Reinforced portable integral prefabricated masonry arch bridge

An overall prefabricated and portable technology, applied in arch bridges, bridges, bridge forms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

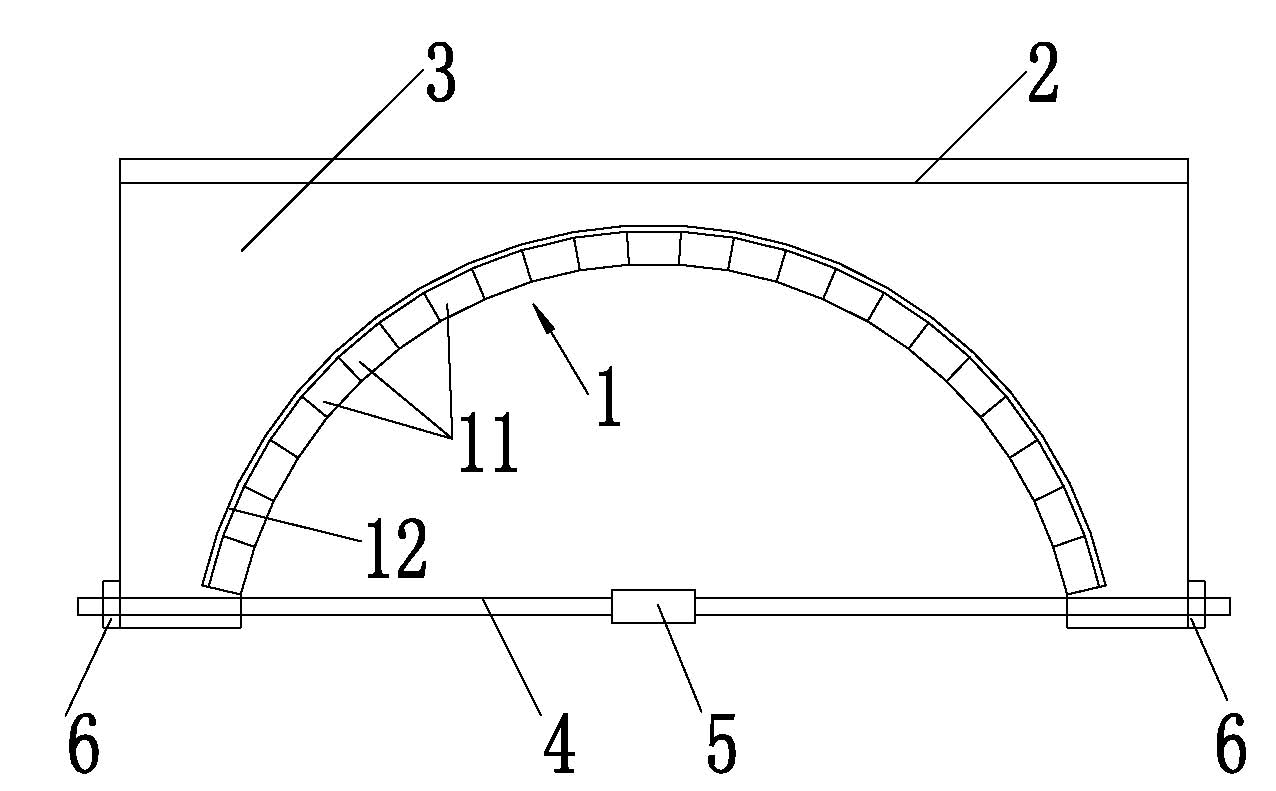

Embodiment 1

[0035] One of the specific implementations of a reinforced portable integral prefabricated masonry arch bridge of the present invention, such as figure 1 As shown, it includes a bridge body 3 and a bridge deck 2. The inner side of the bridge body 3 is provided with an arch ring 1. The arch ring 1 includes a main body composed of a plurality of prefabricated arch blocks 11 arranged in sequence, and is fixedly pasted on The fiber reinforced composite material connection layer 12 on the upper surface of the main body, the sides of two adjacent prefabricated arch blocks 11 are attached to each other, and the lower surfaces of all the prefabricated arch blocks 11 form the lower surface of the arch ring 1, the The connecting layer 12 of fiber reinforced composite material is fixedly connected with the upper surface of each prefabricated arch block 11 . Above-mentioned technical feature is identical with the structure of portable whole prefabricated masonry arch bridge in the prior a...

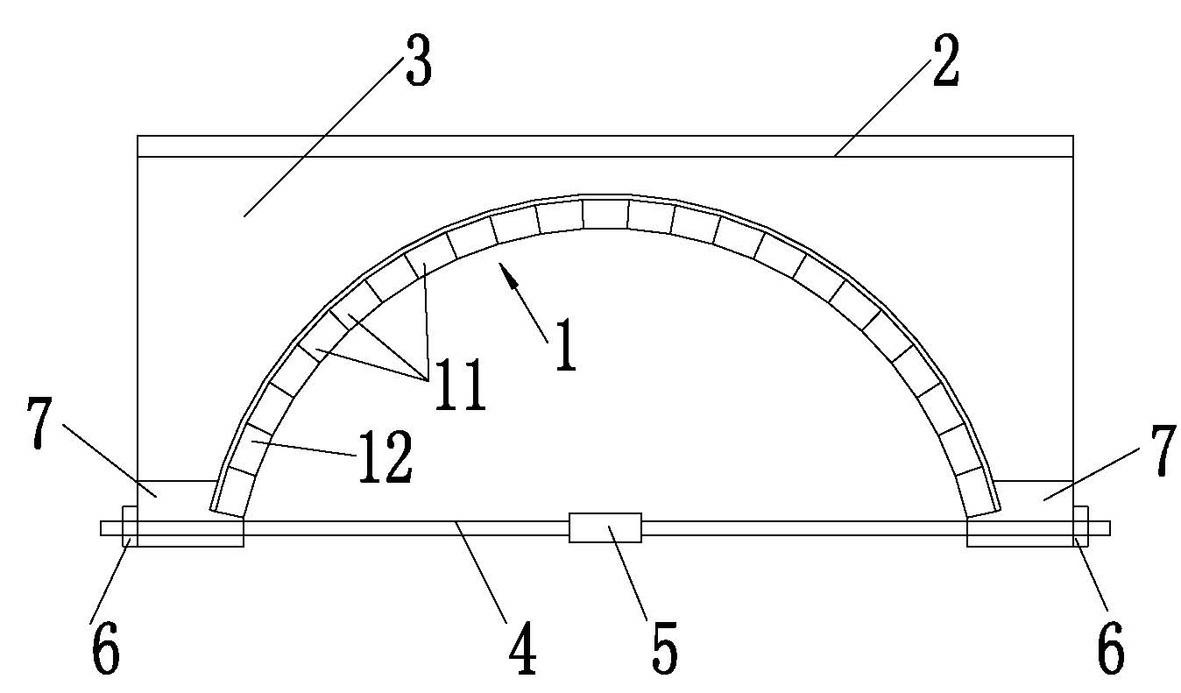

Embodiment 2

[0042] The second embodiment of a reinforced portable integral prefabricated masonry arch bridge of the present invention, as figure 2 As shown, the main technical solutions of this embodiment are the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that: the bottom end of the arch foot of the bridge body 3 is provided with an abutment 7, and the abutment 7 is closely connected with the bottom end of the arch foot of the bridge body 3, The transverse tie rods 4 are arranged between the abutments 7 .

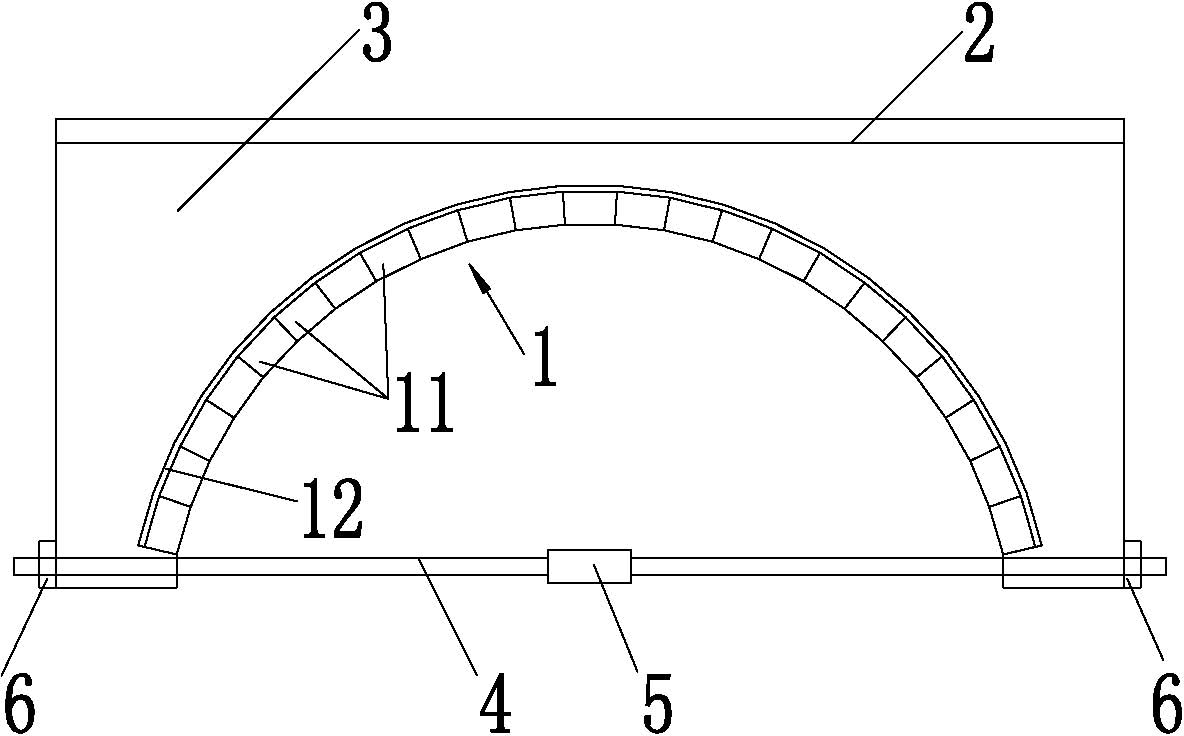

Embodiment 3

[0044] The third specific embodiment of a reinforced portable integral prefabricated masonry arch bridge of the present invention, the main technical solution of this embodiment is the same as that of embodiment 1, and the features not explained in this embodiment shall be explained in embodiment 1 , which will not be repeated here. The difference between this embodiment and Embodiment 1 is that: the middle part of the transverse tie rod 4 is provided with a pre-tensioning member. Pretension is provided by pretension elements.

[0045] Specifically, the pre-tensioning member is a bolt sleeve 5 . The bolt sleeve 5 is a bolt sleeve 5 with an internal thread.

[0046] Specifically, the bolt sleeve 5 is made of stainless steel. The effect in practical application is better, and it is not easy to be damaged, and the service life is longer.

[0047] Specifically, the bolt sleeve 5 is made of fiber reinforced plastic (FRP).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com