Masonry arch bridge using lightweight concrete as arch filler

A lightweight concrete and concrete technology, which is applied in arch bridges, bridges, bridge construction, etc., can solve the problems of increased self-weight of fillers, large internal forces of arches, unfavorable structural forces, etc., to improve safety reserves, increase bearing capacity, and improve stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

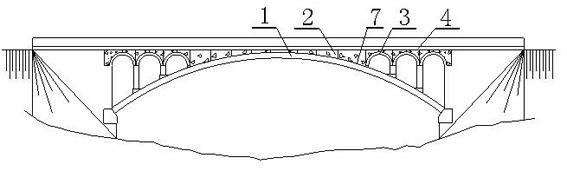

Embodiment 1

[0030] As shown in the attached figure, the masonry arch bridge using lightweight concrete as the filler on the arch adopts the internal force control design of the vault section, including the main arch ring 1, the belly arch 3 and the filler layer 2 on the arch. The filling layer 2 on the arch in the 1 / 4 to 3 / 4 section is poured with an apparent density of 1000kg / m 3 The lightweight concrete layer is made of lightweight concrete, and the arch filler layer 2 in other sections is poured with an apparent density of 1800kg / m 3 A lightweight concrete layer made of lightweight concrete; a leveling layer 4 is arranged on the top surface of the filler layer 2 on the arch, and the leveling layer 4 is a plain concrete layer with a thickness of 8cm and C15 plain concrete as the material; There is also a waterproof layer 7 between the arch ring 1 and the filling layer 2 on the arch. The waterproof layer 7 is paved with permanent concrete or asphalt; along the horizontal direction of the...

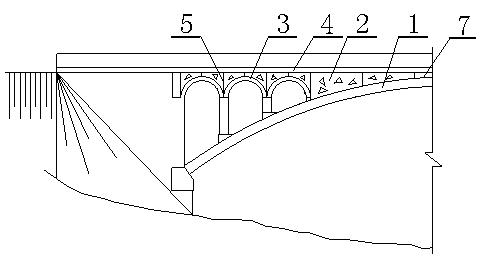

Embodiment 2

[0032] As shown in the attached figure, the masonry arch bridge using lightweight concrete as the filler on the arch adopts the internal force control design of the arch foot section, including the main arch ring 1, the belly arch 3 and the filler layer 2 on the arch. The filling layer 2 on the arch in the 1 / 4 to 3 / 4 section is poured with an apparent density of 1700kg / m 3 The lightweight concrete layer is made of lightweight concrete, and the arch filler layer 2 in other sections is poured with an apparent density of 800kg / m 3 A lightweight concrete layer made of lightweight concrete; a leveling layer 4 is arranged on the top surface of the filler layer 2 on the arch, and the leveling layer 4 is a plain concrete layer with a thickness of 10cm and C20 plain concrete as the material; the main There is also a waterproof layer 7 between the arch ring 1 and the filling layer 2 on the arch. The waterproof layer 7 is paved with permanent concrete or asphalt; along the horizontal dir...

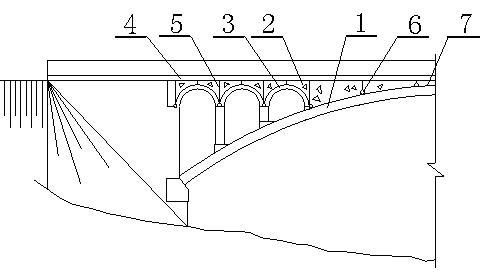

Embodiment 3

[0034]As shown in the attached figure, the masonry arch bridge using lightweight concrete as the filler on the arch adopts the design of equal internal forces in the section of the vault and the arch foot, including the main arch ring 1, the abdominal arch 3 and the filler layer 2 on the arch, and the filler layer on the arch 2. The pouring apparent density is 1250kg / m 3 A lightweight concrete layer made of lightweight concrete; a leveling layer 4 is arranged on the top surface of the filler layer 2 on the arch, and the leveling layer 4 is a plain concrete layer with a thickness of 9cm and C18 plain concrete as the material; the main There is also a waterproof layer 7 between the arch ring 1 and the filling layer 2 on the arch. The waterproof layer 7 is paved with permanent condensate or asphalt; along the horizontal direction of the bridge, there is a sawing kerf 5 with a width of 30 mm. The vertical distance in the circle 1 area is no more than 3m, and the saw seam 5 in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com