Fluidized bed gasifier and building method thereof

A fluidized bed gasifier and furnace body structure technology, which is applied in the field of coal gasification, can solve the problems of weak friction resistance, falling off and cracking, and alkali corrosion resistance of refractory lining, and achieves good integrity and sealing performance, which is convenient and convenient. The effect of pouring, good friction resistance and penetration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

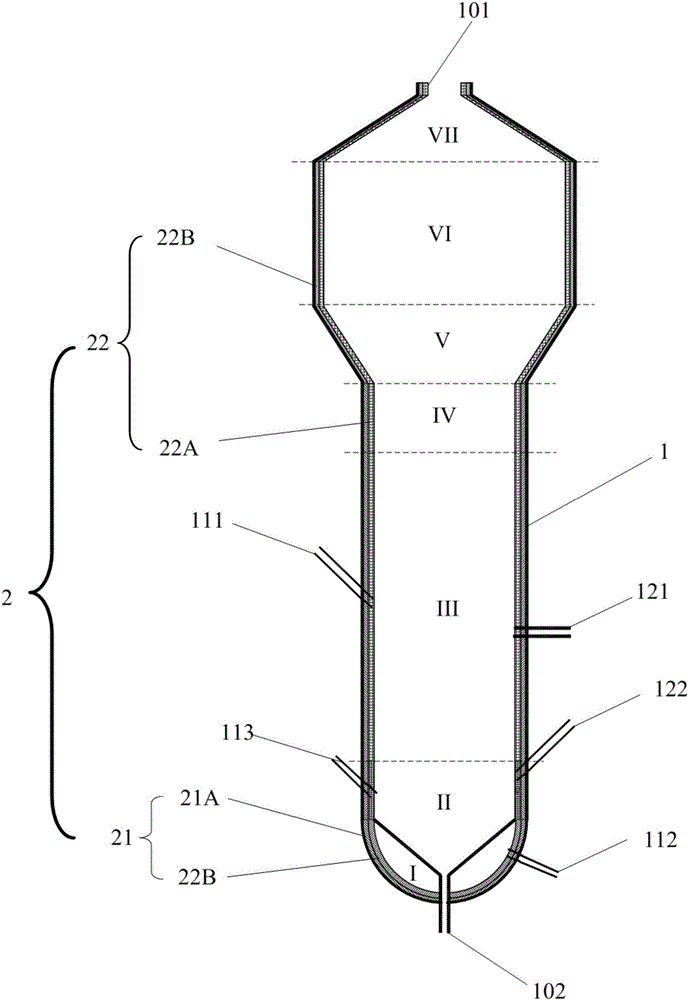

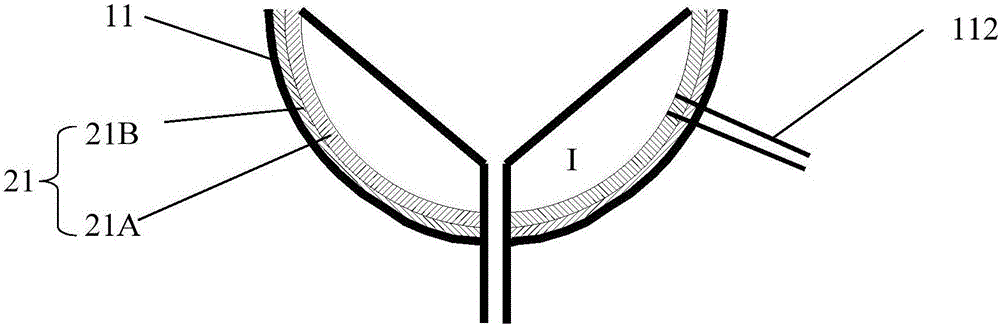

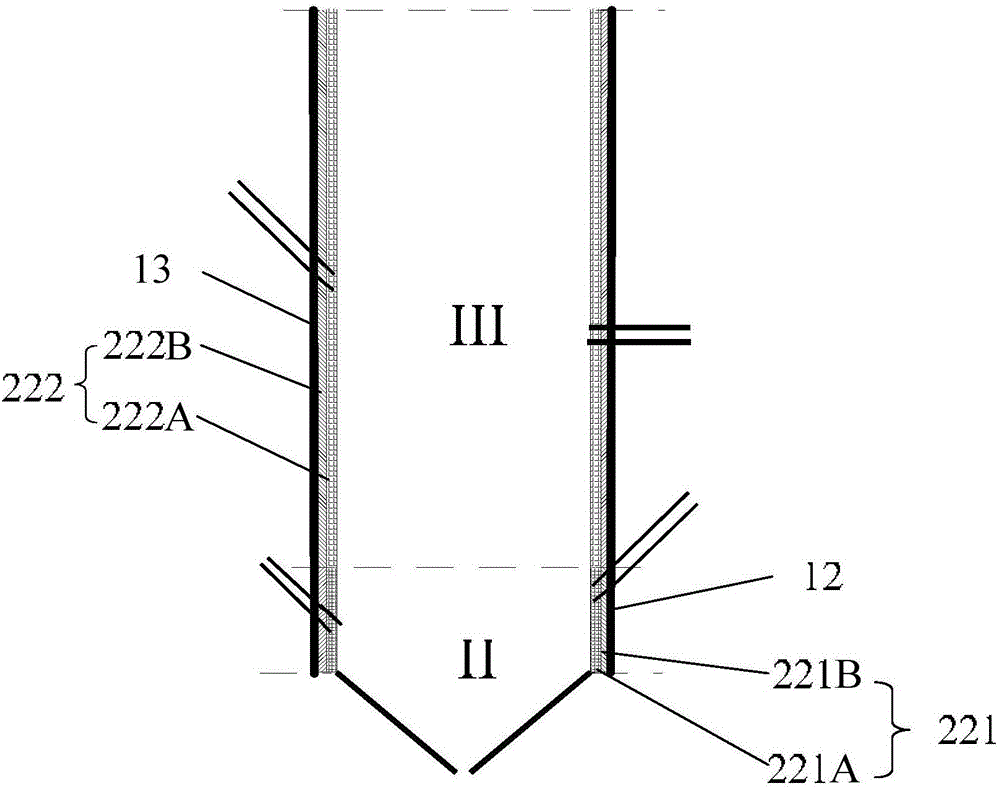

[0022] see figure 1 , the embodiment of the present invention provides a fluidized bed gasifier, including a furnace body structure and a furnace chamber located in the furnace body structure, the furnace chamber includes a gas chamber zone I, a dense phase bed material zone III and a dilute phase zone IV The furnace body structure includes a pressure-resistant shell 1 and a refractory lining 2, the material used in the refractory lining 2 contains alkali-resistant materials, and the refractory lining includes a first lining part 21 and a second lining part 22 , the first lining portion 21 and the second lining portion 22 are distributed along the direction of the furnace chamber from low to high; the part of the refractory lining 2 corresponding to the gas chamber area I is defined as the first lining portion 21, and the inner lining of the refractory material The part of the lining corresponding to the dense-phase bed material zone III and the dilute-phase zone IV is defined...

Embodiment 2

[0071] see figure 1 , the embodiment of the present invention also provides a construction method of a fluidized bed gasifier; specifically including the following steps:

[0072] The first step is to provide a pressure-resistant casing 1; the third refractory pouring layer 21B is made on the inner wall of the pressure-resistant casing 1 corresponding to the gas chamber area 1 by pouring method, and the third refractory pouring layer 21B faces the furnace by pouring method. The second refractory casting layer 21A is made in the cavity, so that the second refractory casting layer 21A and the third refractory casting layer 21B constitute the first inner lining part 21;

[0073] In the second step, the second inner lining part 22 is made by a segmented method; wherein, each section of making the second inner lining part 22 includes:

[0074] The refractory brick masonry method is used to make the masonry sub-layer of the refractory brick masonry layer 22A in the part correspondi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com