Novel RC-masonry combined arch bridge structure and construction method

A technology for masonry and arch bridges is applied in the field of structure and construction of a new type of upper-supported composite arch bridge, which can solve the problems of high risk, complicated construction and increase of construction cost of arch bridges, avoid bridge head jumping, facilitate maintenance management, The effect of low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

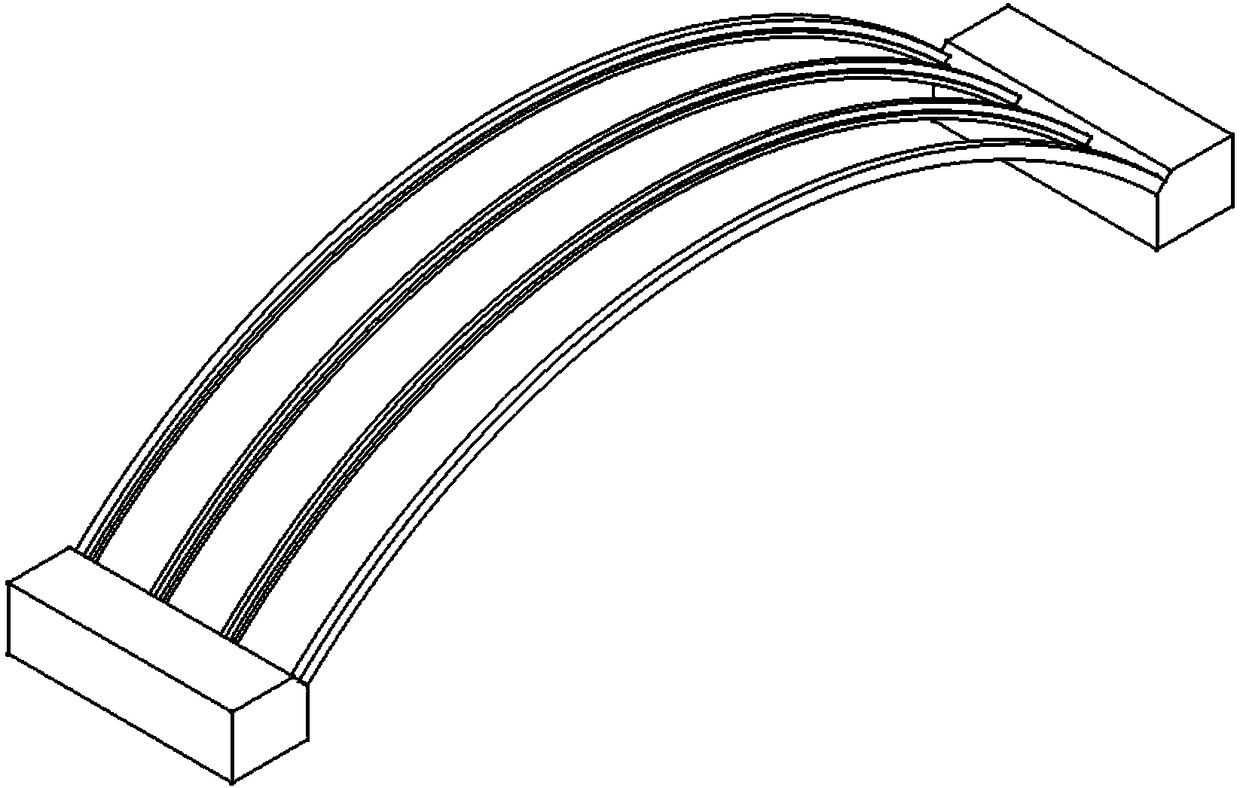

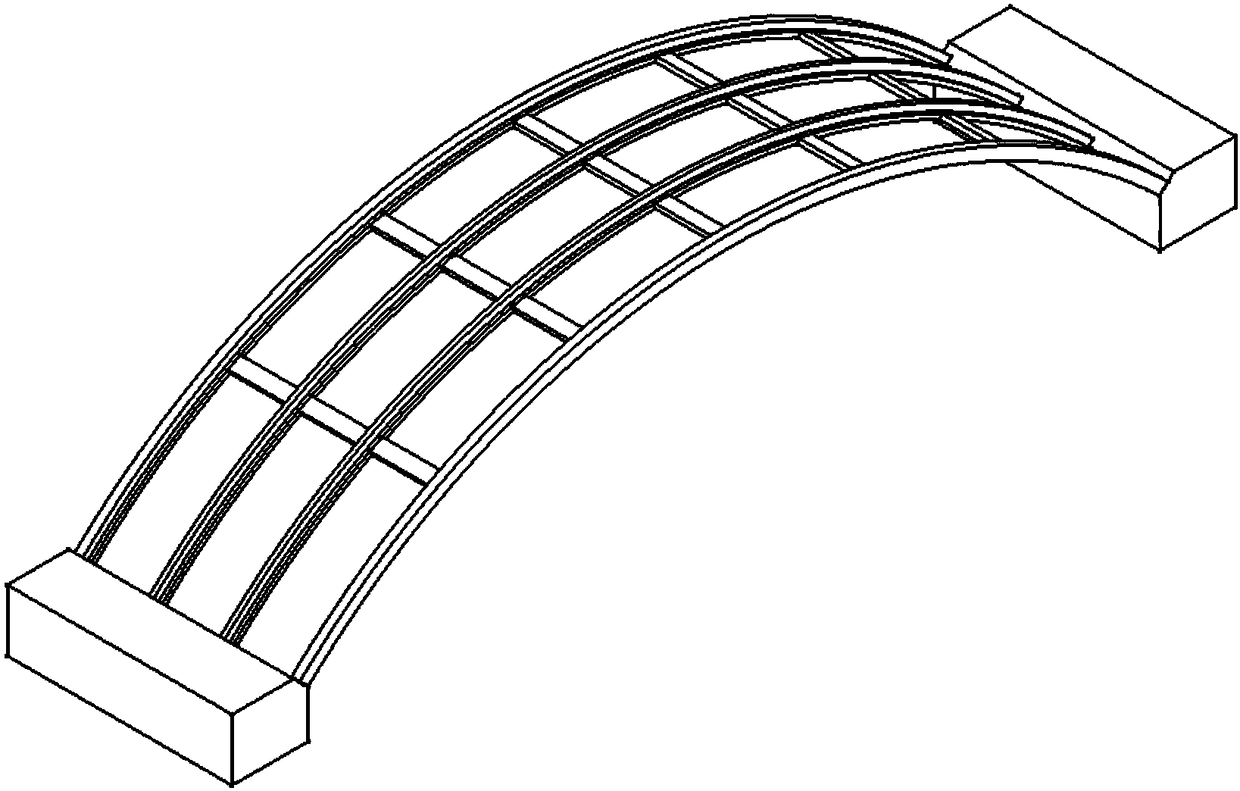

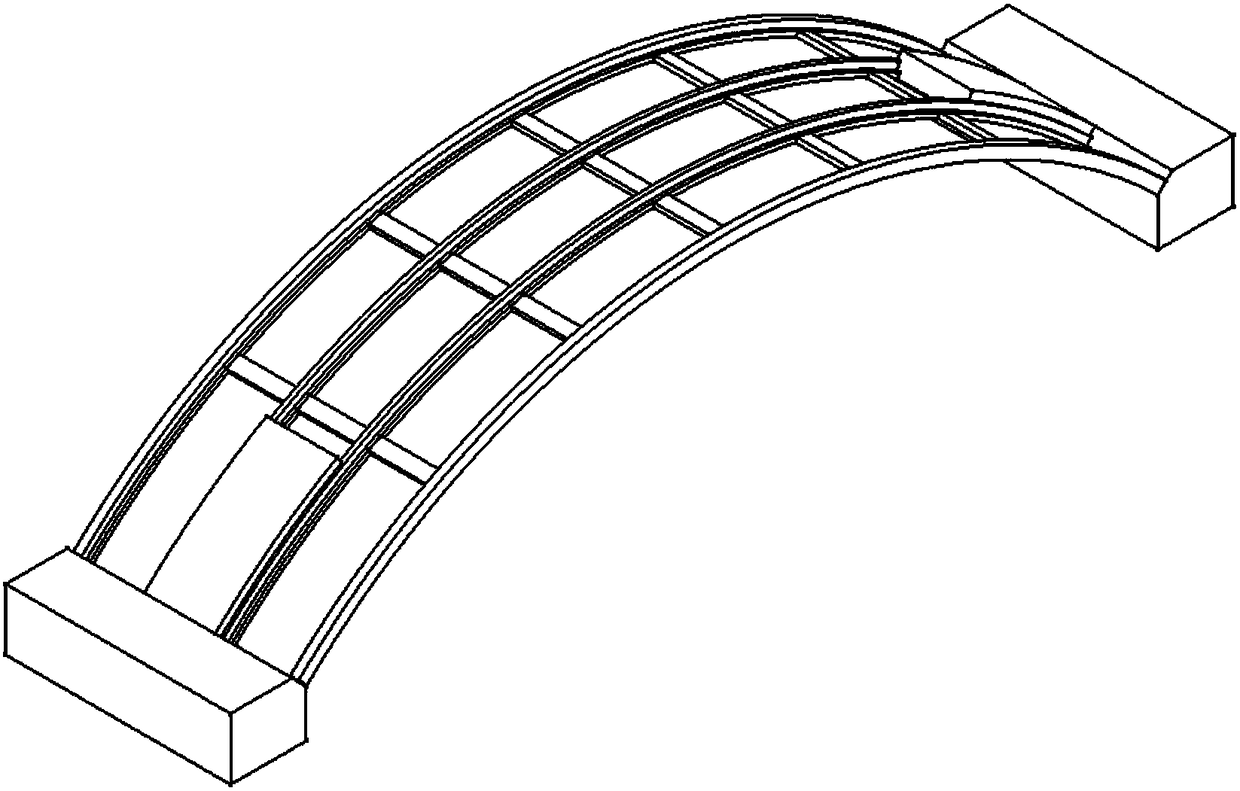

[0039] exist Figure 1 to Figure 11 Among them, the structure of a novel RC-masonry composite arch bridge of the present invention is to construct the arch foot abutment 1 of the arch bridge at the bridge site. After the construction is completed, at least two RC arch ribs 2 are hoisted between the arch foot abutments 1 of the arch bridge, RC arch rib 2 is poured with beam 3 in sections. RC arch rib 2 and beam 3 are prefabricated by reinforced concrete according to the geological and hydrological conditions at the bridge site and design drawings. The shape and number of RC arch rib 2 and RC arch rib 2 are segmented The number of sections and the number of crossbeams 3 are determined by bridge design factors such as the span, rise-span ratio, and bridge width of the arch bridge.

[0040] In this embodiment, when the span of the arch bridge is 5m to 15m, the main arch circle is a steep arch line, and each RC arch rib is prefabricated in two sections, and the vault top is spliced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com