Separator

A technology of clamping device and inner separation, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of cam drive guide accuracy wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

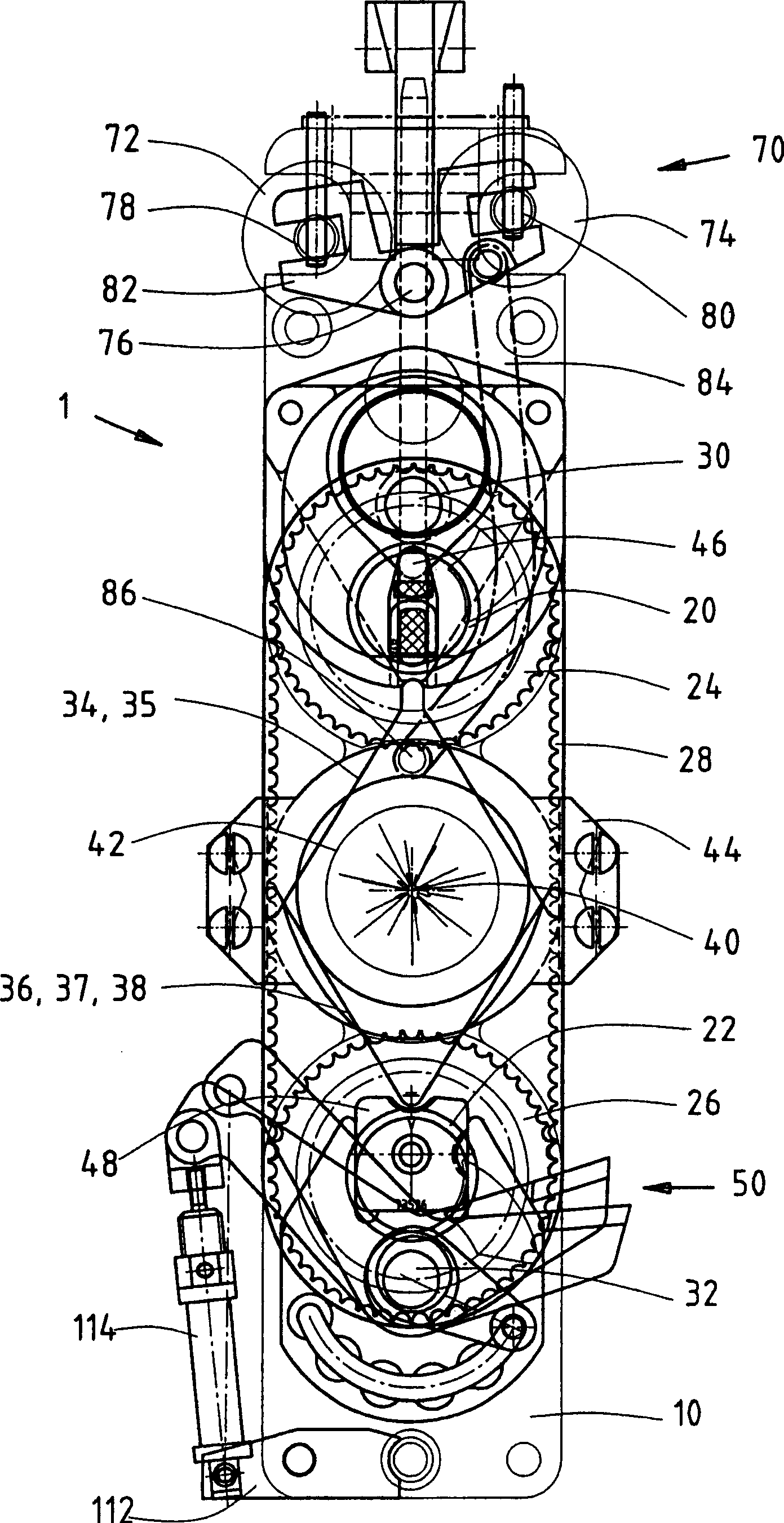

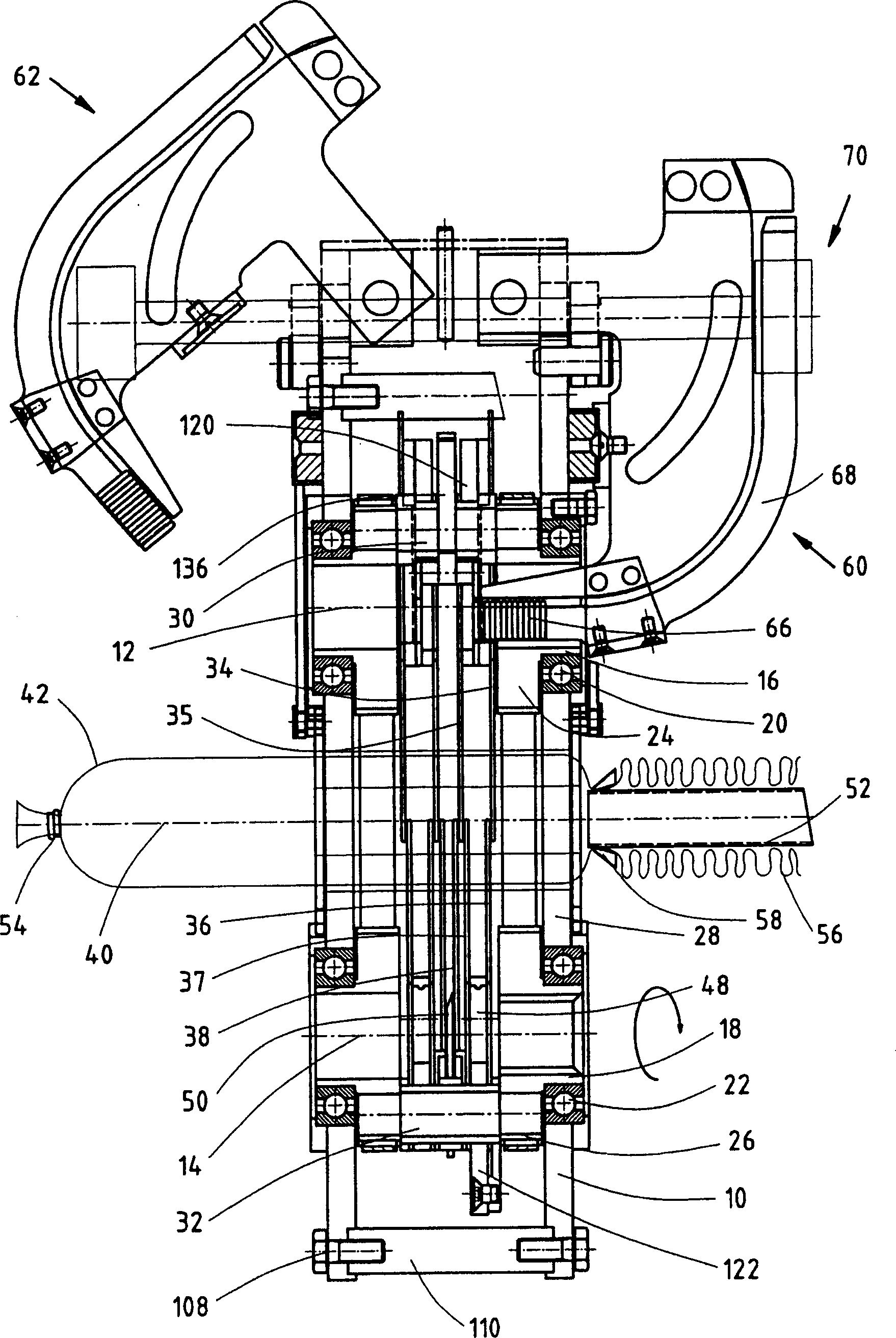

[0028] Figure 1A with 2A The embodiment shown is relative to a Figure 2A The central planes where the planes of the drawings intersect perpendicularly are roughly mirror-symmetrical, so that in the following (to a useful extent) only reference is made to the symmetrical half of the part (and the simplified jig machine) for clarity.

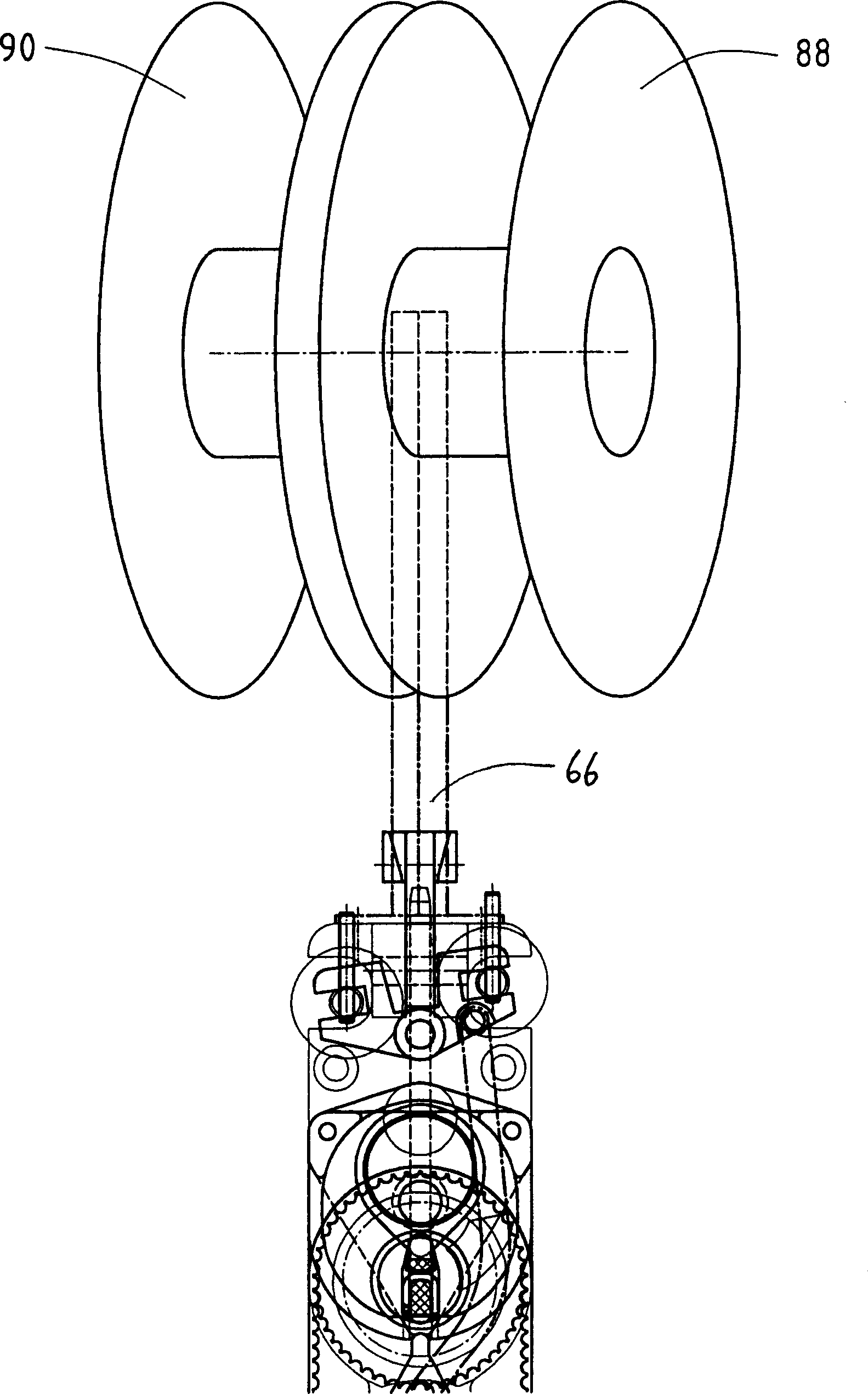

[0029] The dividing device 1 has a fixed support 10, such as a support mounted on a support table not shown. In the frame, an upper hollow shaft 16 and a lower hollow shaft 18 are movably mounted about upper and lower rotational axes 12 , 14 . For this purpose, at one axial end thereof, the hollow shaft 16 , 18 is mounted on one side in a ball bearing 20 , 22 . At their other shaft ends, these hollow shafts support pulleys 24, 26, respectively. The two pulleys 24, 26 can be linked by a toothed belt 28 and thus can be rotated synchronously by a drive (not shown) connected thereto ( Figure 4 ).

[0030] Each pulley 24 , 26 is connected to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com