Ultra-high-performance concrete lattice reinforcement structure and method thereof for reinforcing masonry arch bridge

An ultra-high-performance, structural reinforcement technology, applied in arch bridges, bridge reinforcement, bridges, etc., to achieve the effect of improving overall stiffness, reducing loads, ensuring feasibility and construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The ultra-high-performance concrete provided in this embodiment has excellent mechanical properties, the compressive strength is generally higher than 150MPa, the tensile strength is 8MPa, high toughness, and good durability, so that the ultra-high-performance concrete structure can still be used in overloaded environments or earthquakes. It has more excellent structural reliability. Moreover, the ultra-high performance concrete provided by this embodiment can greatly increase the service life of the structure and reduce the maintenance cost of the structure. The self-weight of the ultra-high performance concrete structure is about 1 / 3 to 1 / 2 of the traditional concrete structure, which significantly reduces the dead load effect. Therefore, the ultra-high performance concrete lattice reinforcement structure provided in this embodiment can effectively improve the reinforcement effect of masonry arch bridges.

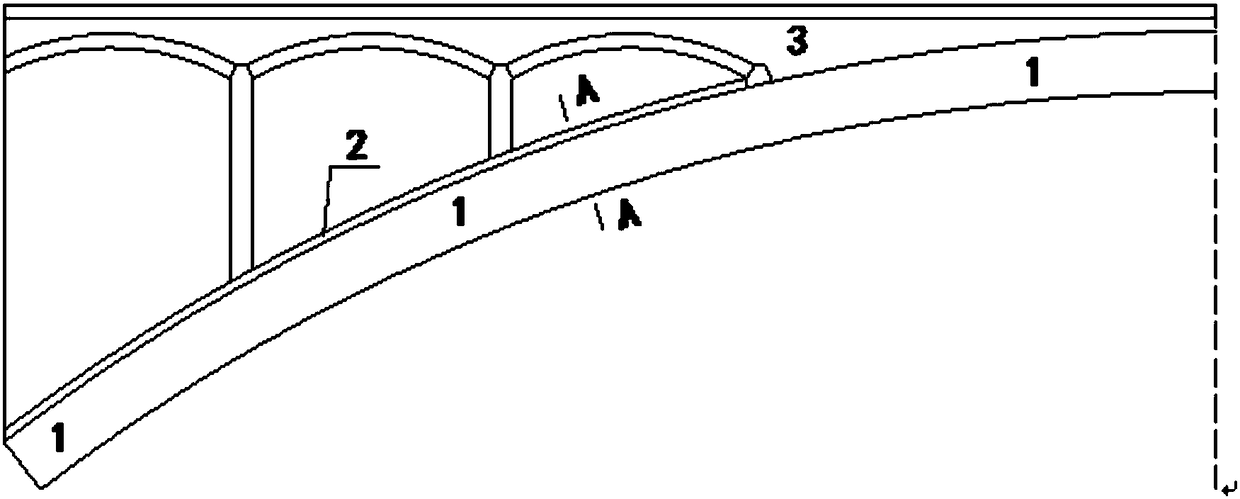

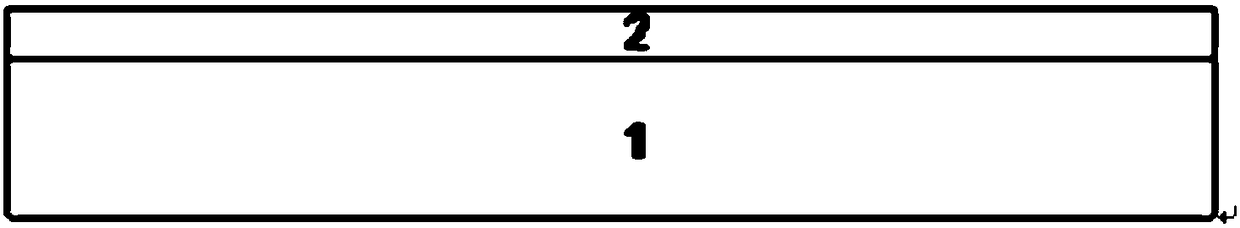

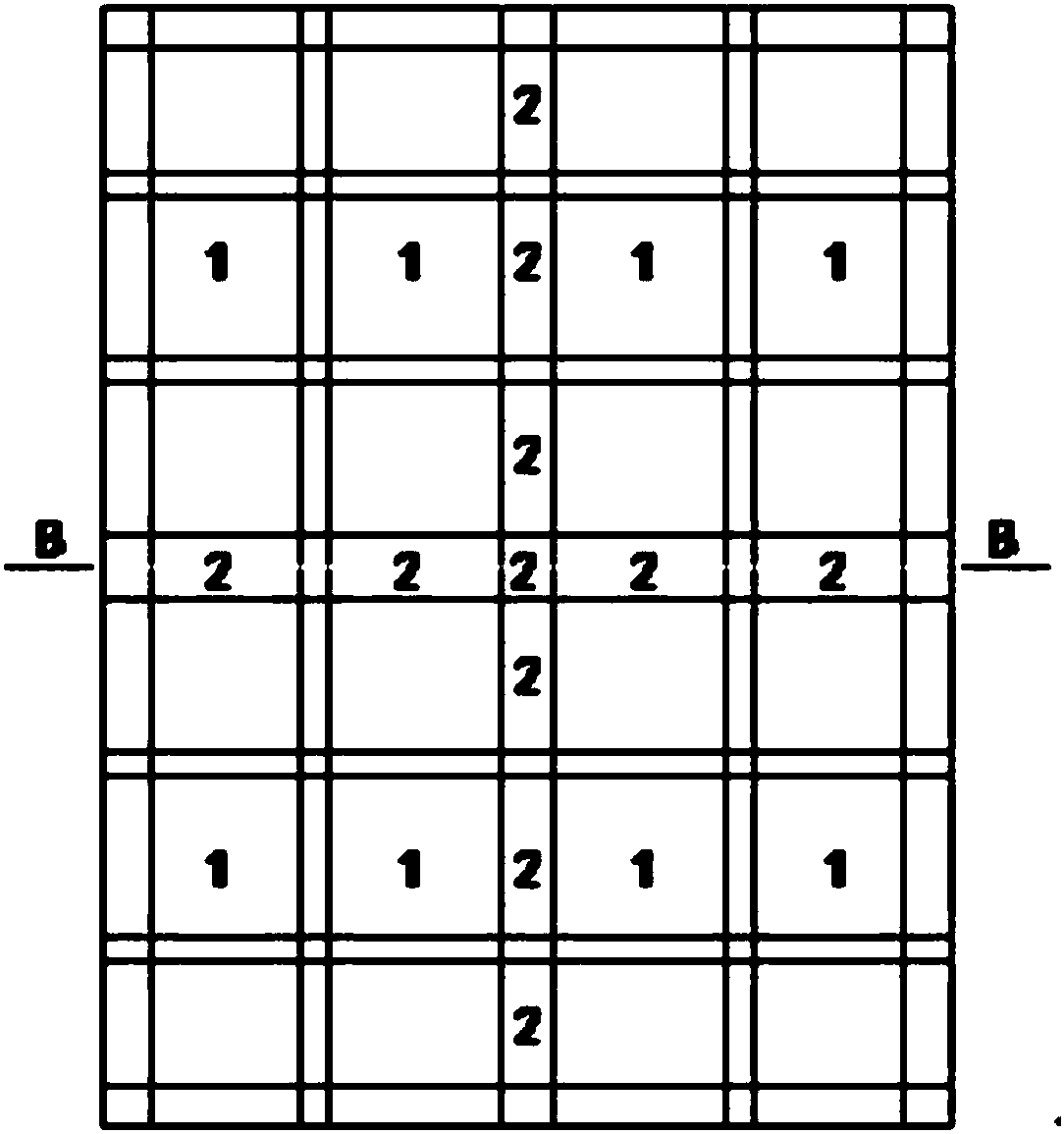

[0041] figure 1 It is a schematic structural diagram of an ...

Embodiment 2

[0048] This embodiment provides a construction method for reinforcing masonry arch bridges using the ultra-high performance concrete lattice reinforcement structure provided in Embodiment 1. For a specific description of the ultra-high performance concrete lattice reinforcement structure, please refer to Embodiment 1, which is not mentioned here Let me repeat.

[0049] The construction method for reinforcing the masonry arch bridge provided by this embodiment includes: using the anchor shotcrete method and / or partial repair method to repair the original main arch ring for the first time; demolishing the arch building above the original main arch ring; removing all Describe the loose, peeling surface of the original main arch ring; wash and clean the original main arch ring; set a shear connector and a steel mesh on the original main arch ring, and the shear connector is a planting bar or an anchor rod; According to the balanced and symmetrical pouring method, the vertical and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com