Reverse rib laminated floor slab and construction method thereof

A technology of laminated floor slabs and ribs, which is applied to floors, building components, buildings, etc., can solve the problems of affecting the appearance of buildings, the span of prefabricated laminated floors is not large enough, and the lack of connection between prefabricated slabs and post-cast concrete, etc., to improve Construction efficiency, saving formwork consumption, and beautiful architectural effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below.

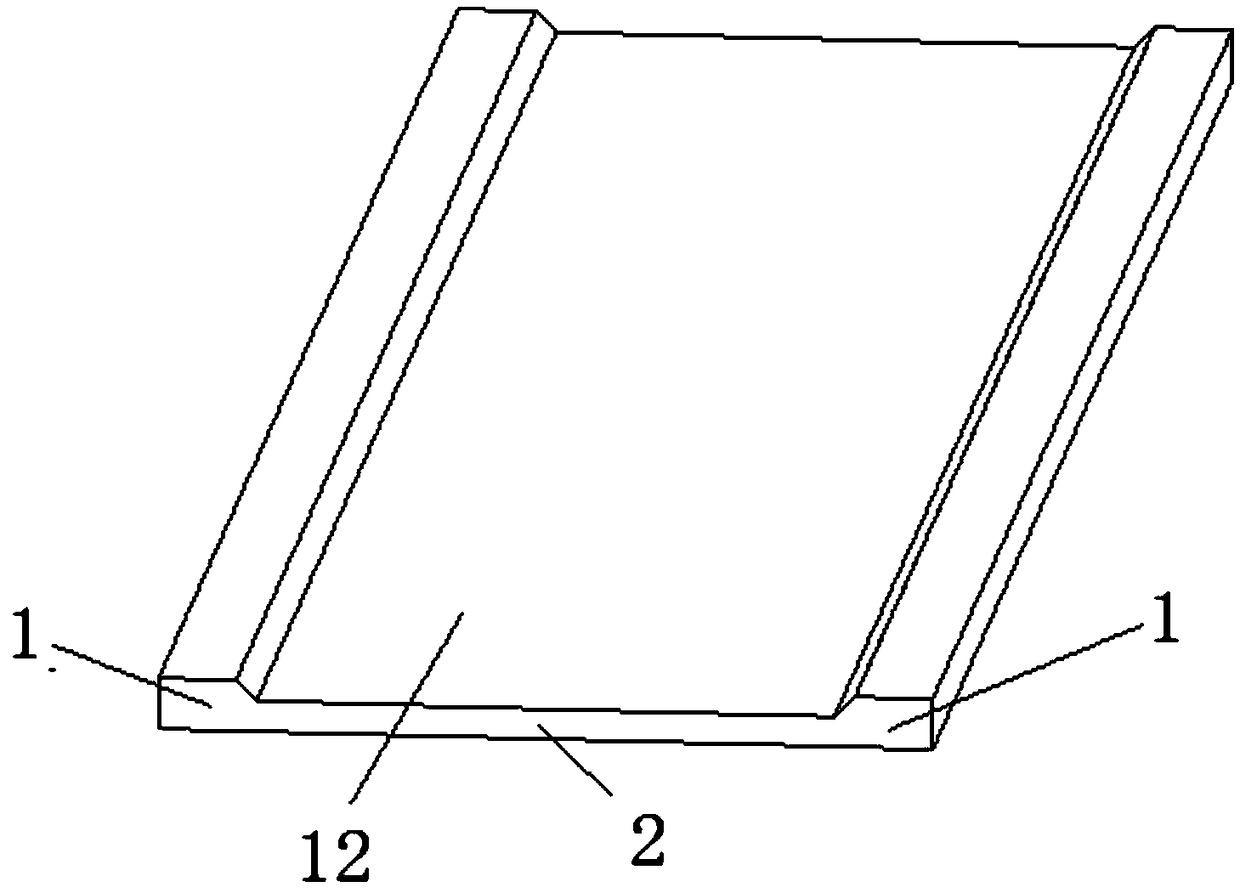

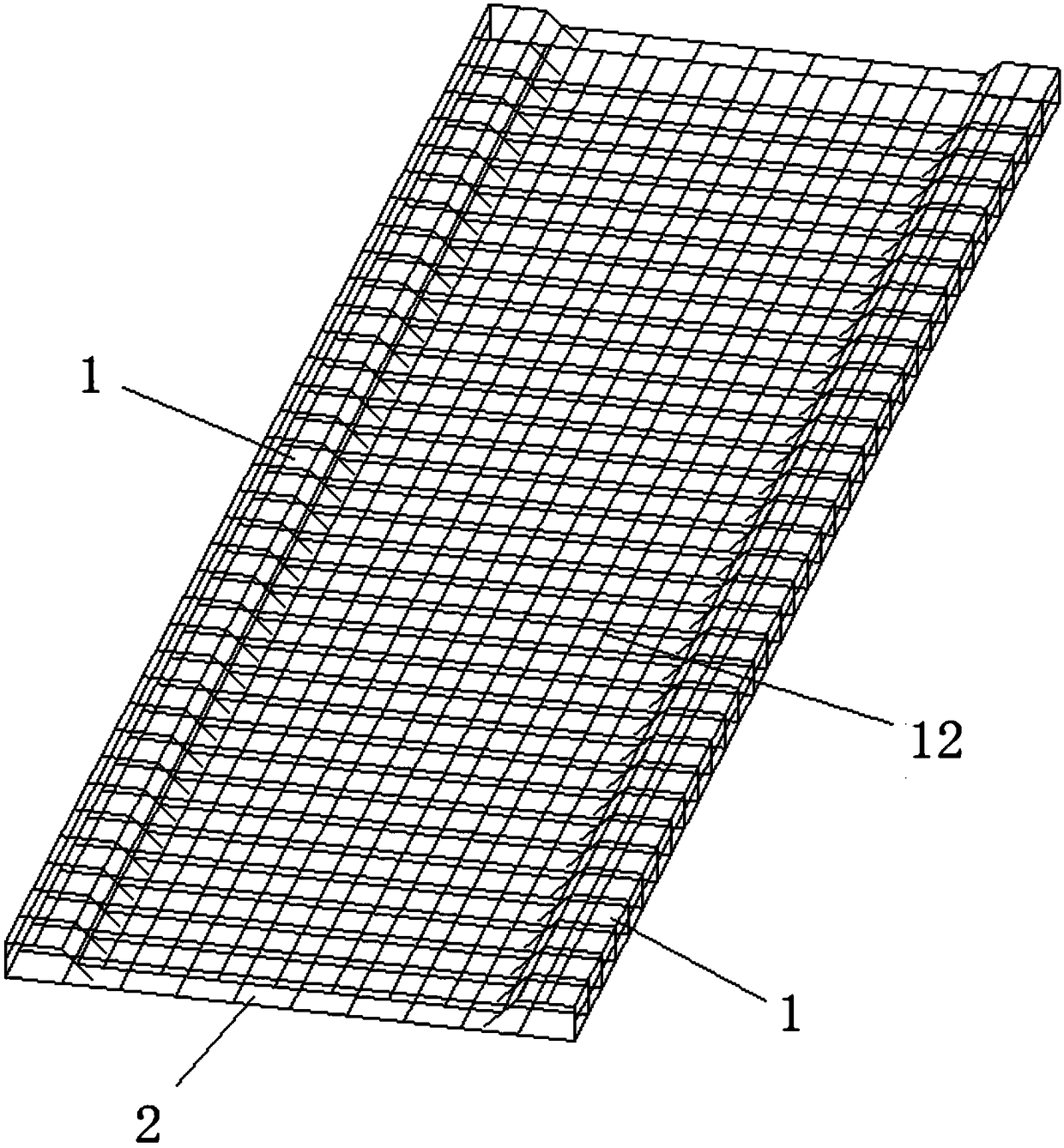

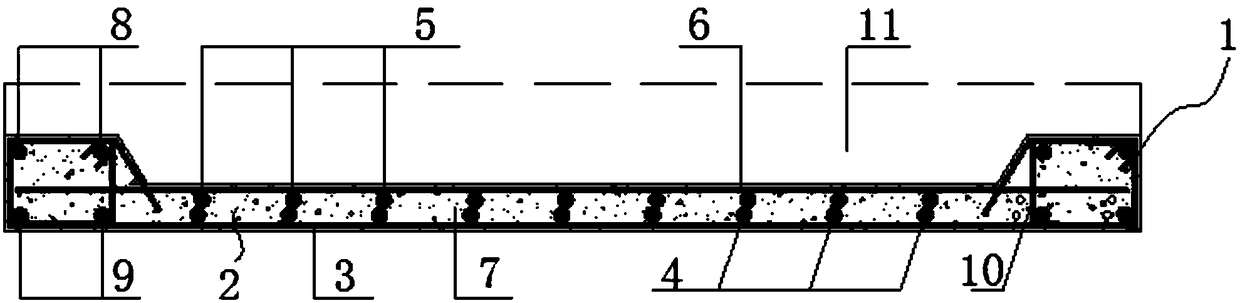

[0036] An anti-rib laminated floor slab includes a plurality of prefabricated anti-ribs spliced together, the upper surface of each prefab anti-rib is provided with a downward recessed groove 12, and a plurality of prefab anti-ribs spliced together A post-poured concrete layer 11 is provided above. The groove 12 makes the post-cast concrete layer 11 and the prefabricated anti-ribbed slab more closely combined. The prefabricated anti-rib plate includes a plate body 2 and two ribs 1 located at both ends of the plate body 2. The bottom surfaces of the two ribs 1 are flush with the bottom surface of the plate body 2, and the top surfaces of the two ribs 1 protrude from the plate. The top surface of the body 2, the inner sides of the two ribs 1 and the top surface of the board 2 form a groove 12, and the two ribs 1 and the board 2 are an integral structure. Both the slab body 2 and the rib body 1 are reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com