Sterile connector

A connector, connecting to technology, applied in the direction of connecting pipes, pipe joints, couplings, etc., can solve the problems of expensive production process, complexity and difficulty of sterile connection production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

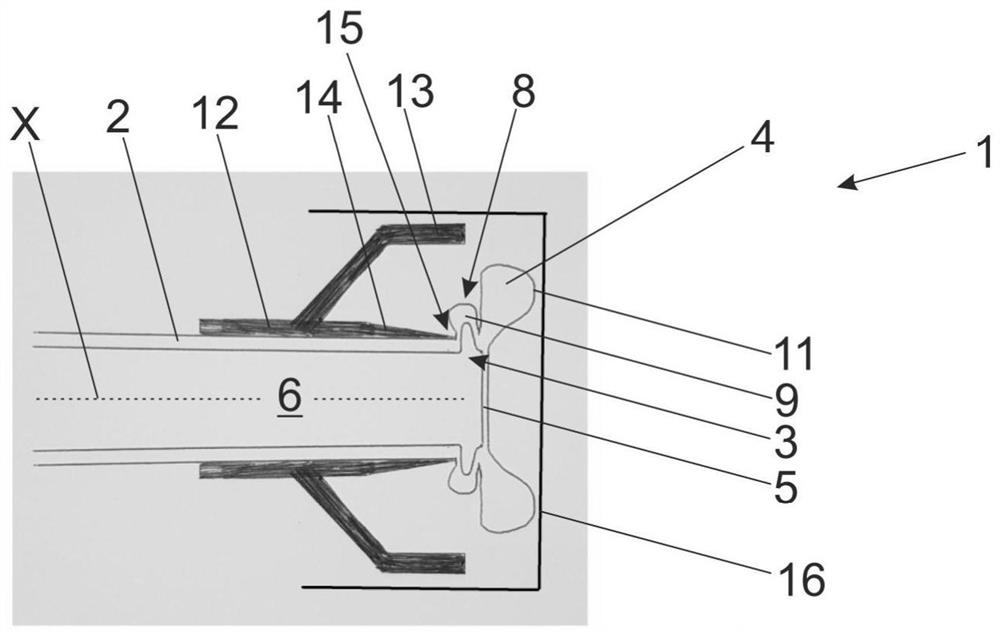

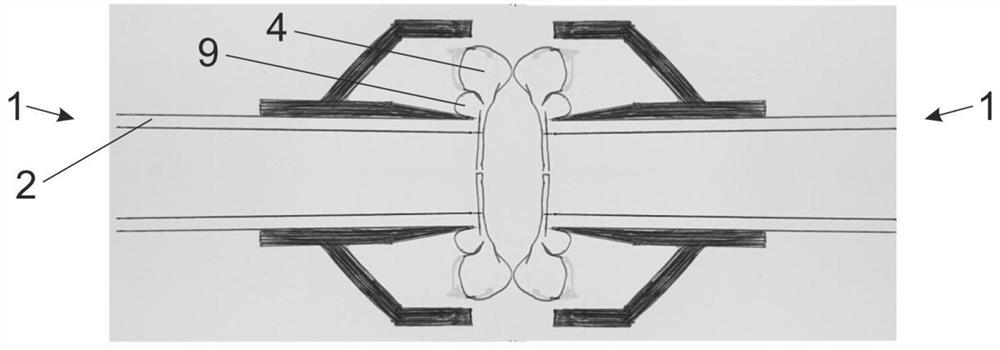

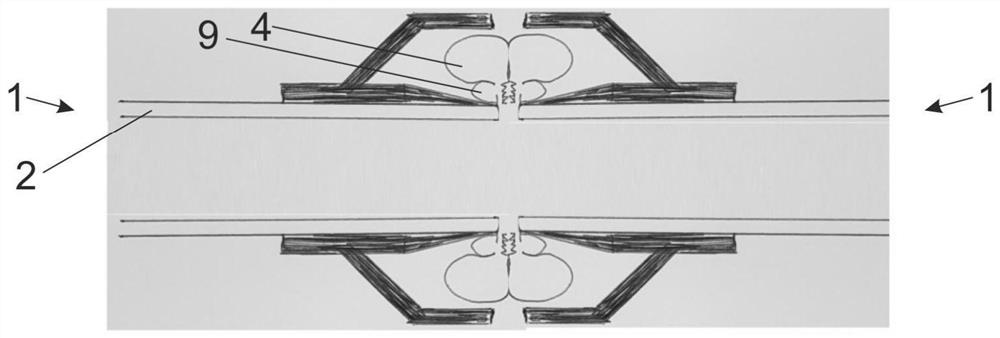

[0055] figure 1 A sterile connector 1 according to the invention is shown. It comprises a pipe section 2 at the end of which an axial projection 4 and a separating layer 5 which closes off the interior 6 of said pipe section 2 are arranged. The interior 6 is the area where the subsequent fluid is delivered. The interior extends along the central axis X of the pipe section 2 .

[0056] A U-shaped element 9 is provided which connects the end section 3 of the pipe section 2 with the base part of the axial projection 4, wherein the first leg of the U-shaped section 9 is attached to the pipe section The end section 3 of 2 and the second leg of said U-shaped section 9 are attached to said axial protrusion 4 .

[0057] Accordingly, a connector element 12 is provided which comprises a skirt 13 configured to surround the end of said pipe section 2 when said pipe section 2 is connected to said other pipe section and / or said other corresponding part. section 3 and the axial protrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com