Mechanism for the recovery of energy in self-propelled vehicles

An energy recovery device, technology for motor vehicles, applied in the field of new systems, capable of solving problems such as shortened service life, mechanical vibration, unbalance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

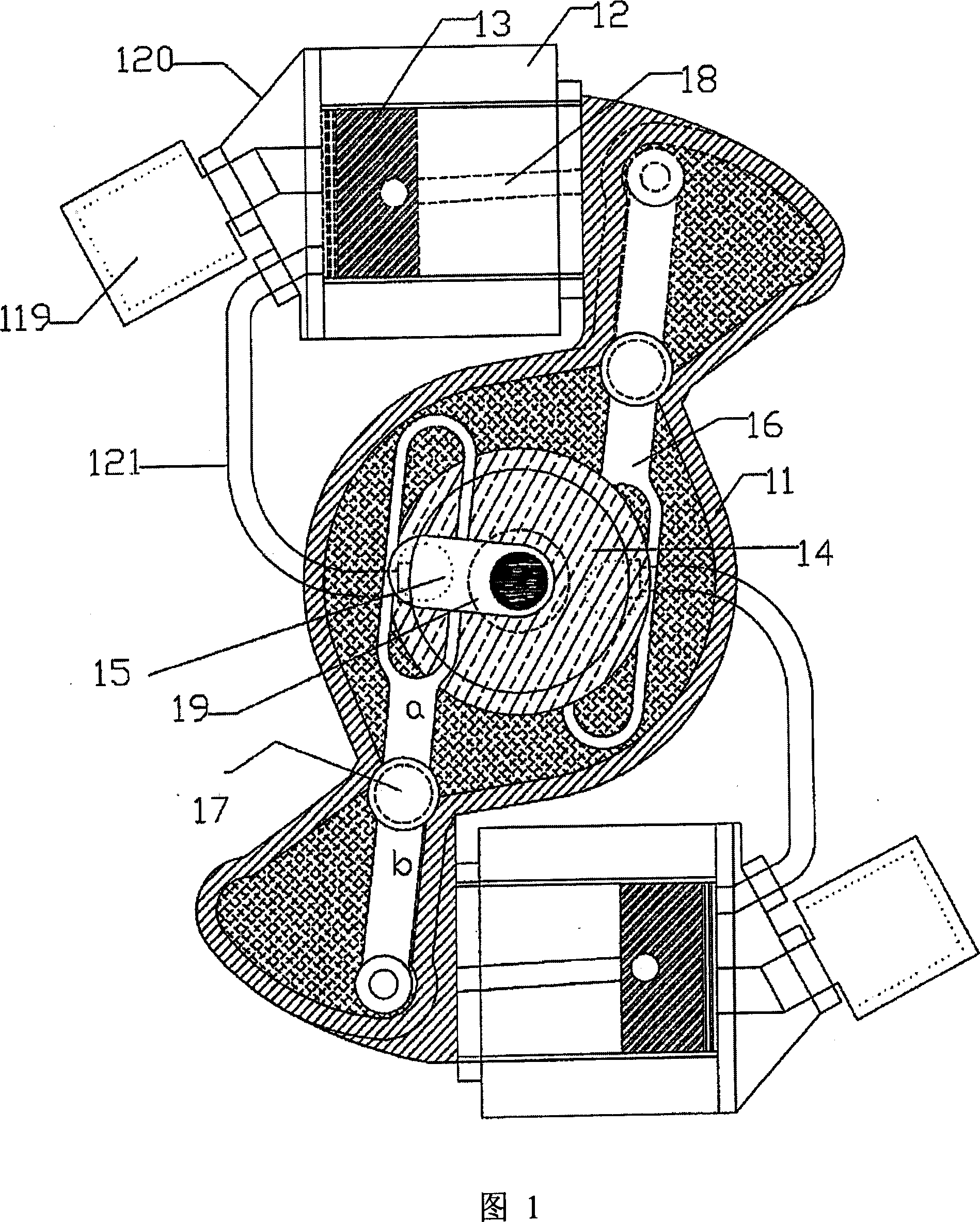

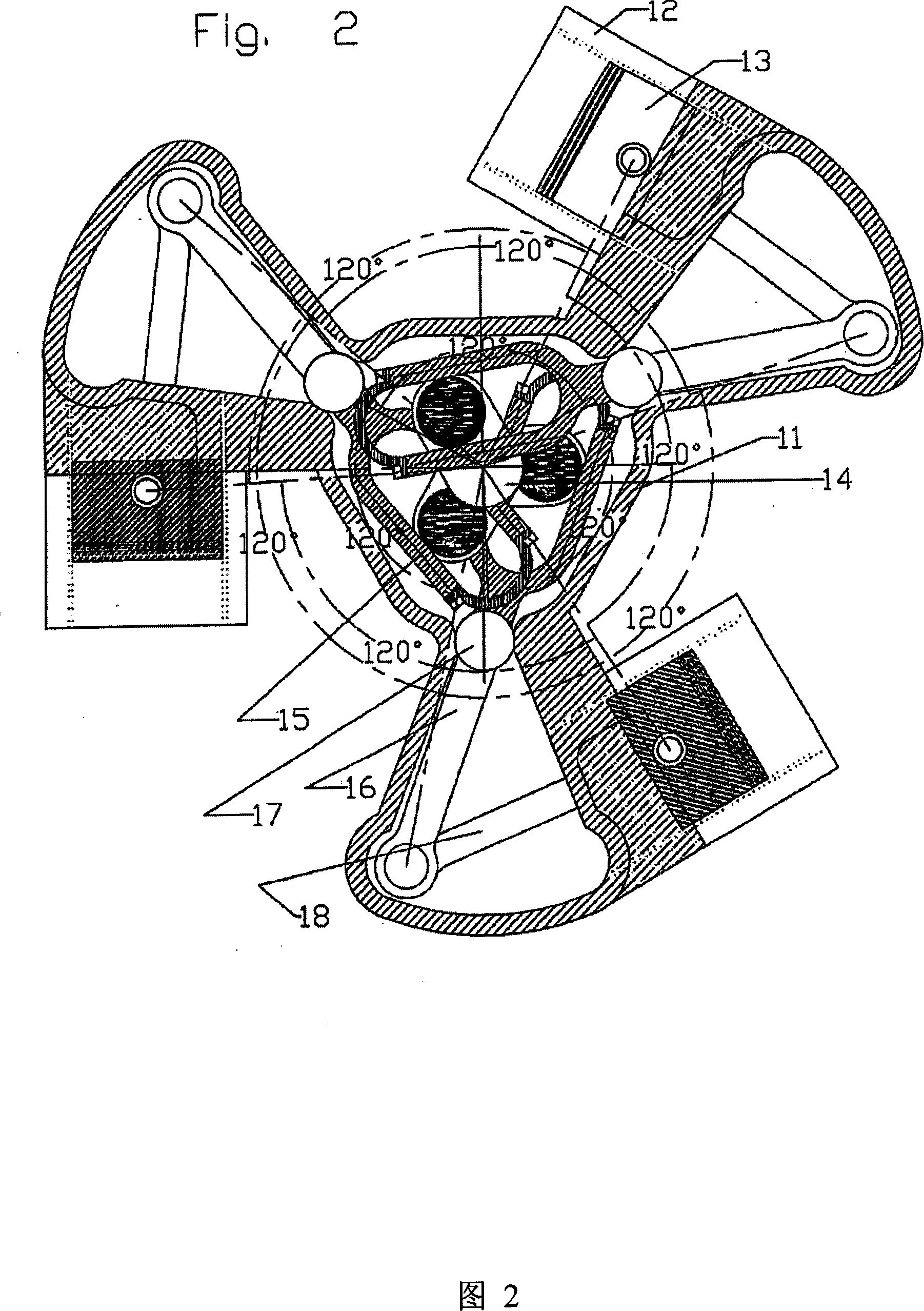

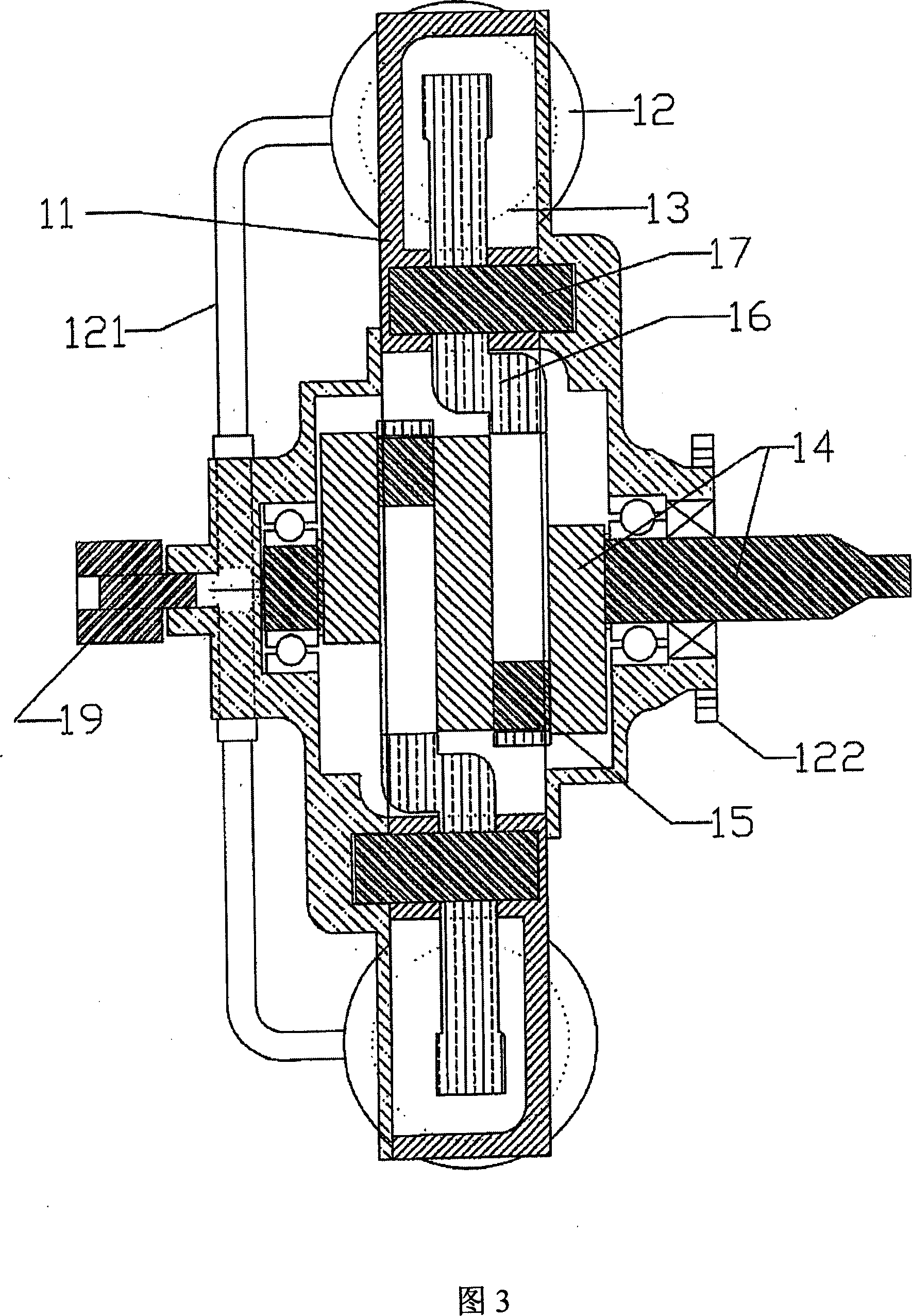

[0021] It can be seen from Figure 1 that the object of the present invention, namely an energy recovery device in a motor vehicle, comprises in the solution shown in Figure 1 a balanced rotary compressor with tangential pistons, including two Pulley module (11) of cylinder (12) and crank (14) with two pins (15). Upon activation of the brake connected to the drive shaft by the clutch, the assembly rotates and the crank (14) remains fixed relative to the system or support. After said rotation has started, the inner arm "a" of the swivel rod (16) slides on the pin (15) of the crank (14), since the crank (14) is fixed, this makes the swivel rod (16) relative to its The shaft (17) is inclined. This angular motion is transferred to the piston (13) via the outer arm "b" and the connecting rod (18). In this way, each rotation of the pulley module drives the piston to complete a complete cycle.

[0022] The cylinder (12) is completely reversed, the piston (13) in the cylinder (12) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com