Pre-construction method for hearth bricks of multi-layer roasting furnace

A multi-layer roasting furnace and hearth brick technology, which is applied in the direction of lining repair, etc., can solve the problems of brick loss, serious hearth brick masonry quality, hearth wear and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Exemplary embodiments according to the present invention will be described in detail below with reference to the accompanying drawings. These embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art.

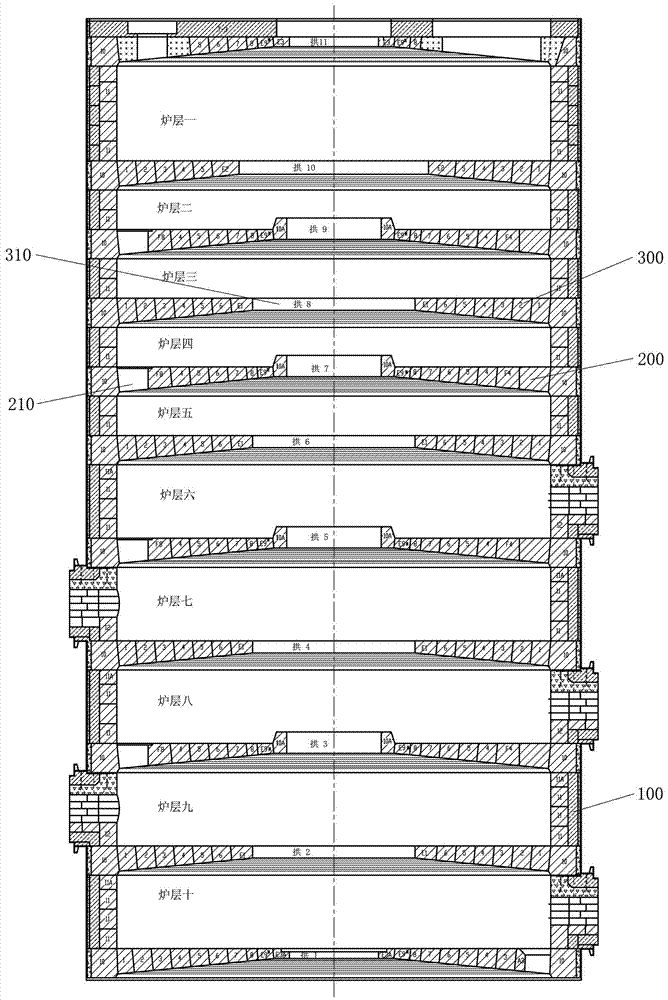

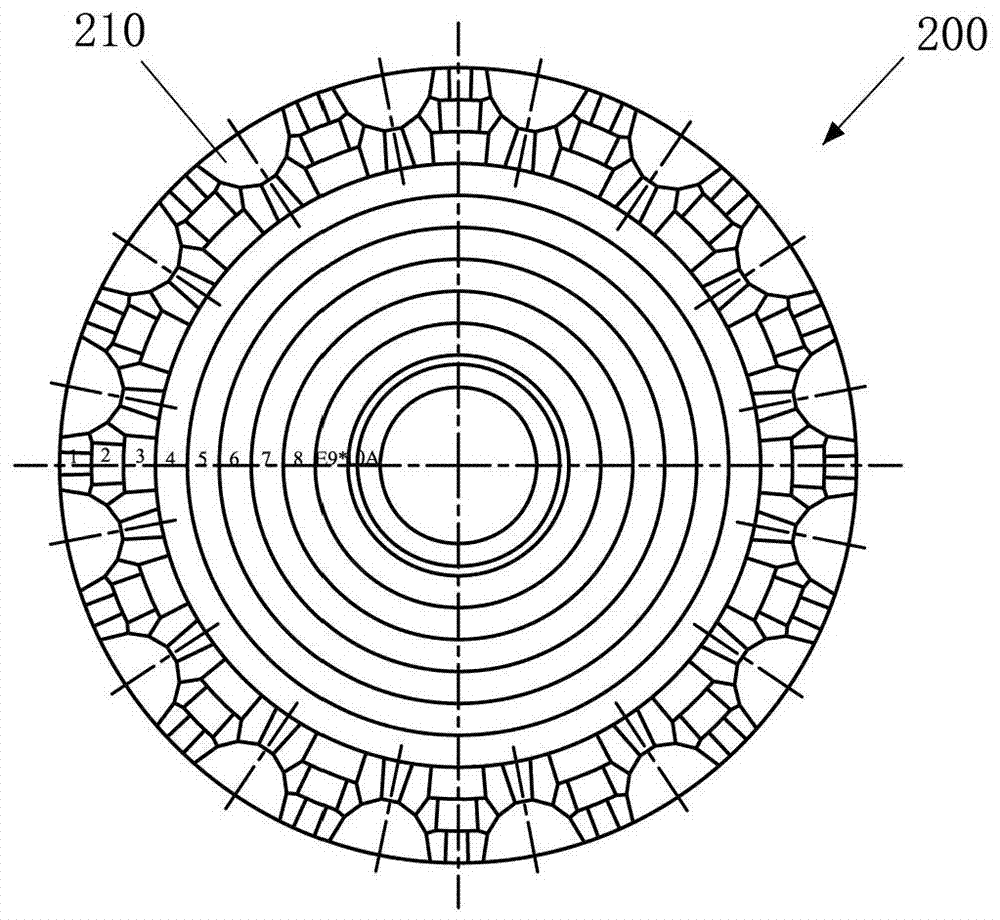

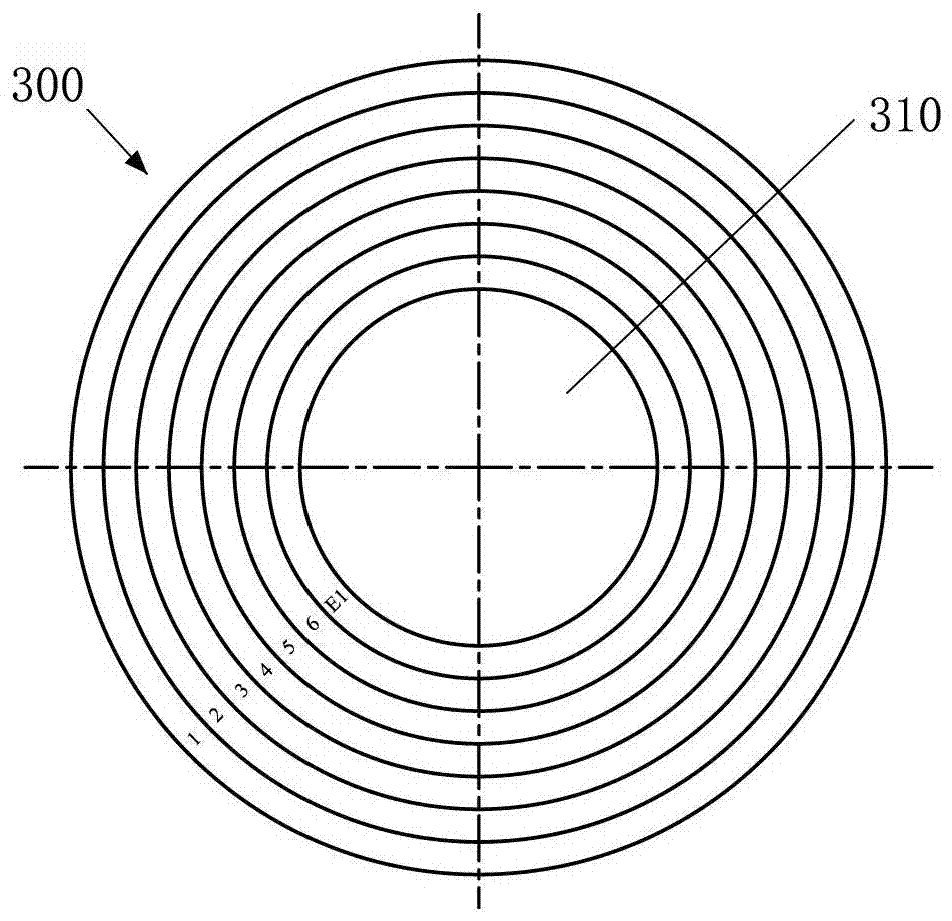

[0014] figure 1 is a schematic cross-sectional view of a multi-layer baking furnace according to an embodiment of the present invention. Figure 2A is a top view of a hearth with an edge feed opening according to an embodiment of the present invention, Figure 2B It is a top view of a hearth with a central feed opening according to an embodiment of the present invention. refer to Figure 1 to Figure 2B , the multi-layer baking furnace according to the embodiment of the present invention includes a furnace wall 100 and a plurality of first hearths 200 and a plurality of second hearths 300 , wherein the first hearths 200 and the second hearths 300 are arranged alternately....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com