High-ductility fiber concrete combined brick masonry wall and method for constructing same

A fiber reinforced concrete, high ductility technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of brittleness, poor crack resistance and seismic performance, and achieve the effect of improving seismic performance, high damage resistance and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

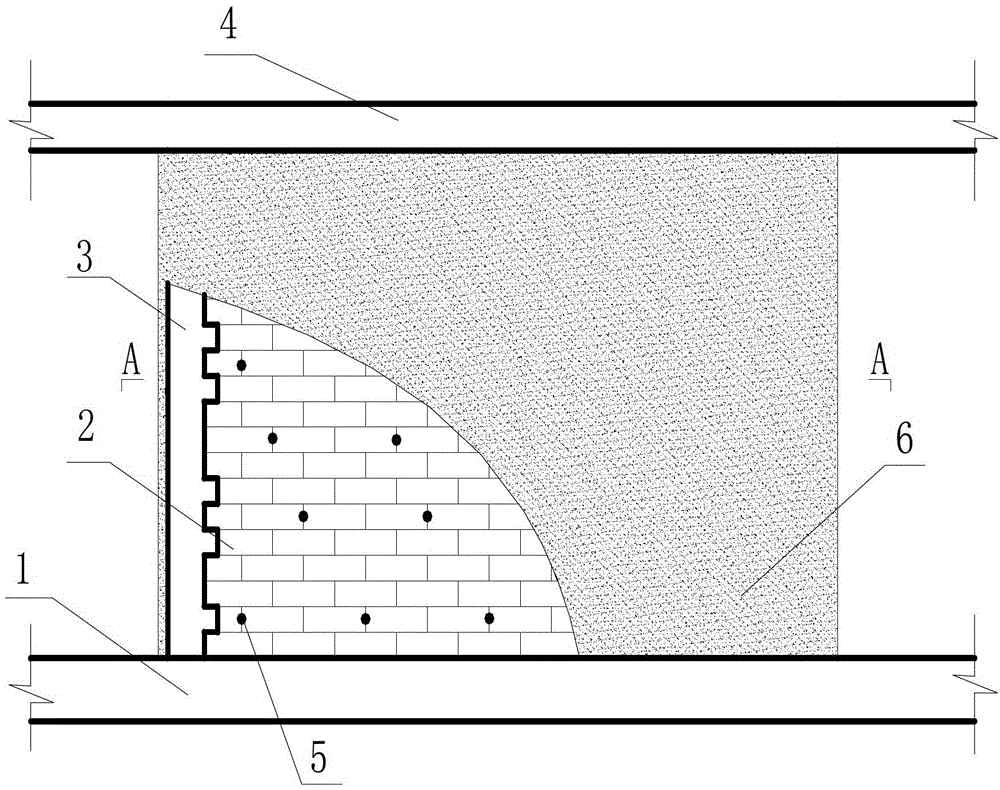

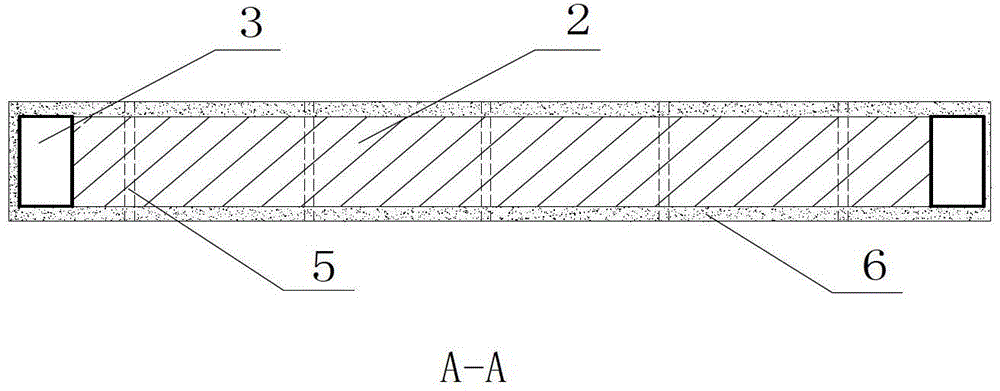

[0026] refer to figure 1 and figure 2 , the brick wall 2 in this embodiment has structural columns 3 and ring beams (1, 4), and the size of the sintered ordinary bricks is 240mm×115mm×53mm; the length of the brick wall 2 is 4.2m, the height is 3m, and the thickness is 240mm The section size of structural column 3 is 120mm×240mm; the section size of ring beam 1 is 340mm×400mm; the section size of ring beam 4 is 180mm×240mm; A short steel bar 4; the outer surface of the brick wall 1 is coated with a high ductility fiber concrete surface layer 6. Its specific construction process is:

[0027] Step 1: Build the brick wall 2, and embed several short steel bars 5 in the vertical mortar joints of the brick wall 2, and then pour the structural columns 3 and the ring beams 1, 4;

[0028] Step 2: Spread a 20mm thick high ductility fiber concrete surface layer 6 on the surface of the brick wall 2 that has been built, and the high ductility fiber concrete surface layer covers the bric...

Embodiment 2

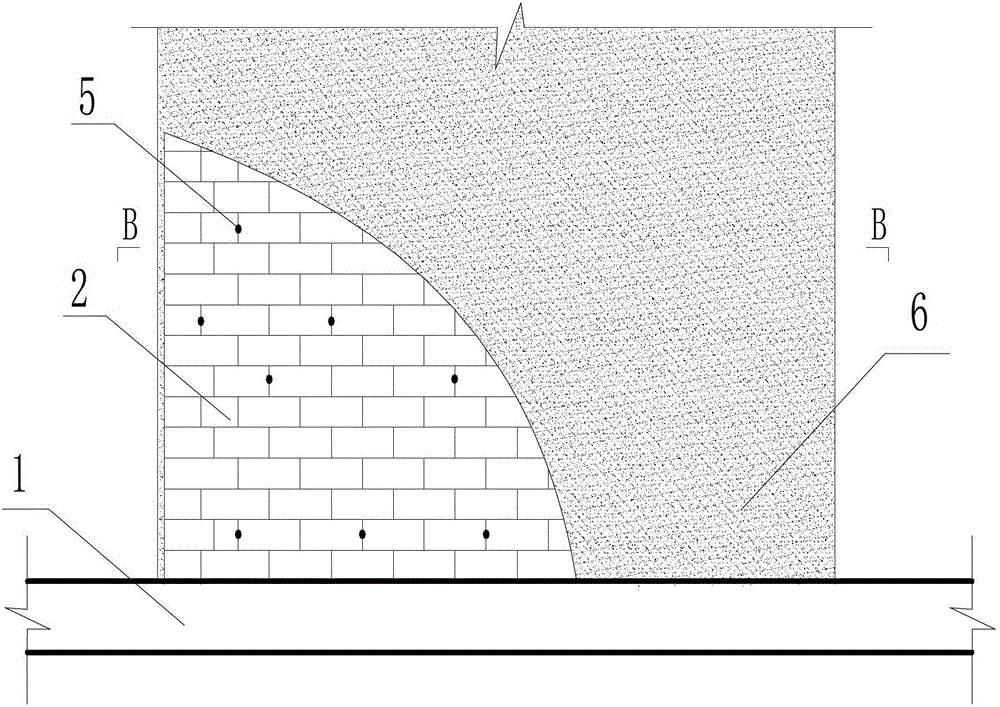

[0038] refer to image 3 and Figure 4 , the brick wall 2 in this embodiment does not have a structural column, and the size of sintered ordinary bricks is 240mm×115mm×53mm; the length of the brick wall 2 is 4.2m, the height is 3m, and the thickness is 240mm; the cross-sectional size of the ring beam 1 is 340mm × 400mm; other construction procedures are the same as in Embodiment 1.

[0039]The present invention utilizes the advantages of the mechanical properties of high ductility fiber concrete and the good viscous properties with the brick masonry wall, which not only produces a large lateral active restraint force on the brick masonry wall, but also improves the shear strength of the brick masonry wall and It can improve the integrity of the brick masonry wall, effectively inhibit the cracking of the brick masonry wall, greatly improve the deformation capacity of the brick masonry wall itself, thereby significantly improving the stability and seismic performance of the bri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com