Heat accumulating type dividing-wall heating industrial furnace

An industrial kiln and regenerative technology, which is applied in the field of industrial shaft kilns and industrial kilns with regenerative partition heating, can solve the problem of inability to recover carbon dioxide, unutilized exhaust flue gas, and low preheating temperature of combustion-supporting air. and other problems to achieve the effect of improving comprehensive economic benefits, reducing energy consumption and reducing exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

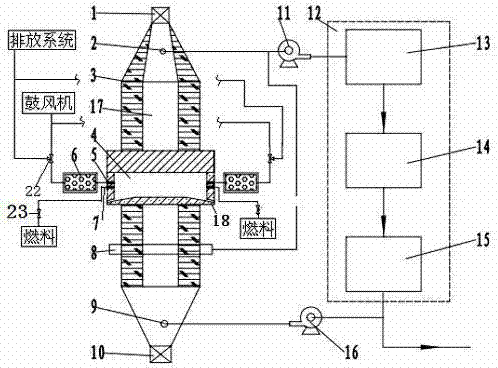

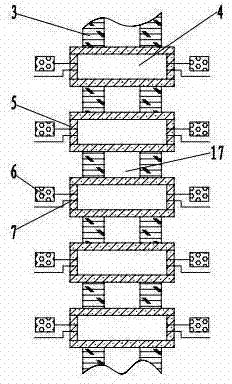

[0016] The industrial furnace kiln of the present invention heat storage type partition heating such as figure 1 , figure 2 As shown, a vertical kiln and a carbon dioxide treatment unit 12 are included. The vertical kiln is provided with a material inlet 1, a material outlet 10, a decomposition gas outlet 2 and a cooling air inlet 9. The carbon dioxide processing unit is provided with a carbon dioxide purification device 13, a carbon dioxide cooling device 14 and a carbon dioxide storage tank 15, and the carbon dioxide purification device, the carbon dioxide cooling device and the carbon dioxide storage tank are connected in sequence. The decomposition gas outlet is connected to the carbon dioxide processing unit through the induced draft fan 11, the cooling air inlet is connected to the outlet of the cooling fan 16, and the inlet of the cooling fan is connected to the carbon dioxide storage tank. The kiln chamber 17 of the lime kiln is provided with a preheating zone, a ca...

Embodiment 2

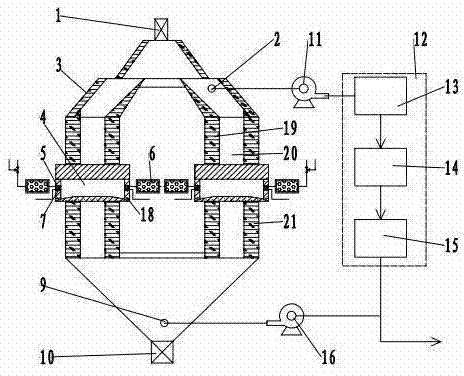

[0019] Another embodiment of the present invention is an annular kiln, such as image 3 , Figure 4 As shown, it is composed of an inner ring 19 and an outer ring 21, and the annular space 20 between the inner ring and the outer ring is a kiln chamber for processed materials. The 8 combustion chambers are evenly distributed across the inner ring, annular space and outer ring. Regenerators 6 are arranged on both sides of each combustion chamber, and the air ports on both sides of the combustion chamber are respectively connected with the regenerators. The heat accumulator on the outside of the combustion chamber preheats the combustion air, the fuel nozzles on the outside of the combustion chamber (outside the outer ring) spray fuel for combustion, and the generated flue gas is stored in the heat accumulator 6 inside the combustor chamber (inside the inner ring). Then reversing the fuel outlet inside the combustor chamber to spray fuel for combustion, the regenerator in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com