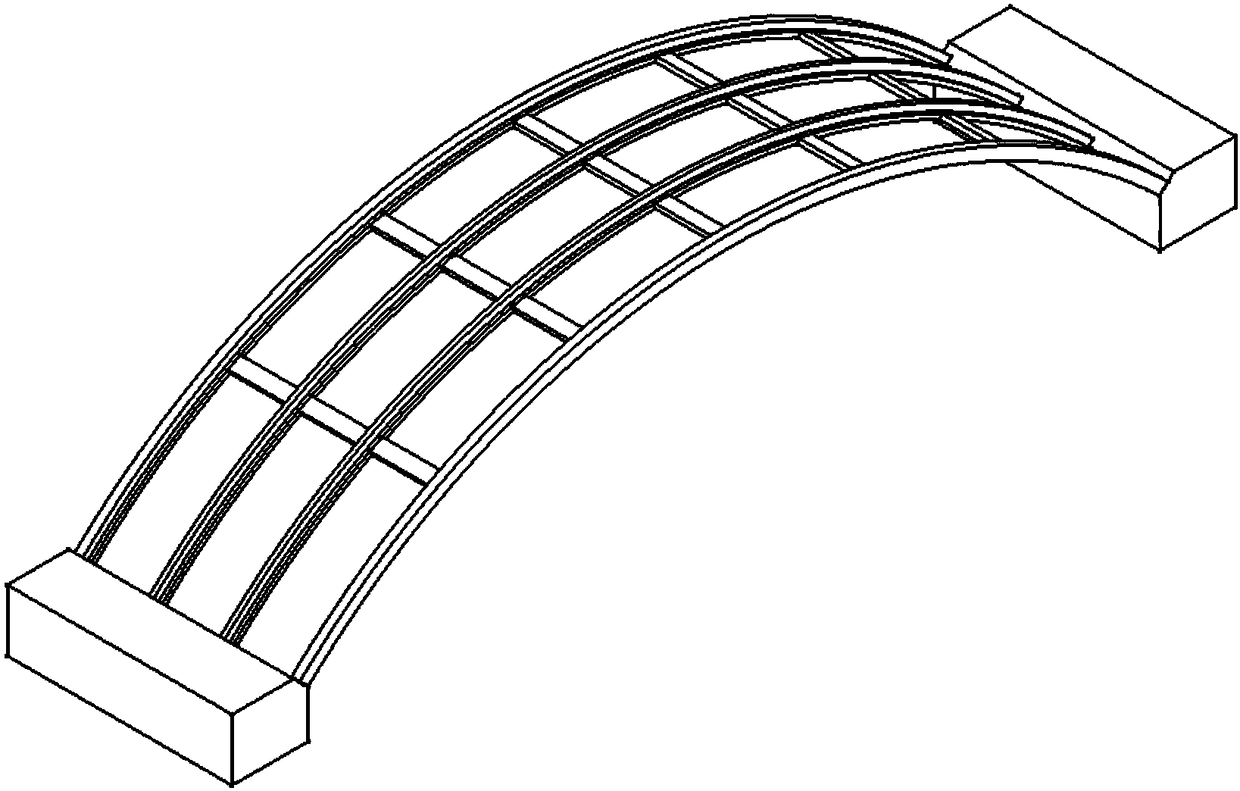

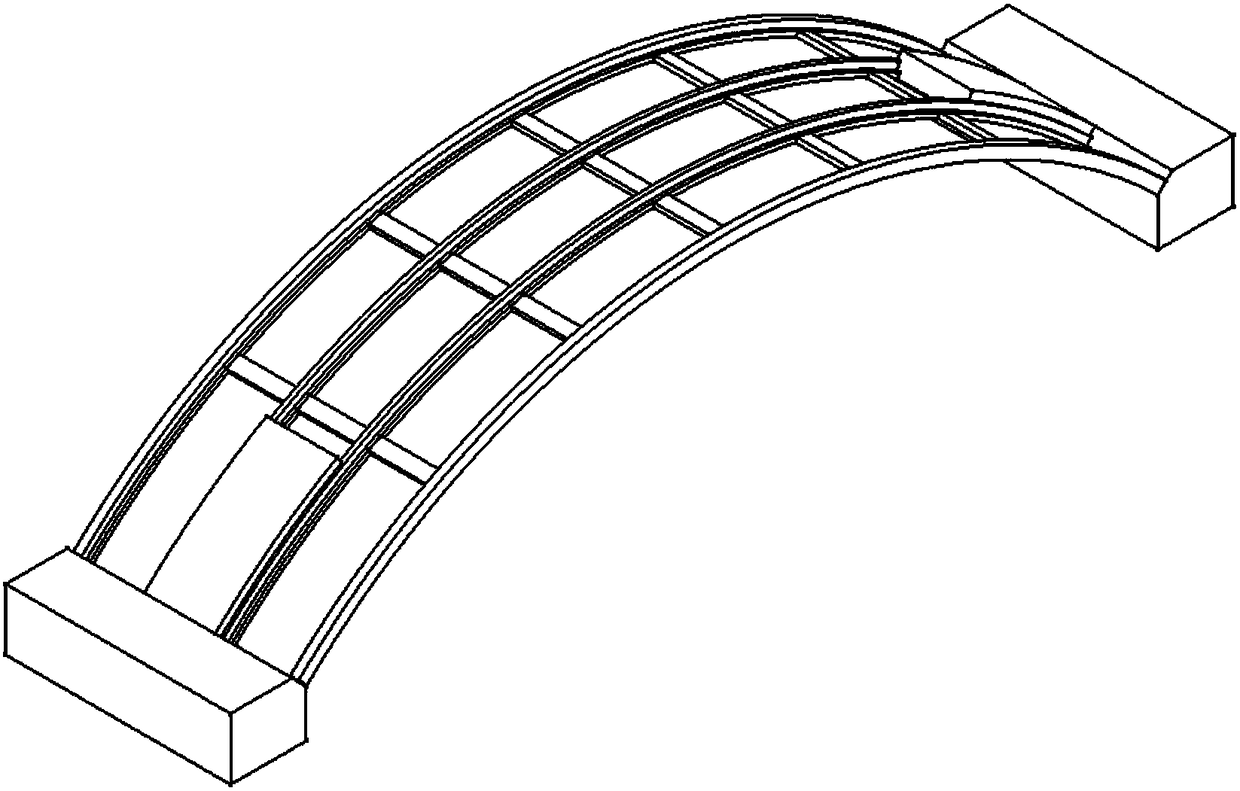

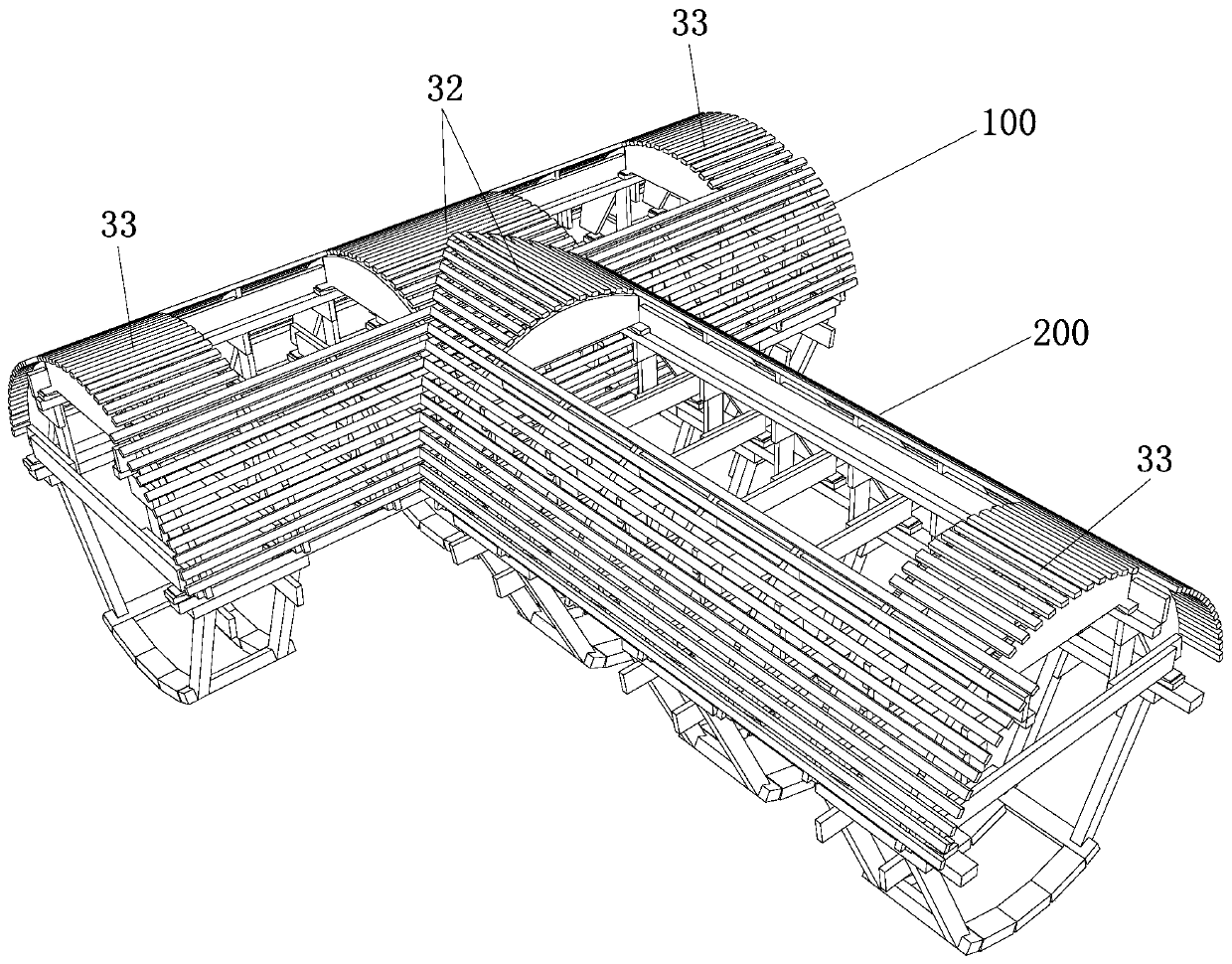

Novel RC-masonry combined arch bridge structure and construction method

PendingCN108374320AIncrease section sizeAvoid losing practical use valueBridge structural detailsBridge erection/assemblyFull bridgeAbutment

A novel RC-masonry combined arch bridge structure is composed of a first-stage structure, a second-stage structure and a building on an arch, wherein a whole space structure composed of RC arch ribs,RC cross beams and pier abutments serves as the first-stage structure; the RC arch ribs and the cross beams of the first-stage structure are prefabricated section by section in the early stage of construction, hoisted section by section, combined and cast in place into a whole. When the whole first-stage structure reaches design strength, masonry arch plates are built on the first-stage structurestrip by strip and section by section to serve as the second-stage structure, wherein the middle arch rib masonry arch plate is built first, and then the edge arch rib masonry arch plates are built. According to the thickness of a main arch ring, a later-stage structure or the building on the arch built on the second-stage structure layer by layer is determined till the whole bridge is formed, andconstruction is finished. According to the construction method, the RC arch ribs play a role in bearing components, and an arch frame formed by the arch ribs is a formwork support for later-stage structure construction, so that the waste caused when the arch frame in a traditional masonry arch bridge support construction method only serves as a construction support and is detached after the archring is built is avoided.

Owner:CHANGAN UNIV

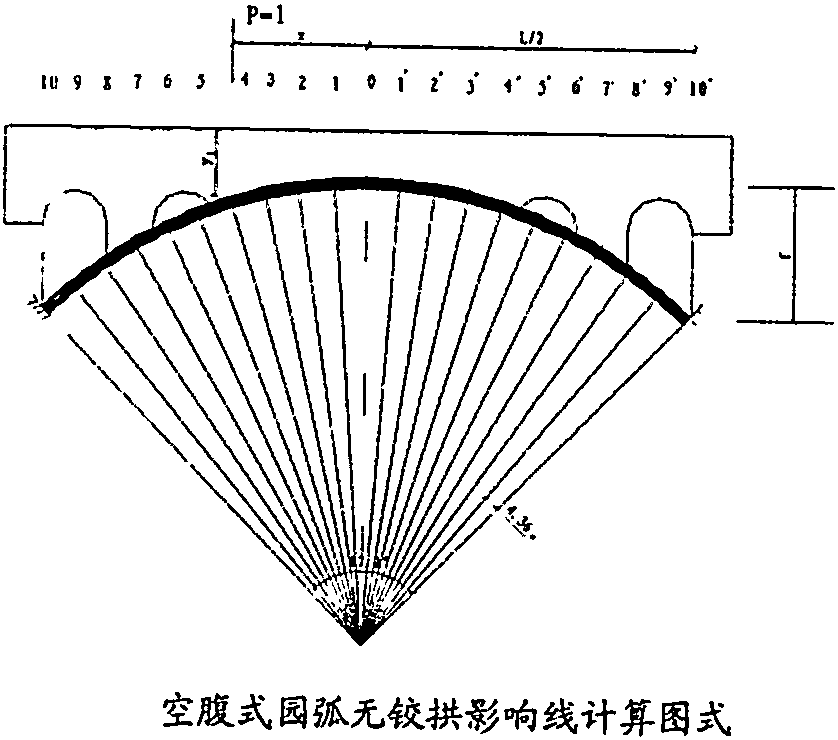

Method for reinforcing open-spandrel masonry arch bridge with corrugated steel plate hoop method

InactiveCN108330847AIncrease the strength design valueImprove bearing capacityBridge erection/assemblyBridge strengtheningCross wallStrength design

The invention discloses a method for reinforcing an open-spandrel masonry arch bridge with a corrugated steel plate hoop method. The open-spandrel masonry arch bridge comprises an arch ring and an arch bridge foundation, wherein the arch ring is arranged on the arch bridge foundation, a spandrel cross wall is arranged on the arch ring, distributed reinforcing steel bars are arranged at the upper end of the arch ring, a mortar protection layer is arranged on the outer side of the distributed reinforcing steel bars, the distributed reinforcing steel bars comprise longitudinally distributed reinforcing steel bars and horizontally distributed reinforcing steel bars, a self-compaction concrete filling body is arranged on the bottom side of the arch ring, a corrugated steel plate is arranged onthe outer side of the self-compaction concrete filling body, and L-shaped distributed reinforcing steel bars are arranged at two ends of the inner wall of the corrugated steel plate and integrally welded and tightened with the corrugated steel plate and the distributed reinforcing steel bars to form a hoop tightened original masonry structure. The strength design value of a material is increased,stone weathering is prevented, the tolerance of the structure to non-uniform tensile stress is improved, limited brackets can be adopted for construction, and the construction progress is acceleratedwhile the measure expense is reduced.

Owner:中顾国际工程咨询有限公司

Ultra-high-performance concrete lattice reinforcement structure and method thereof for reinforcing masonry arch bridge

InactiveCN108457201AMake up strengthMake up durabilityBridge erection/assemblyBridge strengtheningStructure of the EarthEngineering

The invention discloses an ultra-high-performance concrete lattice reinforcement structure and a method thereof for reinforcing a masonry arch bridge. The reinforcement structure comprises primary main arch rings, shear-resistant connectors and ultra-high-performance concrete longitudinal and transverse reinforcement strips. The original main arch rings are provided with the shear-resistant connectors, so that the ultra-high-performance concrete longitudinal and transverse reinforcement strips are integrated with the original main arch rings. The defects of low material strength, low bonding strength, poor durability and the like of ordinary concrete are compensated, so that reinforcement layers and the original main arch rings form an integrated part to jointly bear stress, and the application status of deviation between a reinforcement design calculation theory and the actual stress state is improved. The consumption amount of reinforcing materials is small, loads of the original main arch rings are reduced, and meanwhile ultra-high-performance concrete reinforcement layers share more live load effects. The long-term use performance and durability of a bridge are improved, the situations of cracking, damage, water seepage and other damage of concrete at the junctions of the reinforcement layers and the original main arch rings are avoided, and the lifetime cost of reinforcement of the masonry arch bridge is reduced.

Owner:SHANXI PROVINCIAL RES INST OF COMM

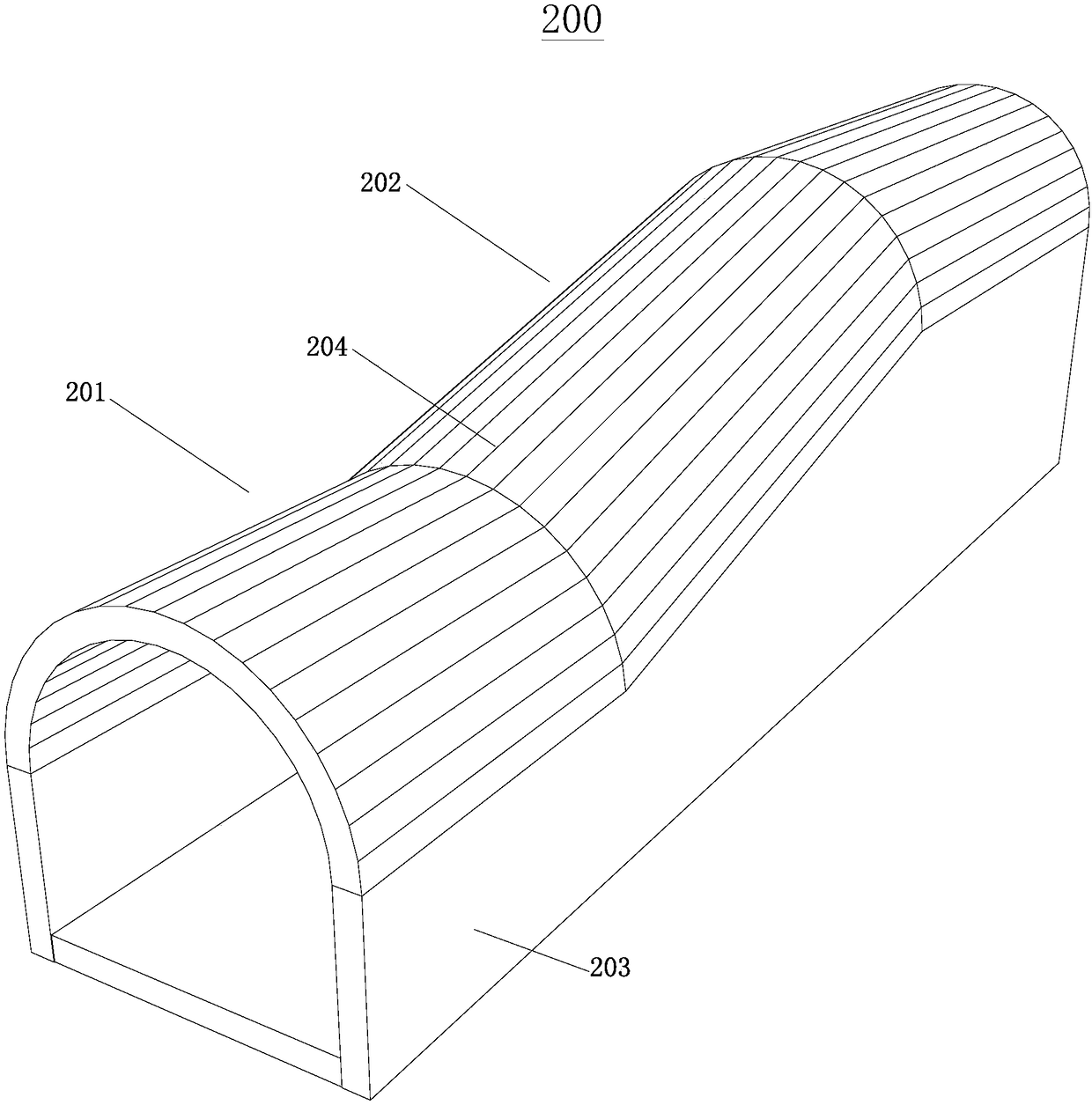

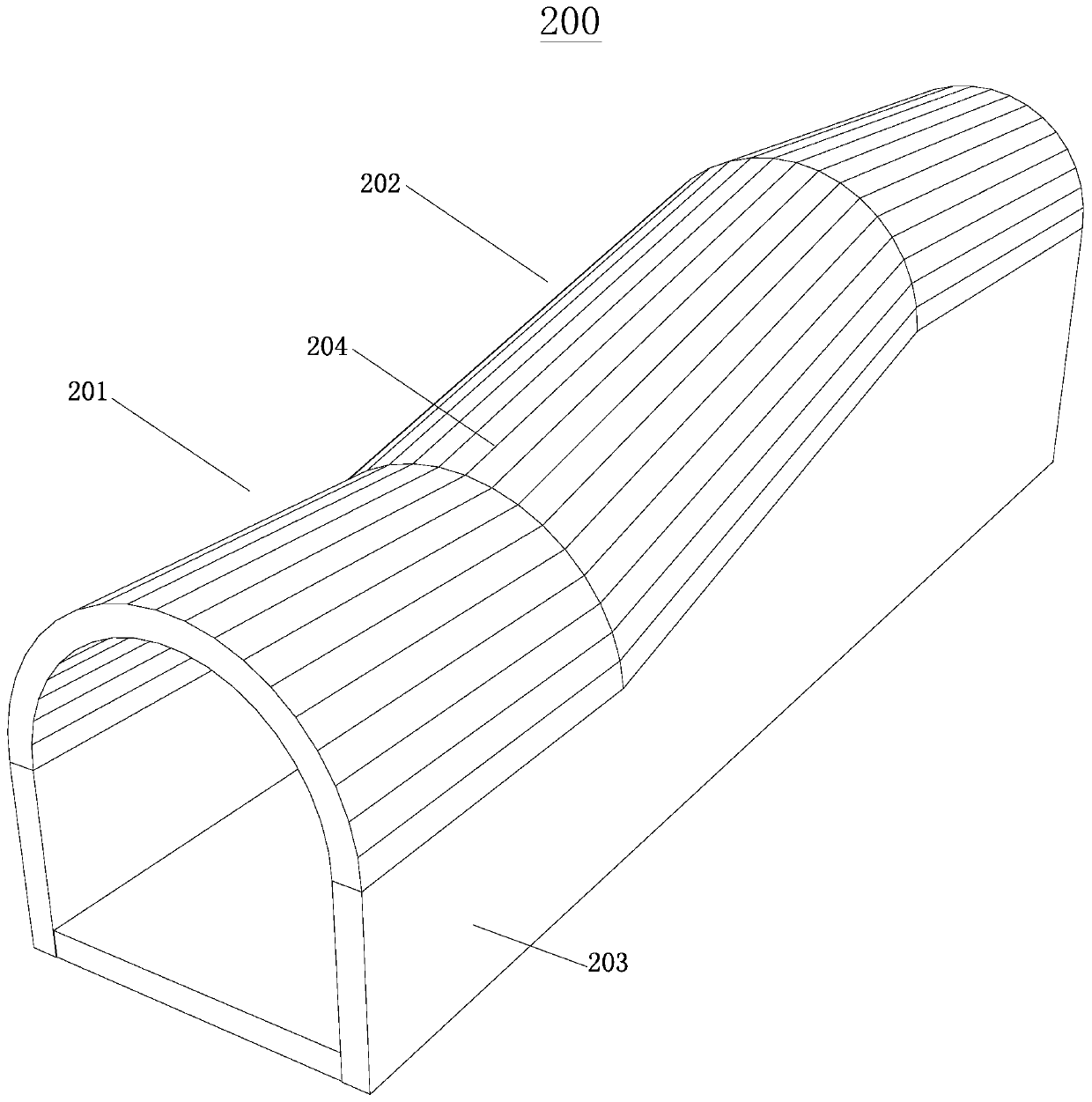

Novel reinforcing method of fabricated masonry arch body

PendingCN110055905ALarge widthEffective reinforcementBridge erection/assemblyBridge strengtheningPrecast concreteMaterials science

The invention discloses a novel reinforcing method of a fabricated masonry arch body. The novel reinforcing method comprises the following steps: a, concrete arch blocks are prefabricated; b, the concrete arch blocks are linearly arrayed and flatly laid to be orderly so as to form an arch block linear array; c, an FRP cloth is flatly laid on the upper surface of the arch block linear array to obtain the flexible arch body; d, a mortar protective layer is poured; e, left and right side permanent supports are poured; f, left and right side temporary supports are fixedly placed; g, left and rightside jacks are mounted; h, hoisting is prepared; i, the flexible arch body is hoisted, and arch rings are formed; j, lifting eye bolts are dismantled; k, the arch rings are pushed in place; l, the left and right side jacks are reset; m, the step h to the step l are repeated to complete subsequent arch ring mounting operation till all the needed arch rings are mounted below a bridge floor of an original bridge; and n, the left and right side temporary supports are dismantled. According to the reinforcing method, an original bridge structure can be effectively machined, the construction processis convenient and quick, and durability is good.

Owner:DONGGUAN UNIV OF TECH

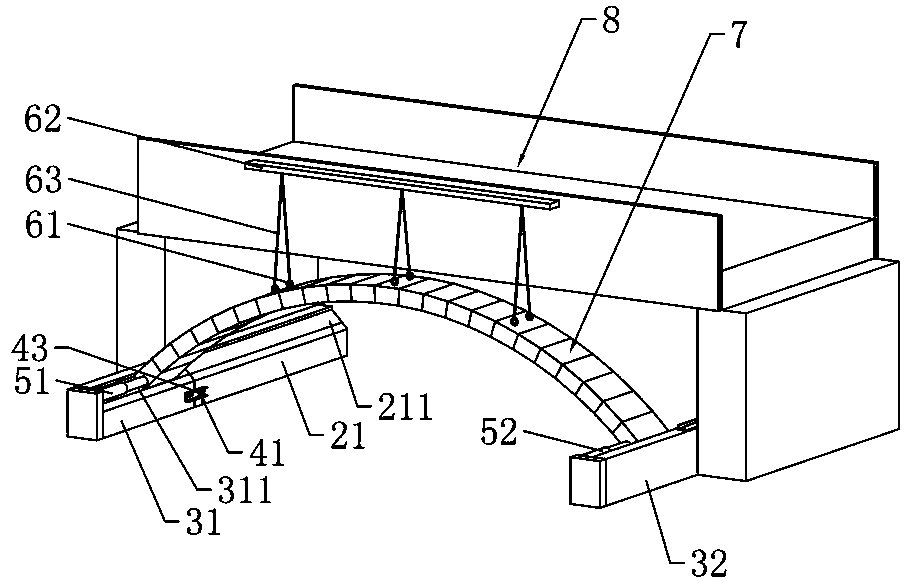

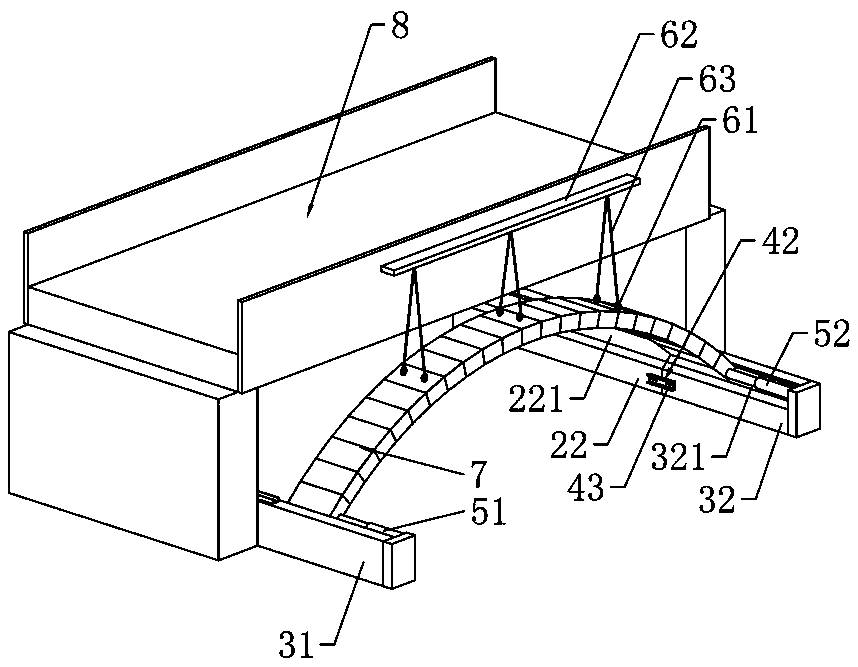

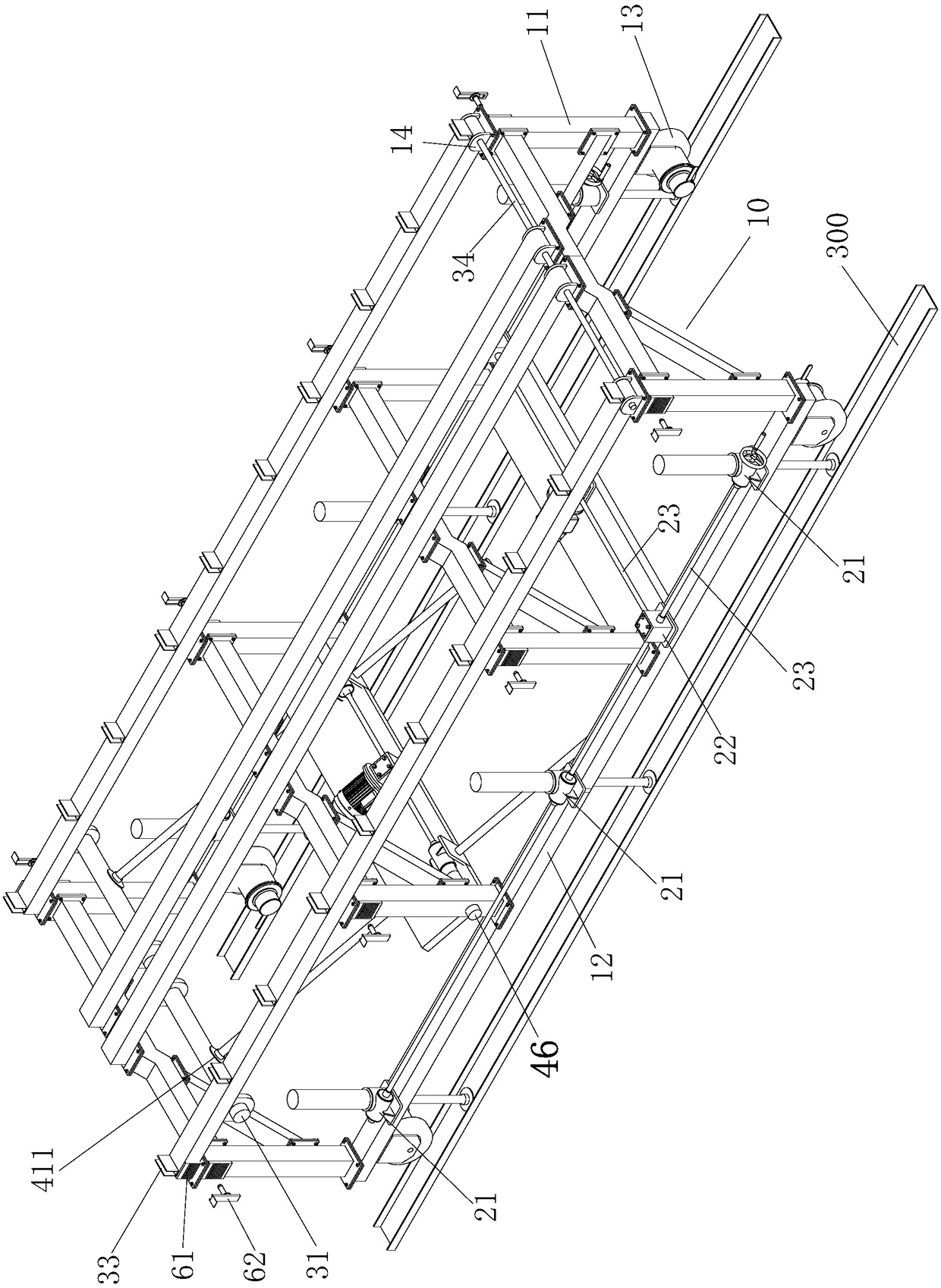

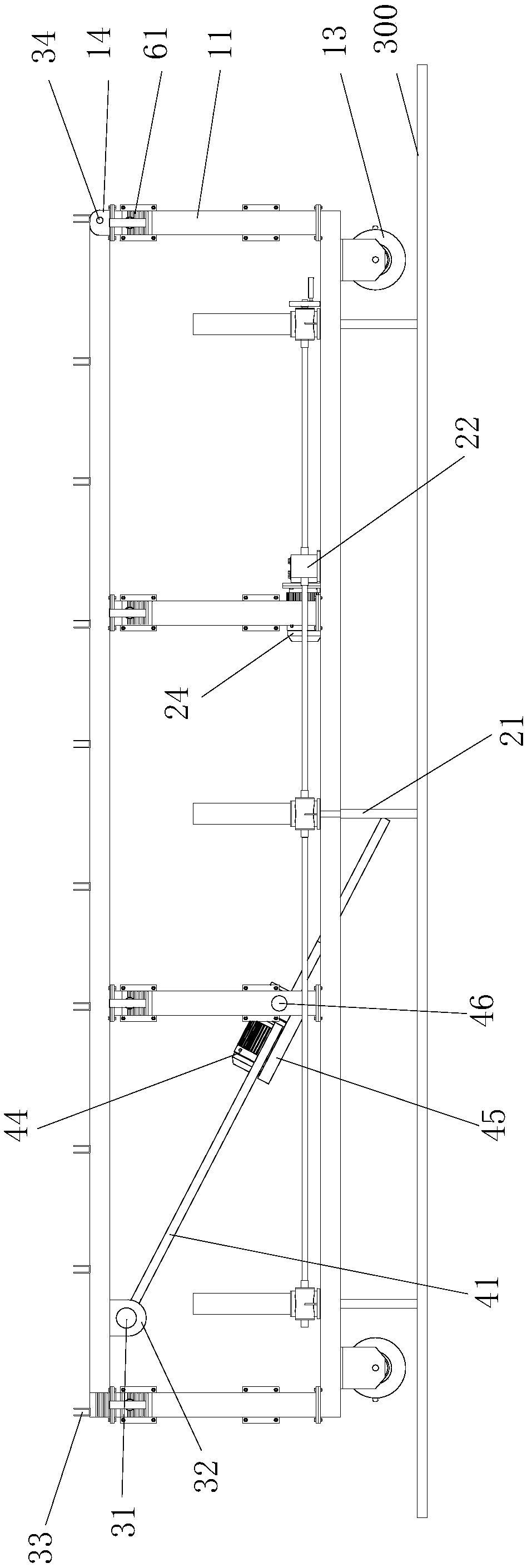

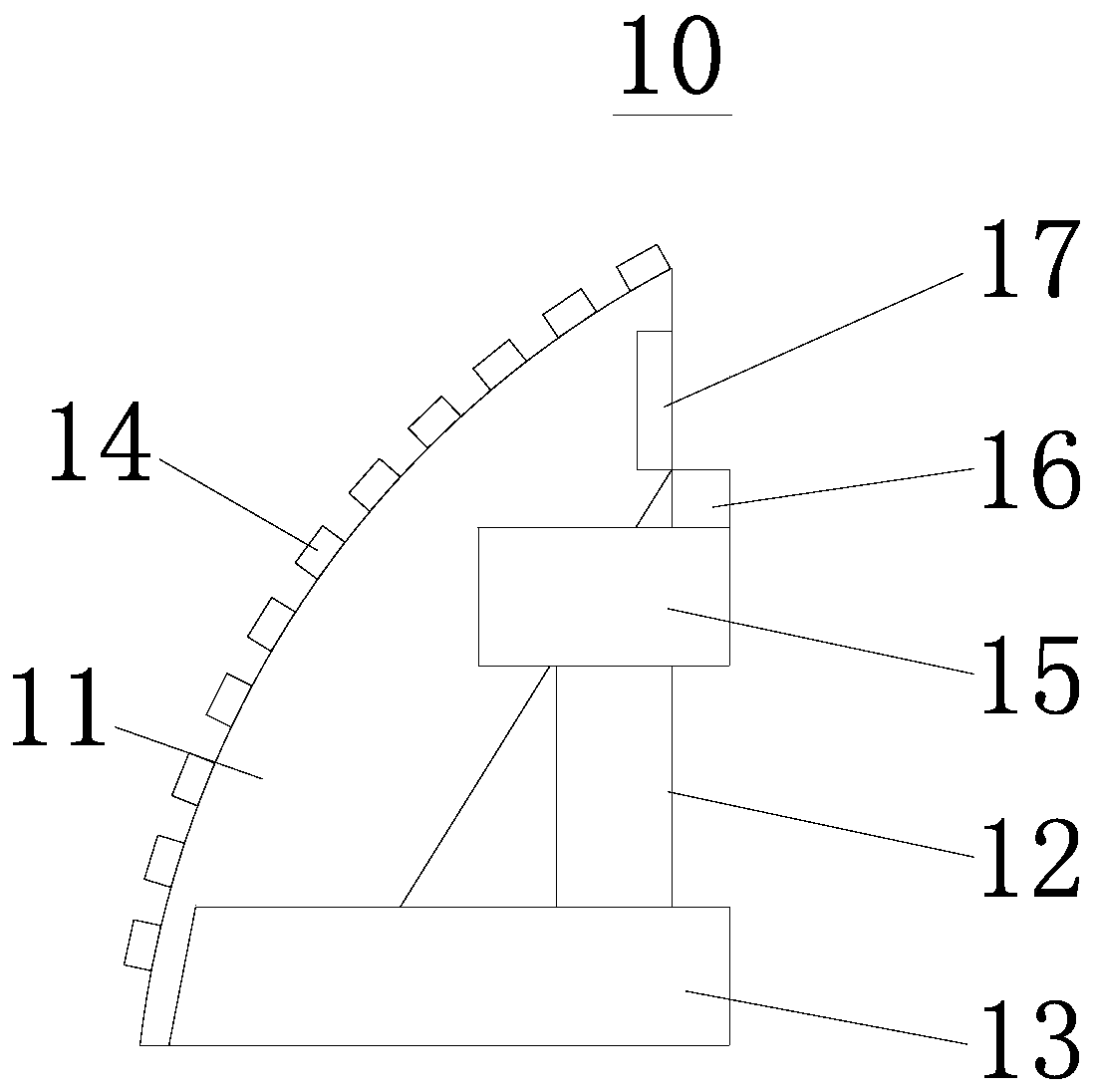

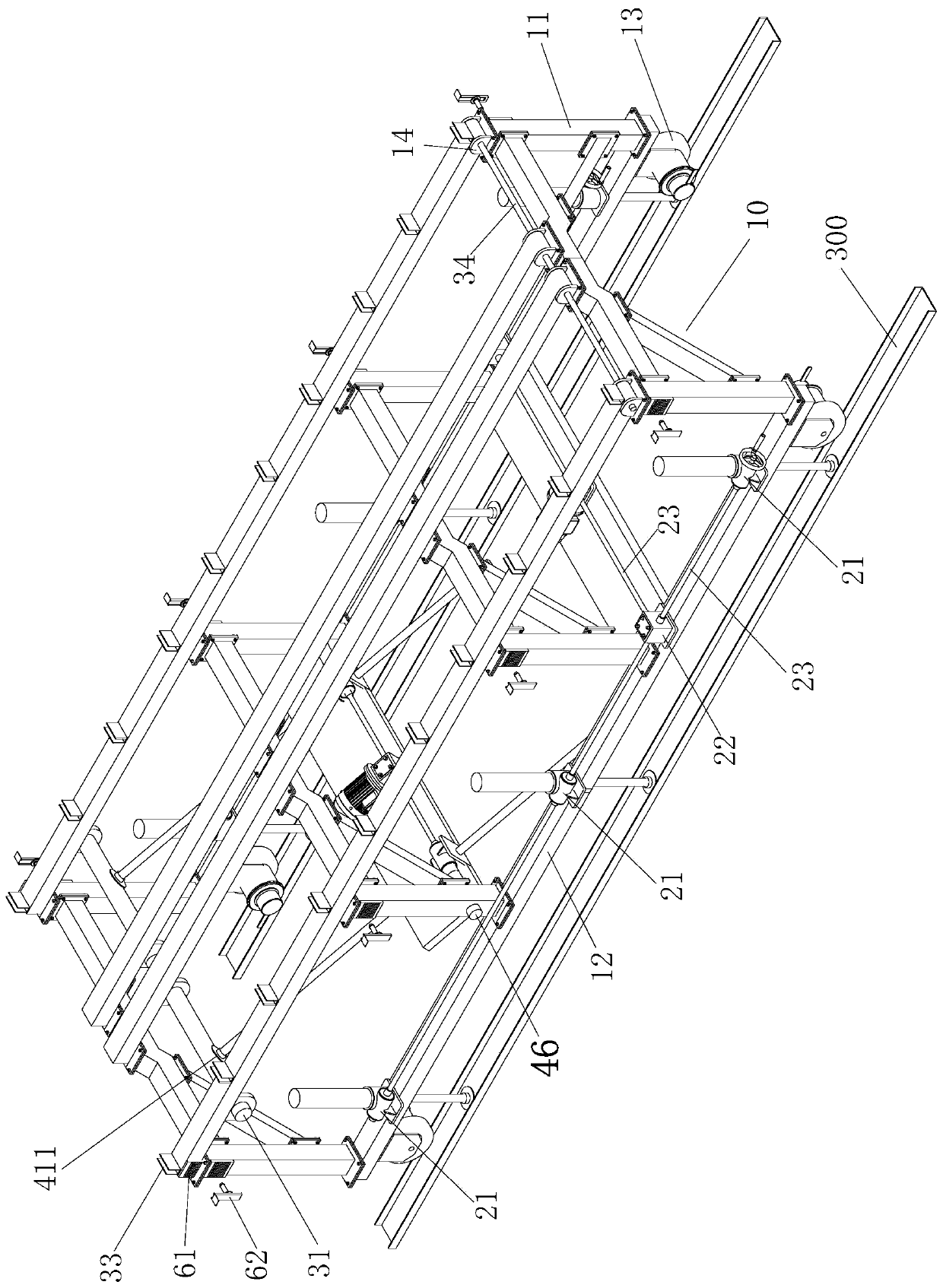

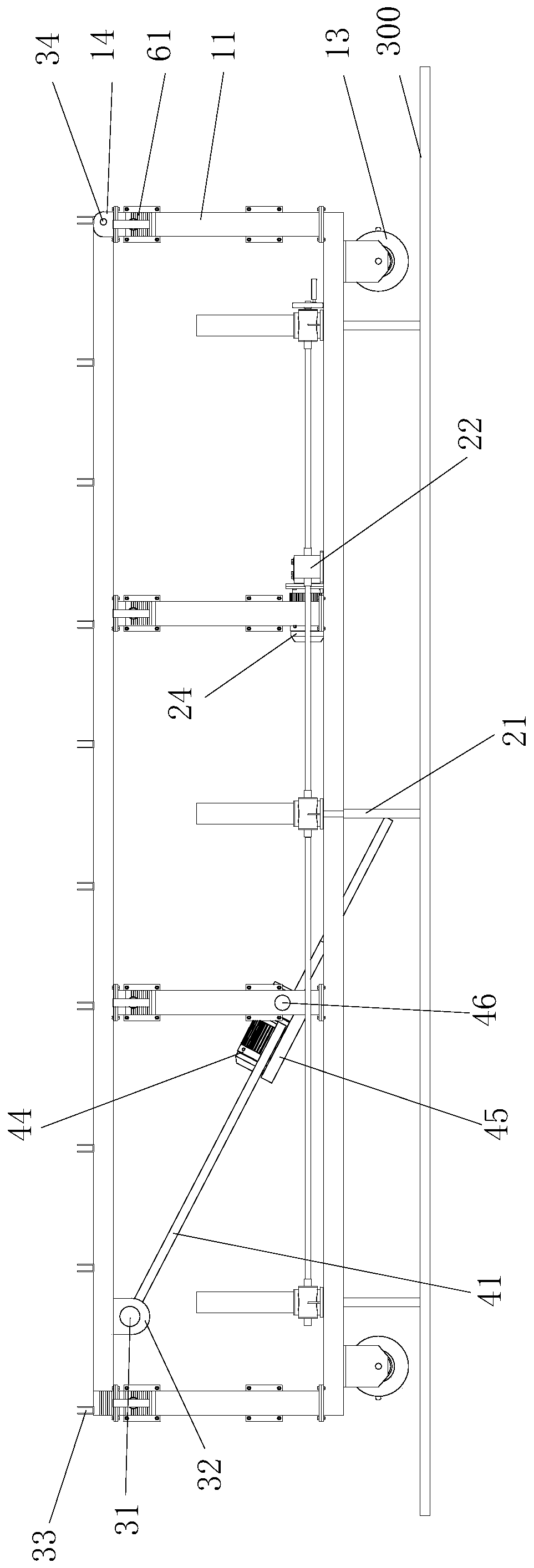

Industrial furnace flue masonry arch vaulting construction vehicle and arch vaulting setting method

ActiveCN108457477AIncrease profitSatisfy oblique connection requirementsBuilding material handlingDrive wheelVehicle frame

The invention relates to an industrial furnace flue masonry arch vaulting construction vehicle. The industrial furnace flue masonry arch vaulting construction vehicle comprises a frame, a frame lifting mechanism, an arch vaulting, a bracket and a bracket lifting mechanism and is characterized in that the frame comprises drive wheels mounted at the bottom end, the frame lifting mechanism drives thewhole frame to ascend and descend, the bracket is mounted at the top of the frame, one end of the bracket is hinged to the frame, the other end of the bracket is arranged on the frame, the lower endof the bracket is connected with the bracket lifting mechanism, the bracket lifting mechanism drives the other end of the bracket to ascend and descend, and the arch vaulting is mounted on the bracket. The industrial furnace flue masonry arch vaulting construction vehicle has the advantages that one drive motor is used to drive multiple worm gear-screw lifters to conveniently synchronously jack the frame to allow the arch vaulting to fast ascend to designed elevation; the bracket is hinged to one end of the frame, the bracket is driven to rotate through the bracket lifting mechanism so as to perform angle adjustment, and the arch vaulting setting requirements of a horizontal flue can be satisfied while the oblique connection requirements of two arch vaulting of different elevation differences can be satisfied.

Owner:CHINA FIRST METALLURGICAL GROUP

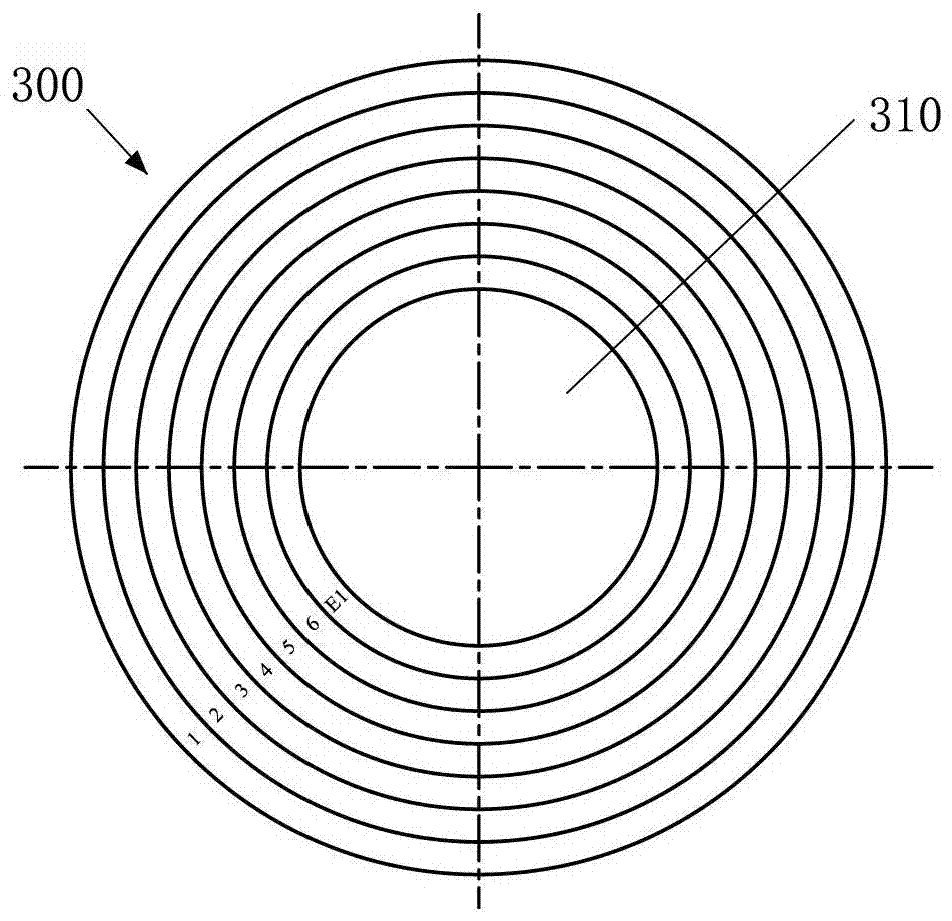

Method of enlarging the space beneath a masonry arch bridge, and a masonry arch bridge

InactiveCN106536824AMaximize lift heightMaximize downtimeBuilding repairsBridge erection/assemblyStructural engineeringEngineering

A method of enlarging the space beneath a masonry arch bridge 301, the masonry arch bridge 301 comprising a masonry arch 303 and a spandrel wall at each end of the masonry arch 303, the method comprising forming a moveable portion 332 of the masonry arch bridge 301 by cutting the spandrel walls to form a cut 330 on each side of the masonry arch 303, applying a lifting force to the masonry arch 303 to raise the masonry arch 303 to a raised position, and securing the masonry arch 303 in the raised position.

Owner:SOLETANCHE FREYSSINET SA

Reinforcing method of masonry arch bridge

InactiveCN102322026BReduce dosageImprove bearing capacityBridge erection/assemblyBridge strengtheningReinforced concreteEngineering

The invention discloses a reinforcing method of a masonry arch bridge, which comprises the following steps of: a, planting ribs on an arch ring of the arch bridge along the cambered surface direction of the arch bridge; b, planting ribs at the position close to the two sides, on the circular arc surface of the arch ring along the cambered surface direction of the arch bridge; and c, forming symmetrically distributed reinforced concrete ribs along the distribution direction of the planted ribs in the step a and the step b in a way of casting molding, wherein the cross section of the reinforcedconcrete ribs is L-shaped. The reinforced concrete ribs which are of integral structures are formed along the two sides of the arch ring in the way of planting the ribs and casting concrete, then load can be directly transferred to an arch base through the symmetrically distributed reinforced concrete ribs of which the cross section is L-shaped, and the stress to the reinforced concrete ribs is equal to that to a ribbed arch bridge. When the method is compared with the method of singly increasing the area of the arch ring, the dependence on the primary arch ring is smaller, even the primary arch ring can be supported, the damage to the primary arch ring is small, the requirement of increasing the loading capacity of the masonry arch bridge is met, and the damage to the primary old arch ring is avoided to the maximal degree.

Owner:CHONGQING JIAOTONG UNIVERSITY

Masonry arch bridge using lightweight concrete as arch filler

ActiveCN102587268BNon-uniformly distributed load reductionImprove carrying capacityBridge structural detailsBridge erection/assemblyApparent densityCarrying capacity

The invention discloses a masonry arch bridge using lightweight concrete as arch filler. The masonry arch bridge comprises a main arch ring (1), a spandrel arch (3) and an arch filler layer (2) and is characterized in that the arch filler layer (2) is a lightweight concrete filler layer, and the apparent density of the lightweight concrete filler layer is 800kg / m<3>-1950kg / m<3>; a leveling layer (4) is arranged on the top surface of the arch filler layer (2); a waterproof layer (7) is arranged between the main arch ring (1) and the arch filler layer (2); and saw joints (5) are arranged along the transverse direction of the bridge; and water permeating pipes (6) are arranged in the lowest position of each filler formed by the pairwise saw joints (5) and at two sides of a side wall. The waterproof layer (7) is formed by laying a permanent condensate or asphalt. The masonry arch bridge has the advantages that the stress of the arch can be effectively improved, the internal force of a dead load is reduced, and the carrying capacity of a bearing live load of the masonry arch bridge is increased.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

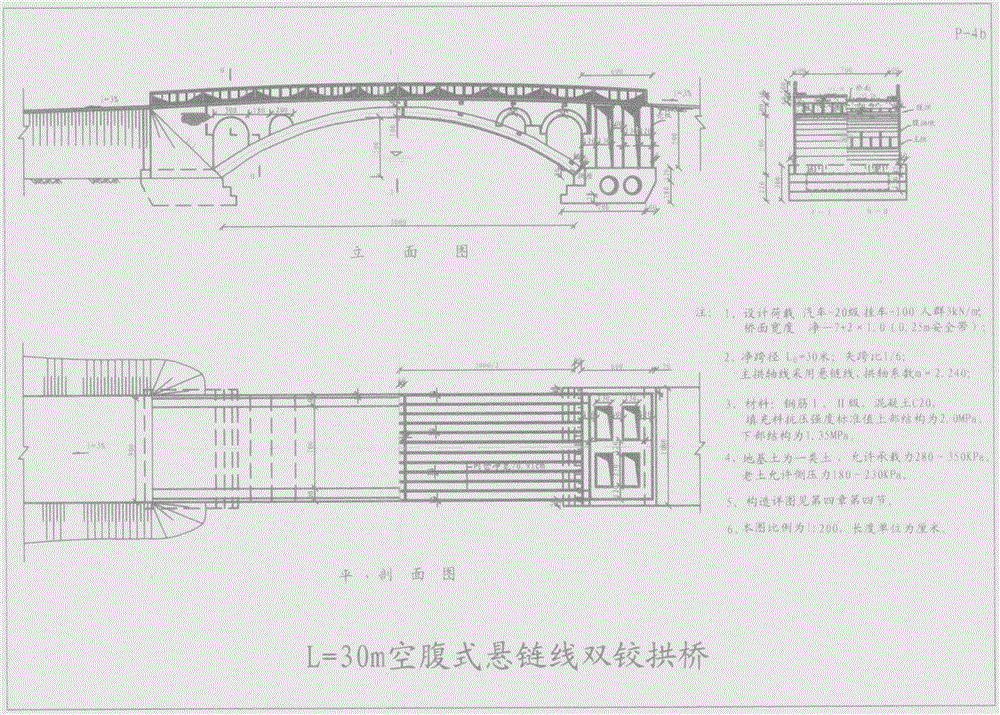

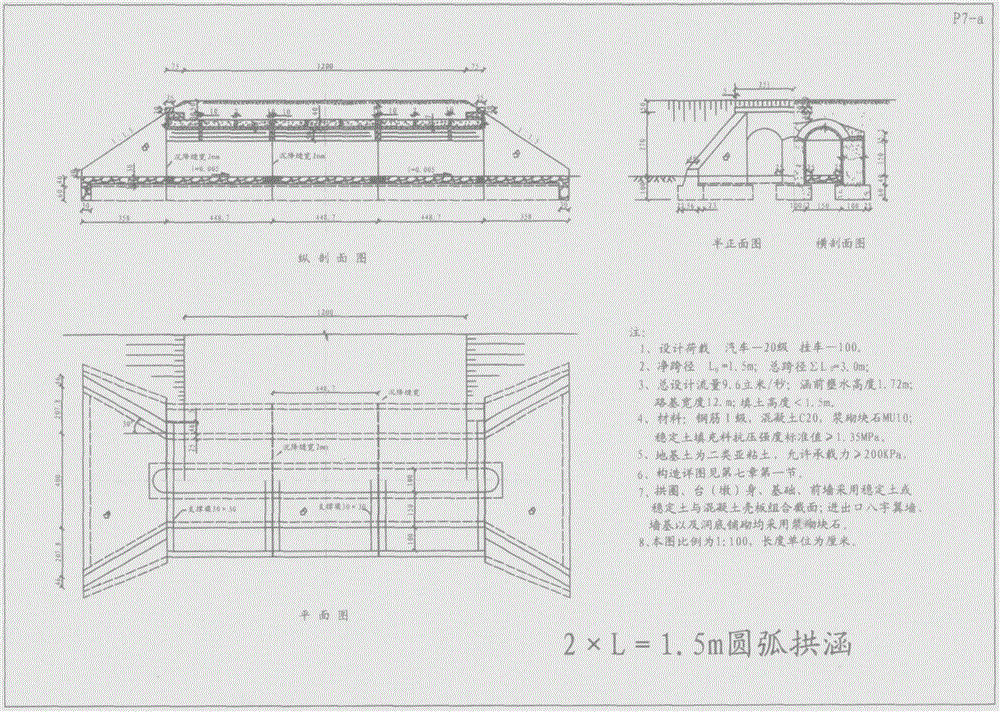

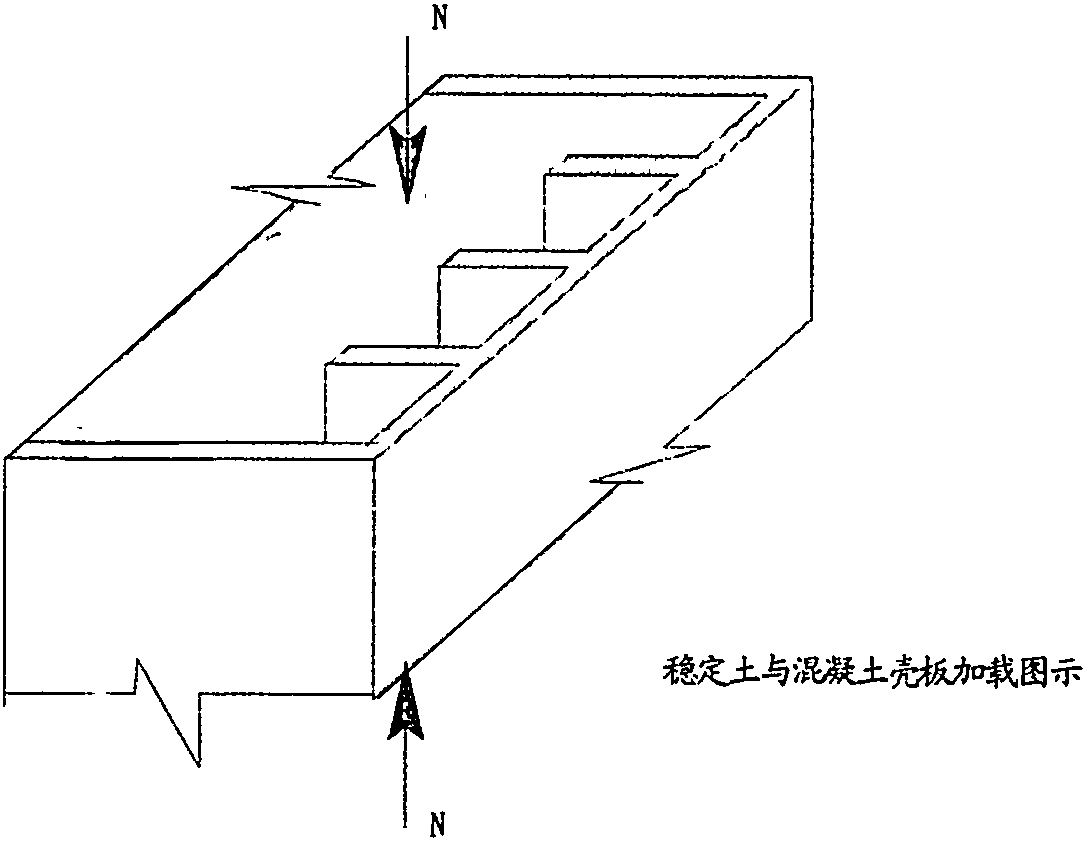

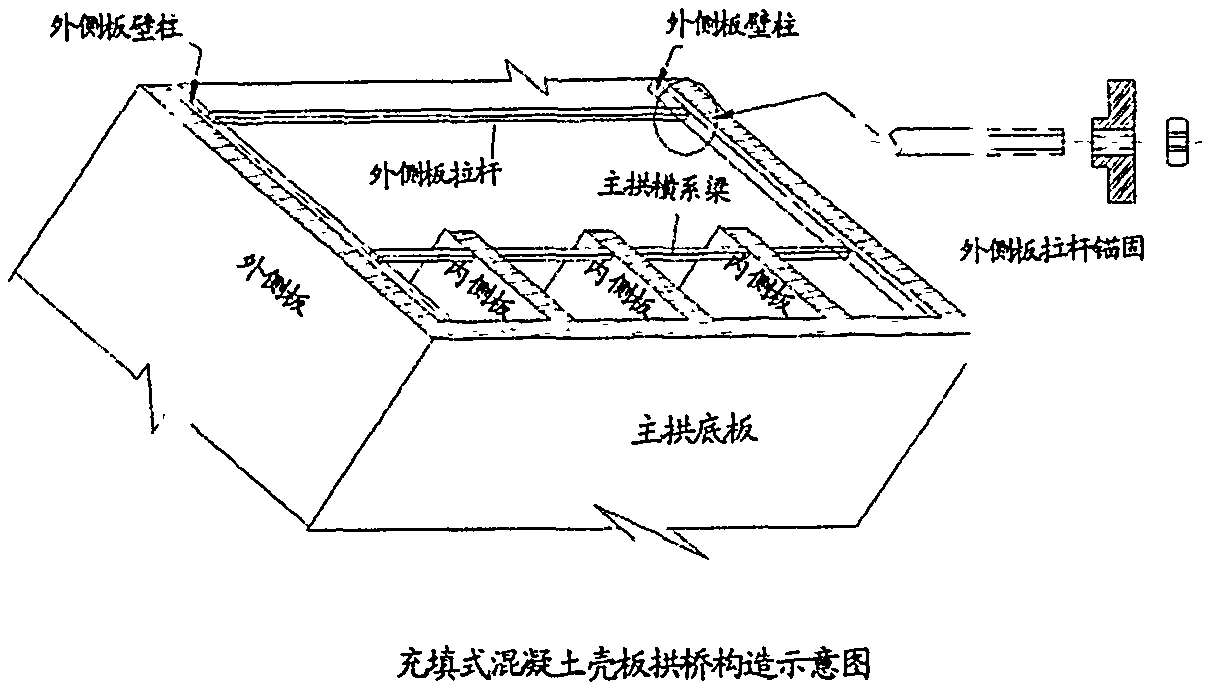

Filling type concrete shell plate arch bridge

The invention provides a filling type concrete shell plate arch bridge. The filling type concrete shell plate arch bridge is an innovative bridge type structure of a masonry arch bridge and has the advantages that material obtaining is easy and convenient, the force is reasonable, the manufacturing cost is low, and the application range is wide. Based on original computational examples, brief introduction PPT slides and a WORD manuscript of the filling type concrete shell plate arch bridge are further summarized and supplemented from the aspects of structural sketches, force principle analysis, section calculation methods, side wall stability checking, material strength design indexes and the like. 'Five different' and 'five first' of the bridge type are outstandingly reflected, specifically, 'five different' comprises that the structures are different, materials are different, the force is different, calculation methods are different, and construction is different; and 'five first' comprises that the stabilized soil materials are used for the bridge structure for the first time; the stabilized soil materials are proposed to be used for bridge structure strength calculation indexes through tests for the first time; the masonry composite system arch bridge is designed for the first time, and a series of internal force and section strength checking is conducted; the calculation method for an arch building to participate in calculation of the force of a main arch ring is put forward for the first time; and related formulas of a 'stabilized soil-reinforced concrete' composite structure to conduct section strength calculation according to a reinforced concrete structure section calculation mode are deduced for the first time.

Owner:朱传培

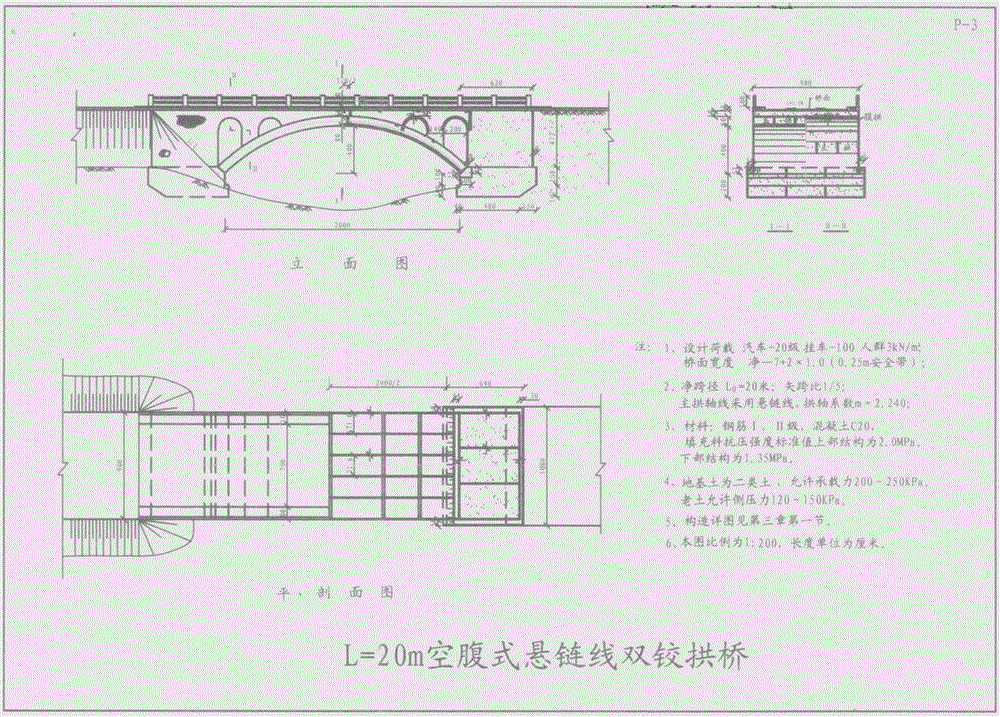

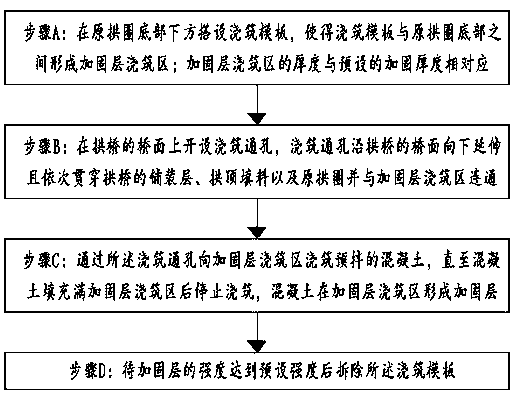

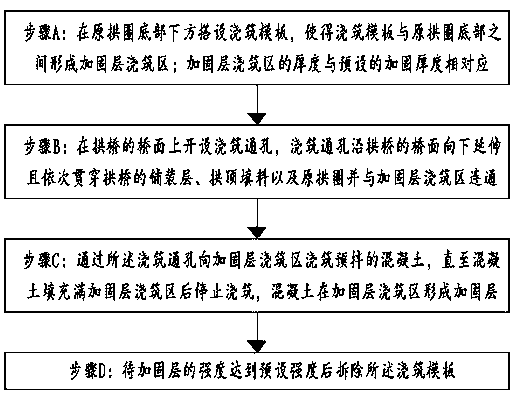

Reinforcing construction method of solid-web masonry arch bridge

InactiveCN111119079AQuality improvementImprove the effect of reinforcement constructionBridge erection/assemblyBridge strengtheningArchitectural engineeringBridge deck

The invention relates to the technical field of solid-web masonry arch bridge reinforcement, in particular to a reinforcing construction method of a solid-web masonry arch bridge. The method comprisesthe steps: A, a pouring formwork is erected below the bottom of an original arch ring of an arch bridge, and a reinforcement layer pouring area is formed between the pouring formwork and the bottom of the original arch ring; B, a pouring through hole is formed in the bridge deck of the arch bridge, extends downwards along the bridge deck of the arch bridge, sequentially penetrates through a pavement layer, an arch crown filler and the original arch ring of the arch bridge and communicates with the reinforcing layer pouring area; c, premixed concrete is poured into the reinforcing layer pouring area through the pouring through hole till the reinforcing layer pouring area is filled with the concrete, pouring is stopped, and the concrete forms a reinforcing layer in the reinforcing layer pouring area; and D, after the strength of the reinforcing layer reaches the preset strength, the pouring formwork is dismounted. According to the reinforcing construction method of the solid-web masonryarch bridge, the quality of the reinforcing layer can be improved, the thickness of the reinforcing layer is reduced, and the reinforcing construction process is simplified.

Owner:CHONGQING JIAOTONG UNIVERSITY

Masonry arch bridge rapid forcible entry method capable of releasing bridge deck constraint

ActiveCN114592446AWithout compromising securityReduce vibrationBuilding repairsBridge strengtheningArchitectural engineeringBridge deck

The invention discloses a quick break-in method for a masonry arch bridge capable of releasing bridge deck constraints. The quick break-in method comprises the steps that firstly, structural parameters of the masonry arch bridge to be broken in a measured mode are collected or actually measured; 2, calculating critical values of the number, the thickness and the width of the steel bars paved on the bridge deck through a critical equation; thirdly, the to-be-broken masonry arch bridge deck is cut, and the number, the thickness and the width of steel bars laid on the to-be-broken masonry arch bridge deck are all smaller than the critical value; fourthly, a long-arm hook machine is adopted for breaking and dismantling an arch foot on one side of the masonry arch bridge, and the bridge span of the masonry arch bridge can collapse in the whole span; and fifthly, the collapsed and fallen masonry materials are cleared and transported, and masonry arch bridge forcible entry operation is completed. According to the method, the whole-span collapse can be realized, the masonry material is crushed into small blocks by utilizing the falling energy of the whole-span collapse, the quick breaking and removing and clearing are realized, the breaking and removing safety risk is reduced, the construction period is shortened to the greatest extent, the construction cost is reduced, and the interference and influence on the surrounding environment are reduced.

Owner:广西北投交通养护科技集团有限公司 +1

Construction method for quickly breaking and dismantling masonry arch bridge based on bridge floor cutting

ActiveCN114808773AWithout compromising securityReduce vibrationBuilding repairsBridge strengtheningArchitectural engineeringBridge deck

The invention discloses a construction method for quickly breaking and dismantling a masonry arch bridge based on bridge deck cutting, which comprises the following steps of: 1, collecting or actually measuring structural parameters of the masonry arch bridge to be broken and dismantled, and acquiring span, rise, bridge deck pavement thickness, width and steel bar arrangement condition; step 2, cutting the to-be-broken masonry arch bridge deck, wherein the cutting position at least comprises bridge deck pavement right above an arch foot on one side; thirdly, a long-arm hook machine is adopted for breaking and dismantling an arch foot on the other side of the masonry arch bridge, and the whole span of the masonry arch bridge collapses and falls off; and fourthly, the collapsed and fallen masonry materials are cleared and transported, and masonry arch bridge forcible entry operation is completed. According to the method, the whole-span collapse can be realized, the masonry material is crushed into small blocks by utilizing the falling energy of the whole-span collapse, the quick breaking and removing and clearing are realized, the breaking and removing safety risk is reduced, the construction period is shortened to the greatest extent, the construction cost is reduced, and the interference and influence on the surrounding environment are reduced.

Owner:广西北投交通养护科技集团有限公司 +1

A method for adjusting the weight of filling on the arch of a masonry arch bridge by region

ActiveCN104074139BReduce bending momentUniform moment distributionBridge erection/assemblyBridge strengtheningApparent densityCarrying capacity

The invention discloses a method for adjusting the weight of fillers on a masonry arch bridge in a partitioning manner. The masonry arch bridge comprises a main arch ring (1), spandrel arch rings (2), a filler layer (3) on arches, and a bridge panel (4). The method comprises the steps: the filler layer (3) on the arches is divided into an arch top area (31) and spandrel arch areas (32), wherein the arch top area (31) is formed between the main arch ring (1) and the bridge panel (4), and the spandrel arch areas (32) are formed between the spandrel arch rings (2) and the bridge panel (4); lightweight concrete fillers with the apparent density from 800kg / m3 to 1200 kg / m3 are filled into the arch top area (31), and lightweight concrete fillers or ordinary soil quality fillers with the apparent density from 1200kg / m3 to 1950 kg / m3 are filled into the spandrel arch areas (32); and the weight of the filler layer (3) on the arches is adjusted by calculating three objective functions, i.e. bending moments Md, M1 / 4 and Mj generated by the main arch ring on the arch top, the one quarter of an arch span, and arch feet, and the like. The method has the advantages that the utilization efficiency of arch ring materials can be improved, the distribution of the internal force of the main arch ring is improved, and the carrying capacity of the arch bridge is improved.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

Arch tires for lining masonry of industrial furnace pipe tee and construction method of tee masonry

Owner:CHINA FIRST METALLURGICAL GROUP

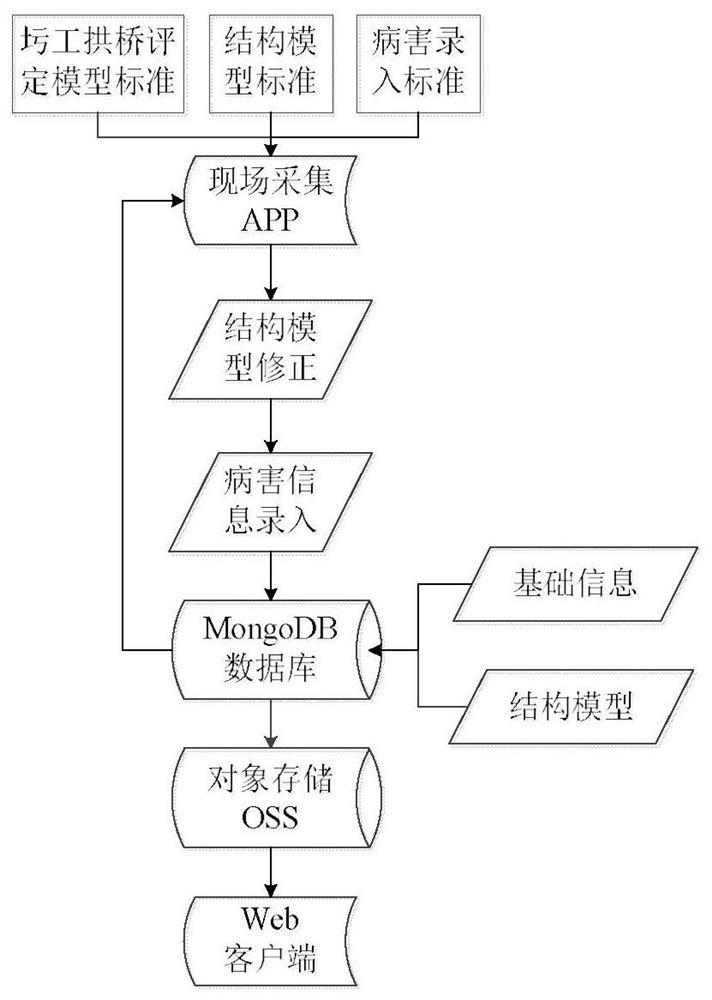

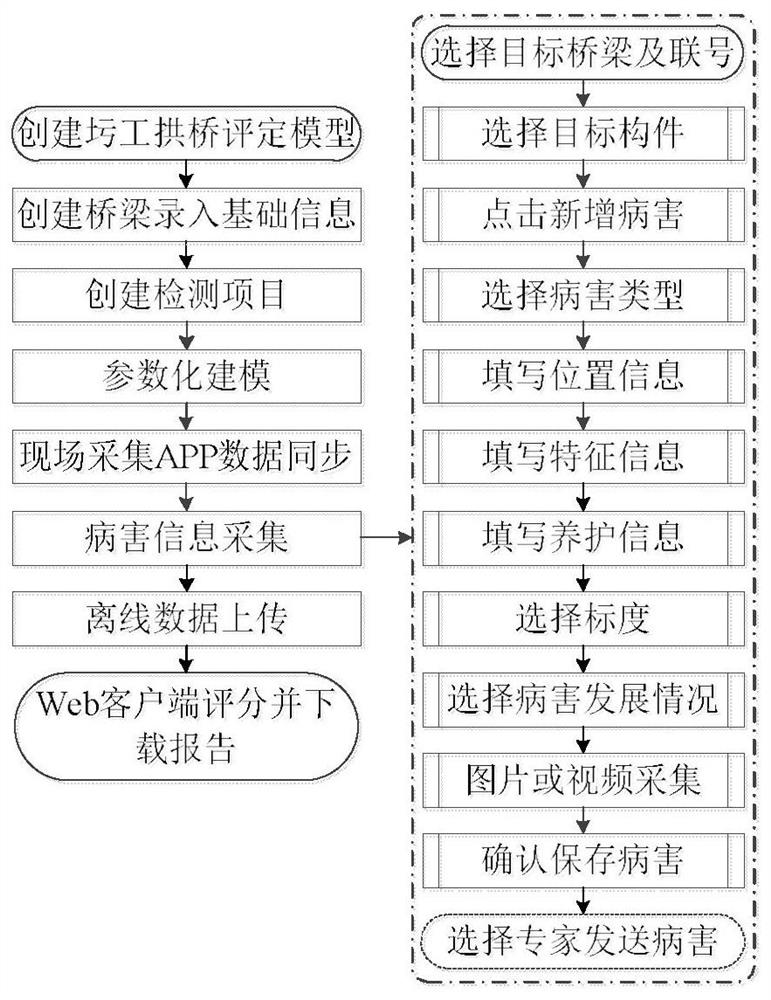

Masonry arch bridge technical condition parametric structure modeling and intelligent evaluation system

ActiveCN112464348AEasy entryPromote generationGeometric CADDesign optimisation/simulationStructural engineeringObject storage

The invention discloses a masonry arch bridge technical condition parametric structure modeling and intelligent evaluation system, which comprises a masonry arch bridge evaluation model unit, a structure model unit, a disease input unit, a Web client, a field acquisition unit, a MongoDB database and an object storage unit, and is characterized in that the evaluation model unit sets composition ofa structure model and an intelligent evaluation algorithm; the structural model unit determines modeling parameters and component number rules of a masonry arch bridge, and the Web client accesses andedits a MongoDB database and an object storage unit, automatically and manually associates diseases, checks scores and generates a report. On the basis of the evaluation model unit, the structure model unit and the disease input unit, parameterized structure modeling and intelligent evaluation are achieved, and the problems that the masonry arch bridge technical condition evaluation recording process is tedious, not visual, low in efficiency, not standard, prone to making mistakes in the evaluation process and the like are solved.

Owner:山西省智慧交通研究院有限公司

Filled concrete shell plate arch bridge

The invention provides a filling type concrete shell plate arch bridge. The filling type concrete shell plate arch bridge is an innovative bridge type structure of a masonry arch bridge and has the advantages that material obtaining is easy and convenient, the force is reasonable, the manufacturing cost is low, and the application range is wide. Based on original computational examples, brief introduction PPT slides and a WORD manuscript of the filling type concrete shell plate arch bridge are further summarized and supplemented from the aspects of structural sketches, force principle analysis, section calculation methods, side wall stability checking, material strength design indexes and the like. 'Five different' and 'five first' of the bridge type are outstandingly reflected, specifically, 'five different' comprises that the structures are different, materials are different, the force is different, calculation methods are different, and construction is different; and 'five first' comprises that the stabilized soil materials are used for the bridge structure for the first time; the stabilized soil materials are proposed to be used for bridge structure strength calculation indexes through tests for the first time; the masonry composite system arch bridge is designed for the first time, and a series of internal force and section strength checking is conducted; the calculation method for an arch building to participate in calculation of the force of a main arch ring is put forward for the first time; and related formulas of a 'stabilized soil-reinforced concrete' composite structure to conduct section strength calculation according to a reinforced concrete structure section calculation mode are deduced for the first time.

Owner:朱传培

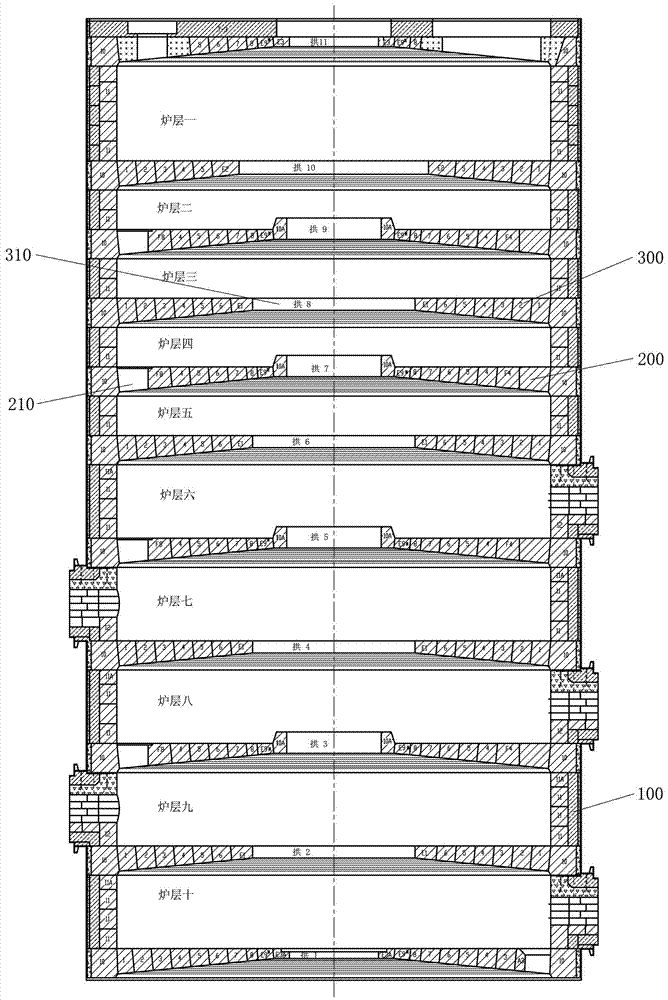

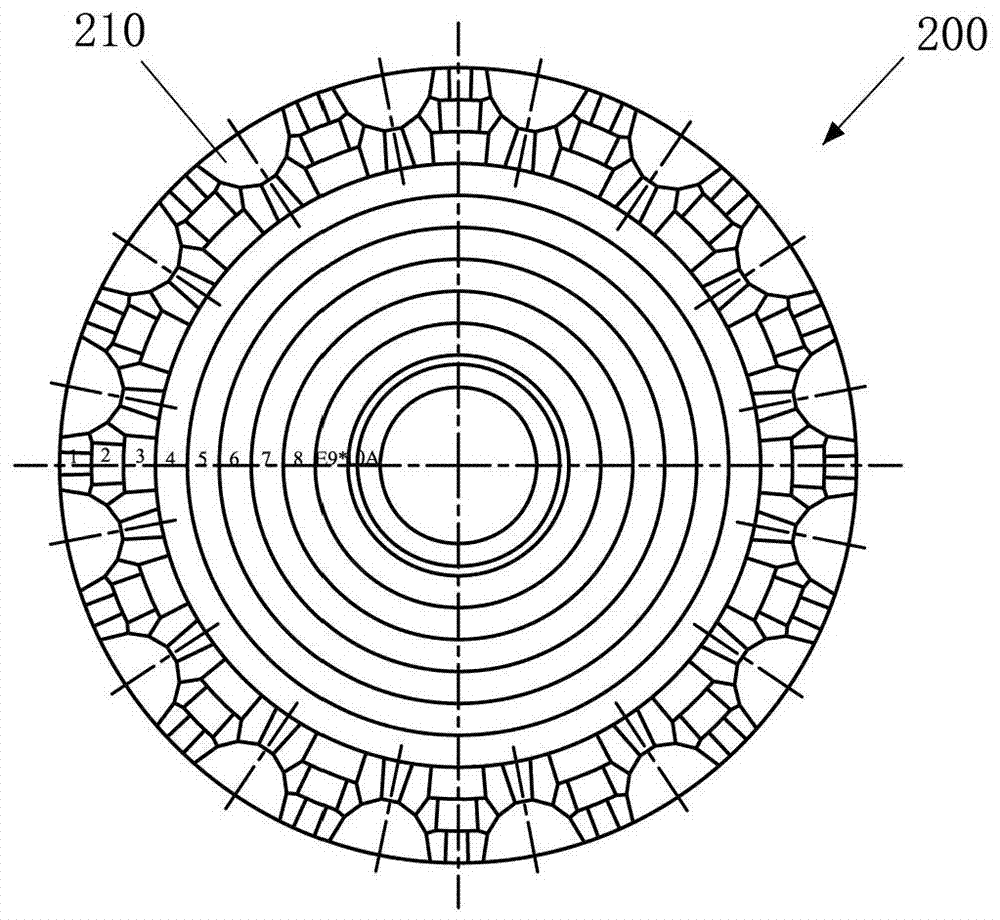

Pre-construction method for hearth bricks of multi-layer roasting furnace

The invention discloses a pre-laying method for hearth bricks of a multi-layer roasting furnace. The method comprises: selecting and classifying the bricks according to the main dimension tolerance of the bricks with a grade of 1mm, and checking the shape of the bricks, Exclude unqualified bricks; grind the ash surface of the selected bricks to ensure that the bricks can be tightly bonded during masonry; draw a cross center line on the pre-installed platform to make the cone of the hearth brick Facing upwards, starting from the first layer of arches, each layer of arches is lined up one by one from the outer ring to the inner ring. After the completion of the masonry, check the surface evenness, and polish the bricks whose error exceeds the predetermined value; After the arch masonry is polished, draw a cross center line on the surface of the arch, and number the bricks block by block; store the numbered bricks according to the number, wherein, in the process of masonry, the main size of the same ring is the same Grade brick masonry, and when two grades of bricks are required to be used together, large grade bricks are ground into small grade bricks for masonry.

Owner:PANGANG GRP ENG TECH

Reinforcement structure and method for a small-span masonry arch bridge

ActiveCN111455876BAvoid damageImprove stress resistanceBridge erection/assemblyBridge strengtheningArchitectural engineeringArcuate shape

The invention relates to a reinforcement structure of a small-span masonry arch bridge, which comprises an arch bridge body, an arch ring is arranged in the middle of the arch bridge body, and an abutment is respectively arranged at both ends of the arch bridge body, and each abutment is close to the arch bridge One side of the middle part of the main body is provided with a reinforcement seat, and arches are supported on the two reinforcement seats. The arc-shaped back of the arches is provided with a steel plate, and the space between the steel plate and the arch ring is arranged to form a cavity. A reinforcement cage is arranged in the chamber, and concrete is poured in the chamber. The invention has the effect of avoiding damage to the arch ring during the reinforcement process.

Owner:商丘市豫东公路勘察设计有限公司

A Method for Reconstruction of Masonry Arch Bridge with Longitudinal Perforation and Constant Load Balance

InactiveCN106400704BImprove securityReduce weightBridge erection/assemblyBridge strengtheningConstant loadRetrofitting

The invention belongs to the technical field of bridge construction, and discloses a masonry arch bridge longitudinal perforation dead load balance transformation method. The masonry arch bridge longitudinal perforation dead load balance transformation method comprises the following steps: (a) a part of concrete of a bridge floor cast-in-place layer on the downslope side is removed; (b) channeling is carried out on an arch cavity filling along the longitudinal direction of a masonry arch bridge and a longitudinal groove is formed; (c) an abutment is arranged in the longitudinal groove, a perforation cover plate is laid, the abutment and two side walls jointly support the perforation cover plate, with this mode, longitudinal perforation holes are formed between the perforation cover plate and the arch cavity filling; and (d) concrete is poured on the perforation cover plate for filling a gap formed by the concrete removed in the step (a), thereby accomplishing masonry arch bridge longitudinal perforation dead load balance transformation. On the premise that no bridge floor longitudinal slope is changed, symmetrical balance of dead load weight of the left side and the right side of the masonry arch bridge is realized, stress symmetry of a main arch ring is guaranteed, the bridge safety is improved effectively, and the appearance uniformity of the upslope side and the downslope side of the masonry arch bridge is realized.

Owner:河南省安阳西北绕城高速公路有限公司 +1

Industrial Furnace Flue Masonry Arch Tire Construction Vehicle and Arch Tire Supporting Method

ActiveCN108457477BIncrease profitSatisfy oblique connection requirementsBuilding material handlingDrive wheelVehicle frame

The invention relates to an industrial furnace flue masonry arch vaulting construction vehicle. The industrial furnace flue masonry arch vaulting construction vehicle comprises a frame, a frame lifting mechanism, an arch vaulting, a bracket and a bracket lifting mechanism and is characterized in that the frame comprises drive wheels mounted at the bottom end, the frame lifting mechanism drives thewhole frame to ascend and descend, the bracket is mounted at the top of the frame, one end of the bracket is hinged to the frame, the other end of the bracket is arranged on the frame, the lower endof the bracket is connected with the bracket lifting mechanism, the bracket lifting mechanism drives the other end of the bracket to ascend and descend, and the arch vaulting is mounted on the bracket. The industrial furnace flue masonry arch vaulting construction vehicle has the advantages that one drive motor is used to drive multiple worm gear-screw lifters to conveniently synchronously jack the frame to allow the arch vaulting to fast ascend to designed elevation; the bracket is hinged to one end of the frame, the bracket is driven to rotate through the bracket lifting mechanism so as to perform angle adjustment, and the arch vaulting setting requirements of a horizontal flue can be satisfied while the oblique connection requirements of two arch vaulting of different elevation differences can be satisfied.

Owner:CHINA FIRST METALLURGICAL GROUP

Reinforced portable integral prefabricated masonry arch bridge

ActiveCN102493327BImprove bearing capacityImprove stabilityArch-type bridgeArchitectural engineeringBridge deck

The invention relates to the technical field of arch bridges, in particular to a reinforced portable integral prefabricated masonry arch bridge, which comprises a bridge body and a bridge deck, wherein the inner side of the bridge body is provided with an arch ring; the arch ring comprises a main body consisting of a plurality of prefabricated arch blocks arranged in turn, and a fiber reinforced composite material connecting layer fixedly attached to the upper surface of the main body; side faces of every two adjacent prefabricated arch blocks are attached to each other; lower surfaces of all prefabricated arch blocks form a lower surface of the arch ring; the fiber reinforced composite material connecting layer is fixedly connected with the upper surface of each prefabricated arch block; a transverse pull rod is arranged between arch feet of the bridge body; and two ends of the transverse pull rod are fixedly connected with the bridge body through bolts. Compared with the prior art, the transverse pull rod is arranged between the arch feet of the bridge body and is used for providing self lateral restriction for an arch body, so that the bearing capacity and stability of the arch bridge structure are improved and the arch bridge can be applied to soft foundations.

Owner:DONGGUAN UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com