Industrial furnace flue masonry arch vaulting construction vehicle and arch vaulting setting method

A technology for industrial furnaces and construction vehicles, which is applied in the fields of construction, building structure, and building materials, and can solve the problems of low work efficiency, long period for inclined flue vaults, and difficulty in determining the elevation of inclined arch tires and other issues to achieve the effect of improving utilization rate and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

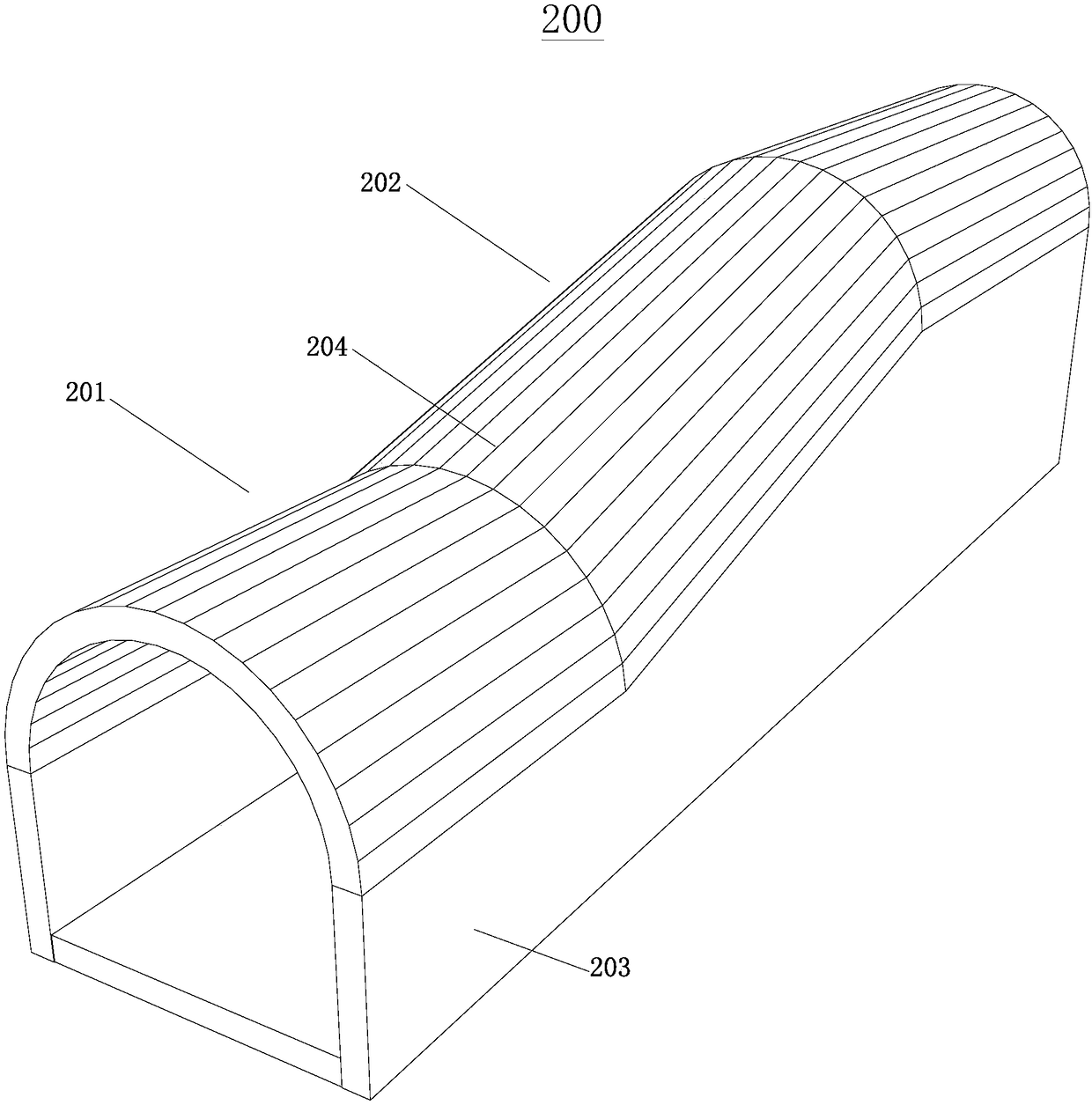

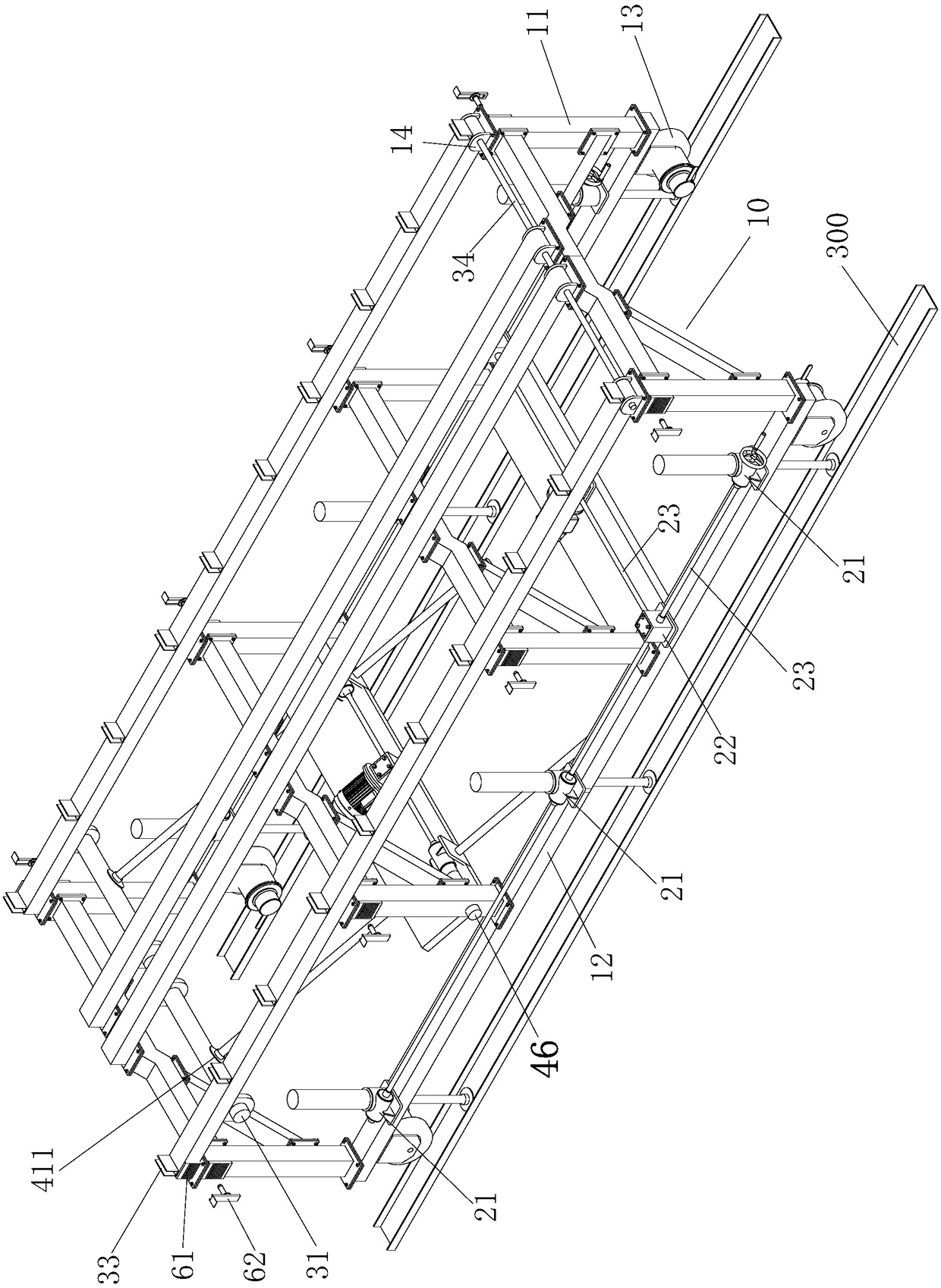

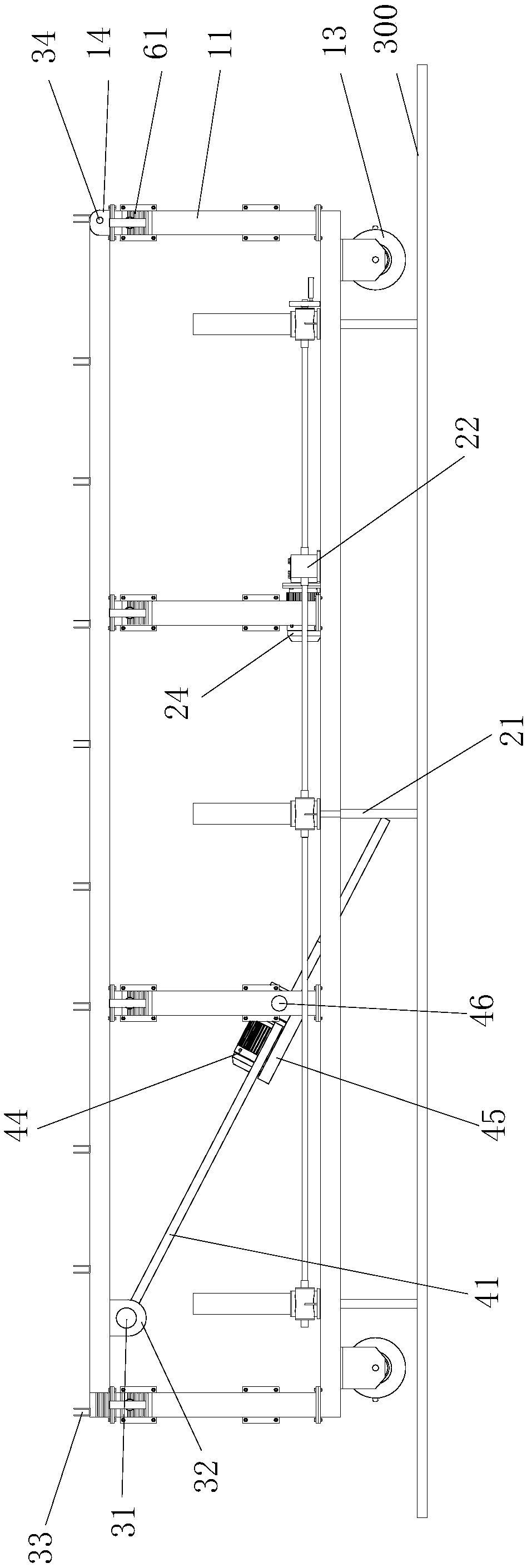

[0034] Such as Figure 2-9Shown is an industrial furnace flue masonry arch tire construction vehicle 100 according to a preferred embodiment of the present invention, including a vehicle frame 10, a vehicle frame lifting mechanism 20 and an arch tire 50, and the vehicle frame 10 includes a drive wheel 13 installed at the bottom , is used to drive the vehicle frame 10 to walk on the track 300, and the vehicle frame elevating mechanism 20 drives the vehicle frame 10 as a whole to perform lifting movement in the vertical direction. The industrial furnace flue masonry arch tire construction vehicle 100 also includes a bracket 30 and a bracket lifting mechanism 40. The bracket 30 is installed on the top of the vehicle frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com