High-strength nanometer silicon carbide strengthening copper-based composite material and preparing method thereof

A technology of copper-based composite materials and nano-silicon carbide, which is applied in the field of high-strength nano-silicon carbide-reinforced copper-based composite materials, can solve the problems of short service life, large replacement costs, and low strength and hardness, and achieve hardness and strength performance. Effect of improving strength and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

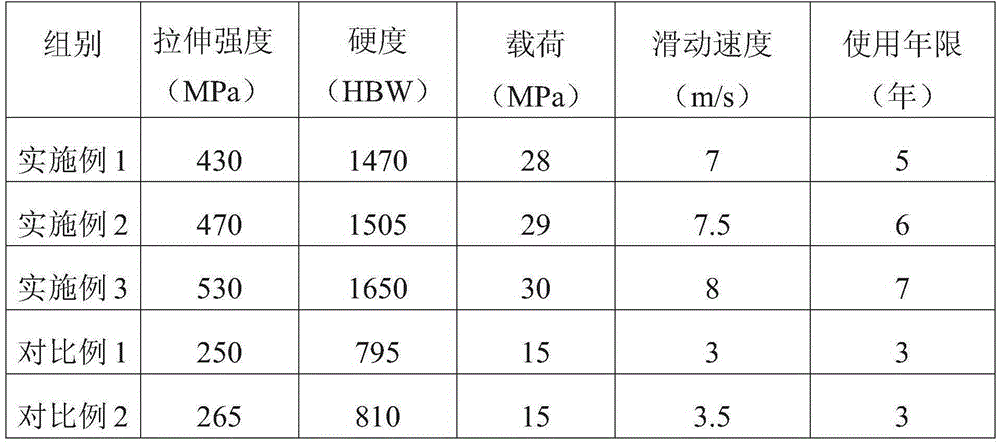

[0028] The high-strength nano-silicon carbide reinforced copper-based composite material for high-load impellers in Example 1 of the present invention is characterized in that it consists of the following components in volume percentage: nano-silicon carbide 1.2%, copper alloy ZCuSn 10 Zn 2 98.8%, wherein the nano-silicon carbide particle size is above 50 μm and below 200 μm.

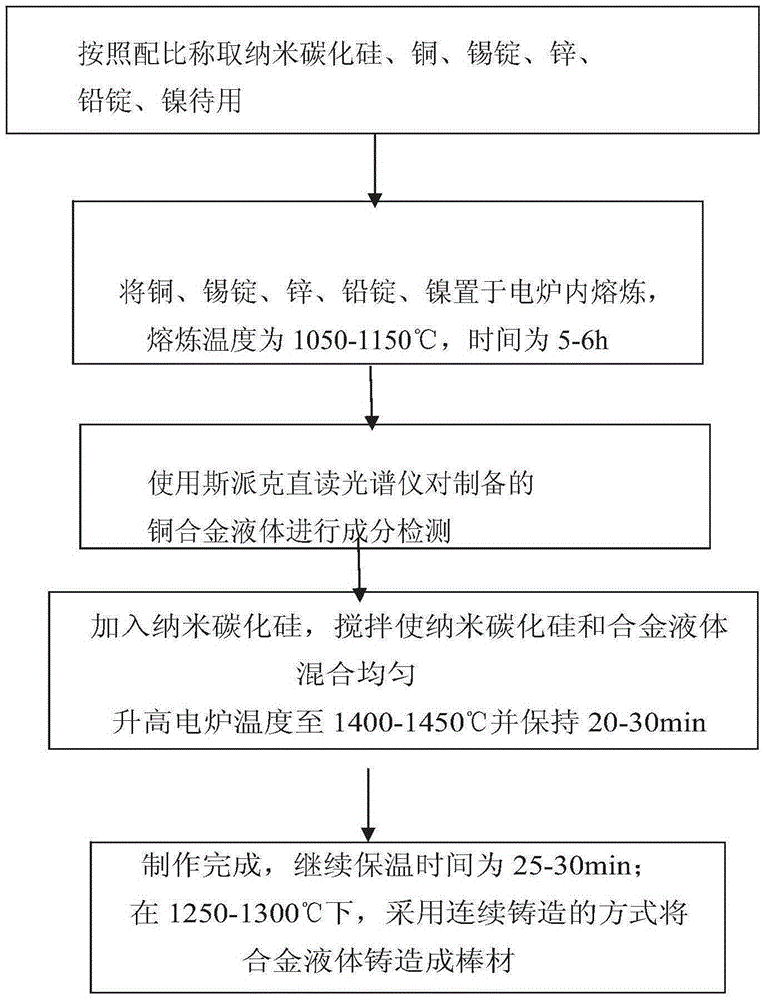

[0029] The preparation method of the high-strength nano-silicon carbide reinforced copper-based composite material for the high-load impeller of the embodiment of the present invention 1 is characterized in that it has the following steps (such as figure 1 shown):

[0030] 1) Preparation of copper alloy ZCuSn 10 Zn 2 : put electrolytic copper, tin ingots, zinc, lead ingots, and nickel into the electric furnace for melting according to the weight ratio mentioned above, the liquid volume of the copper alloy during melting is less than 90% of the volume of the electric furnace; the melting temperature i...

Embodiment 2

[0036] The high-strength nano-silicon carbide reinforced copper-based composite material for high-load impellers in Example 2 of the present invention is characterized in that it consists of the following components in volume percentage: nano-silicon carbide 2.5%, copper alloy ZCuSn 10 Zn 2 97.5%, wherein the nano-silicon carbide particle size is above 50 μm and below 200 μm.

[0037] The preparation method of the high-strength nano-silicon carbide reinforced copper-based composite material for the high-load impeller of the embodiment of the present invention 2 is characterized in that it has the following steps (such as figure 1 shown):

[0038] 1) Preparation of copper alloy ZCuSn 10 Zn 2: put electrolytic copper, tin ingots, zinc, lead ingots, and nickel into the electric furnace for melting according to the weight ratio mentioned above, the liquid volume of the copper alloy during melting is less than 90% of the volume of the electric furnace; the melting temperature is...

Embodiment 3

[0044] The high-strength nano-silicon carbide reinforced copper-based composite material for high-load impellers in Example 3 of the present invention is characterized in that it consists of the following components in volume percentage: nano-silicon carbide 3.5%, copper alloy ZCuSn 10 Zn 2 96.5%, wherein the nano-silicon carbide particle size is above 50 μm and below 200 μm.

[0045] The preparation method of the high-strength nano-silicon carbide reinforced copper-based composite material for the high-load impeller of the embodiment of the present invention 3 is characterized in that it has the following steps (such as figure 1 shown):

[0046] 1) Preparation of copper alloy ZCuSn 10 Zn 2 : Put electrolytic copper, tin ingots, zinc, lead ingots, and nickel into the electric furnace for smelting according to the above-mentioned weight ratio, and the liquid volume of the copper alloy during smelting is less than 90% of the volume of the electric furnace; the melting tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com