Patents

Literature

71results about How to "Mass balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alloyed hot galvanizing bake hardening steel and method for manufacturing same

ActiveCN101230437ANot easy to produceImprove PlatabilityHot-dipping/immersion processesTemperature control deviceCooking & bakingSheet steel

The invention relates to an alloyed hot-galvanized baking-hardened steel plate and the manufacturing method thereof, which solves the problems of the anti-pulverization of the galvanized layer, the surface quality and the baking-hardened value. The mass percentage for the chemical components of a baseplate is as follows: C 0.0015 to 0.0025 percent, Si less than or equal to 0.030 percent, Mn 0.50 to 0.60 percent, P 0.050 to 0.060 percent, S less than or equal to 0.015 percent, N less than or equal to 0.003 percent, sol.Al 0.030 to 0.055 percent, Nb 0.004 to 0.015 percent, O less than or equal to 0.0050 percent and the rest are Fe and unavoidable impurities. The weight of the galvanized layer (for a single side) is 30-60g / m2 and the mass percentage for the Fe component of the galvanized layer is 8 to 12 percent. The steel plate of the invention has excellent anti-pulverization performance of the galvanized layer, excellent surface quality and appropriate baking-hardened value.

Owner:BAOSHAN IRON & STEEL CO LTD

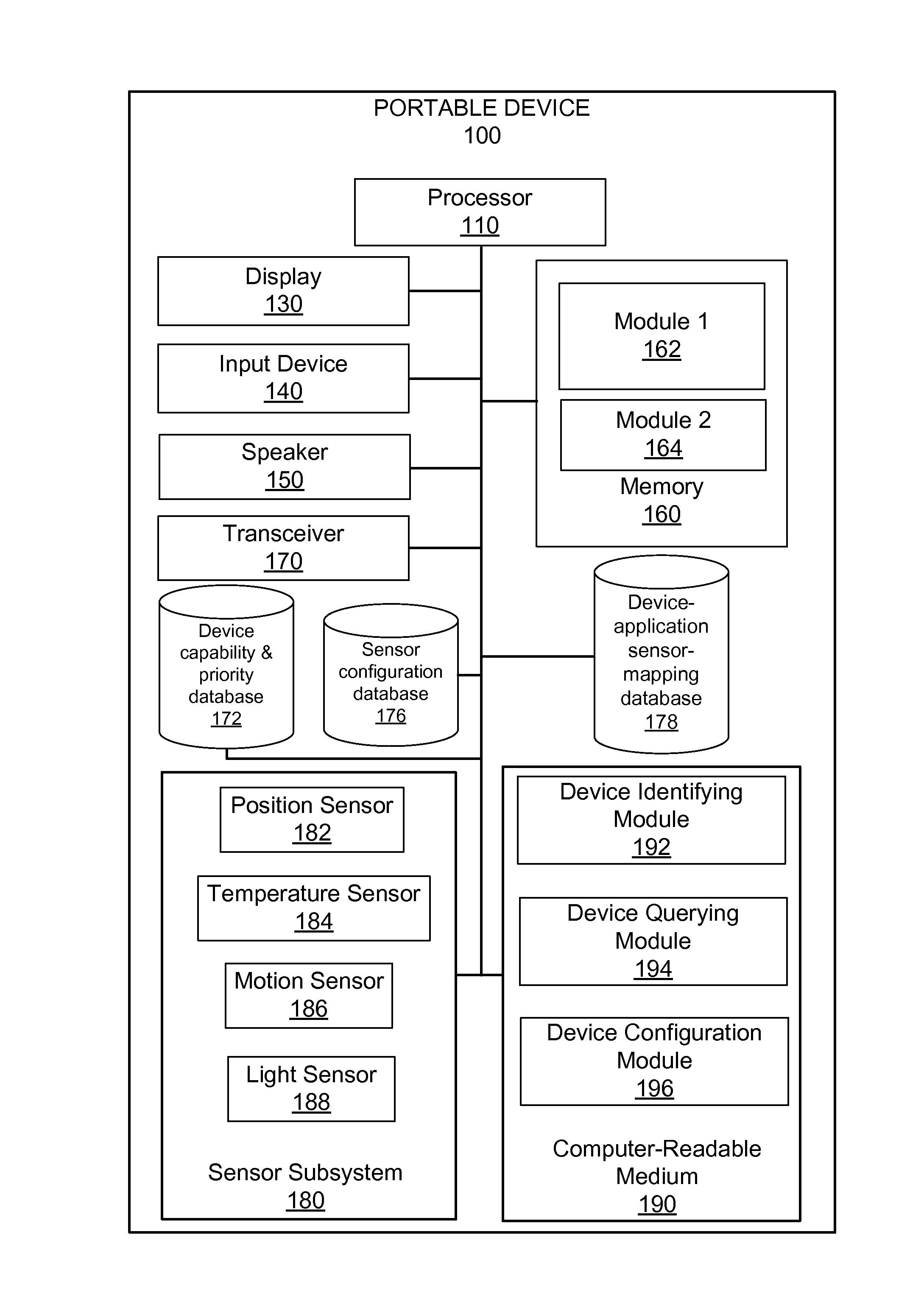

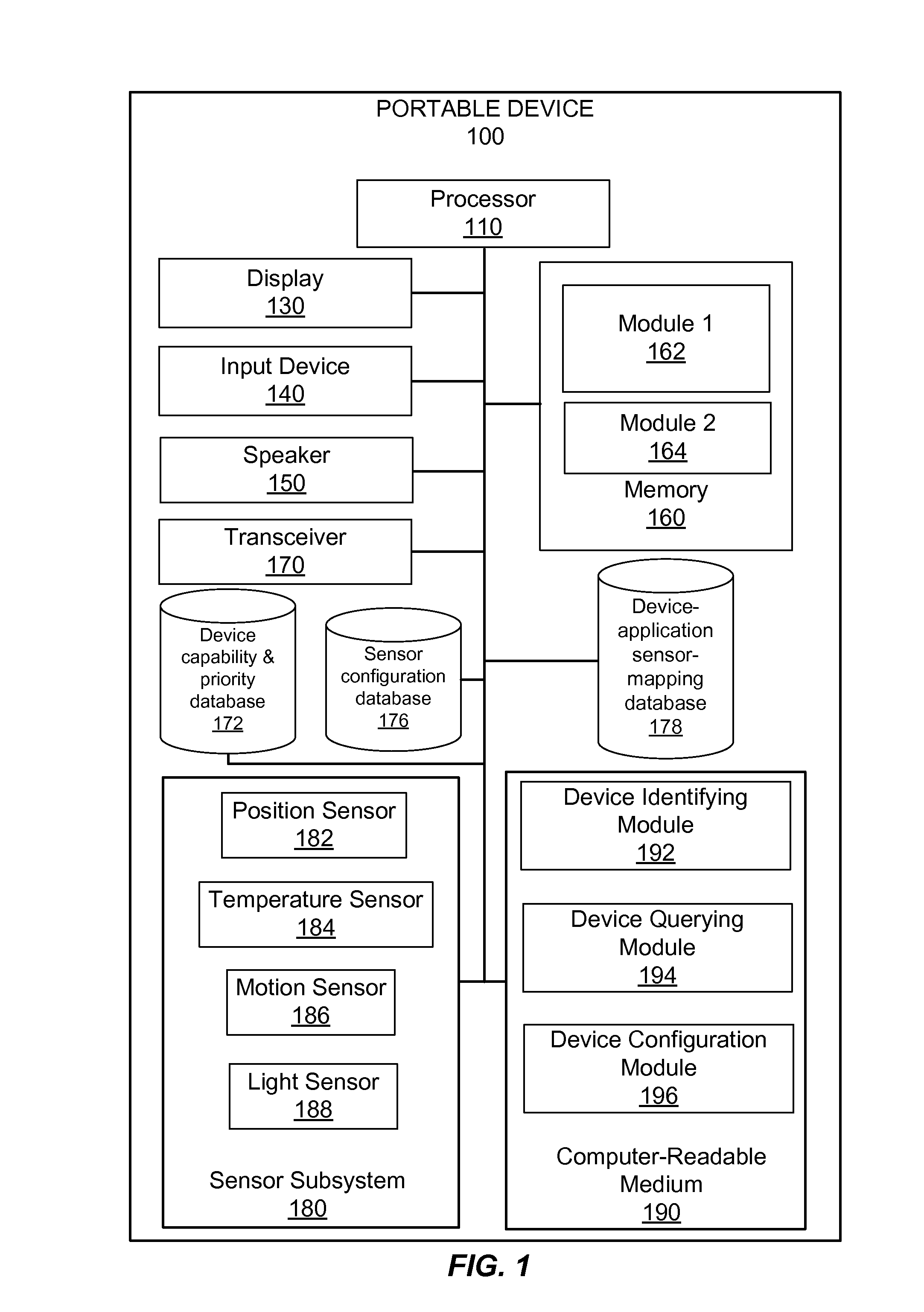

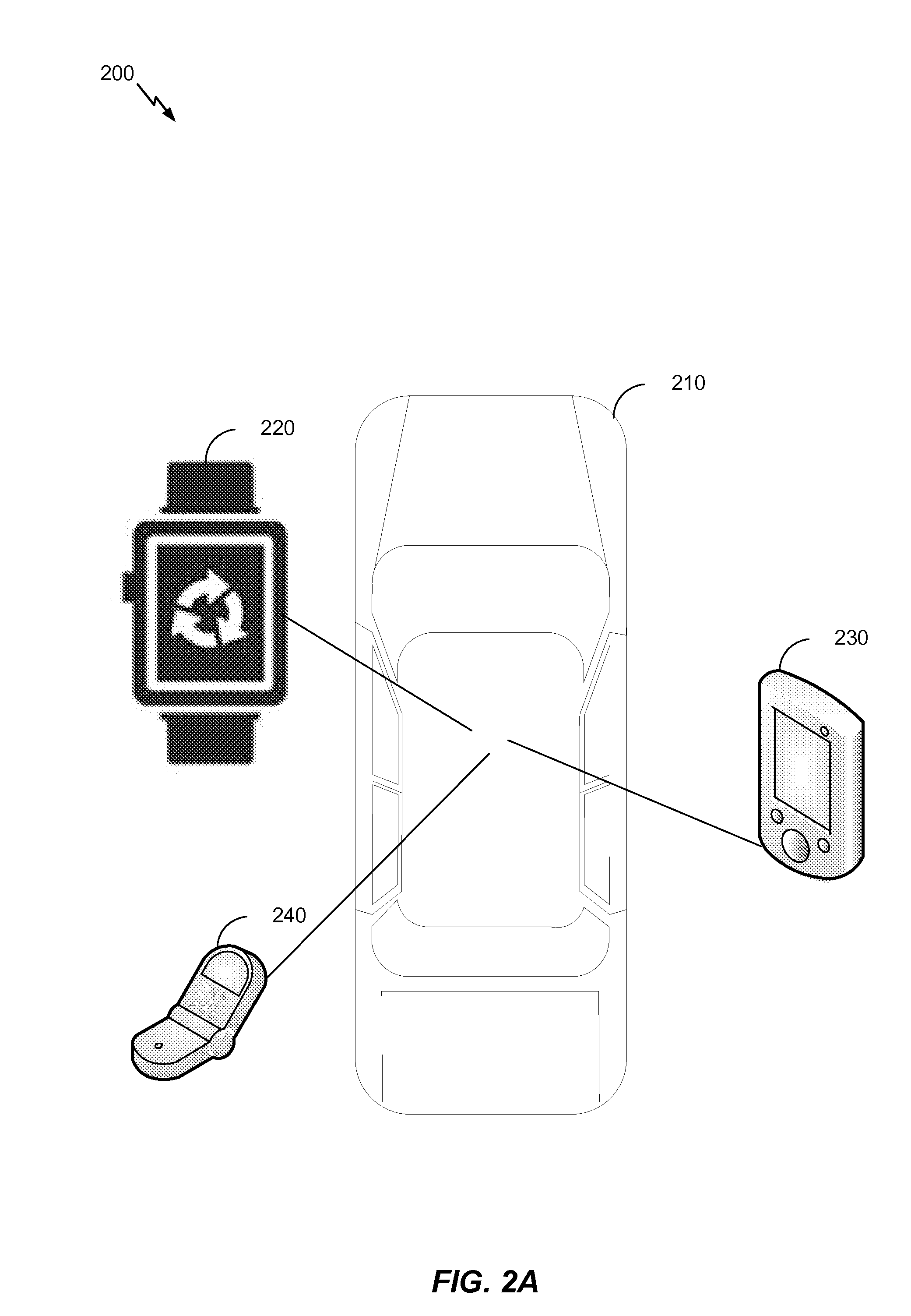

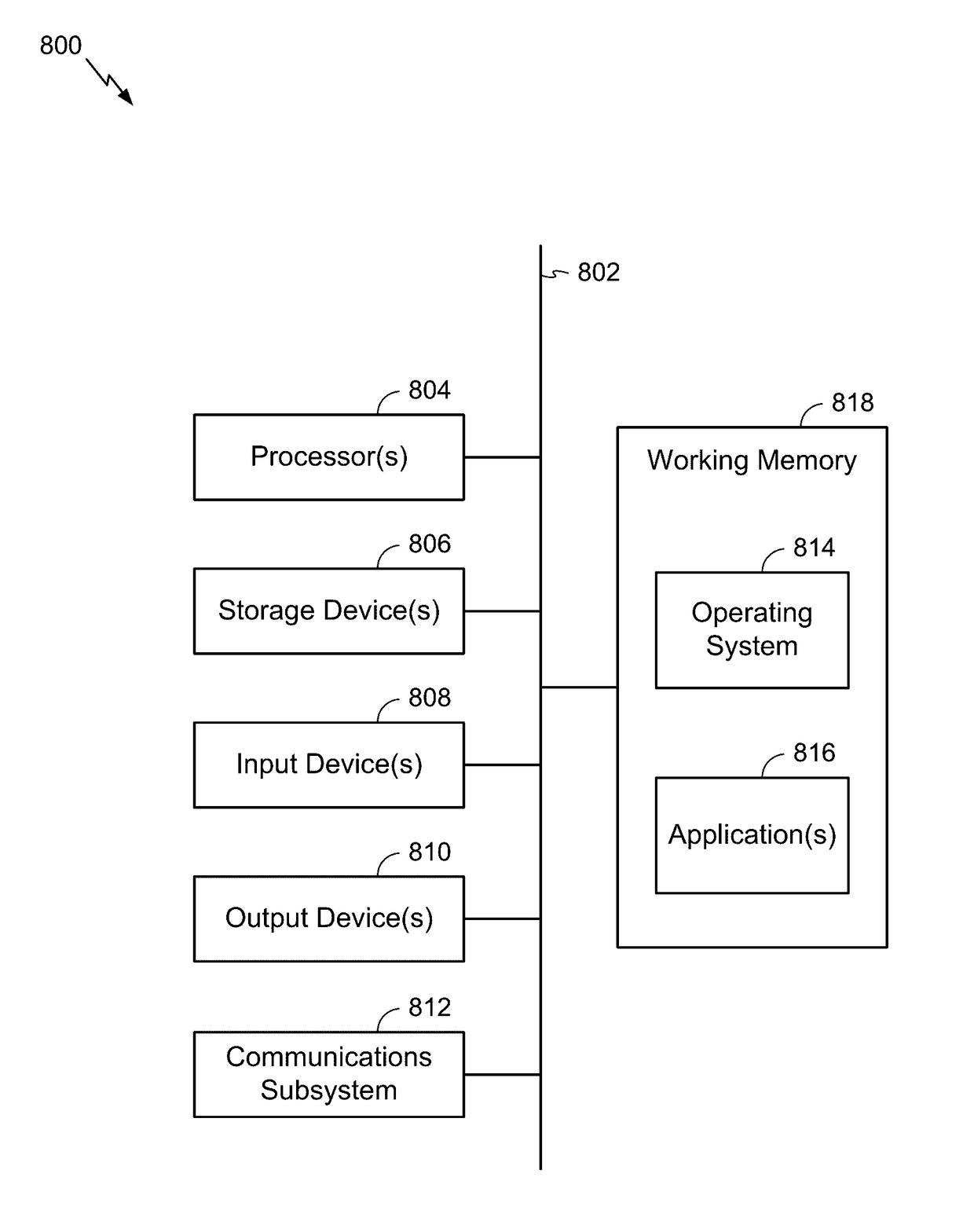

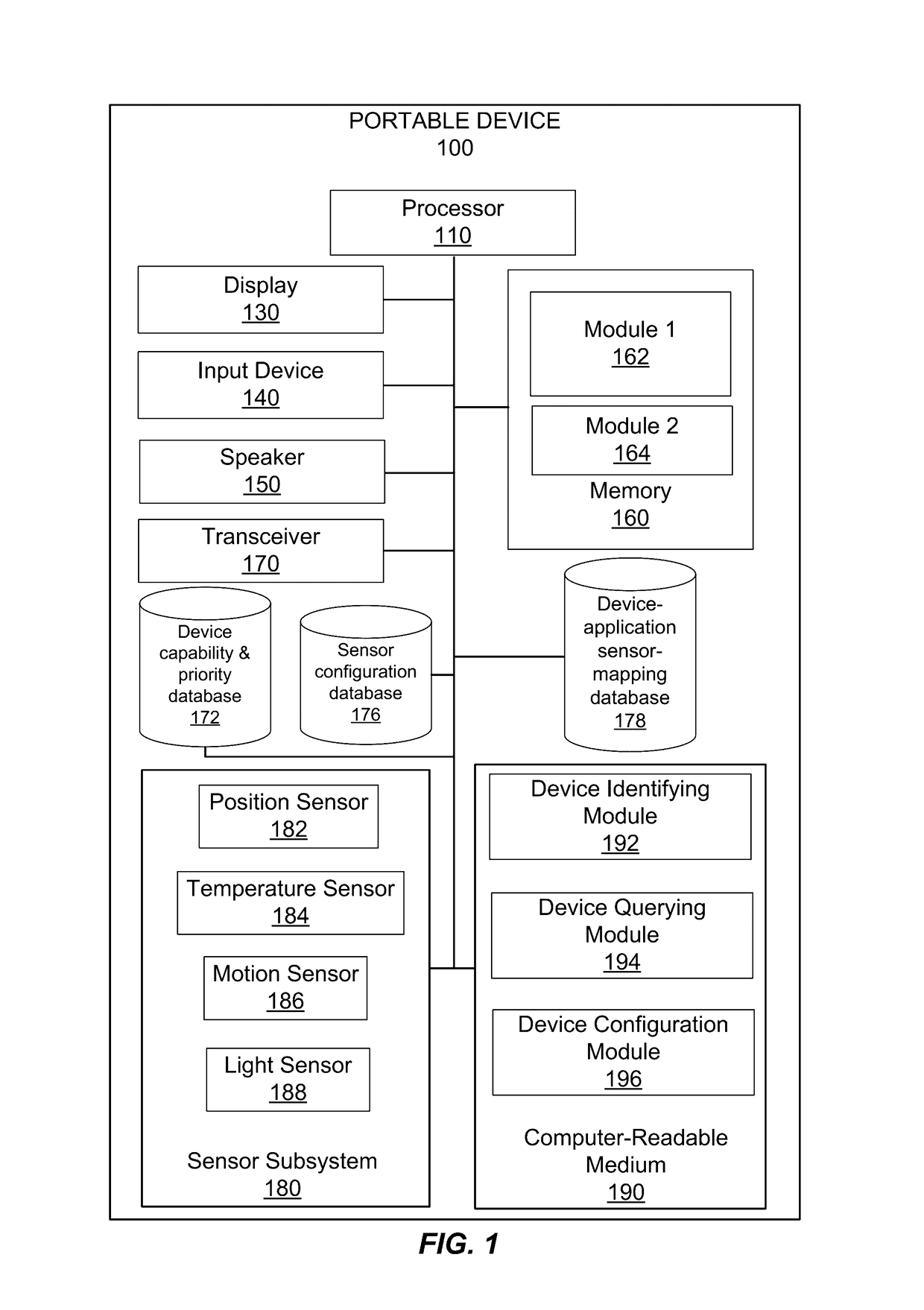

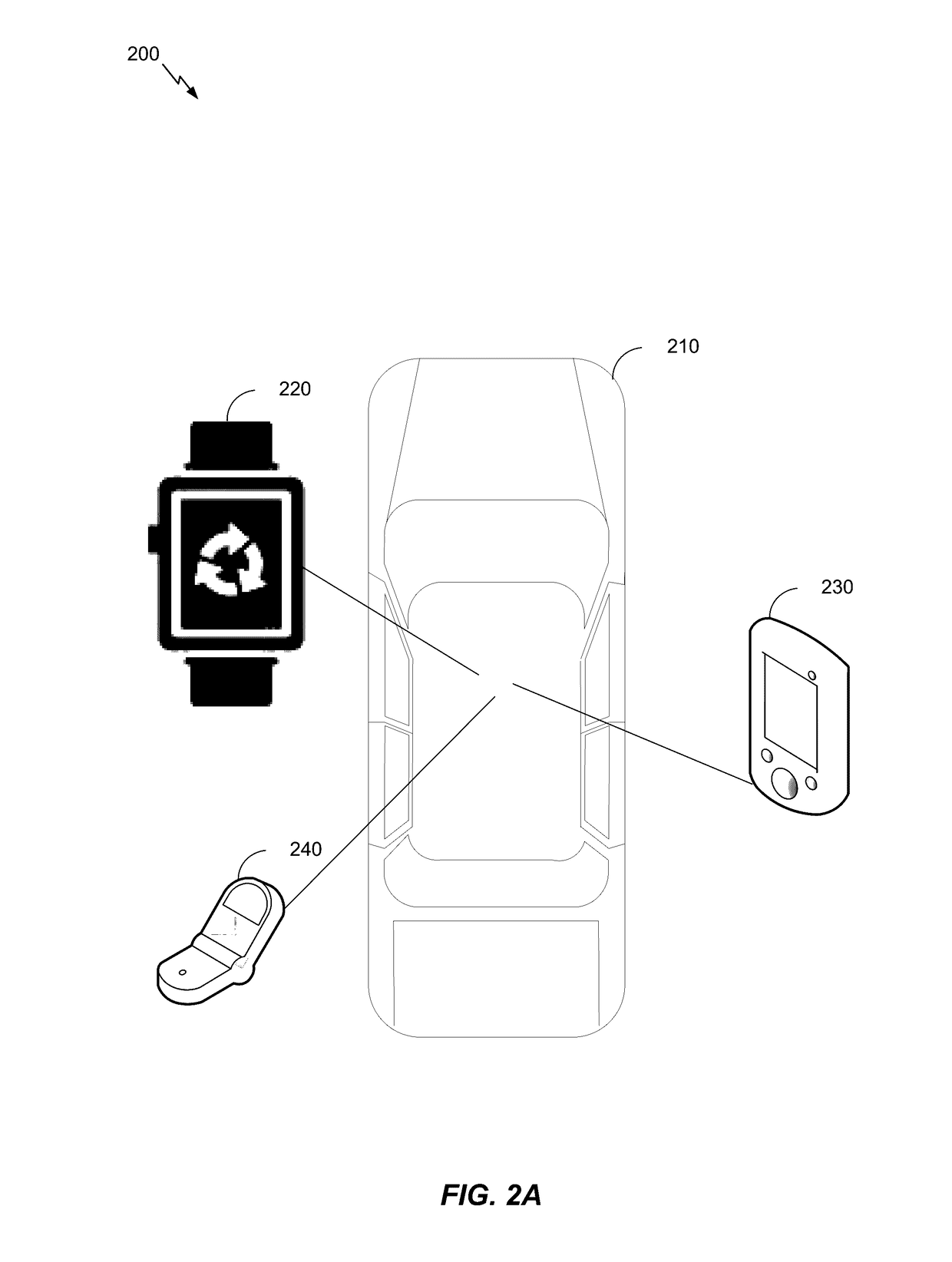

Multi-device sensor subsystem joint optimization

ActiveUS20160050114A1Reduce redundancyReducing sensor redundancyPower managementSynchronisation arrangementMultiple deviceQuality of service

A system and method for reducing sensor redundancy in sensor-equipped devices includes identifying, via a master device, at least one device within an area. The at least one device is queried to determine at least one of a device status or application status for the at least one device. A configuration of one or more sensors within the at least one device based at least in part on the querying is determined. The one or more sensors within the at least one device is configured to balance quality of service across the master device and the at least one device, based at least in part on the determining.

Owner:QUALCOMM INC

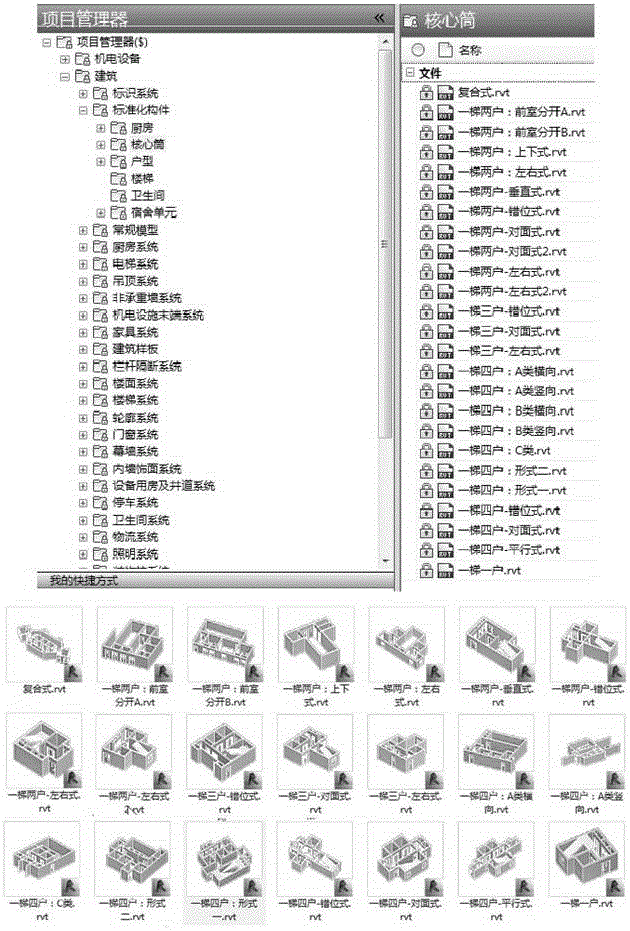

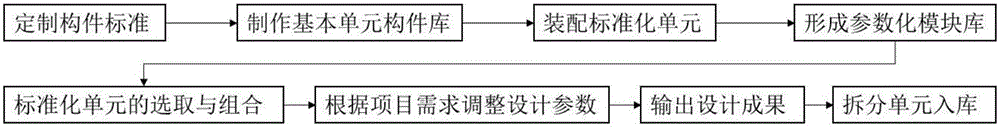

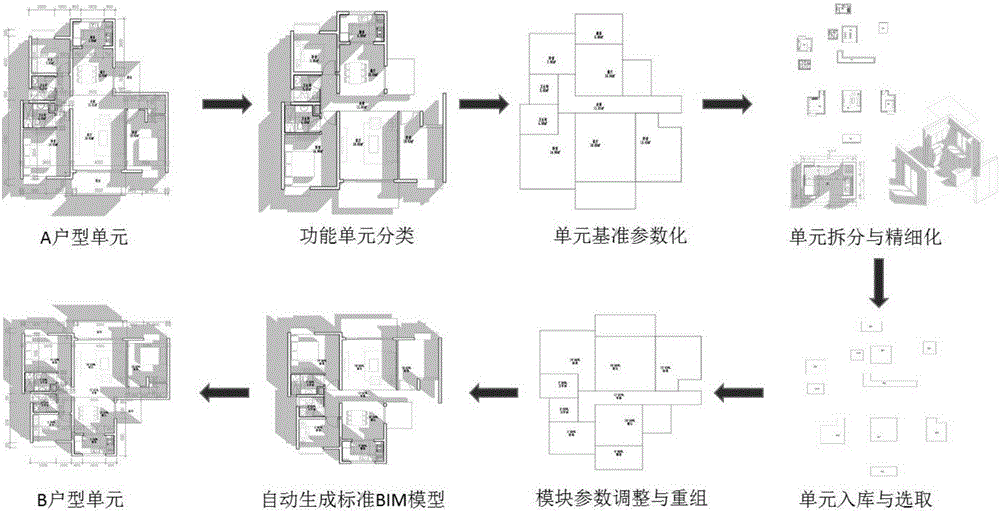

Parametric architectural design method based on design logic

ActiveCN106649908AAchieve efficiency and qualityAchieve balanceGeometric CADSpecial data processing applicationsModularityEngineering

The invention discloses a parametric architectural design method based on design logic, which includes steps: S1, customizing component standards; S2, making basic unit components; S3, assembling standardized units; S4, forming a parametric modular component library; S5, selecting and composing the standardized units; S6, adjusting design parameters according to the program; S7, outputting design results; S8, storing split units. The parametric architectural design method based on the design logic splits design elements into basic unit components. Through benchmark model driven by parameterization in Revit and each unit component according to certain design logic carrying on relation locking, parameter driving a benchmark model, the benchmark model driving unit components and the goal of the integration, collaboration, intellectualization and digitization can be achieved, and design efficiency and quality can be improved. Using the parametric architectural design method based on design logic, the design can be productized to some extent. Through freely assembling mature module components to finish designing products, the balance between quality and efficiency can be achieved, and the duplication of labor and waste can be reduced.

Owner:GUANGZHOU HUASEN ARCHITECTURAL & ENG DESIGN CONSULTING CO LTD

Negative-pressure microwave combined drying method for preparing mushroom chips from dried mushrooms

The invention discloses a negative-pressure microwave combined drying method for preparing mushroom chips from dried mushrooms, which belongs to the technical field of processing of fruit and vegetable foods. The method mainly comprises the following steps of: foaming the dried mushrooms, fully washing, adding a color fixative for bleaching, cutting (or not cutting), adding a steeping liquor for steeping, draining sugar and scattering; performing negative-pressure spray drying on the pretreated mushrooms for 10-15 minutes, and rapidly dehydrating a high-moisture material in the uniform dryingstate till the moisture content is 20-30 percent; taking semi-finished mushrooms out, and putting the semi-finished mushrooms into a vacuum microwave drying box to be dried for 15-20 minutes till thefinal moisture content is below 6 percent; and charging nitrogen and packing to obtain a crisp mushroom product. The method has the advantages of high moisture evaporating speed, short drying time, uniform drying, product crispness, and capability of well keeping the original luster, appearance and nutrients of the mushrooms.

Owner:建德市农家宝食品有限公司 +1

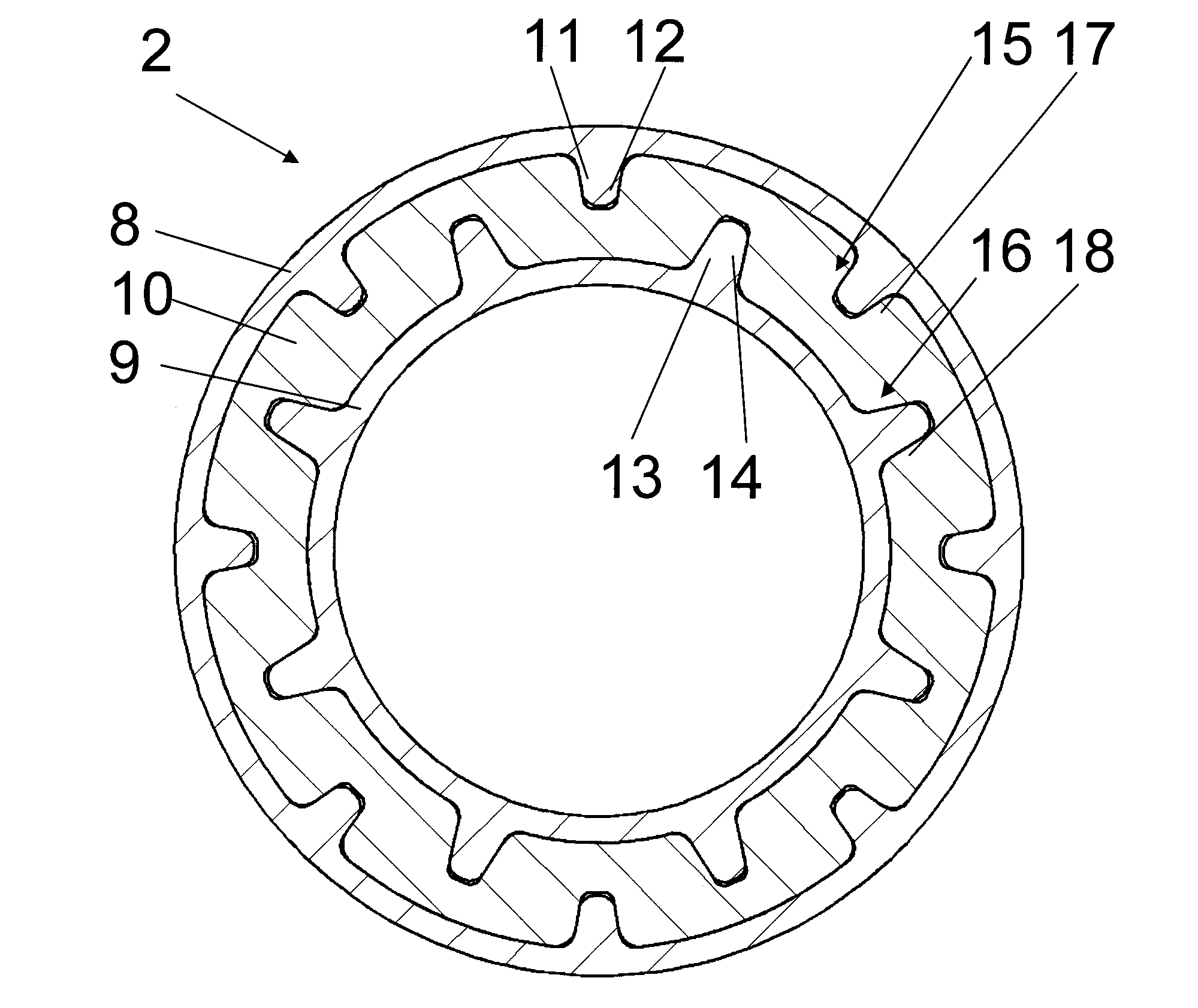

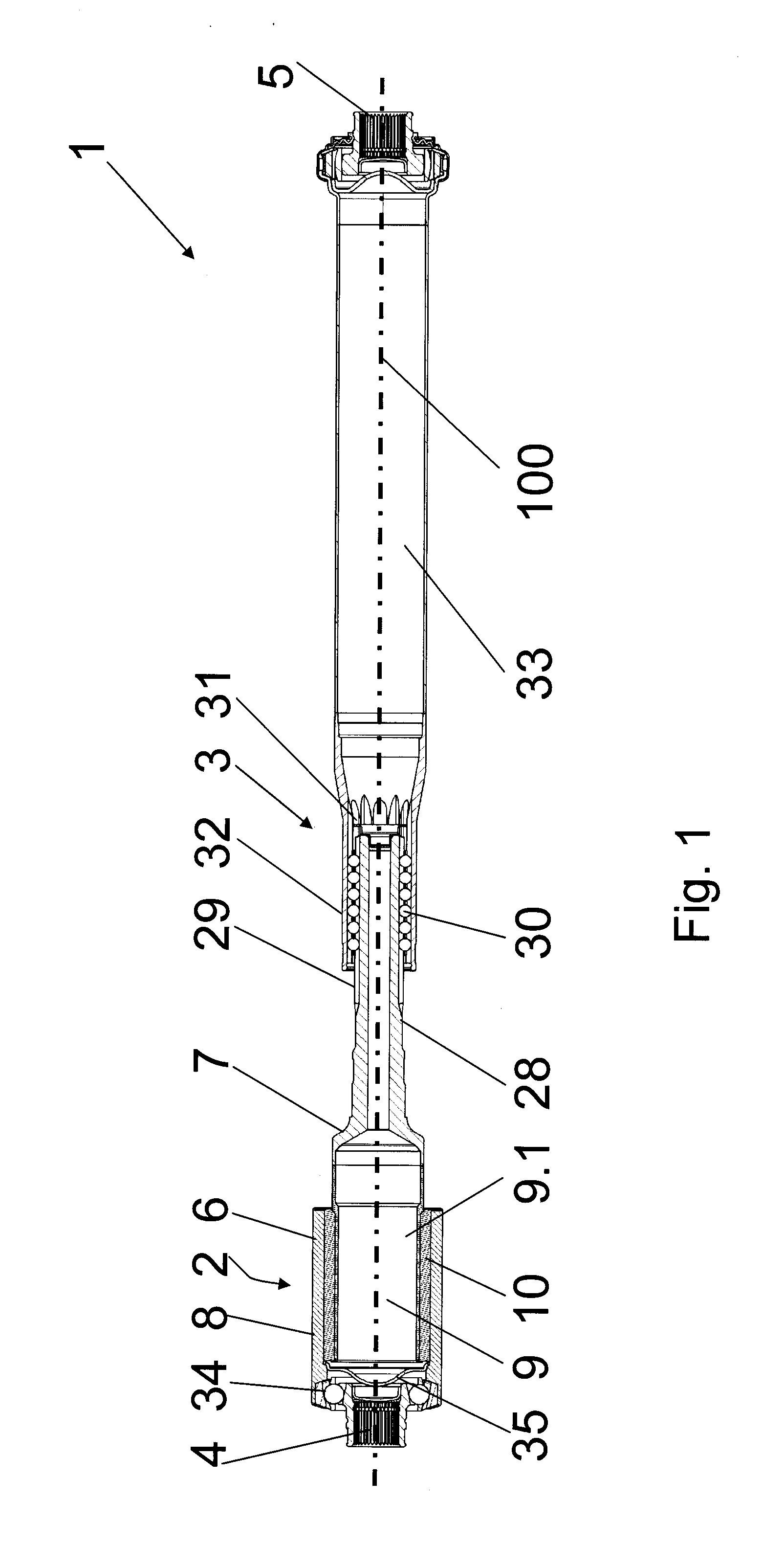

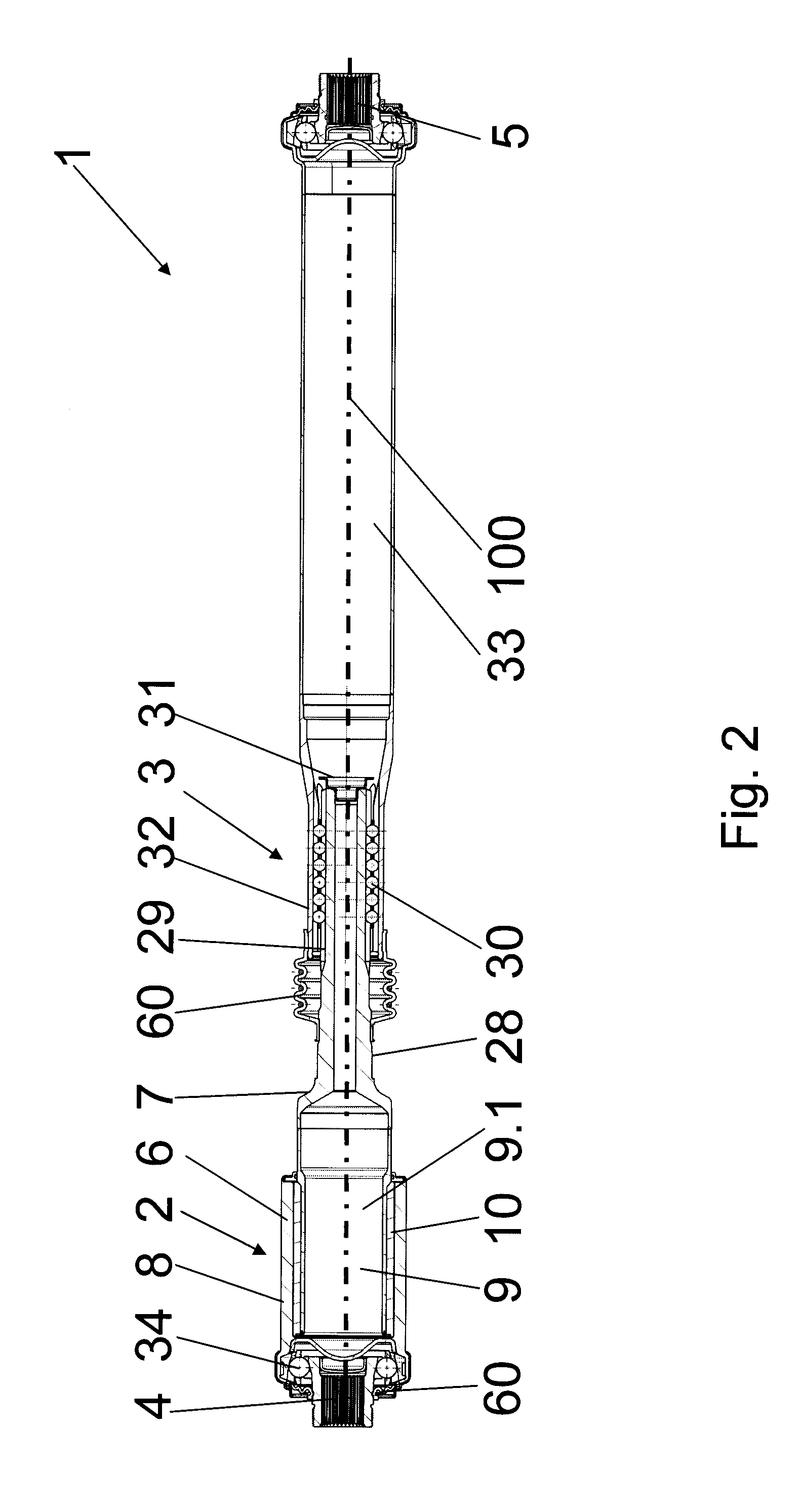

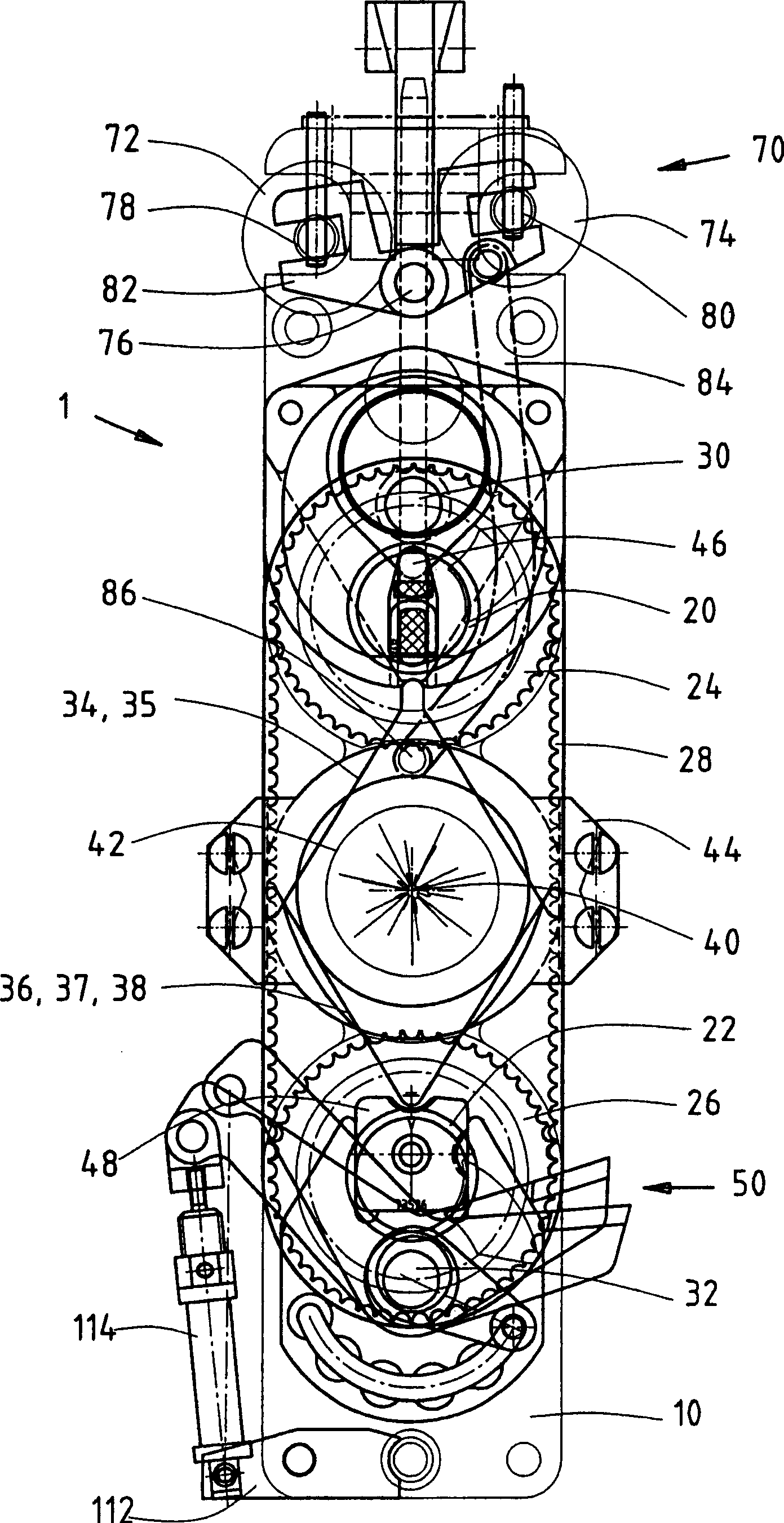

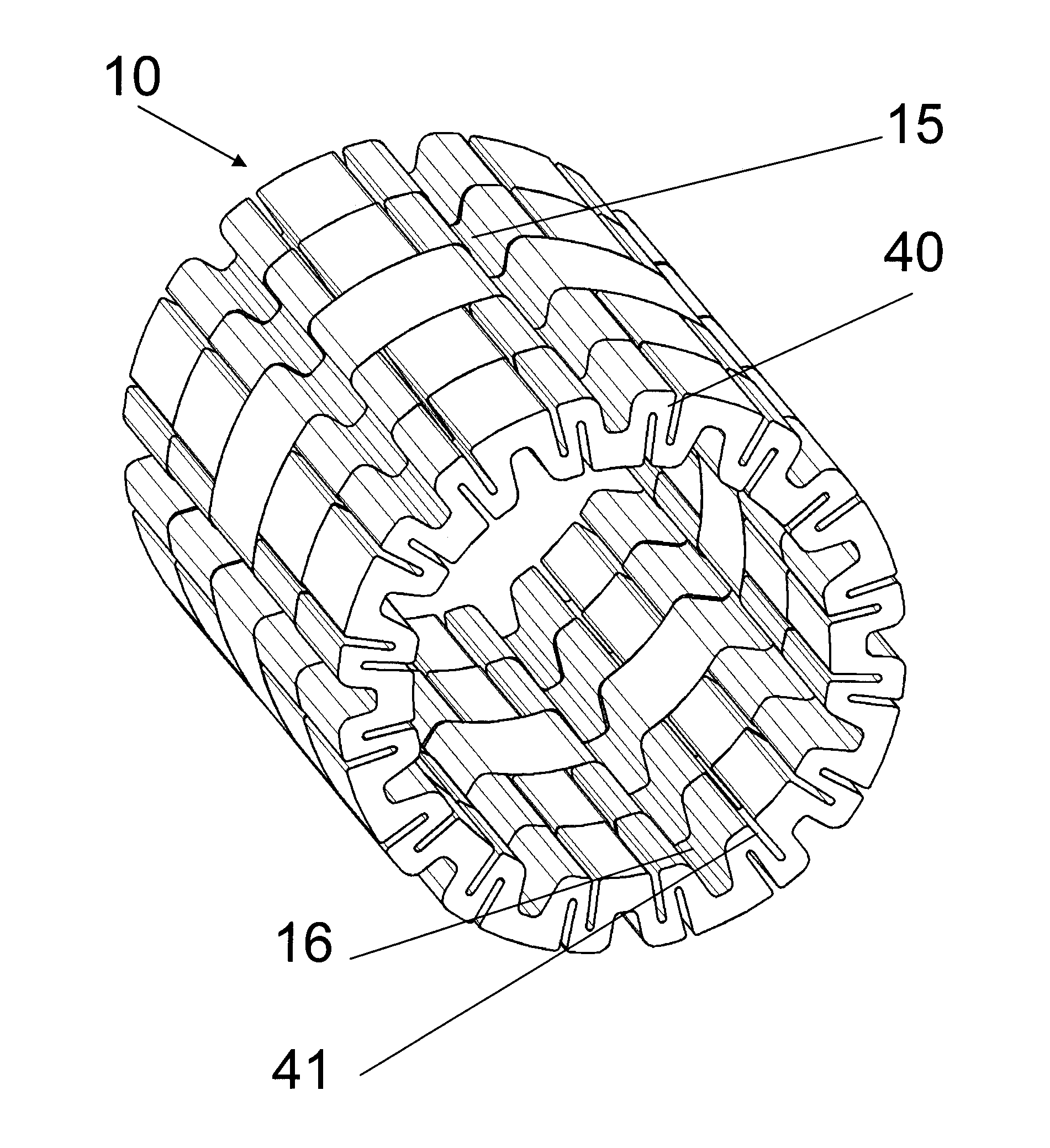

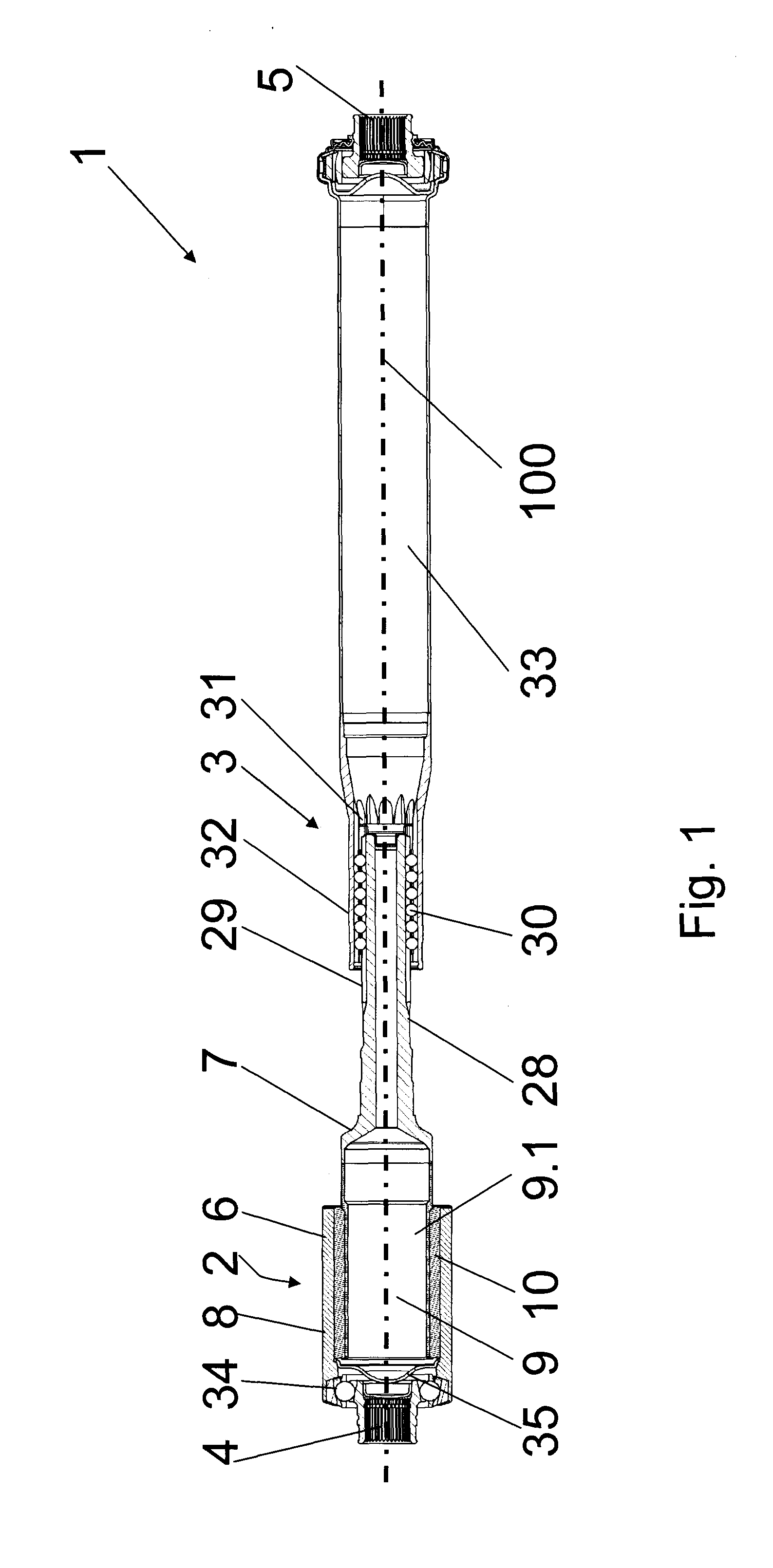

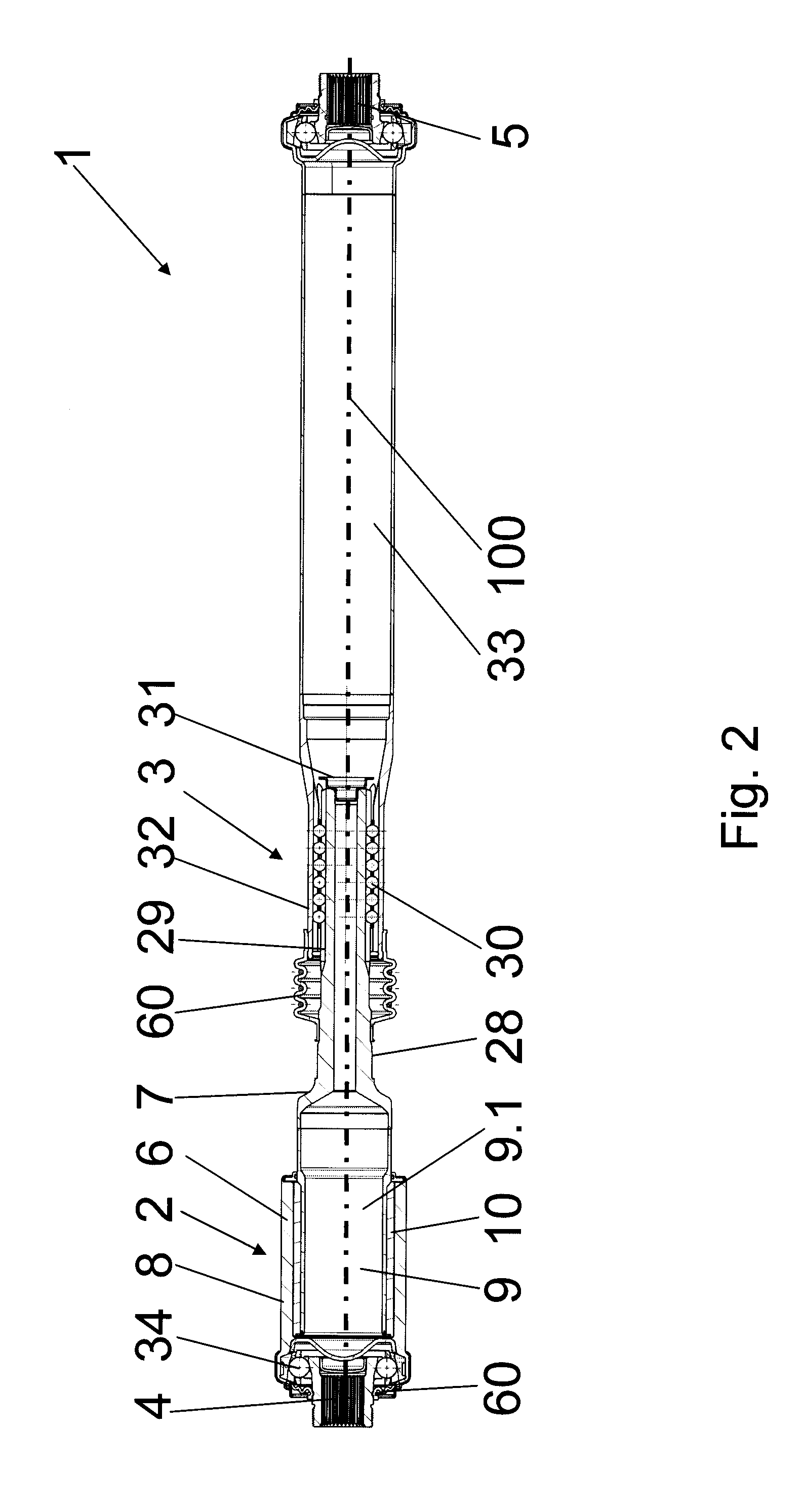

Vibration Damper for a Drive Train

ActiveUS20120004043A1Good synchronous operationImprove bindingYielding couplingVibration suppression adjustmentsDrive shaftControl theory

A vibration damper (2) that is effective in the direction of rotation of a drive shaft and has a small radial extension. For this purpose, a first shaft part (6) is provided as a sleeve (8) and a second shaft part (7) is provided as an inner part extending axially into the sleeve (8). The two shaft parts (6, 7) engage via rotary drivers in complementary negative profiles (15, 16) of an interposed elastic damper part (10) in the direction of rotation. In addition to the negative profiles, the damper part may be provided with recesses (40) which modify its damping characteristics.

Owner:NEUMAYER TEKFOR ENG GMBH

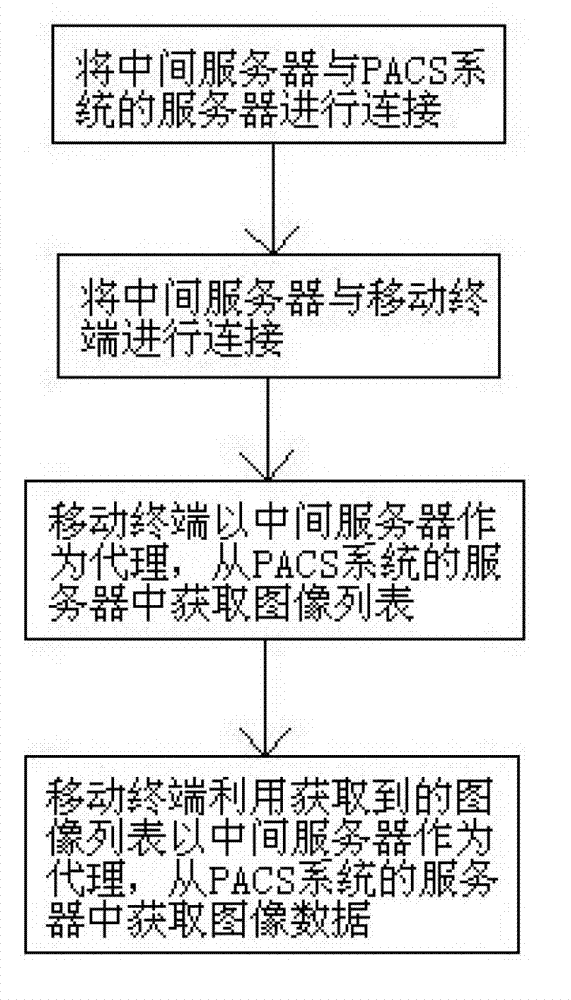

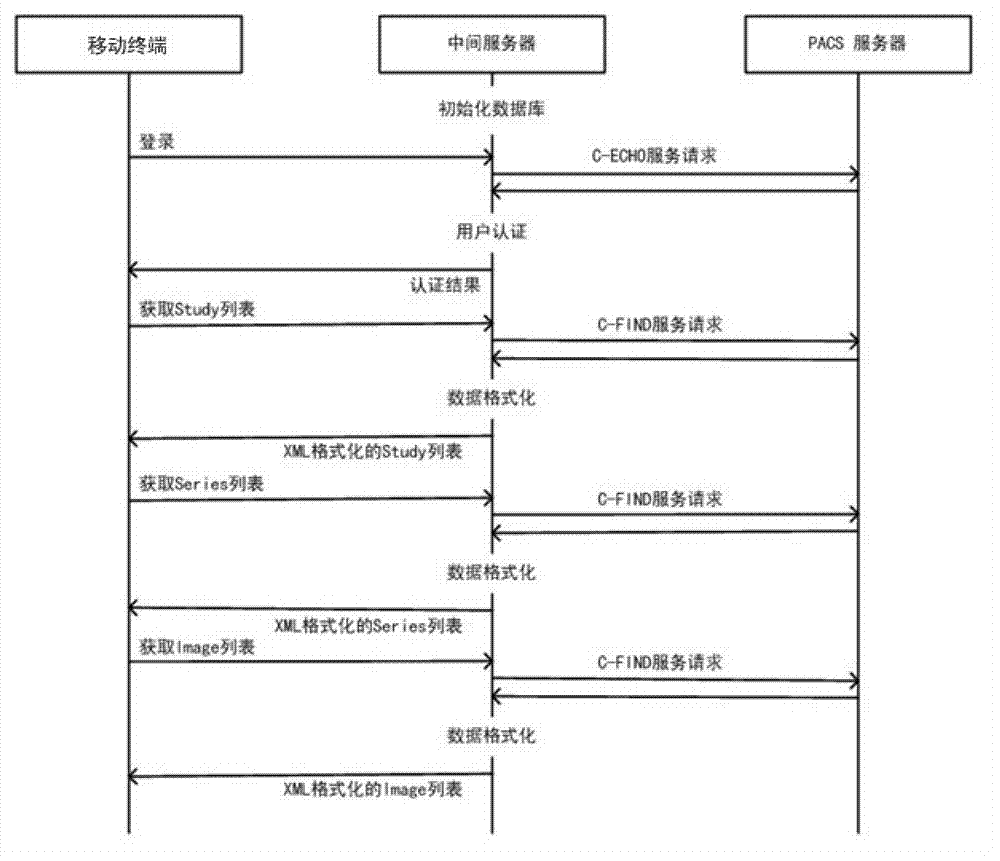

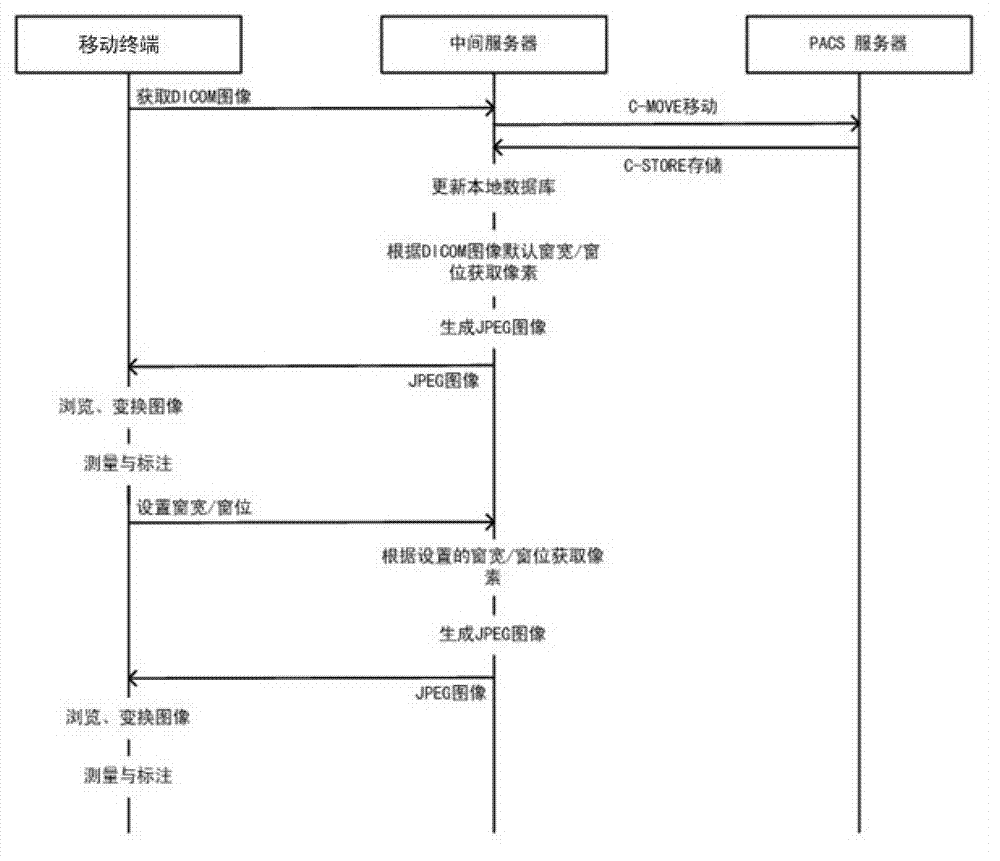

Method for processing and displaying image data in PACS system by mobile terminal

ActiveCN102857791AChange resolution in real timeShorten diagnostic timeSelective content distributionSpecial data processing applicationsImaging processingComputer terminal

The invention relates to the technical fields of medical image processing, three-dimensional visualization and communication, and discloses a method for processing and displaying image data in a PACS (Picture Archiving and Communication System) by a mobile terminal. The method comprises the following steps: taking an intermediate server as a proxy of the mobile terminal and acquiring an image list from a server of the PACS system; and acquiring the image data from the server of the PACS system by using the acquired image list and using the intermediate server as the proxy through the mobile terminal. According to the method disclosed by the invention, original image data in the PACS system are processed and displayed by the mobile terminal, and thus the effect of the image data in the PACS system can be browsed anytime and anywhere.

Owner:武汉善观科技有限公司

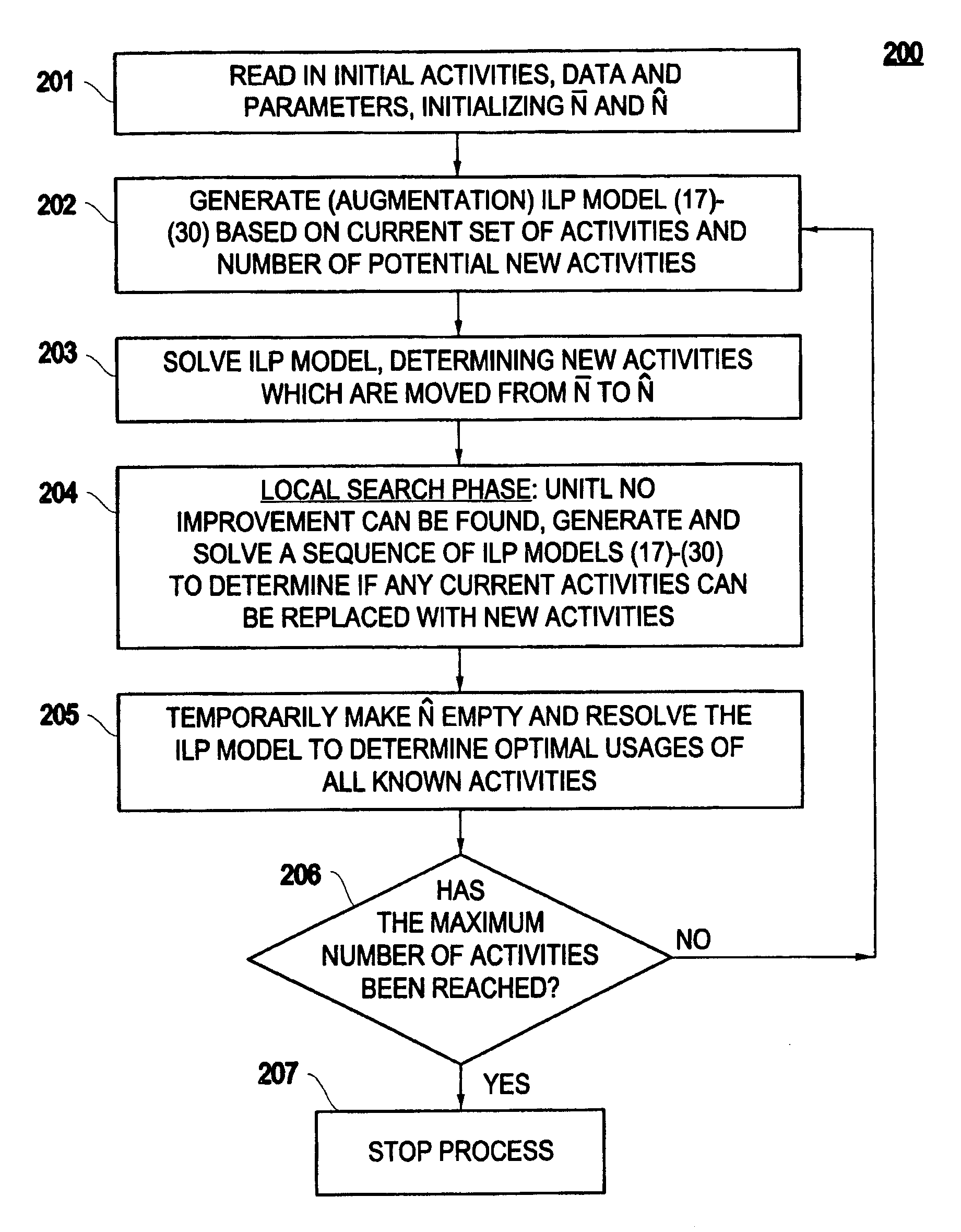

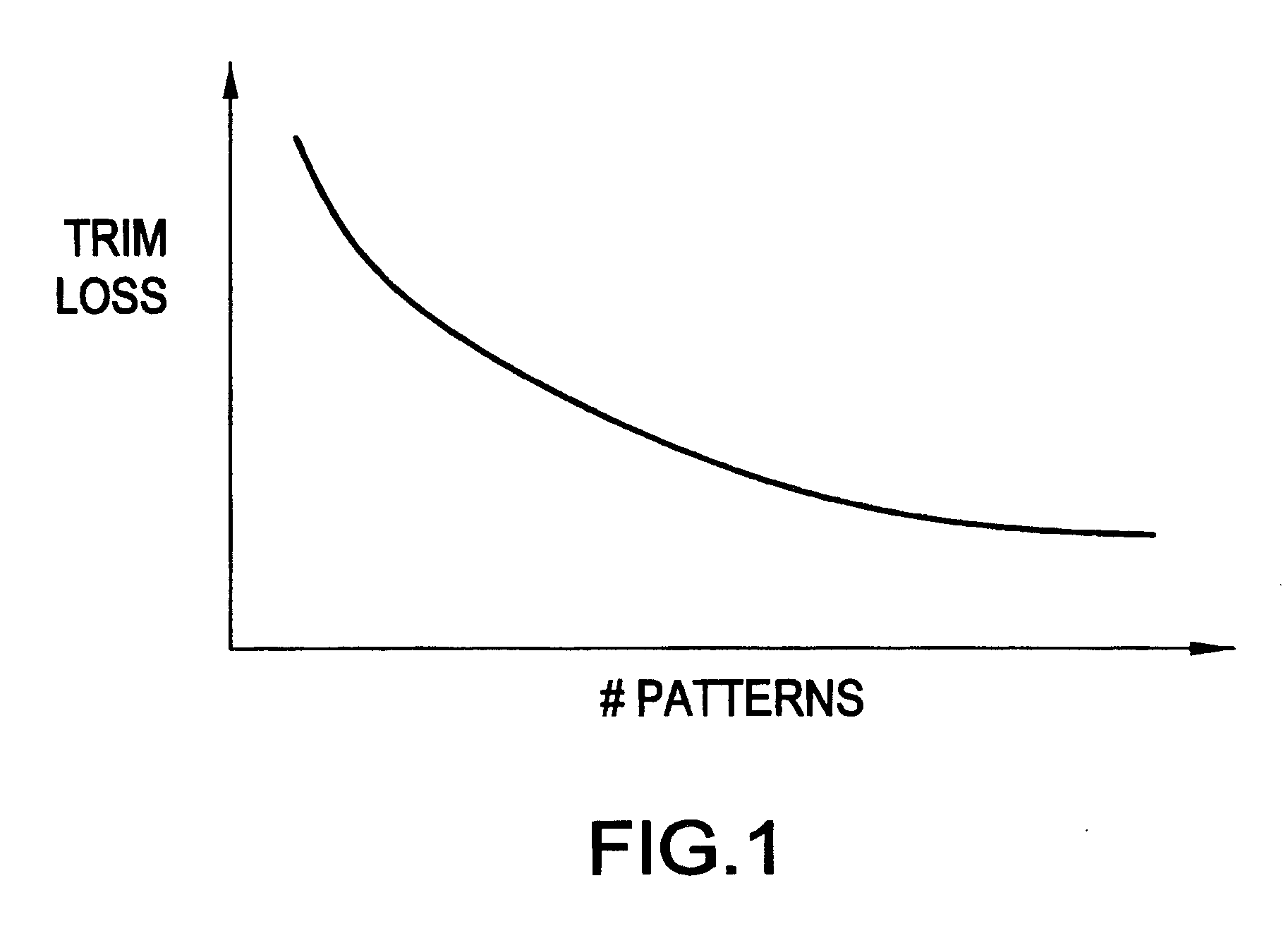

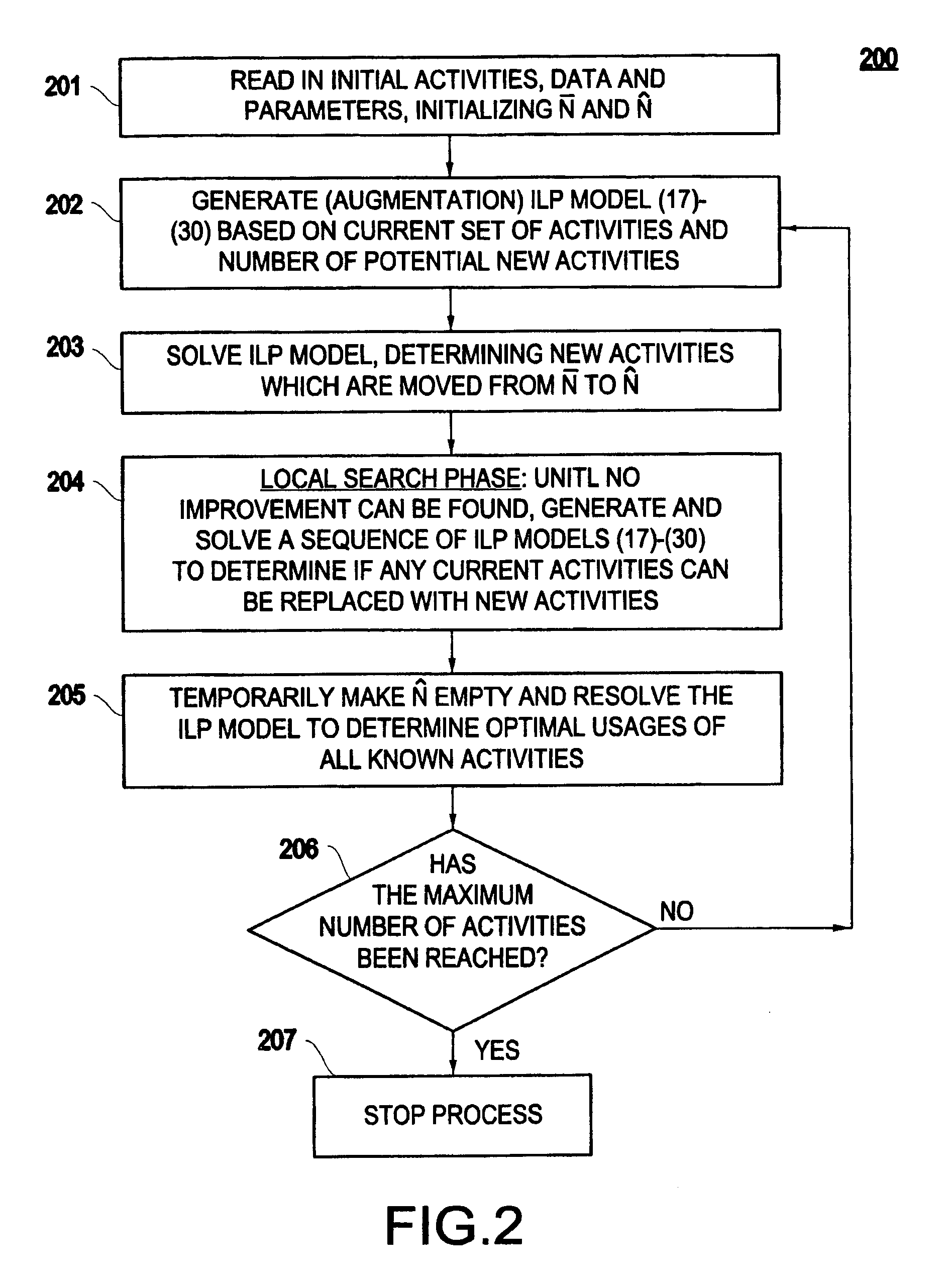

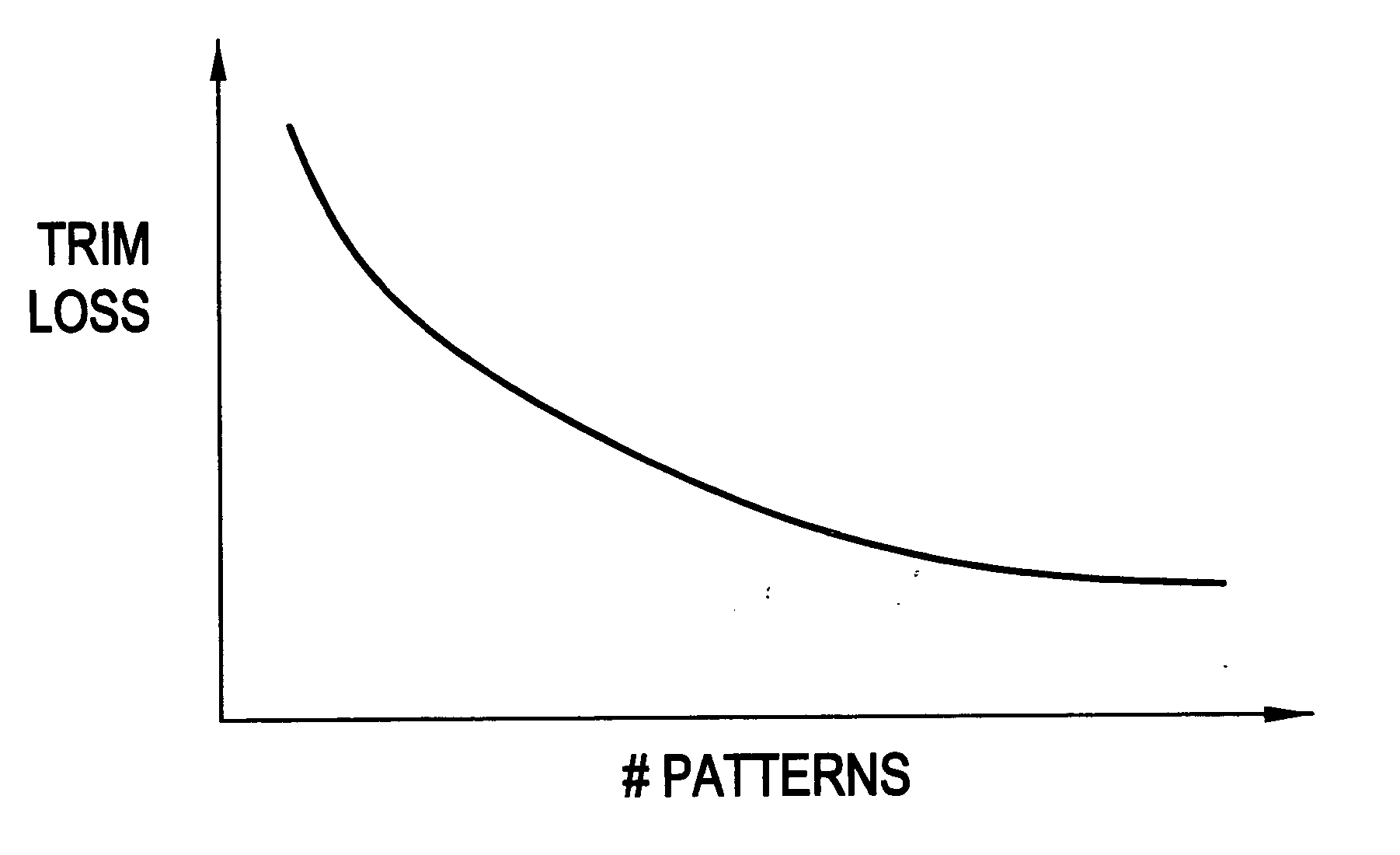

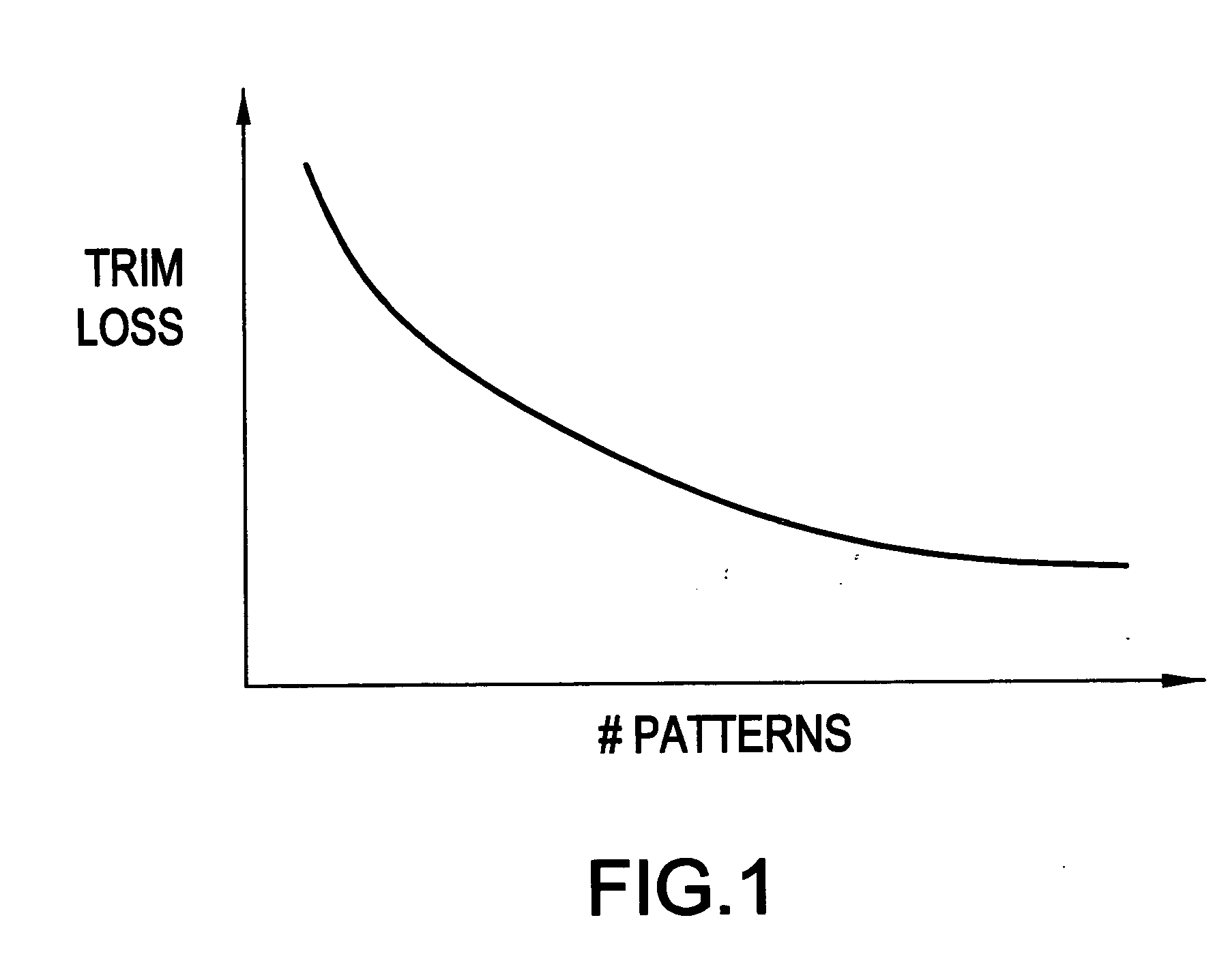

Method and apparatus for generating profile of solutions trading off number of activities utilized and objective value for bilinear integer optimization models

InactiveUS20080189089A1Low costTighten formulationForecastingComputation using non-denominational number representationTrade offsComputer science

A method (and system) of generating at least one of a solution and a profile of solutions for a problem, includes trading off a reduction of an objective of the problem against a number of activities utilized in a solution.

Owner:GLOBALFOUNDRIES INC

Rendering method and rendering device for webpage browsing and mobile terminal

ActiveCN102831209AMeet user experienceSatisfaction experienceWeb data indexingSpecial data processing applicationsWeb pageComputer graphics (images)

Owner:ALIBABA (CHINA) CO LTD

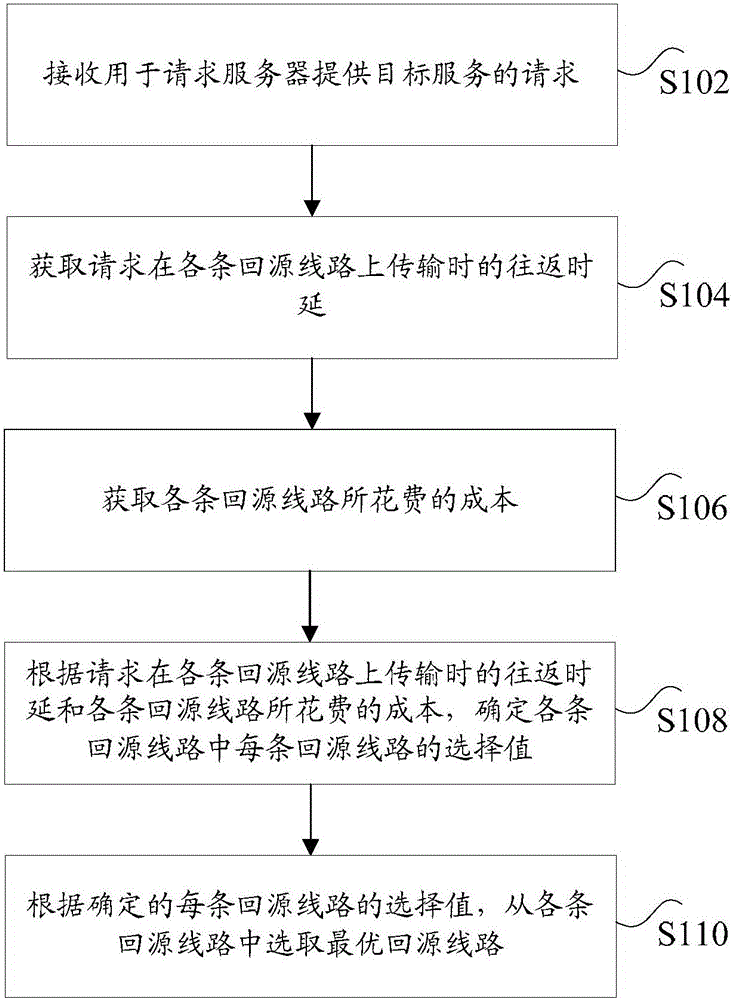

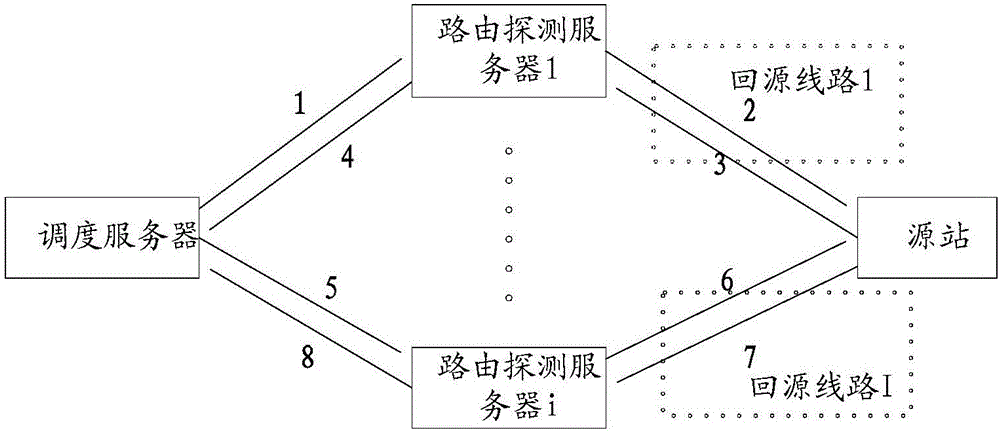

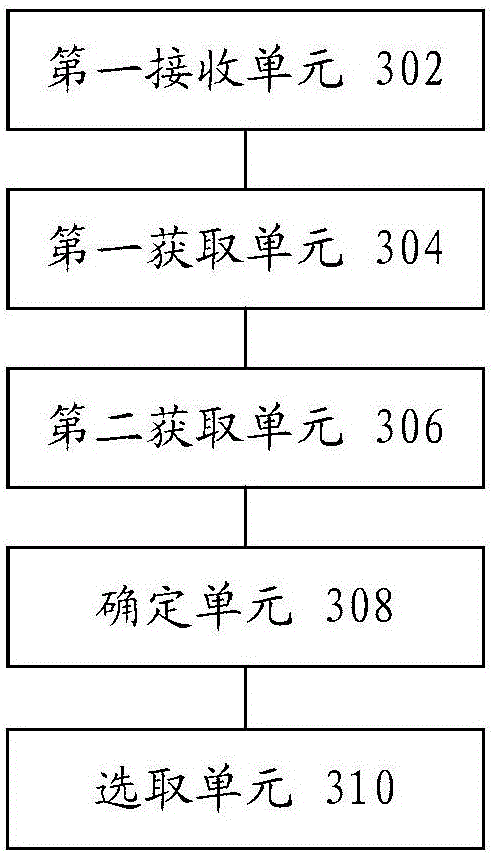

Source return line selection method and device

InactiveCN105812255AMass balanceBalance costData switching networksDistributed computingSelection method

The invention discloses a source return line selection method and device, wherein the method comprises following steps of receiving requests for requesting a server to provide target service; obtaining round-trip time when the requests are transmitted on source return lines; obtaining cost expended by the source return lines; determining the selection value of each source return line in the resource return lines according to the round-trip time obtained when the requests are transmitted on the source return lines and the cost expended by the source return lines; and selecting the optimum source return line form the source return lines according to the determined selection value of each source return line. According to the method and the device, the technical problem that in the prior art, the cost investment of the network operators is increased continuously due to selecting the line with the best quality when most websites execute source return tasks is solved.

Owner:CHINANETCENT TECH

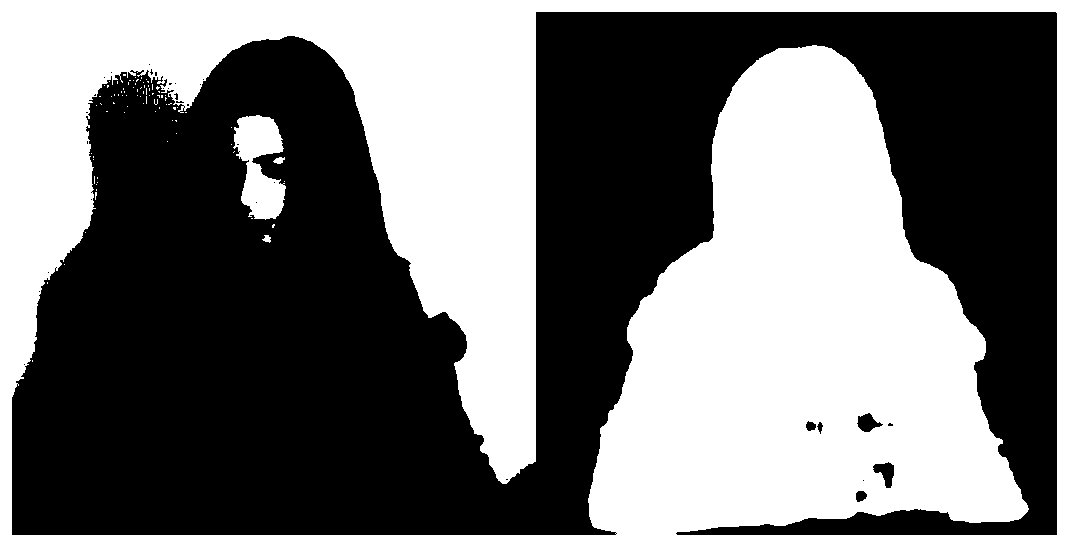

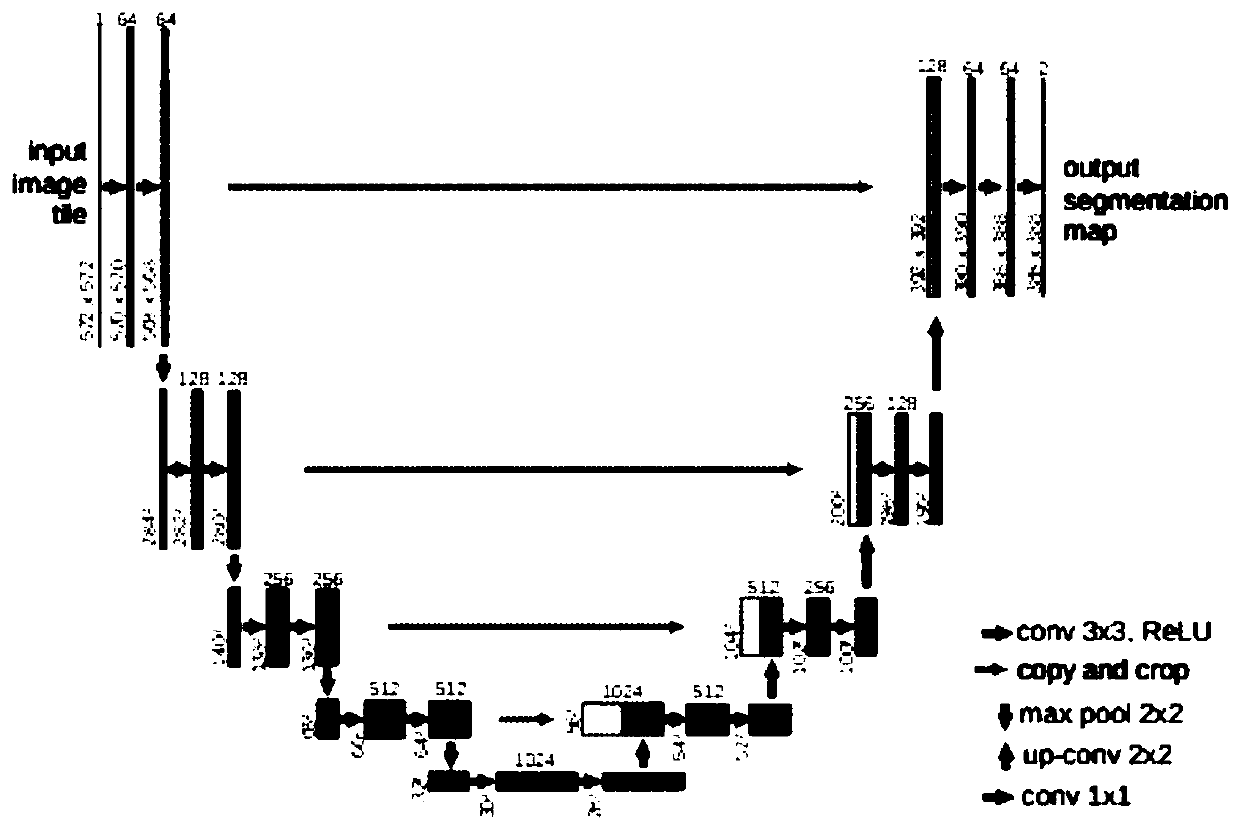

Method for steganography and reading of information in an image

ActiveCN111028308AGood information recovery robustnessImprove image quality2D-image generationCharacter and pattern recognitionNuclear medicineImaging quality

The invention belongs to the technical field of technical vision, and particularly relates to a method for steganography and reading of information in an image. According to the method, information ishidden in a non-salient region and a high-frequency region of an image to improve the human perception quality of a coded image; and meanwhile, the detector and the encoding / decoding system are trained together, so that the decoding system can automatically adapt to the positioning error of the detector to replace manual selection of the analog noise intensity, and finally, the balance between the robustness of the decoding system and the image quality is achieved.

Owner:珠海涵辰科技有限公司

Method and apparatus for generating profile of solutions trading off number of activities utilized and objective value for bilinear integer optimization models

InactiveUS20060197769A1Increasingly difficultOptimally utilizedForecastingCathode-ray tube indicatorsTrade-offComputer science

A method (and system) of generating at least one of a solution and a profile of solutions for a problem, includes trading off a reduction of an objective of the problem against a number of activities utilized in a solution.

Owner:GLOBALFOUNDRIES INC

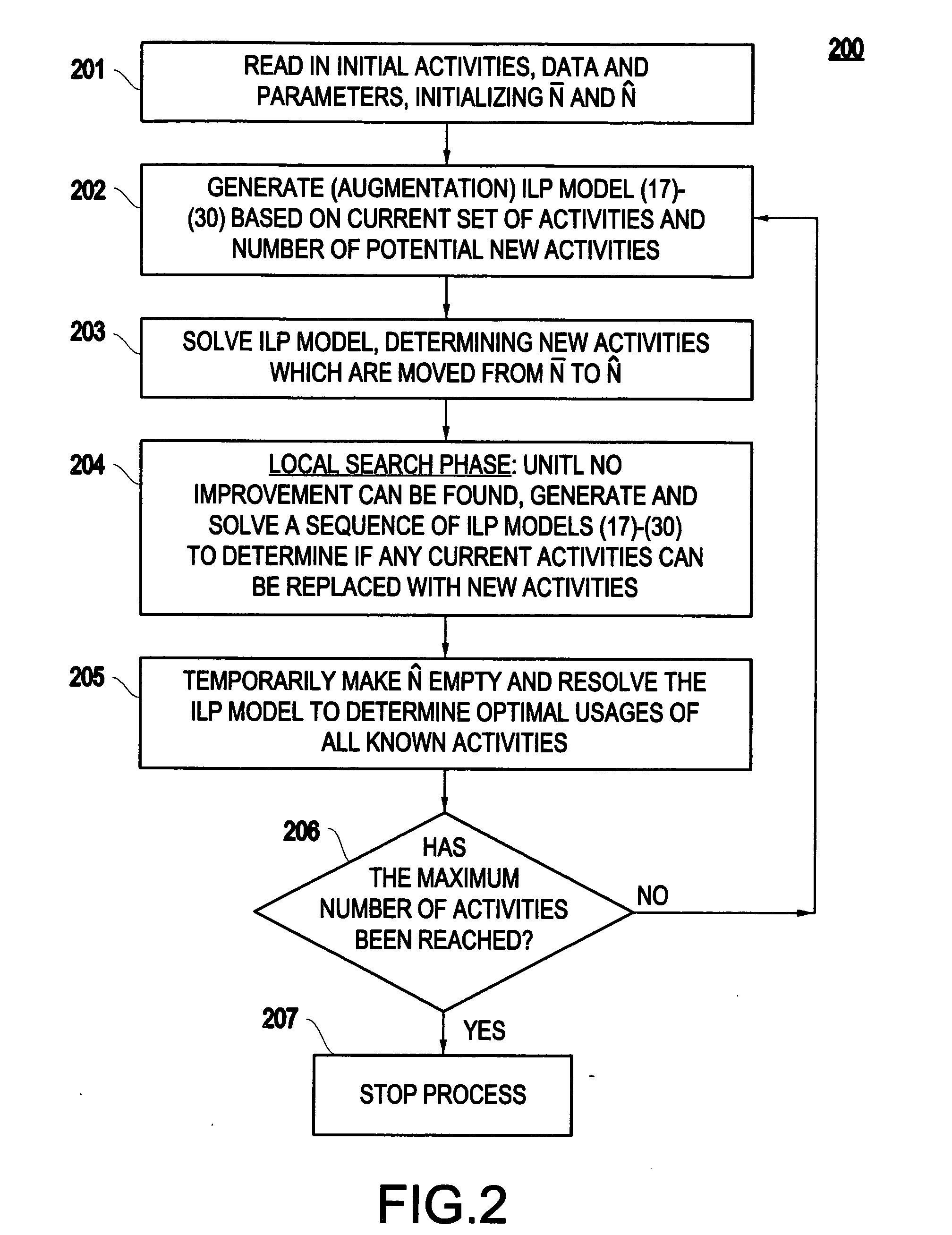

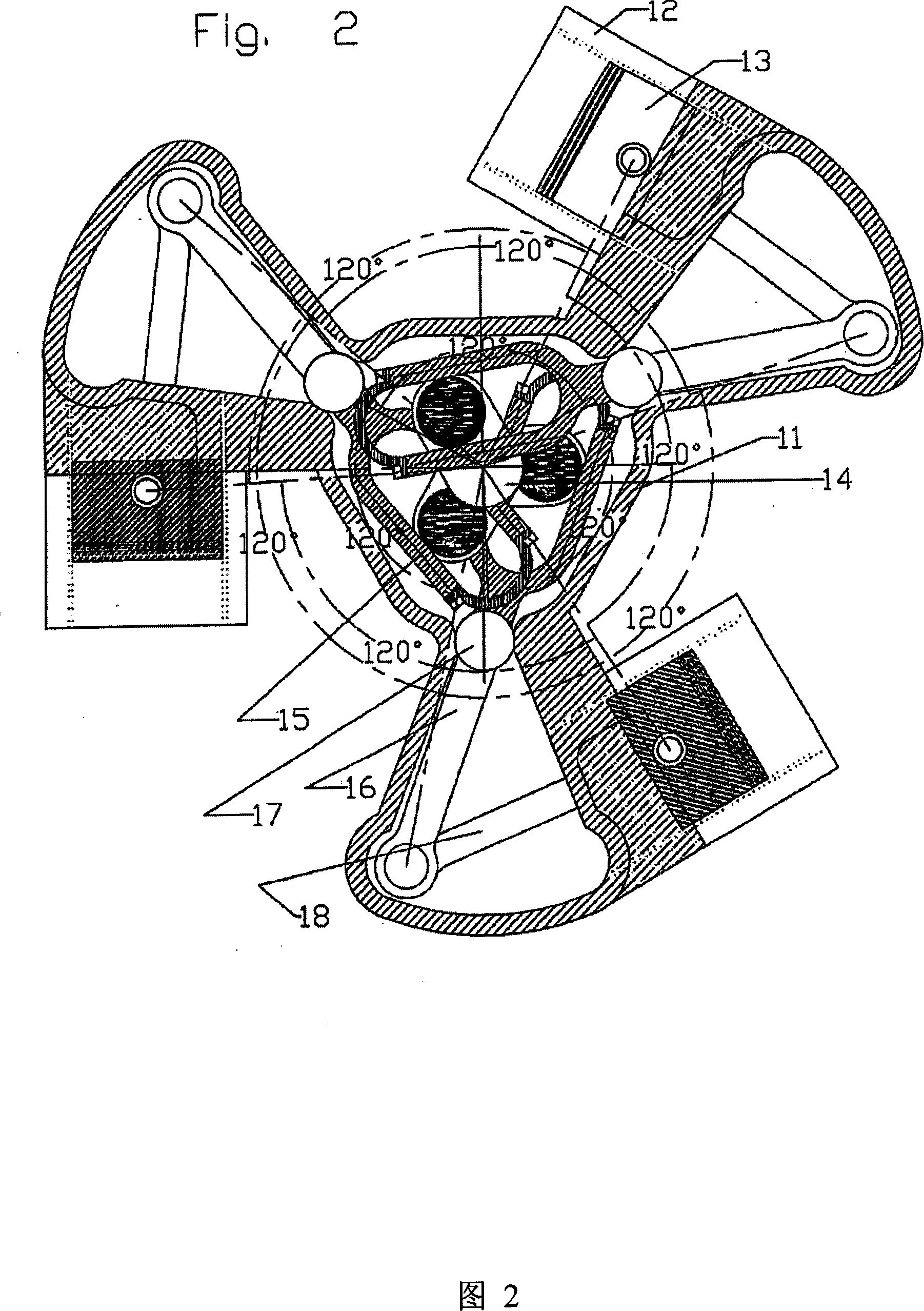

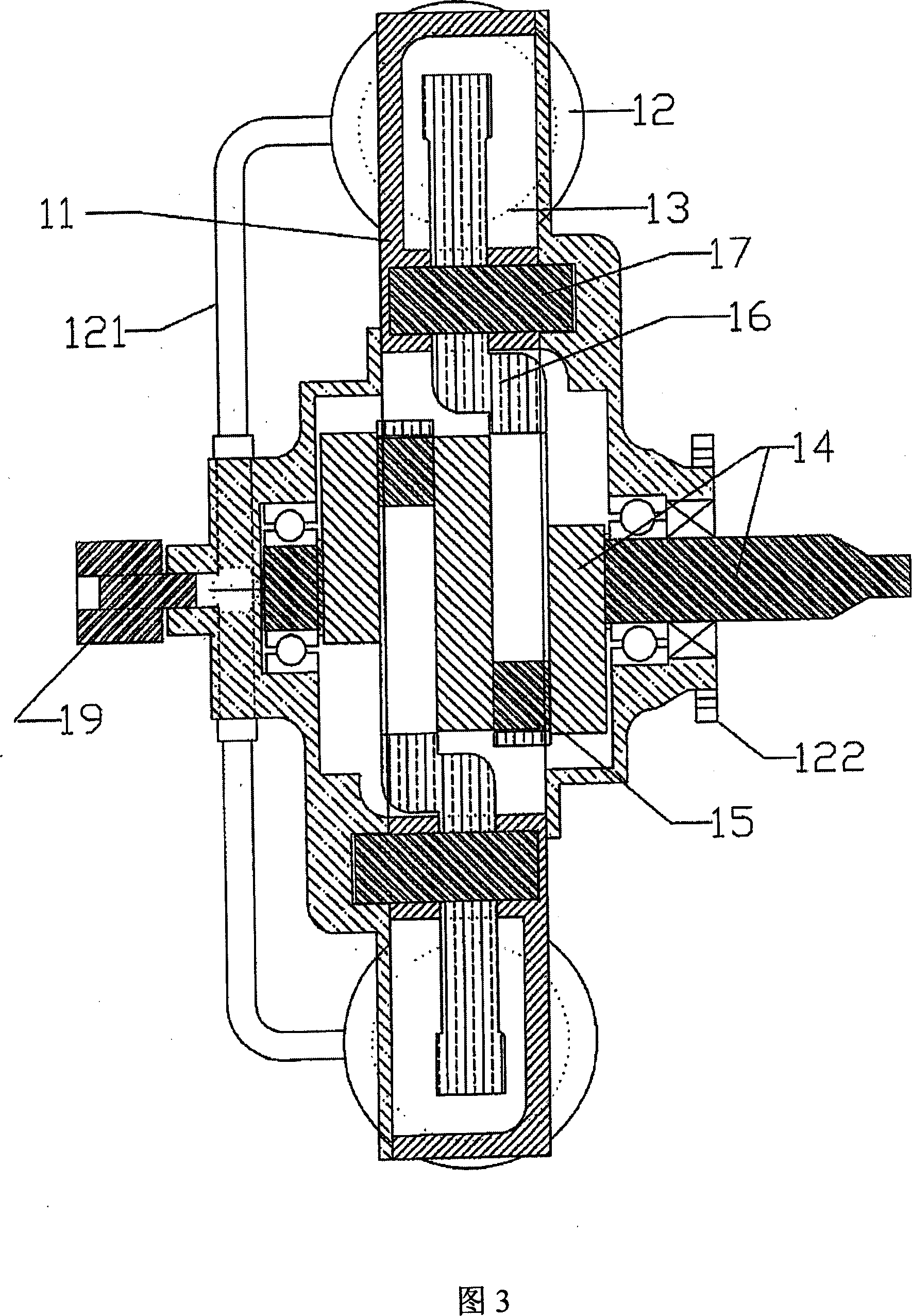

Mechanism for the recovery of energy in self-propelled vehicles

InactiveCN1950230AEvenly distributedDistribution balanceAuxillary drivesPositive displacement pump componentsPistonPneumatic pressure

The invention relates to a mechanism for the recovery of energy in self-propelled vehicles. The inventive mechanism consists of either: (a) a balanced rotary compressor with tangential pistons, comprising two or more cylinders which are connected to a crank having two or more pins; or (b) a rotary compressor with tangential pistons, comprising an extendible crank. The novel system enables the recovery of wasted energy in motor vehicles in the form of pneumatic pressure for the possible use thereof in auxiliary systems belonging to the vehicle or in the engine.

Owner:弗朗西斯科·哈维尔·路易斯·马丁内兹

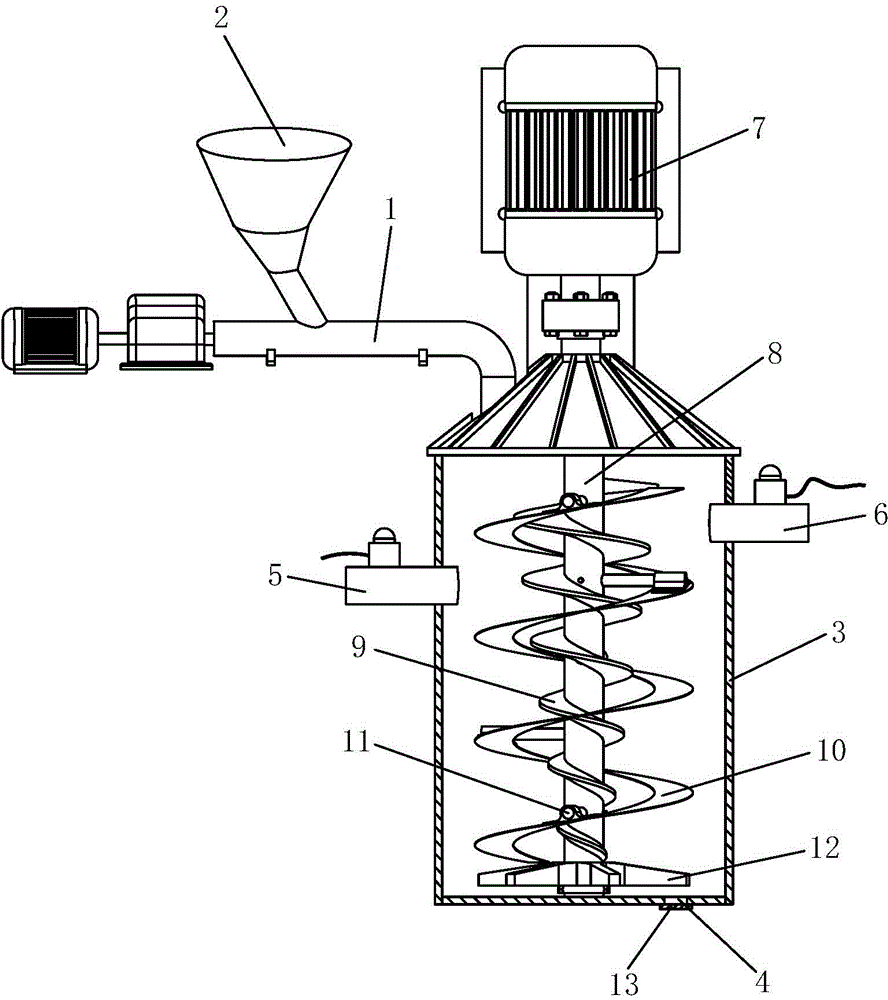

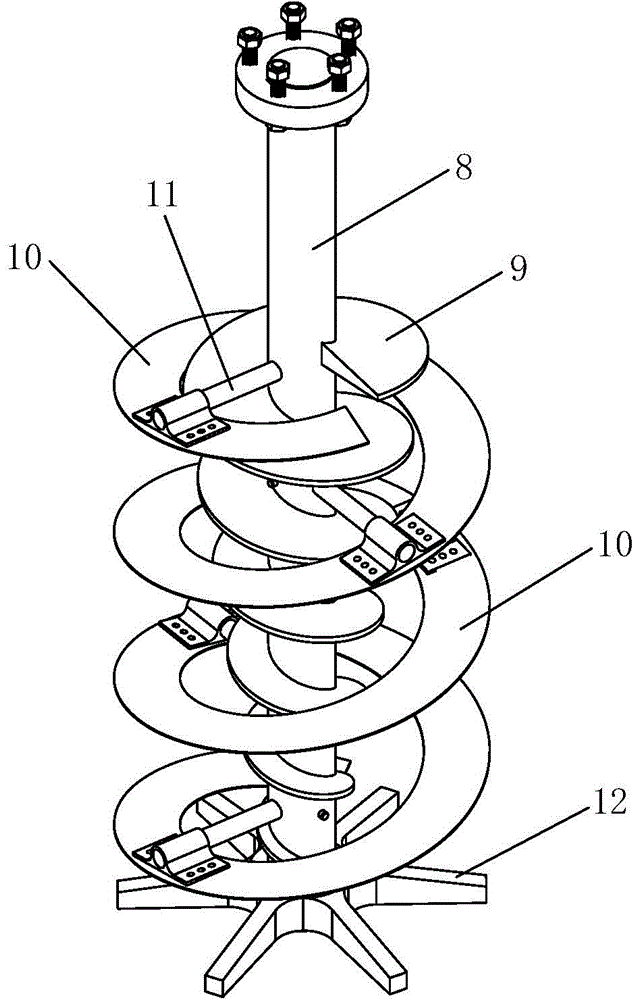

Dry and wet double-purpose stirring ball mill

ActiveCN104984790ASmall granularityRealize three-dimensional circulationGrain treatmentsEngineeringDrive motor

The invention discloses a dry and wet double-purpose stirring ball mill. The dry and wet double-purpose stirring ball mill comprises a stirring ball mill device and a dry material feeding device, wherein the stirring ball mill device comprises a stirring barrel and a stirring ball mill mechanism; a dry material feeding opening is arranged on the a stirring barrel over, and a dry material discharging opening is formed in the bottom of the stirring barrel; a slurry flowing-in pipe and a slurry flowing-out pipe are arranged on the side wall of the stirring barrel; the stirring ball mill mechanism comprises a driving motor, a stirring shaft, a first helical belt and a second helical belt; the first helical belt is wound on the stirring shaft and is fixed to the stirring shaft into a whole, and the first helical belt is sleeved with the second helical belt; the second helical belt is connected with the stirring shaft through a connecting stick, the first helical belt is a left helical belt, and the second helical belt is a right helical belt; the lower end of the stirring shaft penetrates into the barrel over, and a scraper blade is fixed to the stirring shaft; and the first helical belt and the second helical belt are both located in the stirring barrel. The shearing, friction and grinding efficiency needed by the materials is strengthened, the aim of homogenizing crushing of the materials is achieved, the crushing efficiency is high, and dry and wet materials can be crushed.

Owner:XIAN UNIV OF SCI & TECH

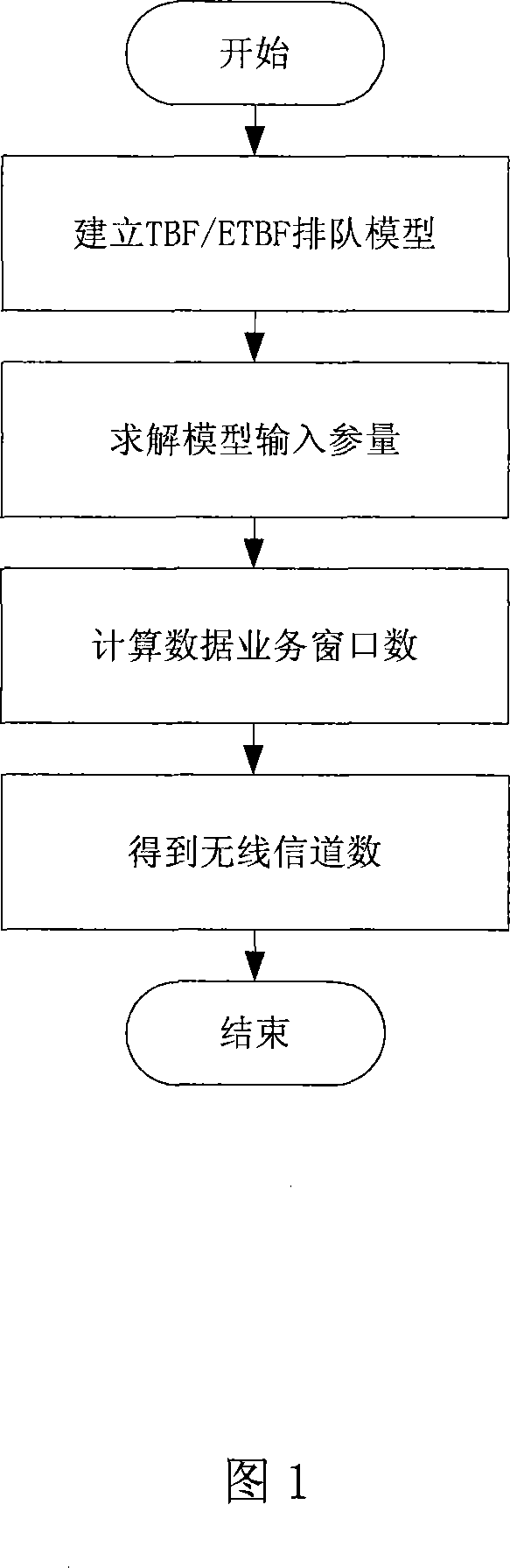

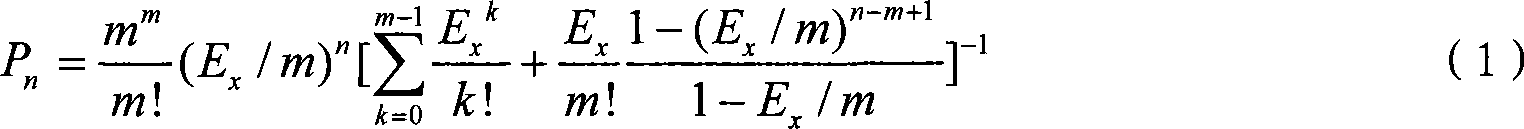

Distribution method of data traffic wireless channel in GPRS/EDGE network

InactiveCN101247556AMeet the minimum requirementsMass balanceRadio/inductive link selection arrangementsRadio transmission for post communicationTraffic capacityQuality of service

The invention discloses a distribution method of data business wireless channel in a GPRS / EDGE network. The invention is aimed at making the number of reasonable data business wireless channel satisfy the lowest request of user for quality of service. The method comprises following steps: establishing a TBF / ETBF timelag rejecting queuing model in the GPRS / EDGE network; solving importing parameter of the TBF / ETBF timelag rejecting queuing model in the GPRS / EDGE network; making use of the TBF / ETBF timelag rejecting queuing model to calculate the number of grouping domain data business windows in the actual EDGE / GPRS network according to a data business flow of user in the network and a data business service quality target; and converting the number of data business windows to the number of the wireless channels in the GPRS / EDGE network. The TBF / ETBF in the GPRS / EDGE network is considered as a fundamental unit of carrying data in the network. Because the TBF / ETBF is fundamental data of a data link layer of data communication, calculation accuracy is greatly improved.

Owner:吉林吉大通信设计院股份有限公司

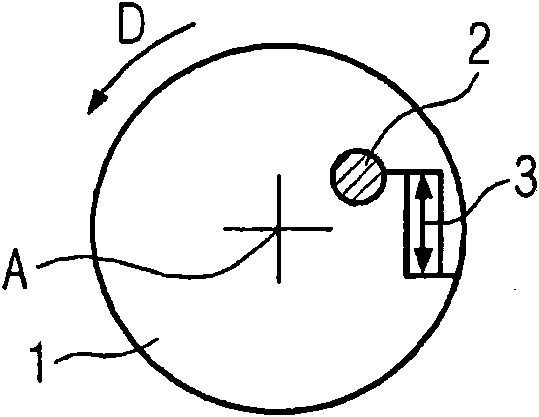

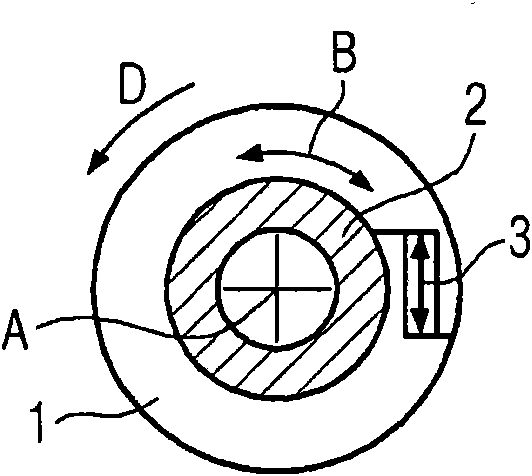

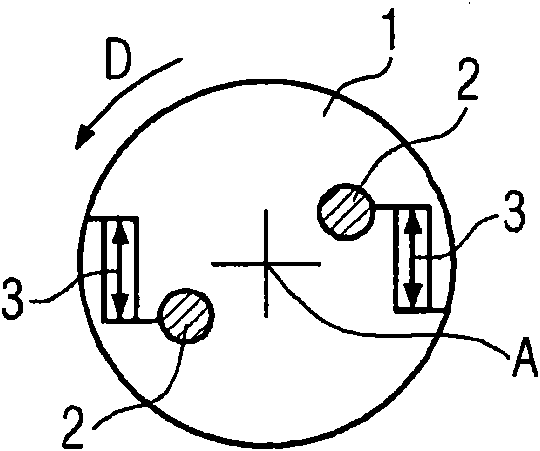

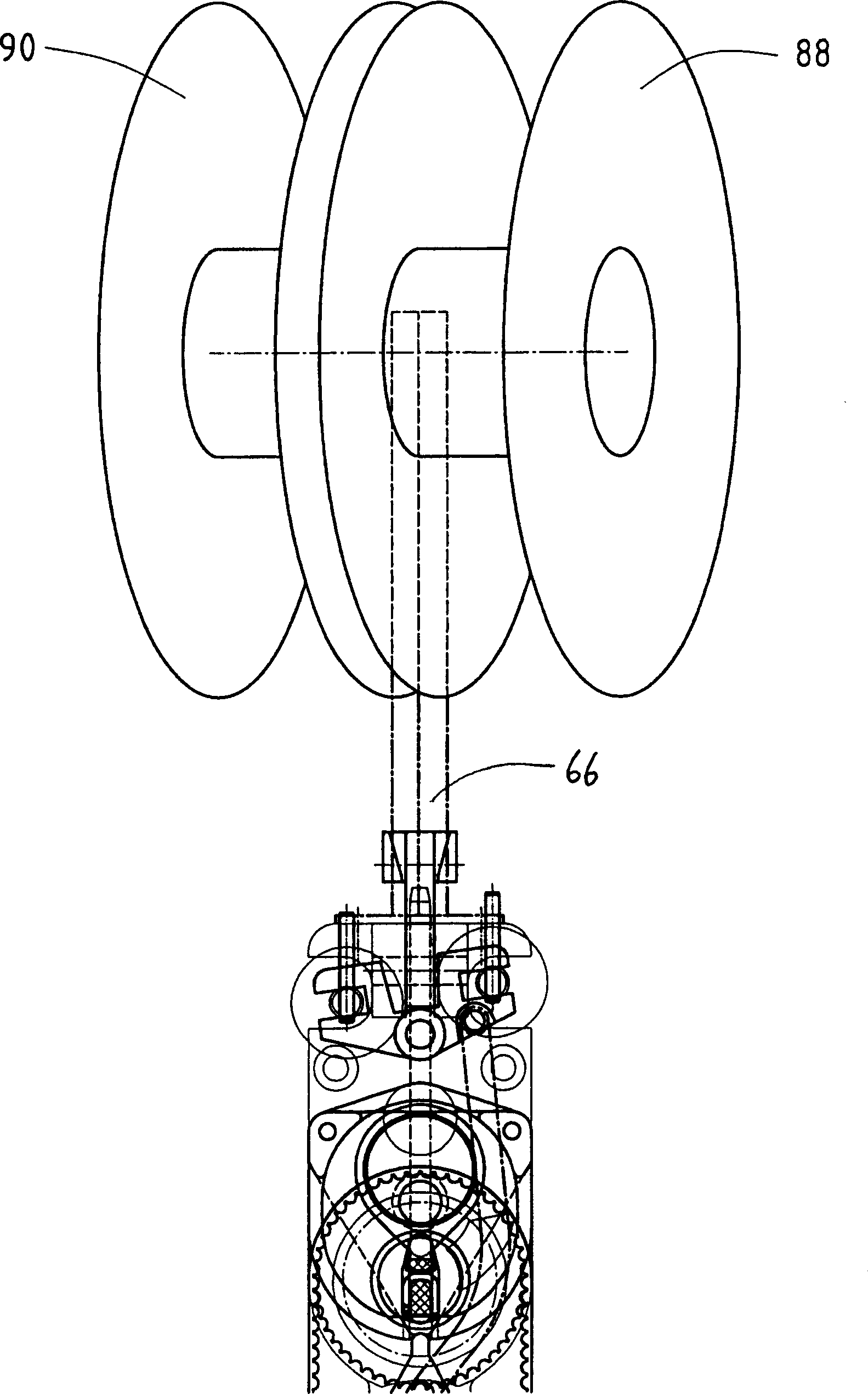

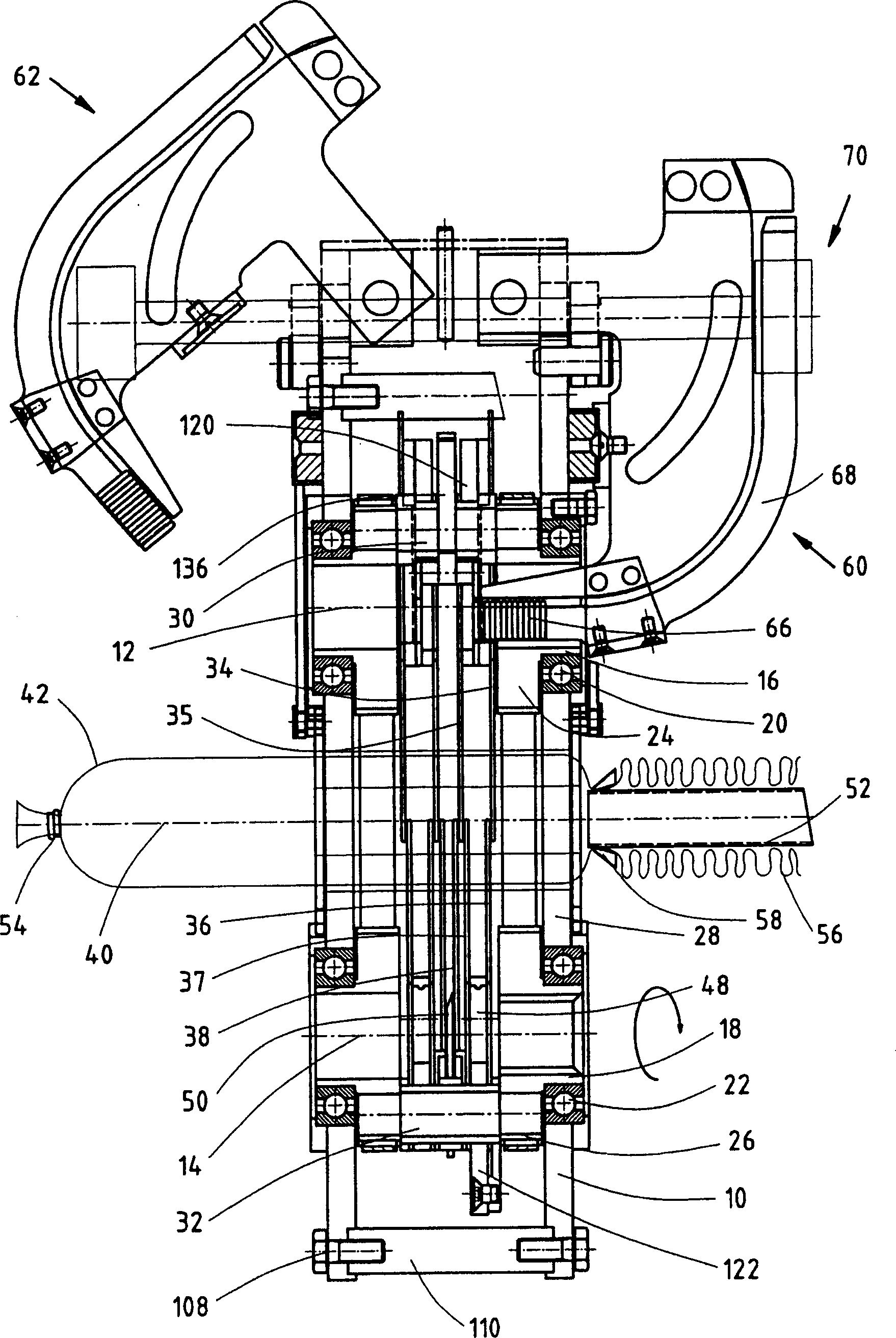

Traction mechanism drive with a compensating device for vibration reduction

InactiveCN101568745AReduce construction costsReduce manufacturing costRotating vibration suppressionValve arrangementsDrive wheelDrive shaft

The present invention relates to a traction mechanism drive with a compensating device for vibration reduction of a driven shaft (4), for example a camshaft, a water pump shaft or an injection pump shaft of an internal combustion engine, having a drive wheel (9) which is coupled to the shaft, having a drive mechanism, and having at least one compensating mass (2) which is relatively movable in the traction mechanism drive and having at least one actuating mechanism (3) for moving the compensating mass. Here, the compensating mass is movable in or counter to the rotational direction of the shaft, and the actuating mechanism is embodied as a tangentially acting actuator for moving the compensating mass. The invention also relates to a method for vibration reduction in a traction mechanism drive, having a driven shaft, having a drive wheel and having a drive mechanism, wherein at least one actuating mechanism moves at least one compensating mass which is relatively movable in the traction mechanism drive, having the steps: activating the actuating mechanism, moving the compensating mass and generating a compensating torque at the driven shaft. In the case of a control drive with a camshaft adjusting system for the angular adjustment of the control time, the camshaft which is movable relative to the traction mechanism drive can simultaneously be used as a compensating mass for vibration reduction.

Owner:IWIS MOTORSYSTEME GMBH & CO KG

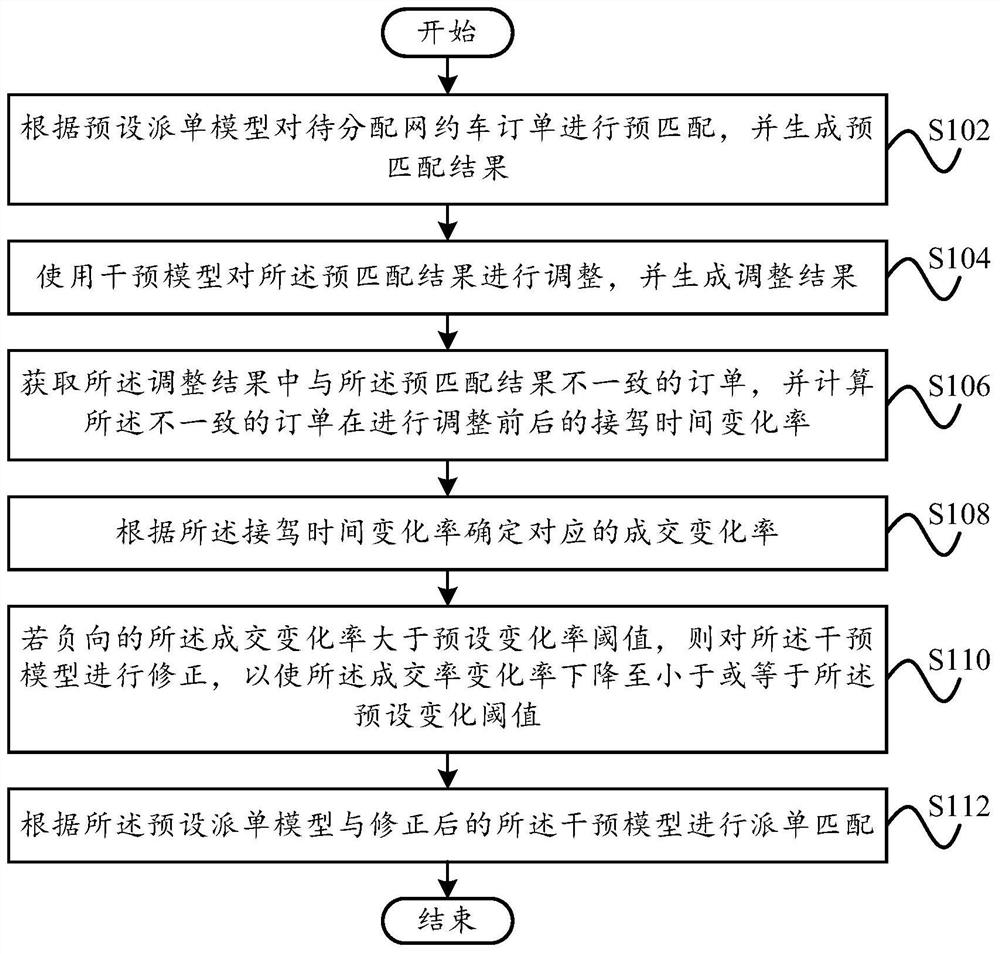

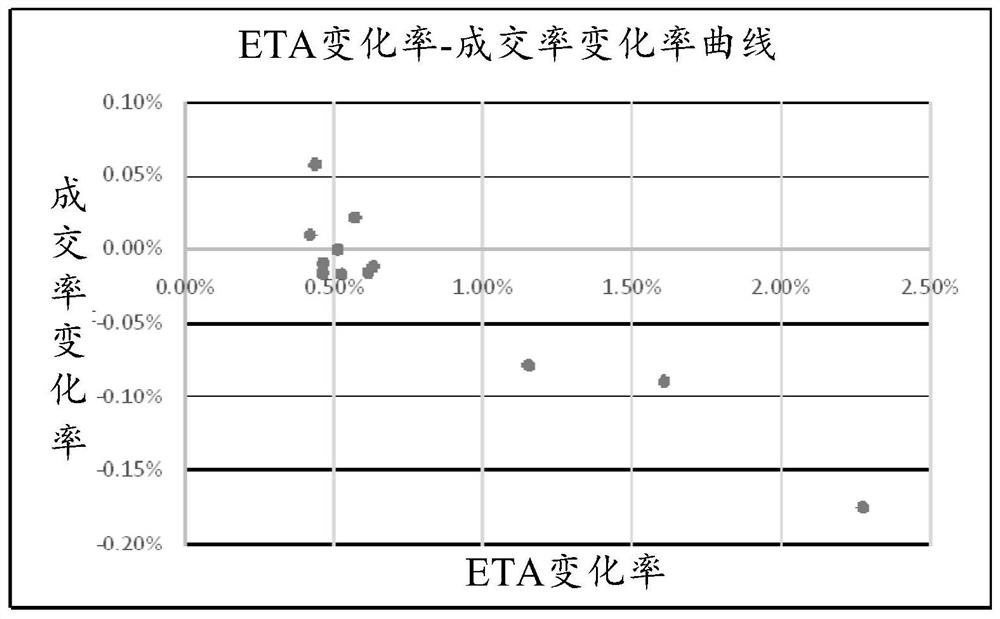

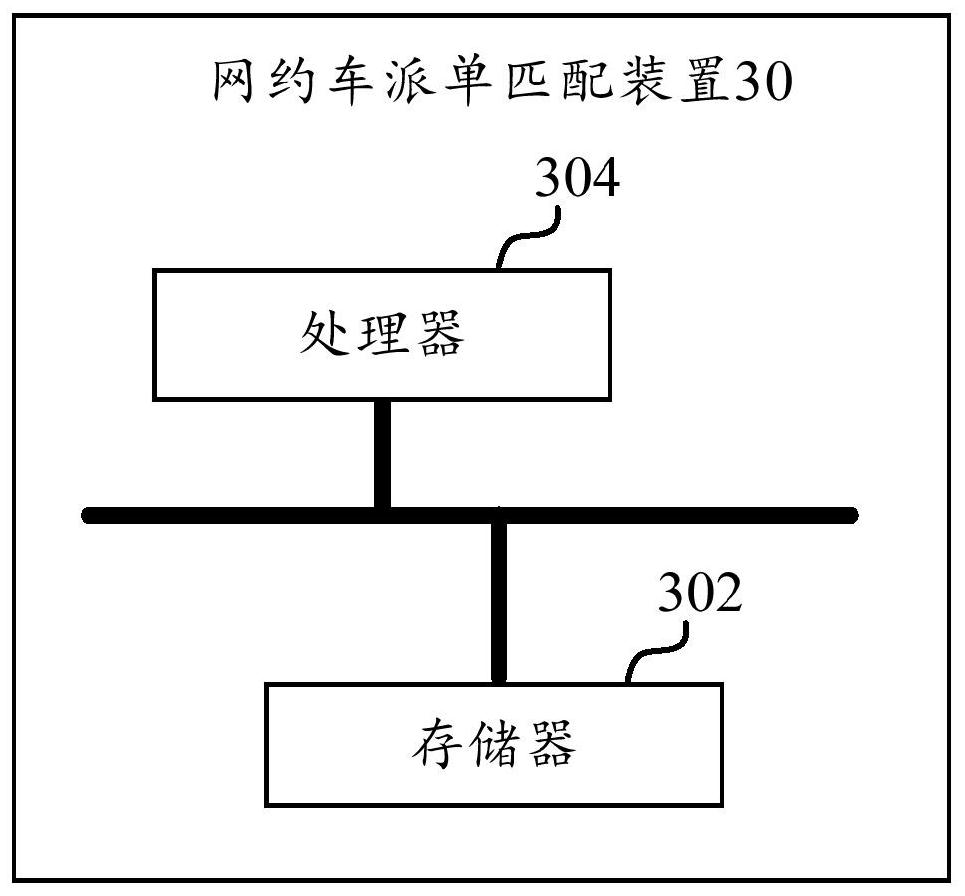

Order dispatching matching method, order dispatching matching device, server and storage medium

PendingCN111784088AImprove user experienceDoes not affect order efficiencyBuying/selling/leasing transactionsResourcesOperations researchIndustrial engineering

The invention provides an online car-hailing order dispatching matching method, an online car-hailing order dispatching matching device, a server and a storage medium, and the order dispatching matching method comprises the steps of carrying out the pre-matching of a to-be-distributed online car-hailing order according to a preset order dispatching model, and generating a pre-matching result; adjusting the pre-matching result by using an intervention model, and generating an adjustment result; obtaining orders inconsistent with the pre-matching result in the adjustment result, and calculatingthe pick-up time change rate of the inconsistent orders before and after adjustment; determining a corresponding transaction change rate according to the pick-up time change rate; if the negative transaction change rate is greater than a preset change rate threshold, correcting the intervention model to reduce the transaction change rate to be less than or equal to the preset change rate threshold; and performing order dispatching matching according to a preset order dispatching model and the corrected intervention model. Through the technical scheme of the invention, the order receiving efficiency of a driver is not influenced while the order service quality is improved, so that the order quality and the order efficiency are balanced.

Owner:BEIJING DIDI INFINITY TECH & DEV

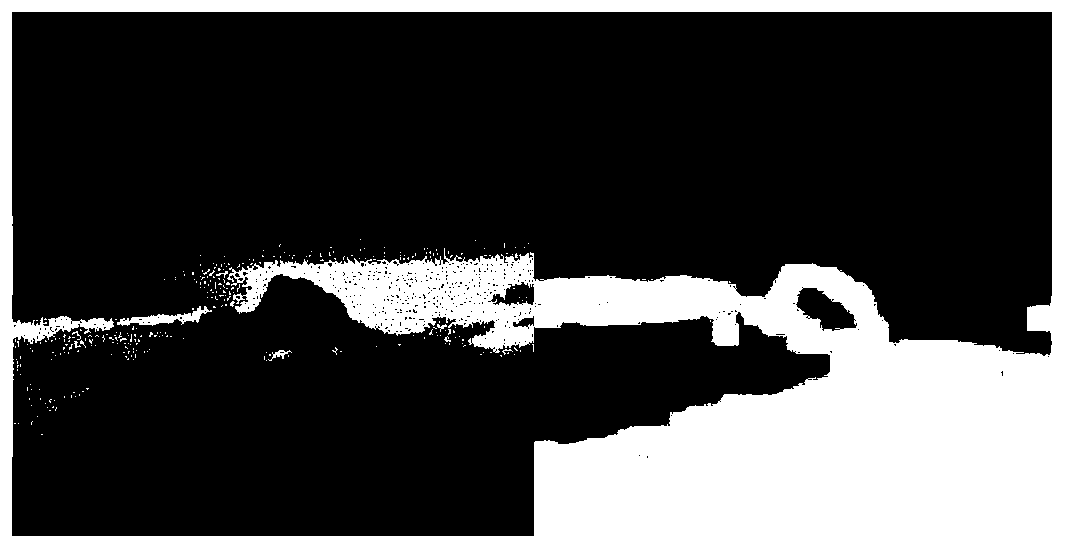

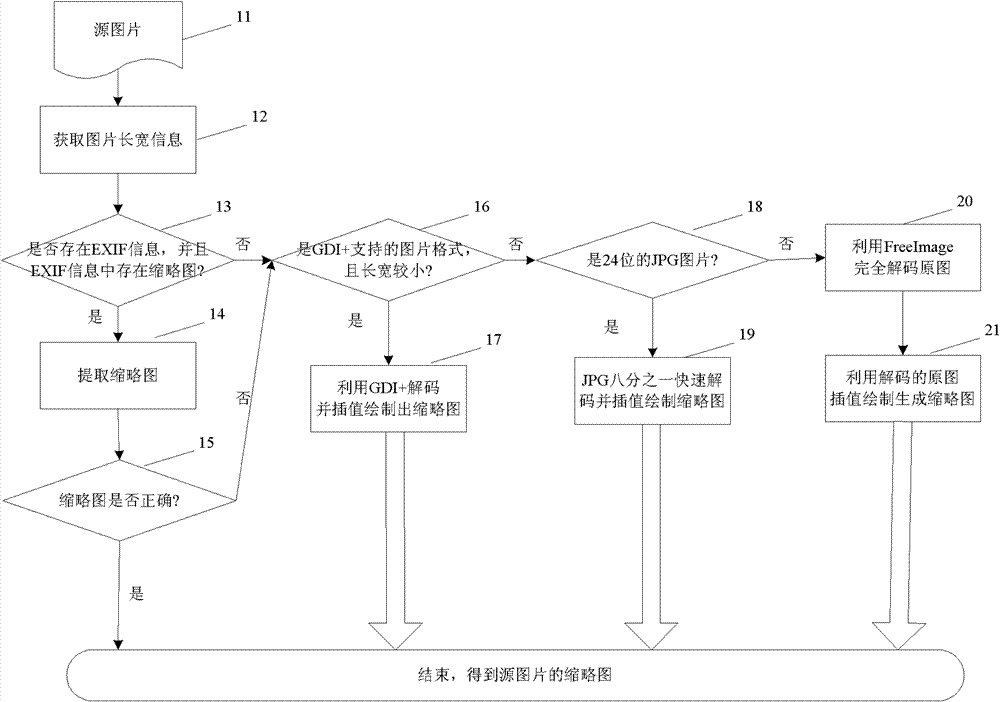

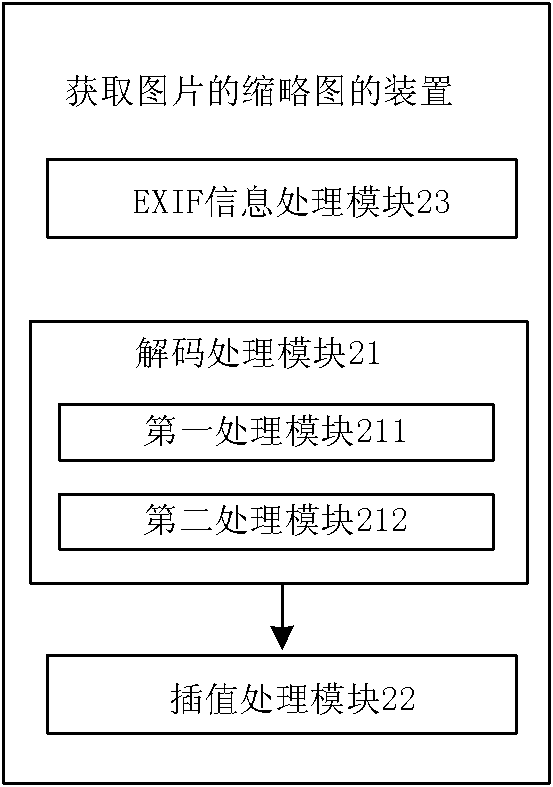

Method and device for obtaining thumbnails of images

ActiveCN102768755ABalancing Variety and CompatibilityMass balanceGeometric image transformationImage codingImage resolutionThumbnail

The invention provides a method and a device for obtaining thumbnails of images. The method comprises the following steps: under the conditions that a source image belongs to the GDI+ (enhanced graphics device interface)-decoding image format, and the resolution of the source image is less than the set value, using GDI+ (enhanced graphics device interface) to decode the source image; under the conditions that the source image does not belong to the GDI+-decoding image format, and / or the resolution of the source image is not less than the set value, judging whether the source image is more than the JPG (joint picture group) file with the set bit; if yes, using the GDI+ to partly decode the source image; and if no, using Freeimage to decode the source image. The method integrates the methods for generating thumbnails, combines the advantages of the methods, and provides a complete solution; and various factors such as type and compatibility of the supported image formats, the thumbnail-generating speed and the thumbnail-generating quality are effectively balanced.

Owner:TENCENT TECH (SHENZHEN) CO LTD +1

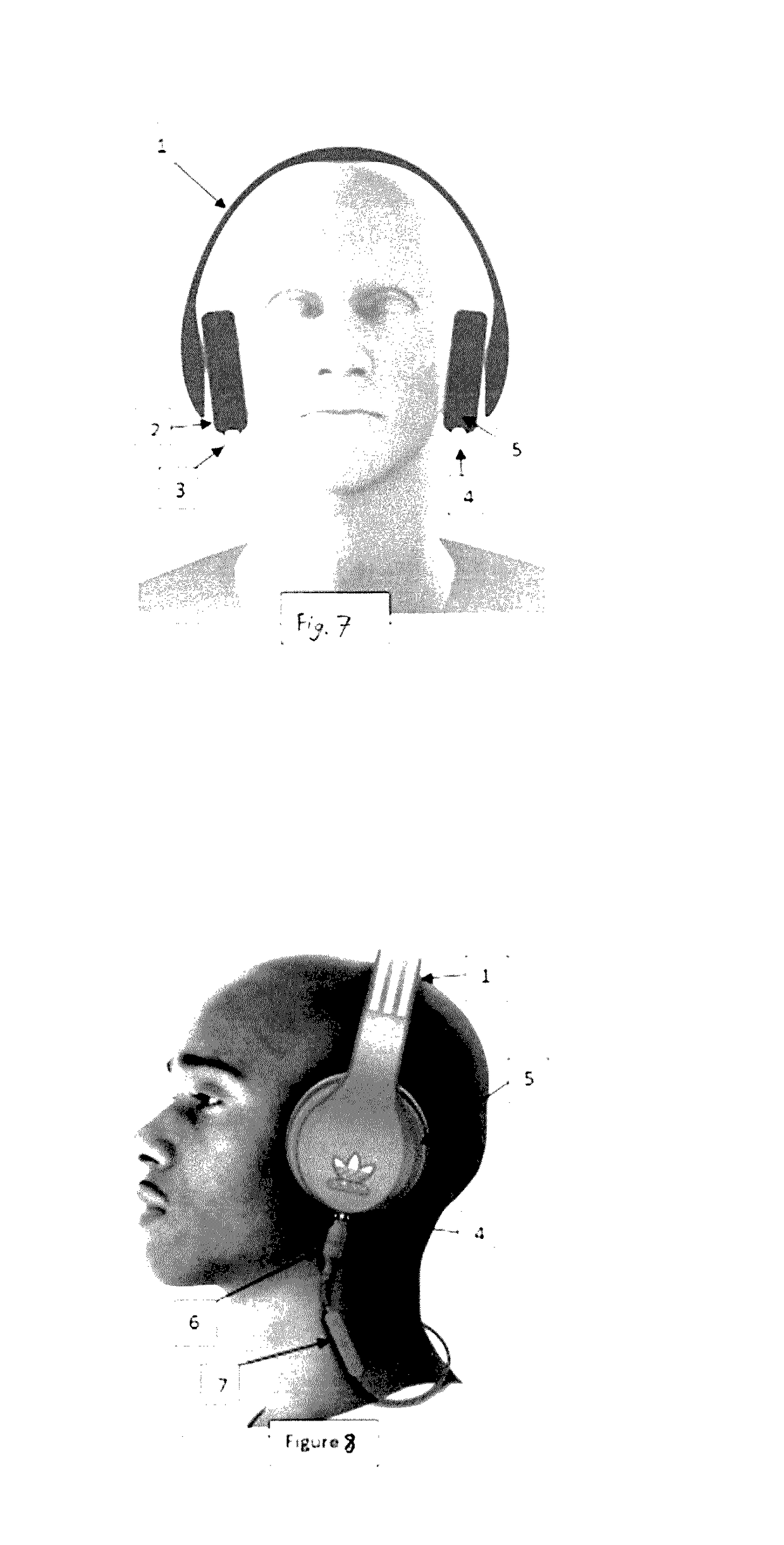

Multifunction Wireless Adapter

InactiveUS20170070804A1Maintain balanceReduce the total massMicrophonesHeadphones for stereophonic communicationHeadphonesBluetooth

The Invention is a Wireless Headphone System (WHS), comprising an adapter that is configured for use with headphones having dual connections for cables with one on each headphone. The invention uses that configuration to support a cable with connectors at both ends of the cable that is at least long enough to connect around the user's head between the ear cups of the headphone. Further it incorporates Bluetooth or other wireless electronics and may have a microphone for a full duplex conversation as well as controls. The preferred embodiment comprises a generally symmetrical cable that balances the mass of the device(s) along its length, which can also be used to share media with an additional headphone set that is also plugged into the device.

Owner:MONSTER

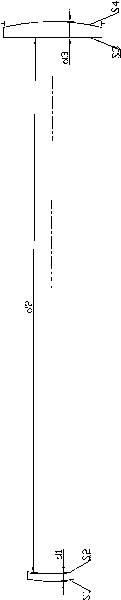

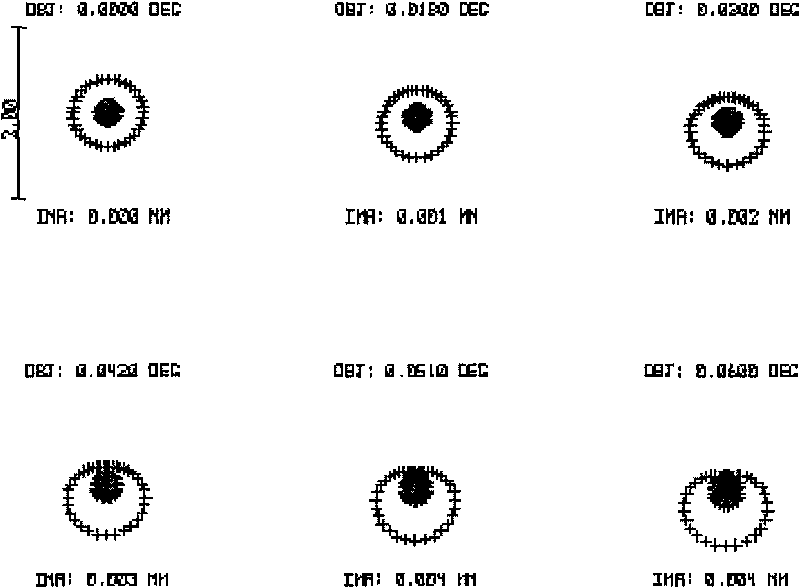

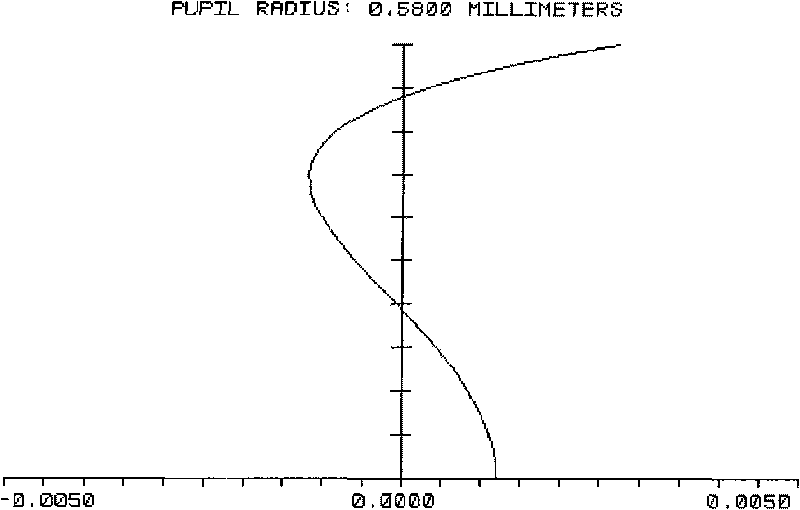

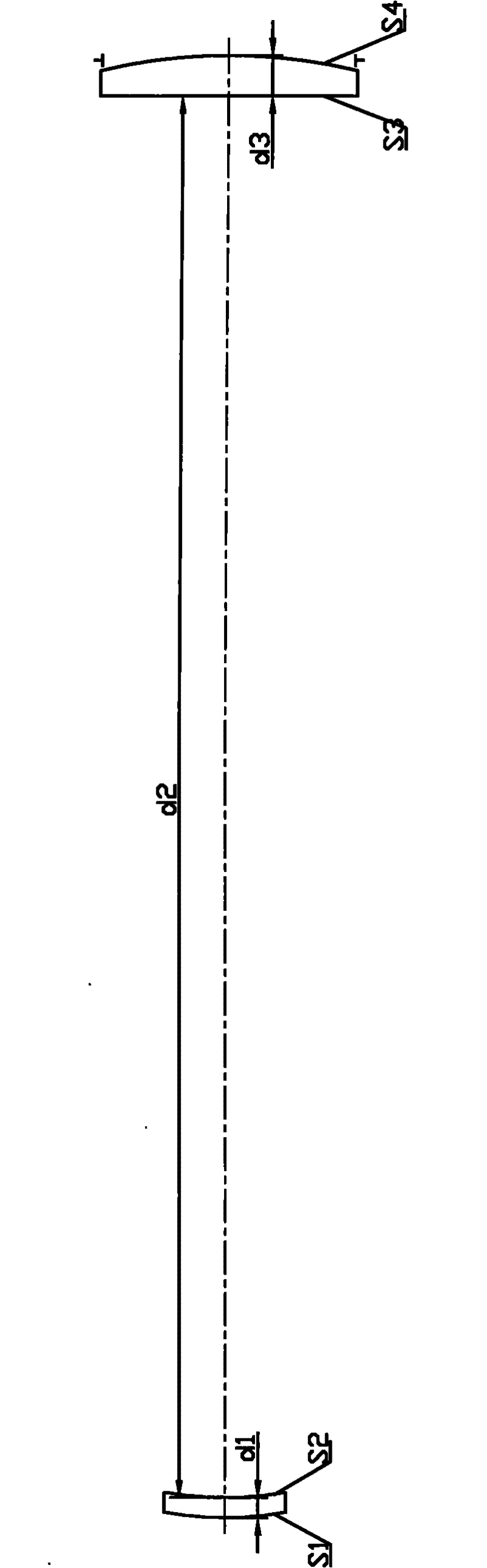

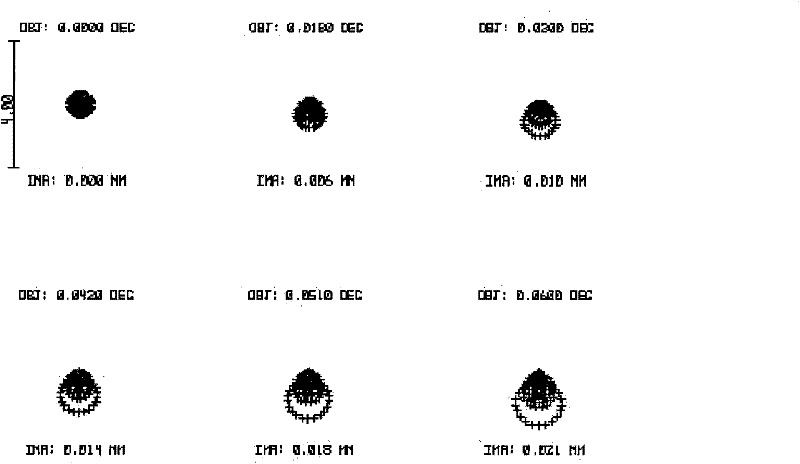

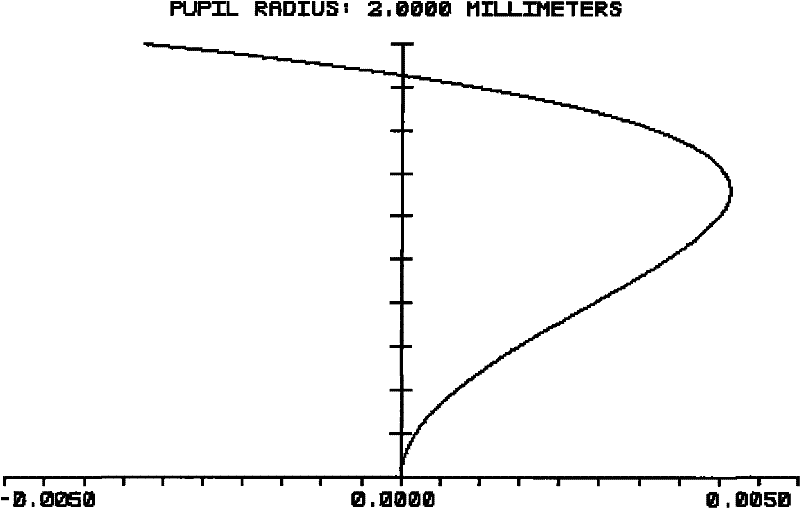

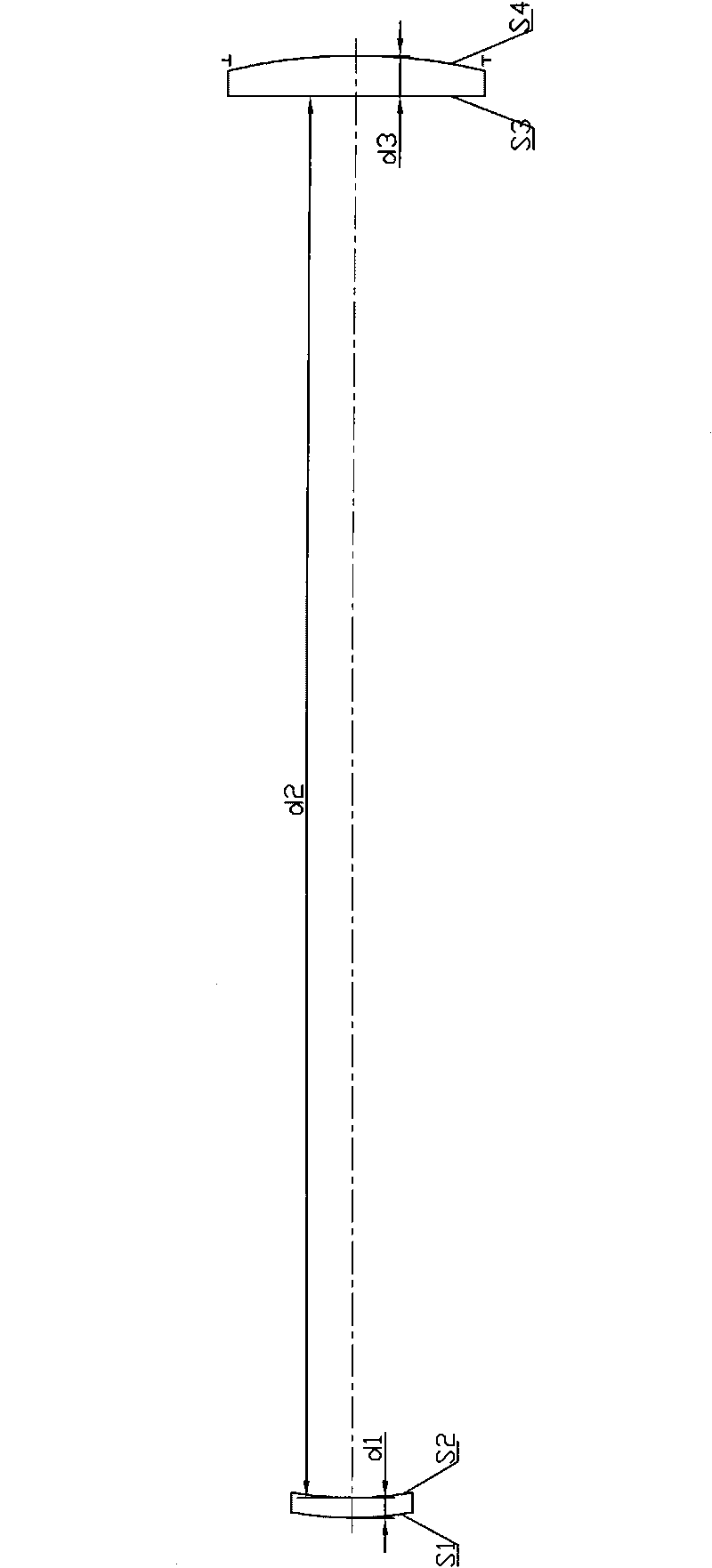

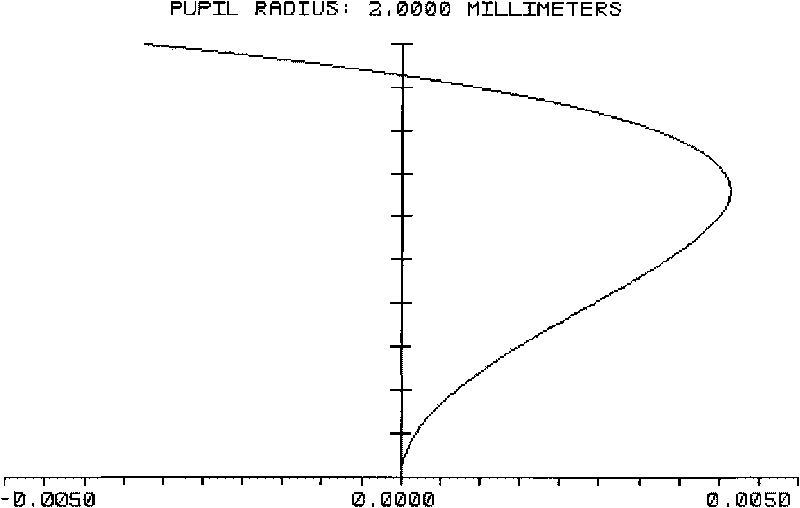

Laser beam expanding system

The invention relates to a location beam expanding system for ultraviolet laser, comprising a first lens and a second lens arranged in the light beam incidence direction; wherein the first lens is a crescent-shaped negative lens with back side thereof bent towards the incidence direction of light ray, the second lens is a plano-convex positive lens; the beam expanding system composed of the first lens and the second lens can expand diameter of incidence laser beam by 12 times and still eject the laser beam in the form of parallel light. As far as the beam expanding system of the invention is concerned, as the negative lens is short in focal length, thus not affecting aberration much; however, the positive lens is the main part which determines quality of outgoing beam from a beam expander. The beam expanding system enjoys a 12 times of beam expanding magnification, therefore a positive lens is enough to ensure quality of expanded outgoing beam; on the basis, not only shaping requirements are met, but also the best imaging quality is achieved; in addition, contour dimension is guaranteed to be the minimum, the imaging quality of the beam expanding system is very ideally balanced and volume of the whole lens is very small.

Owner:HANS LASER TECH IND GRP CO LTD

Multi-device sensor subsystem joint optimization

ActiveUS9602349B2Reducing sensor redundancyMass balancePower managementSynchronisation arrangementQuality of serviceDevice status

A system and method for reducing sensor redundancy in sensor-equipped devices includes identifying, via a master device, at least one device within an area. The at least one device is queried to determine at least one of a device status or application status for the at least one device. A configuration of one or more sensors within the at least one device based at least in part on the querying is determined. The one or more sensors within the at least one device is configured to balance quality of service across the master device and the at least one device, based at least in part on the determining.

Owner:QUALCOMM INC

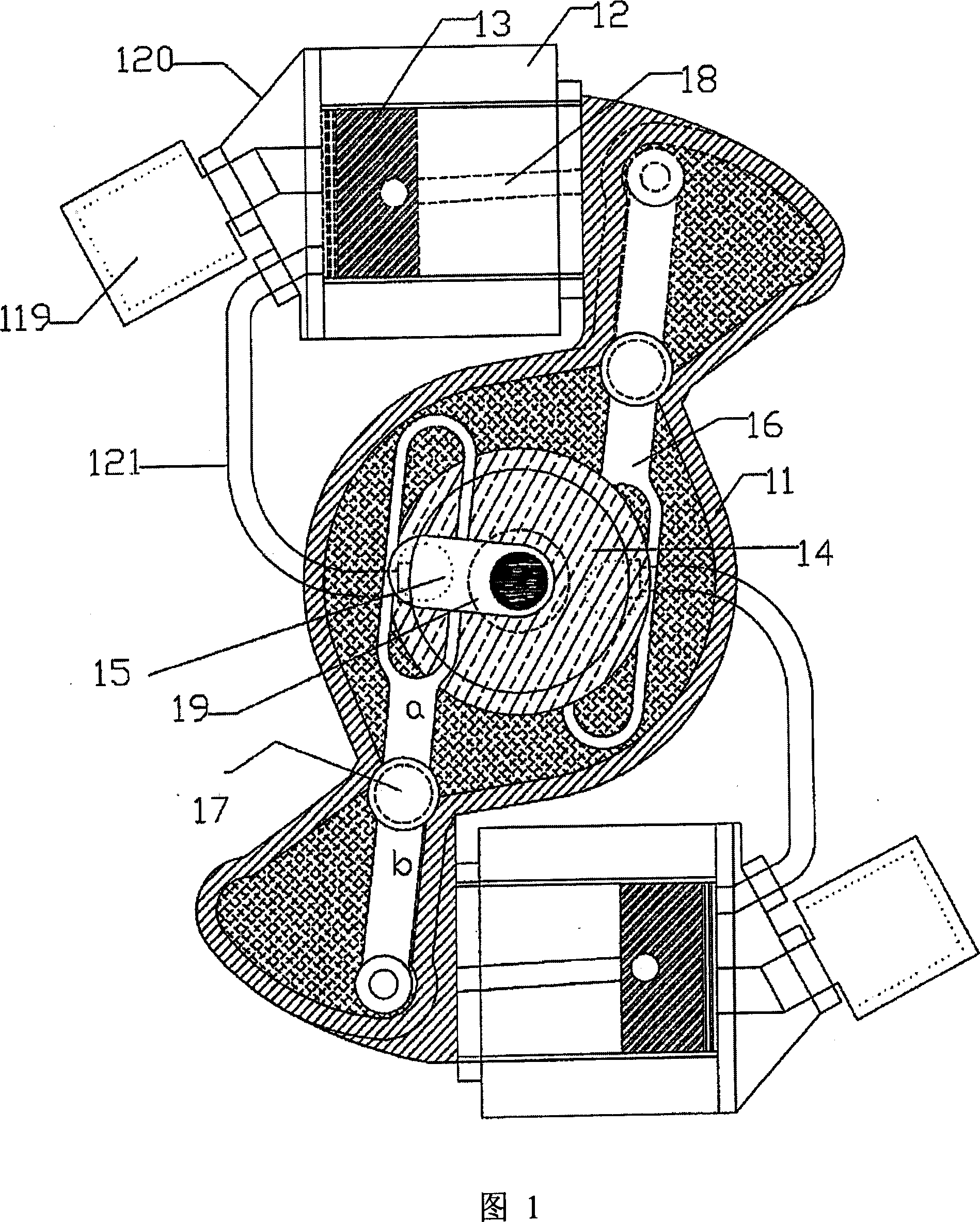

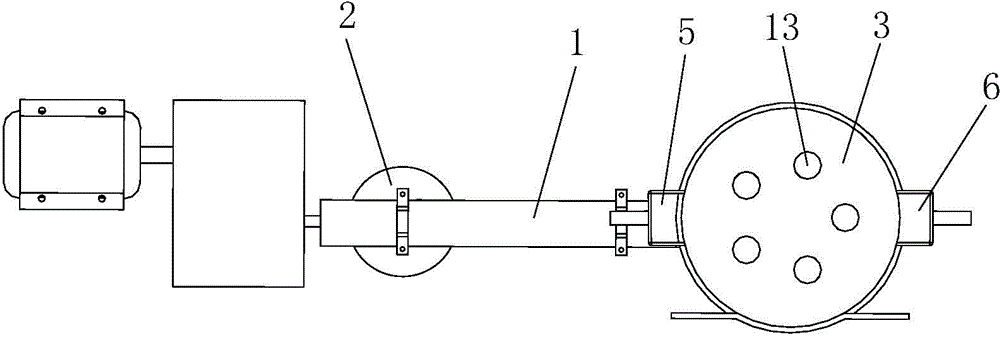

Separator

InactiveCN1417083ALight in massMass balanceWrapper twisting/gatheringSausage casingsCasing stringEngineering

A device for partitioning portion packages from a filled casing string by constricting it and applying at least one closing clip onto the casing string, which consists of two sets of displacement elements and a clipping apparatus consisting of two interacting elements that can move between the displacement element sets in mutually opposite directions, wherein the displacement elements and the elements of the closing apparatus are connected via rotating joints to the cranks driven in the same direction and are guided via a joint guiding element, which is seated in a swiveling manner about the (virtual) casing axis on a carrier holding also the cranks.

Owner:POLY CLIP SYST

Vibration damper for a drive train

ActiveUS8262485B2Reduce developmentLess installation spaceYielding couplingVibration suppression adjustmentsDrive shaftSnubber

A vibration damper (2) that is effective in the direction of rotation of a drive shaft and has a small radial extension. For this purpose, a first shaft part (6) is provided as a sleeve (8) and a second shaft part (7) is provided as an inner part extending axially into the sleeve (8). The two shaft parts (6, 7) engage via rotary drivers in complementary negative profiles (15, 16) of an interposed elastic damper part (10) in the direction of rotation. In addition to the negative profiles, the damper part may be provided with recesses (40) which modify its damping characteristics.

Owner:NEUMAYER TEKFOR ENG GMBH

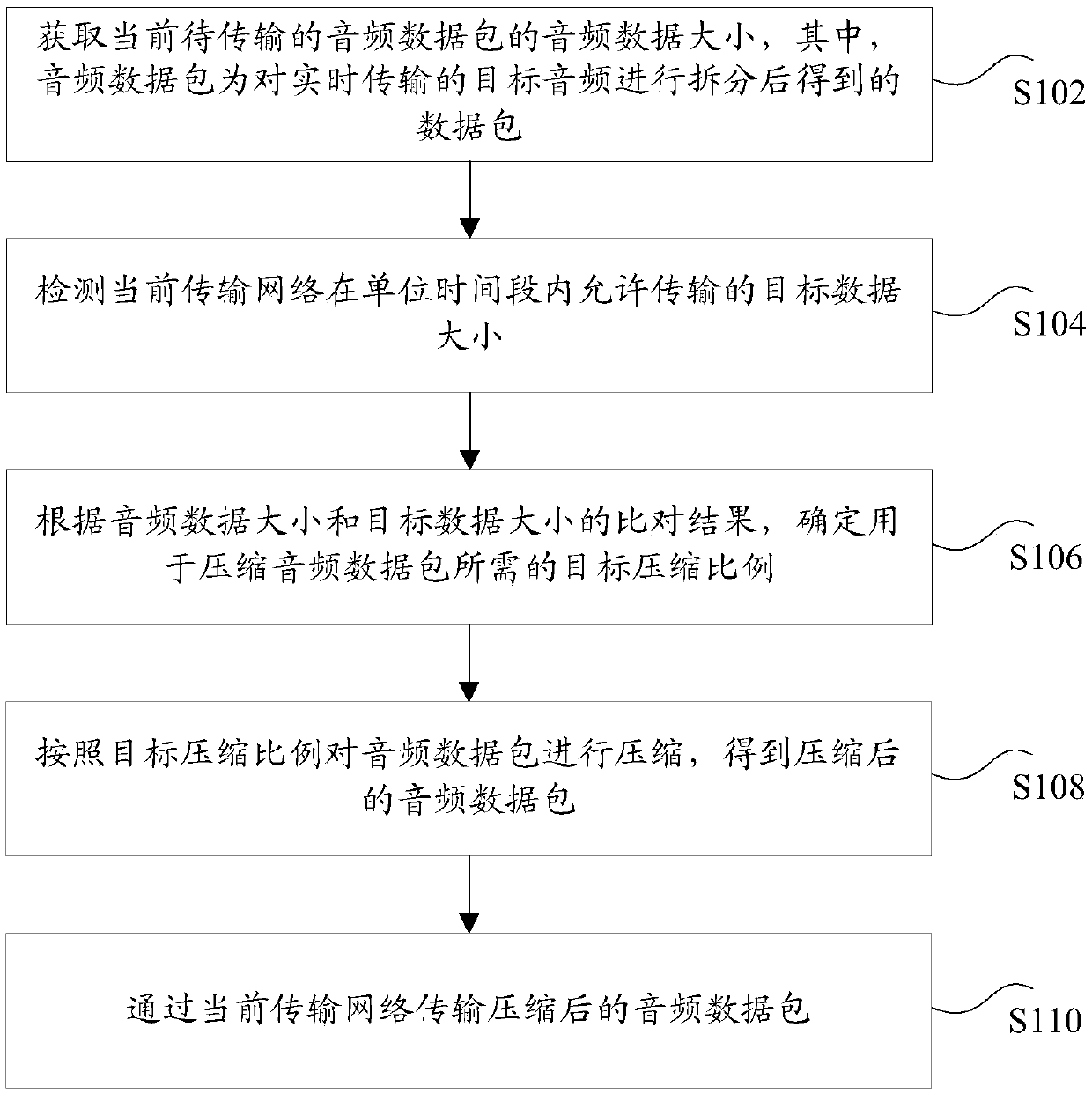

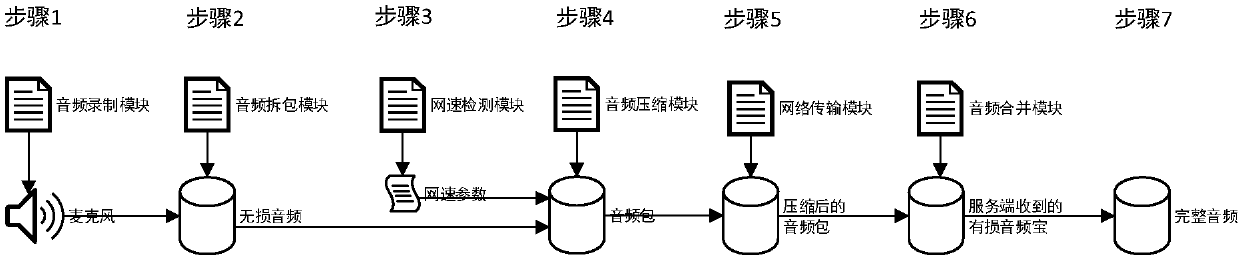

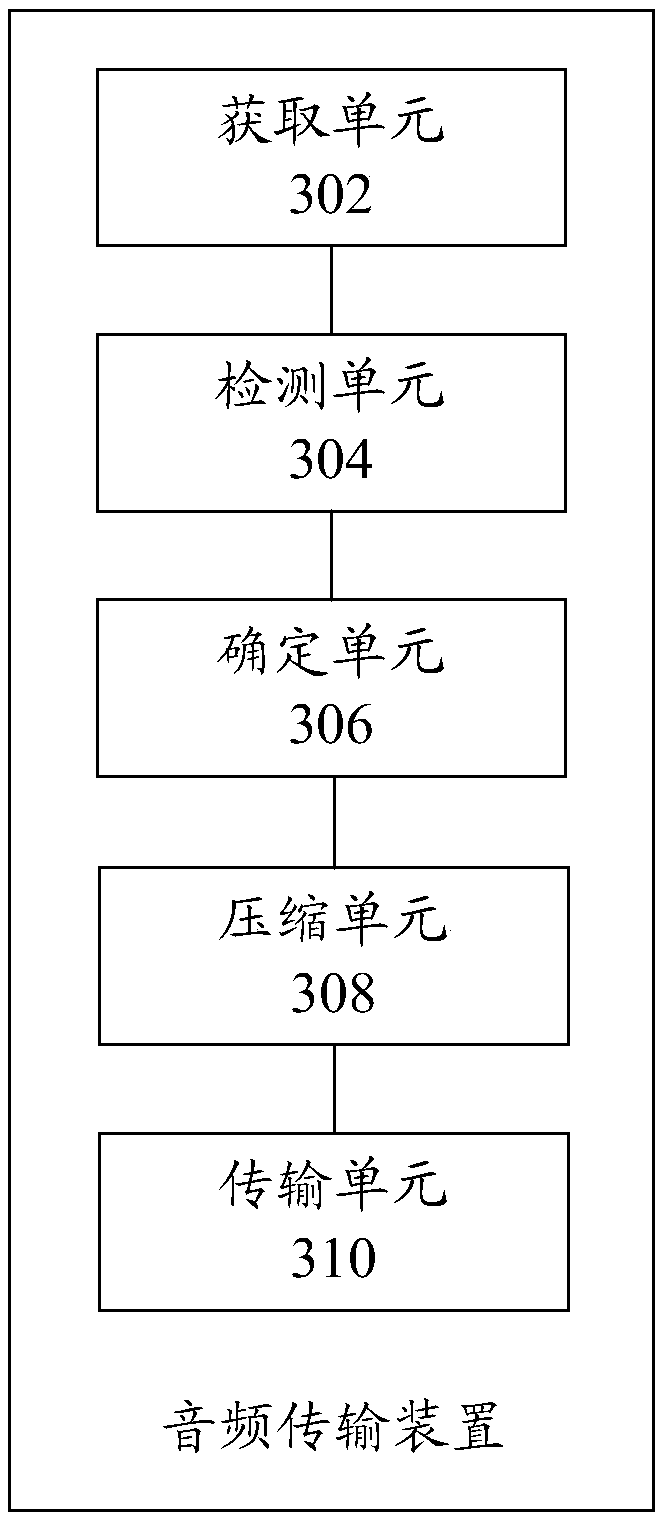

Audio transmission method and device and storage medium

ActiveCN109584889AImprove transmission efficiencyIncrease flexibilitySpeech analysisTransmission format adaptationComputer hardwareNetworked Transport of RTCM via Internet Protocol

The invention discloses an audio transmission method and device and a storage medium. The method comprises the following steps: the size of audio data of an audio data packet to be transmitted currently is acquired, wherein the audio data packet is a data packet obtained by splitting target audio transmitted in real time; the size of target data allowed to be transmitted by the current transmission network in a unit time period is detected; a target compression ratio required for compressing the audio data packet is determined according to a comparison result of the size of the audio data andthe size of the target data; the audio data packet is compressed according to the target compression ratio, and the compressed audio data packet is obtained; the compressed audio data packet is transmitted through the current transmission network. The technical problem of lower audio transmission efficiency in methods provided by related technologies is solved.

Owner:MIAOZHEN INFORMATION TECH CO LTD

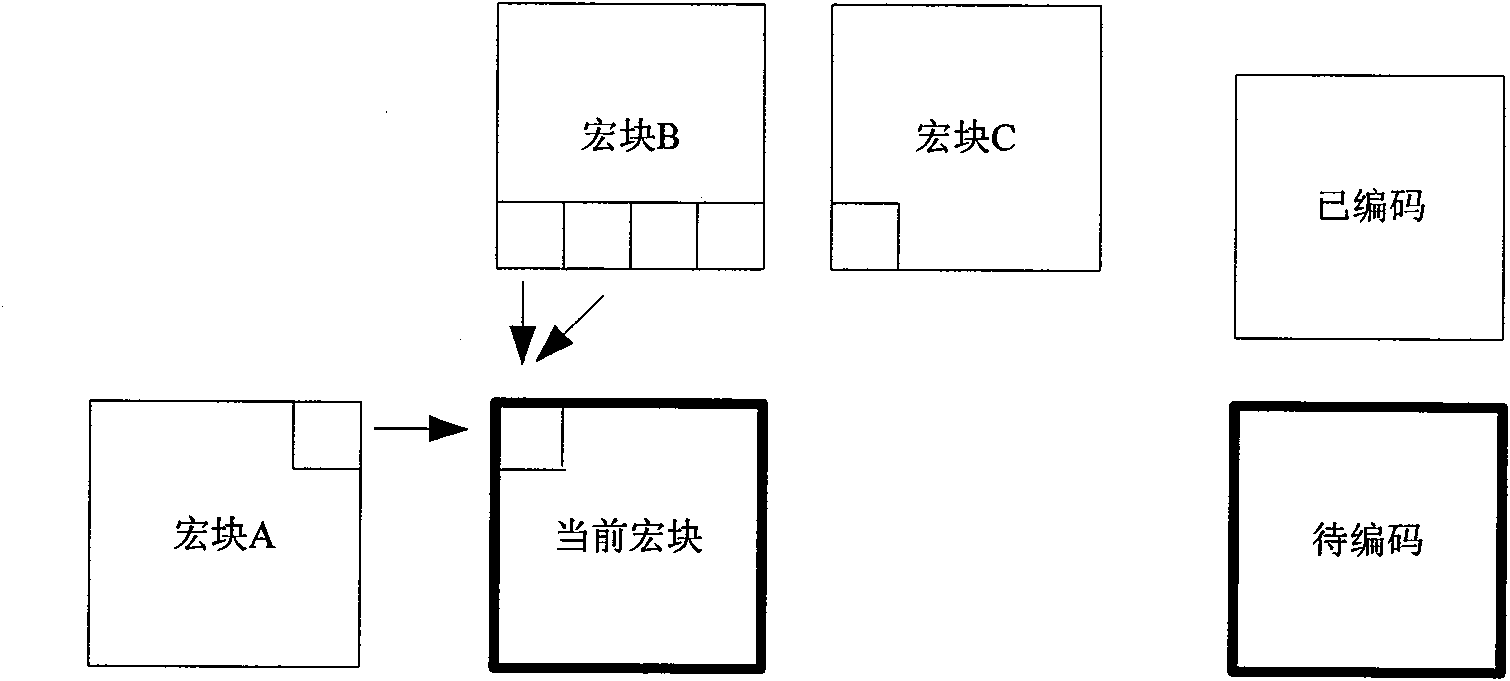

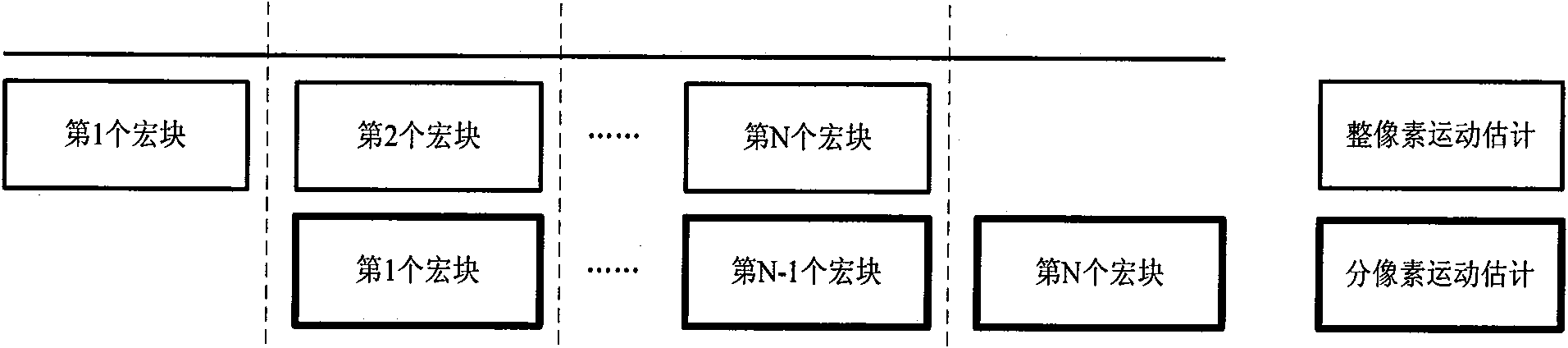

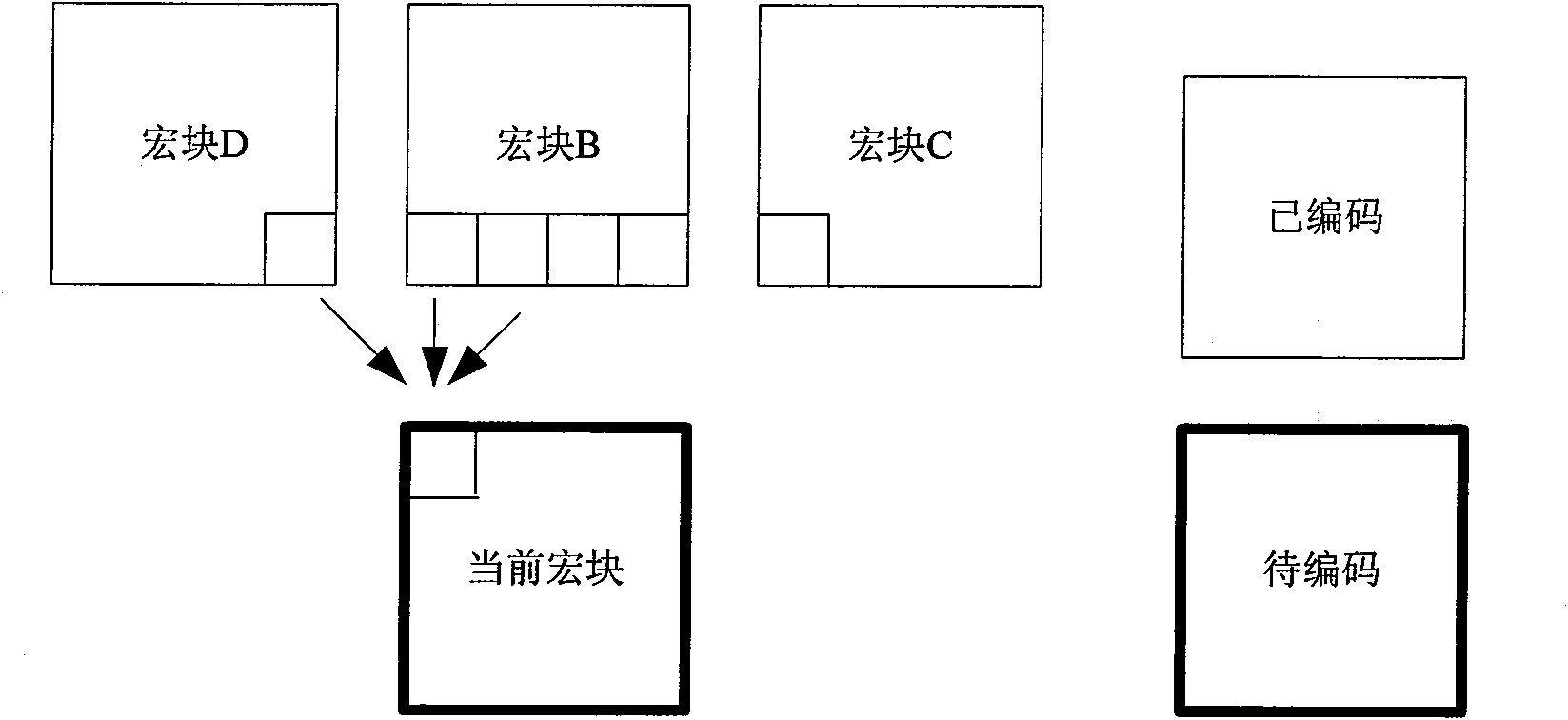

Device and method for estimating hierarchical motion supporting skip mode

ActiveCN101841703AImprove compression efficiencyGuaranteed real-timeTelevision systemsDigital video signal modificationMotion vectorInter frame

The invention provides a device and a method for estimating the hierarchical motion supporting the skip mode. The method for estimating the hierarchical motion supporting the skip mode comprises the following steps: outputting the cost function value of each integer-pixel motion estimation mode with an integer-pixel motion estimation unit, judging the macro-block integer-pixel motion estimation mode with an integer-pixel motion estimation judging unit; outputting the cost function value of each sub-pixel motion estimation mode with an sub-pixel motion estimation unit, and forcibly changing the macro-block interframe prediction mode into the skip mode, or changing the macro-block interframe prediction mode into the integer-pixel motion estimation judging mode to decide the macro-block motion vector according to the position of the minimum cost function value of the sub-pixel motion estimation, or deciding the macro-block interframe prediction mode and the macro-block motion vector according to the minimum cost function value of the sub-pixel motion estimation with an sub-pixel motion estimation judging unit. The invention realizes the comparability of the skip mode and various macro-block partition modes and effectively improves efficiency of compressing the coding system.

Owner:HANGZHOU SILAN MICROELECTRONICS

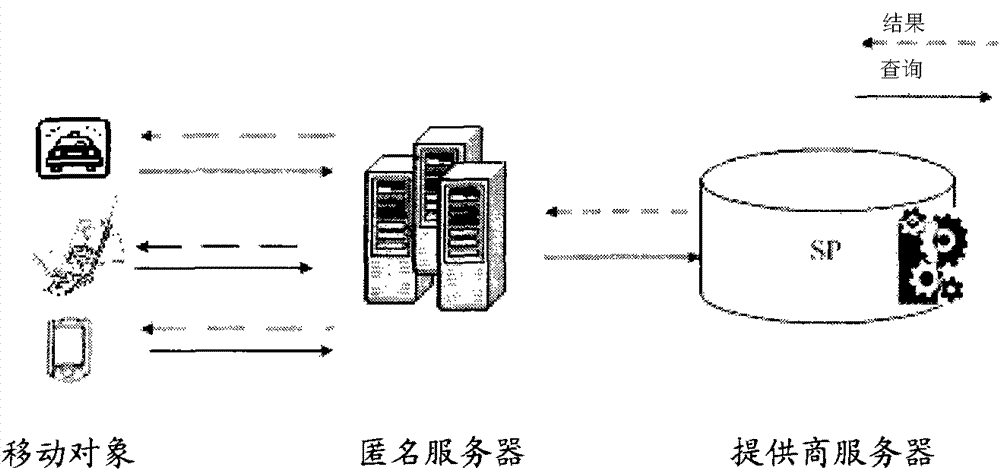

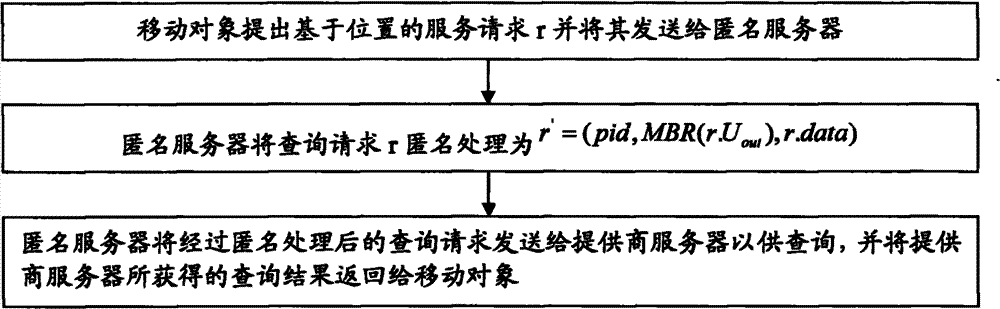

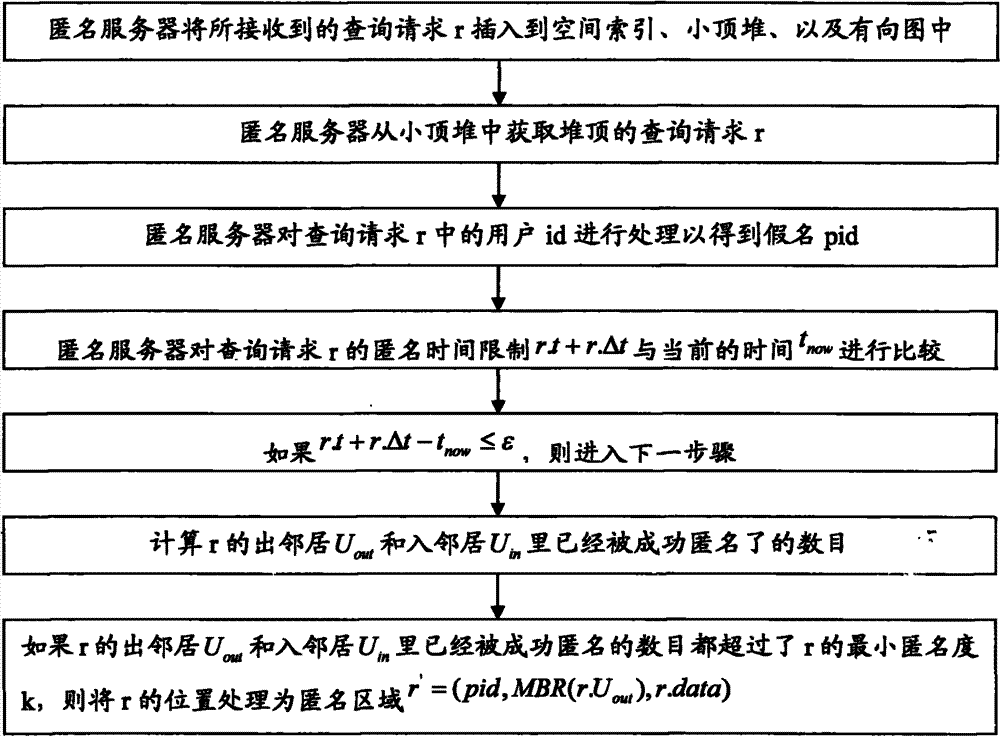

Position privacy protection method for perceiving service quality

InactiveCN101873317BMass balanceLocation information based serviceTransmissionQuality of serviceGranularity

Owner:孟小峰

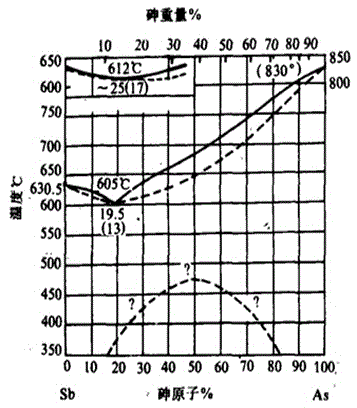

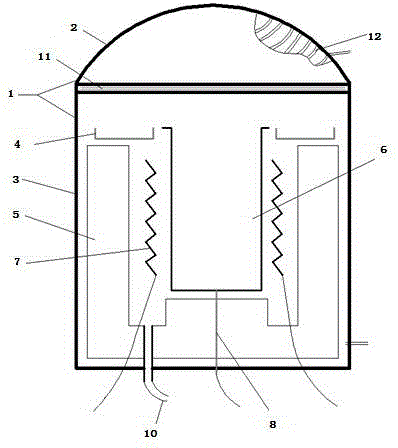

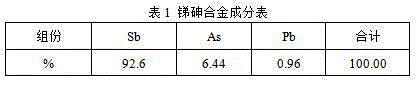

Device and method for treating antimony-arsenic materials

ActiveCN104561605AAvoid secondary pollutionAchieve cleaningProcess efficiency improvementSmelting processRefractory

The invention discloses a device and a method for treating antimony-arsenic materials. The problem that harmful impurities are difficult to remove in the smelting process of antimony-arsenic materials is solved. The device comprises a furnace body, a furnace lid and a furnace body, wherein a cylindrical refractory layer is arranged in the furnace body, and a graphite crucible is arranged at the center of the refractory layer; a volatile collection tank is arranged at the top of the refractory layer and is positioned outside the top of the graphite crucible, and a gap is reserved between the graphite crucible and the volatile collection tank; the bottom of the refractory layer is connected with a vacuum pump through a vacuum pump pipe, and a heating system is arranged between the graphite crucible and the refractory layer. The method for treating the antimony-arsenic materials comprises the steps of feeding, vacuumizing, heating, heat insulating, cooling and discharging. Based on the principle of vacuum metallurgy, arsenic and antimony in the antimony-arsenic material are effectively separated, the treatment process is clean and efficient, and no waste water and waste residues are produced; the secondary pollution of arsenic is avoided, and the recovery rate of metal is high.

Owner:LANZHOU ENG & RES INST OF NONFERROUS METALLURGY

Beam-expanding system

The invention provides a laser beam-expanding system, which comprises a first lens and a second lens which are positioned in the incident direction of a beam and are arranged in turn, wherein the first lens is a crescent-type negative lens; the curved surface of the first lens backs onto the incident direction of a ray and bends; the second lens is a plano-convex positive lens; and the whole beam-expanding system can perform bean expansion on the diameter of an incident laser beam by 5 times and then emit the beam as a parallel beam. Through the two lenses which have focal power assigned in a'negative-positive' form and are arranged in turn, the laser beam-expanding system can perform bean expansion on the diameter of an incident laser beam by 5 times and then emit the beam still as a parallel ray. As the focal length of the negative first lens is short and hardly affects aberration, the bean expansion multiple of the beam-expanding system is not big, so one positive lens is enough to undertake the quality of expanded emitted beams. Therefore, the system ensures shaping need, achieves the best imaging quality, and also ensures minimum overall dimensions. The beam-expanding systemhas the advantages of balanced ideal image quality and small volume of the whole lens.

Owner:HANS LASER TECH IND GRP CO LTD

Beam-expanding system

The invention provides a laser beam-expanding system, which comprises a first lens and a second lens which are positioned in the incident direction of a beam and are arranged in turn, wherein the first lens is a crescent-type negative lens; the curved surface of the first lens backs onto the incident direction of a ray and bends; the second lens is a plano-convex positive lens; and the whole beam-expanding system can perform bean expansion on the diameter of an incident laser beam by 5 times and then emit the beam as a parallel beam. Through the two lenses which have focal power assigned in a 'negative-positive' form and are arranged in turn, the laser beam-expanding system can perform bean expansion on the diameter of an incident laser beam by 5 times and then emit the beam still as a parallel ray. As the focal length of the negative first lens is short and hardly affects aberration, the bean expansion multiple of the beam-expanding system is not big, so one positive lens is enough to undertake the quality of expanded emitted beams. Therefore, the system ensures shaping need, achieves the best imaging quality, and also ensures minimum overall dimensions. The beam-expanding system has the advantages of balanced ideal image quality and small volume of the whole lens.

Owner:HANS LASER TECH IND GRP CO LTD

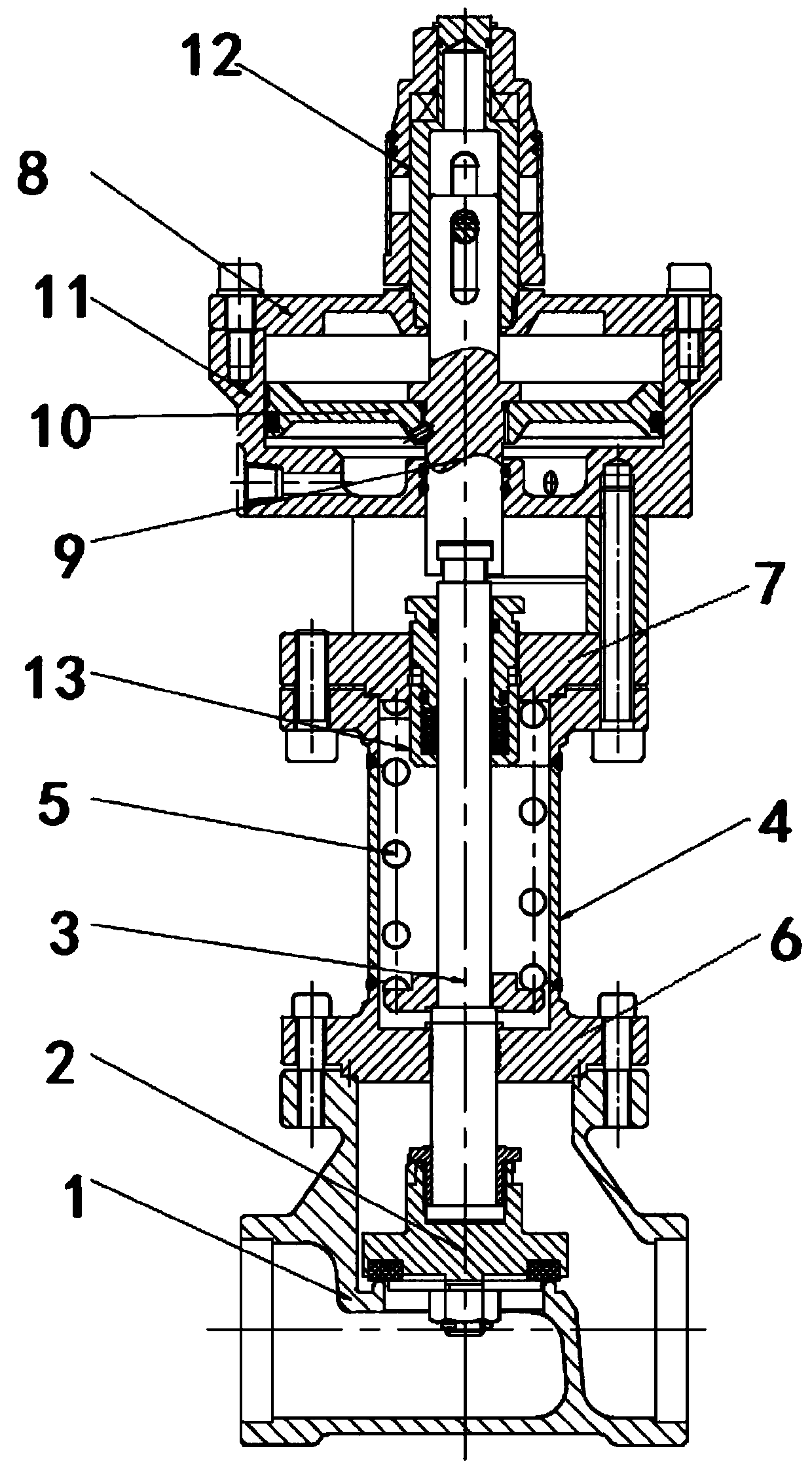

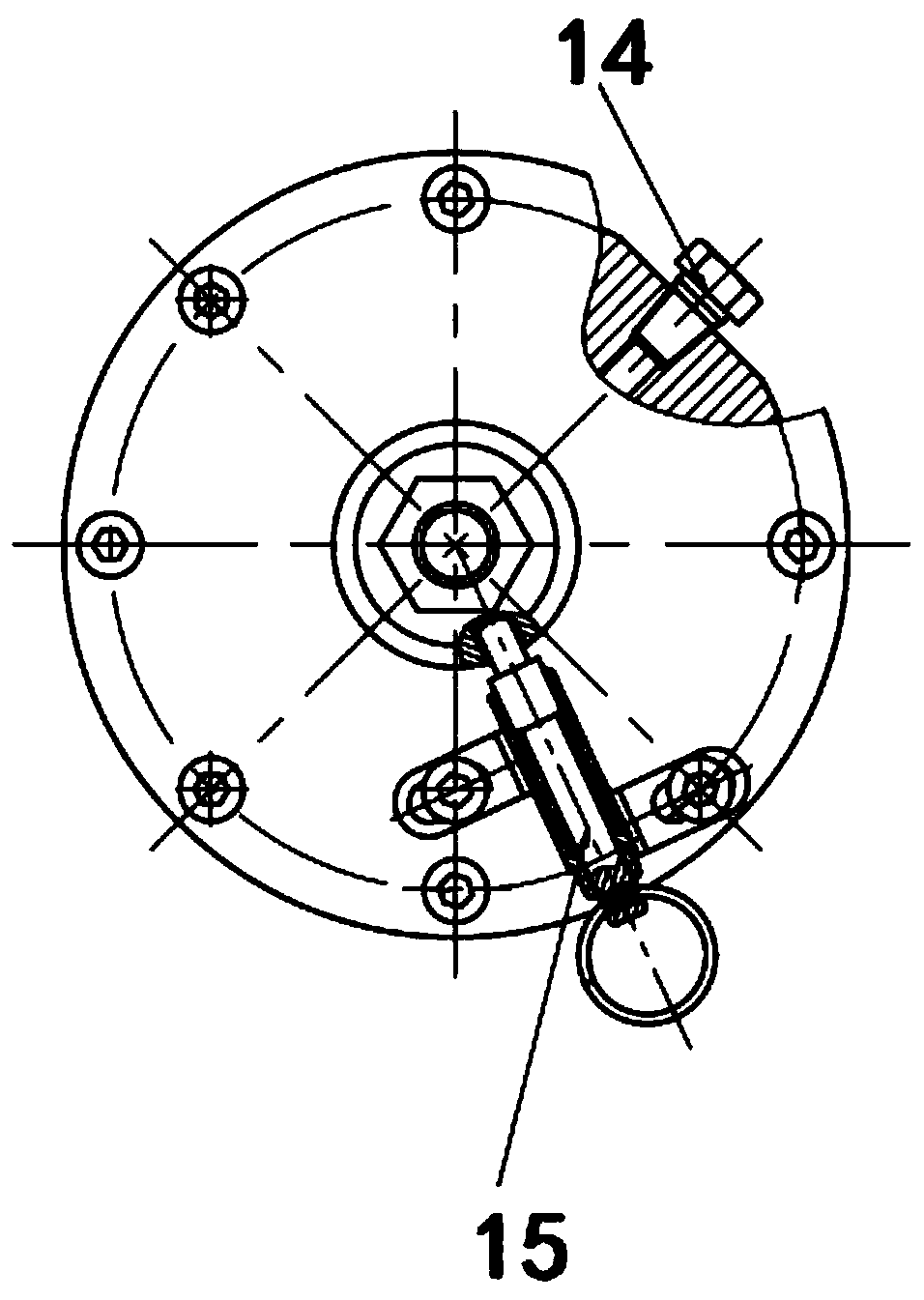

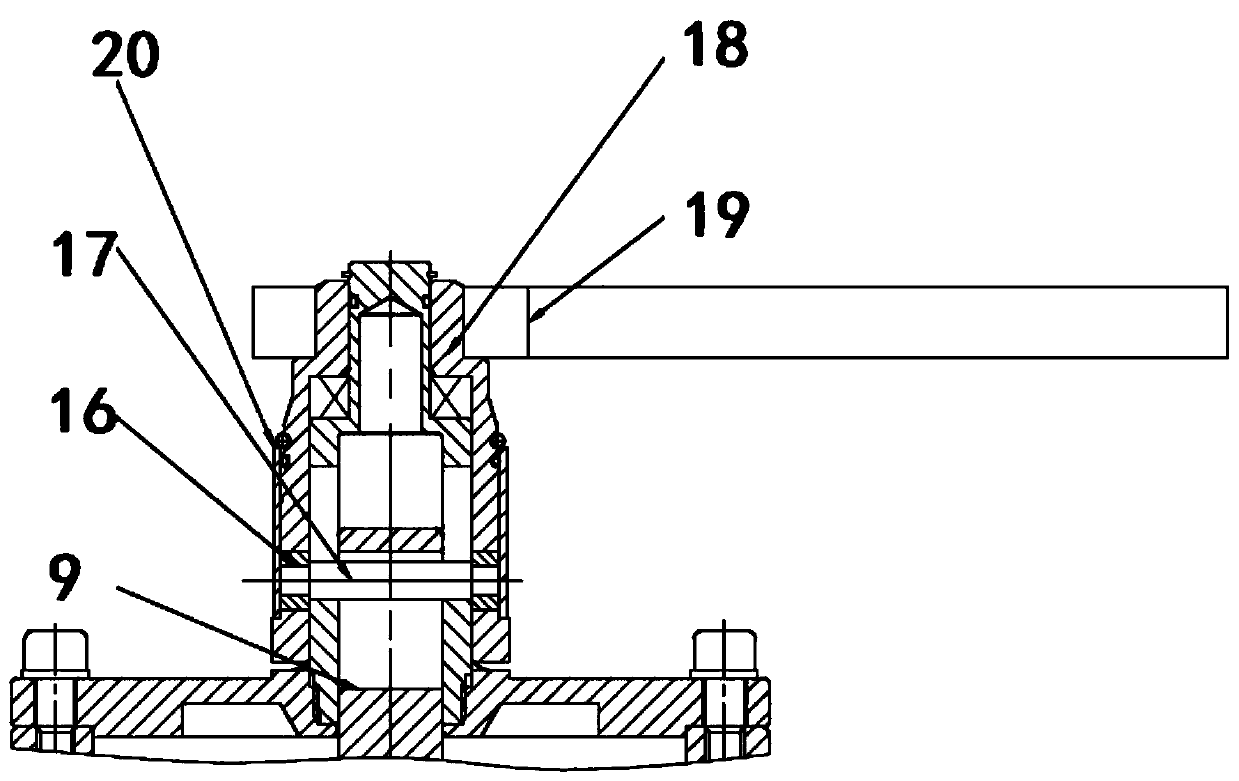

Low-temperature emergency shutoff valve of novel spring air cylinder separation structure

ActiveCN109882624ALower installation heightLowering spring mounting structureSpindle sealingsOperating means/releasing devices for valvesEngineeringMechanical engineering

The invention provides a low-temperature emergency shutoff valve of a novel spring air cylinder separation structure. A valve body is included and comprises a valve cover, an upper cover and a cylinder cover. A valve clack is arranged in the valve body and connected with a valve rod. A connecting pipe is arranged on the outer side of the valve rod. The part between the connecting pipe and the valve rod is sleeved with a spring. The valve rod penetrates through the valve cover and the upper cover to be connected with a connecting rod, and the connecting pipe is located between the valve cover and the upper cover. The connecting rod is fixed to a piston, the piston is connected with an air cylinder body, the air cylinder body is located on the outer side of the piston, and the air cylinder body and the cylinder cover are connected through screws. The valve body further comprises a manual device. The manual device comprises a guiding wheel, a fixing pin, a spiral groove body and a handle,the connecting rod is connected with the fixing pin, the handle is fixedly connected with the spiral groove body, and the guiding wheel and the fixing pin upwards rotate along the spiral groove section of the spiral groove body.

Owner:SHANGHAI FIGURE CRYOGENIC VALVES

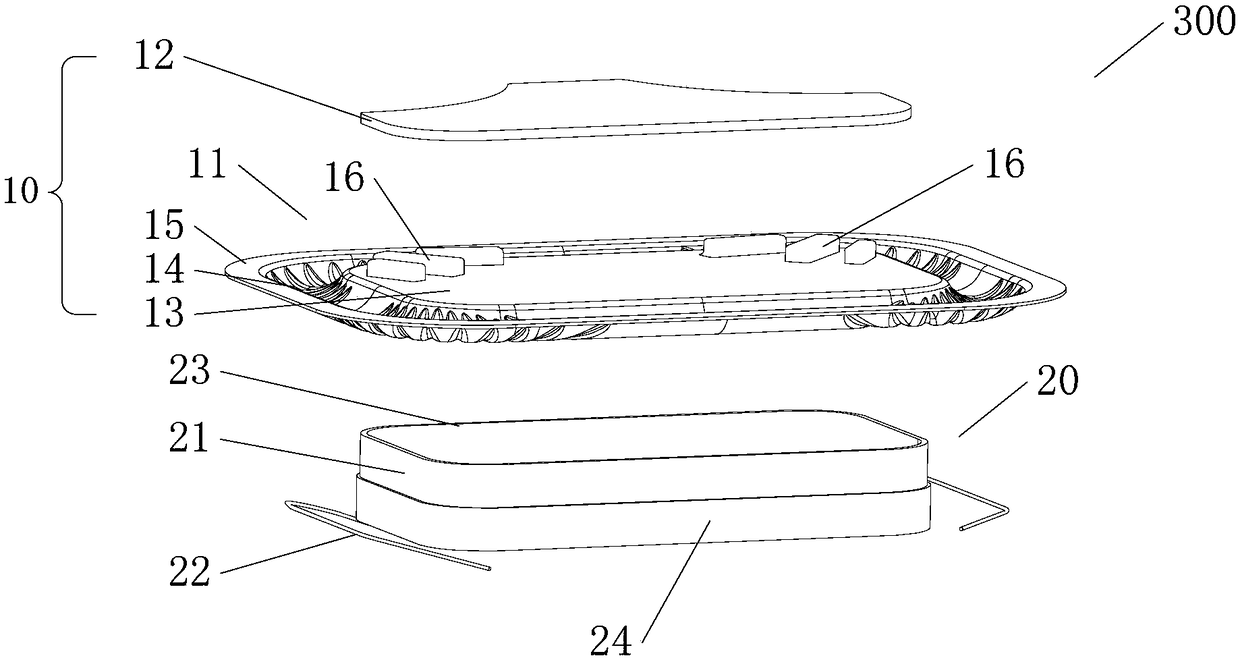

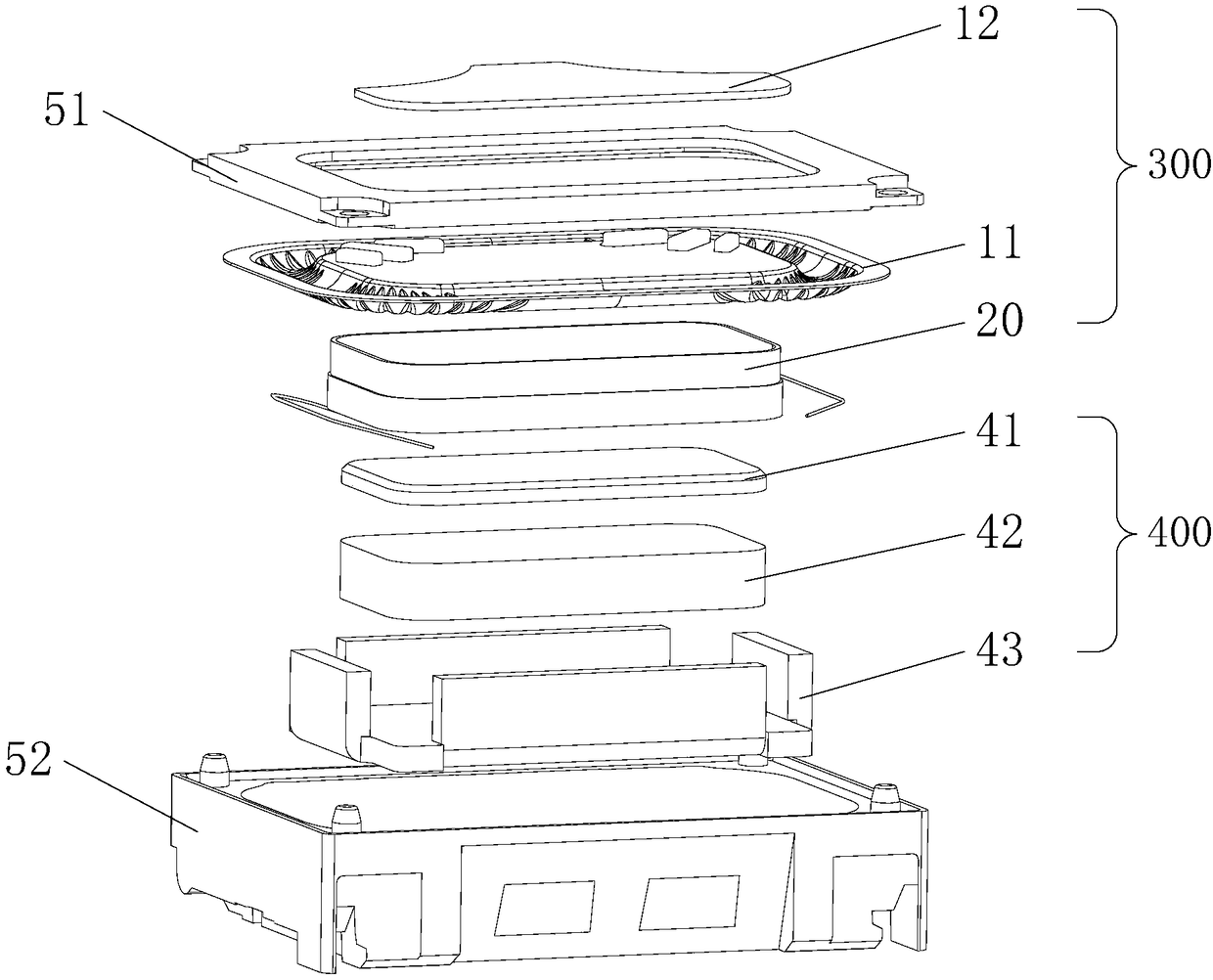

Vibration system and loudspeaker

PendingCN108391214AMass balanceImprove acoustic qualityElectrical transducersLoudspeakersPolarization phenomenonEngineering

The invention discloses a vibration system. The vibration comprises a diaphragm and a voice coil which is fixedly combined with the surface of the diaphragm. The voice coil comprises a circular voicecoil body and a lead wire led out from the same side of the voice coil body, the voice coil body comprises a led out side located at the led out position of the lead wire and a free side opposite to the led out side, the diaphragm comprises a diaphragm body part and a diaphragm reinforcing part which is combined with the surface of the diaphragm body part, and the mass of the part, corresponding to the led out side, of the diaphragm reinforcing part is lower than that of the part, corresponding to the free side, of the diaphragm reinforcing part. According to the vibration system, the mass ofthe part, corresponding to the led out side, of the diaphragm is lower than that of the part, corresponding to the free side of the voice coil, of the diaphragm, so that the quality of the lead wire of the voice coil is balanced, and a polarization phenomenon caused by unbalance mass distribution of the vibration system is relieved, so that the acoustic quality of a loudspeaker is improved.

Owner:GOERTEK INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com