C/C-ZrC-SiC surface-layer iron-based alloy modified composite material and preparation method thereof

A technology of composite materials and iron-based alloys, applied in the direction of metal material coating process, coating, hot-dip plating process, etc., can solve the problems of affecting mechanical properties, reducing mechanical properties, reducing interlayer strength, etc., and achieve high temperature creep resistance Excellent denaturation properties, reducing stress concentration sources, and enhancing the surface density of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

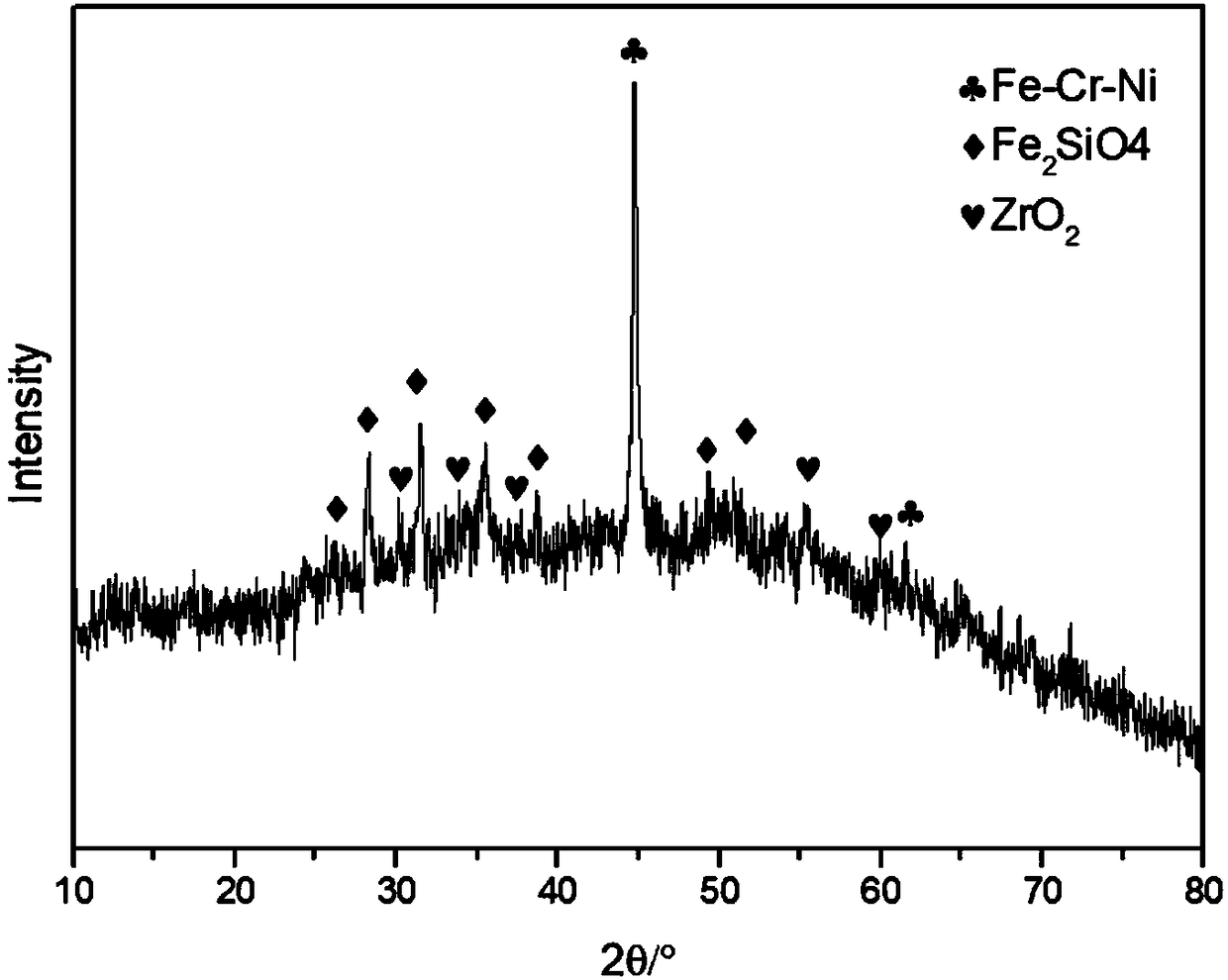

Image

Examples

Embodiment 1

[0056] Set the density to 2.6g / cm 3 The surface of the C / C-ZrC-SiC composite material is polished, ultrasonically cleaned, and dried in a low-temperature vacuum for use; meanwhile, the Fe-15Cr-25Ni series iron-based superalloy powder is dried in a low-temperature vacuum for use.

[0057] Check the quality of the smelting furnace, bake the furnace at 500°C for 1 hour and use it for later use; meanwhile, clean the crucible tongs and dry them for later use.

[0058] Heat the iron-based superalloy powder in the smelting furnace to 10°C-100°C above the melting point (after about 1650°C), then add a deoxidizer accounting for 0.05% to 0.075% of the alloy melt mass, press it to the bottom with a tool and move slowly until until no bubbling; then add slag breaking agent, fully stir with tools, remove slag, and remove impurities in iron-based superalloy liquid; after cleaning slag, sprinkle 0.05%-0.1% iron on the surface of the alloy melt Covering agent to prevent oxygen in the air fro...

Embodiment 2

[0062] Set the density to 2.6g / cm 3 The surface of the C / C-ZrC-SiC composite material is polished, ultrasonically cleaned, and dried in a low-temperature vacuum for use; meanwhile, the Fe-15Cr-25Ni series iron-based superalloy powder is dried in a low-temperature vacuum for use.

[0063] Check the quality of the smelting furnace, bake the furnace at 500°C for 1 hour and use it for later use; meanwhile, clean the crucible tongs and dry them for later use.

[0064] Heat the iron-based superalloy powder in the smelting furnace to 10°C-100°C above the melting point (after about 1650°C), then add a deoxidizer accounting for 0.05% to 0.075% of the alloy melt mass, press it to the bottom with a tool and move slowly until until no bubbling; then add slag breaking agent, fully stir with tools, remove slag, and remove impurities in iron-based superalloy liquid; after cleaning slag, sprinkle 0.05%-0.1% iron on the surface of the alloy melt Covering agent to prevent oxygen in the air fro...

Embodiment 3

[0068] Set the density to 2.6g / cm3 The surface of the C / C-ZrC-SiC composite material is polished, ultrasonically cleaned, and dried in a low-temperature vacuum for use; meanwhile, the Fe-15Cr-25Ni series iron-based superalloy powder is dried in a low-temperature vacuum for use.

[0069] Check the quality of the smelting furnace, bake the furnace at 500°C for 1 hour and use it for later use; meanwhile, clean the crucible tongs and dry them for later use.

[0070] Heat the iron-based superalloy powder in the smelting furnace to 10°C-100°C above the melting point (after about 1650°C), then add a deoxidizer accounting for 0.05% to 0.075% of the alloy melt mass, press it to the bottom with a tool and move slowly until until no bubbling; then add slag breaking agent, fully stir with tools, remove slag, and remove impurities in iron-based superalloy liquid; after cleaning slag, sprinkle 0.05%-0.1% iron on the surface of the alloy melt Coating agent % to prevent oxygen in the air from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com