Traction mechanism drive with a compensating device for vibration reduction

A technology of traction transmission and balance device, which is applied in the direction of valve device, balance rotating body, vibration suppression adjustment, etc., and can solve the problem of high dynamic load of the transmission device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

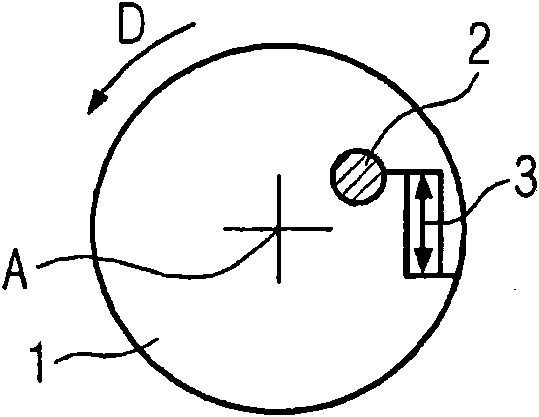

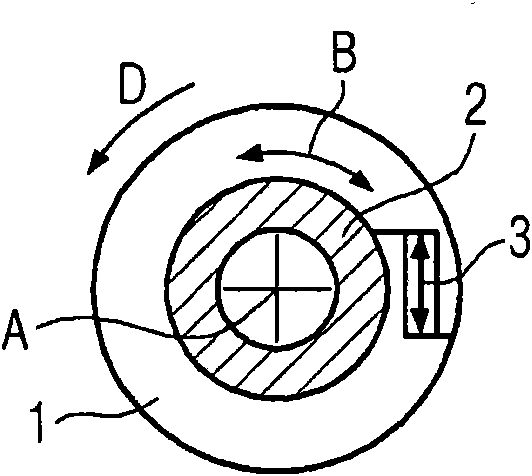

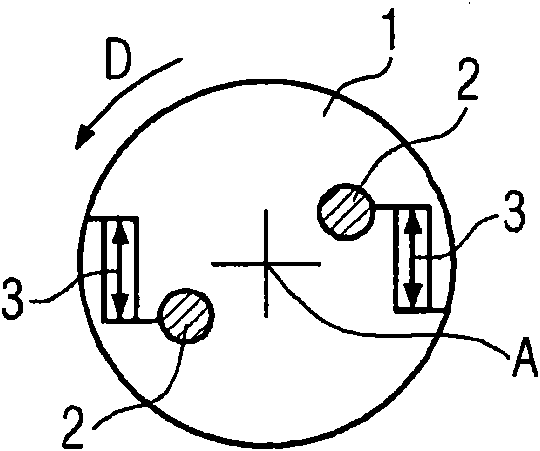

[0037] Figure 1a to Figure 1c Different embodiments of a compensating device for reducing vibrations in a traction drive are shown in plan view from the front. One or two balancing masses 2 are respectively movably arranged on the mass support body 1 of the balancing device and the balancing masses 2 are respectively equipped with an adjustment mechanism 3 , which adjusts the balancing masses 2 in the direction of rotation D of the shaft 4 On or against the direction of rotation D of the shaft 4.

[0038] exist Figure 1aIn the balancing device shown, only one balancing mass 2 is arranged on the mass support body 1 at a distance from the axis of rotation A of the driven shaft 4 . The balancing mass 2 is moved by means of the adjustment mechanism 3 , which is supported on the mass support body 1 , preferably on a circular arc of the center of gravity of the balancing mass 2 about the axis of rotation A along or against the direction of rotation of the shaft. In addition to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com