Discrete face mold device for plate material heat forming

A thermoforming, discrete technology, applied in the field of discrete profile molds, can solve the problems of complex hydraulic cylinder stroke control system, high cost, complex structure, etc., and achieve the effect of convenient operation and maintenance, low cost, and improved forming quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

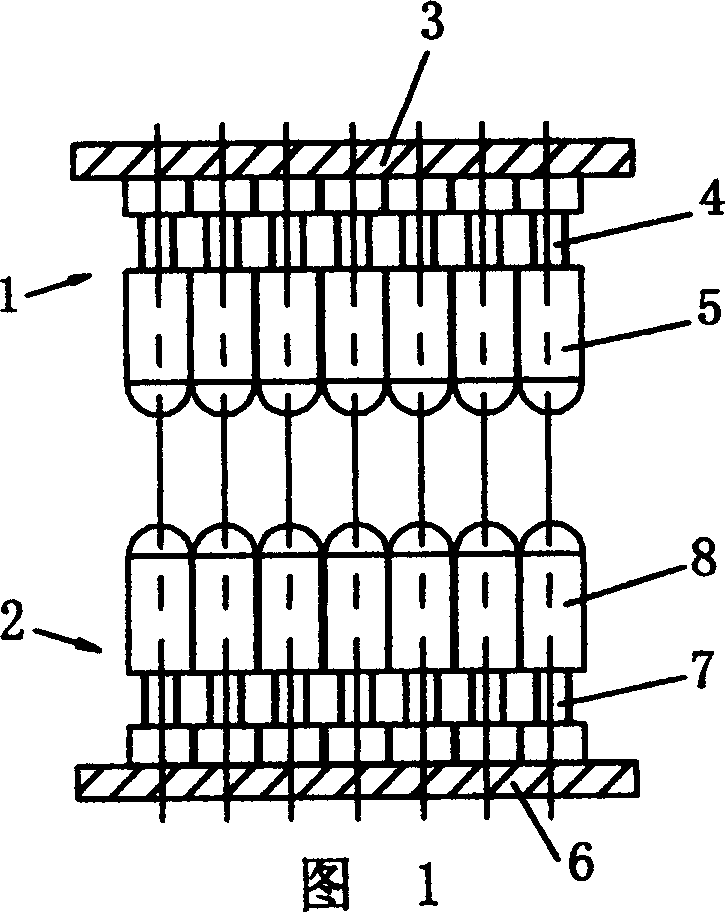

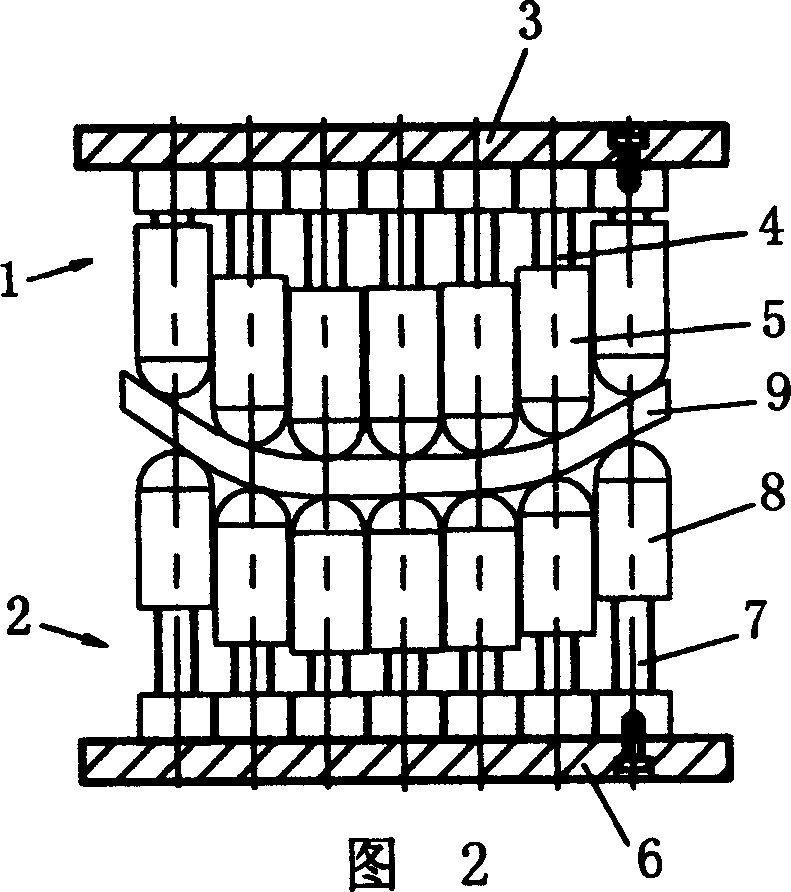

[0022] Example 1. See Figures 1 and 2. Comprising an upper die 1 and a lower die 2, the template 3 of the upper die 1 is provided with a number of closely arranged punches, and the punches are composed of a screw 4 connected to the template 3 and a head body 5 matched with the screw. The body 5 can be displaced along the axial direction of the screw 4; the template 6 of the lower die 2 is provided with a number of closely arranged punches, and the punches are composed of a screw 7 connected to the template 6 and a head body 8 matched with the screw , The head body 8 can be displaced axially along the screw rod 7; the punch on the upper die corresponds to the punch on the lower die. In this example, the corresponding punches on the upper and lower dies are on the same axis. The operation process is, firstly, through an additional adjustment device, adjust the height of the upper and lower die punch heads relative to the template to form the required forming surface, and drive...

Embodiment 2

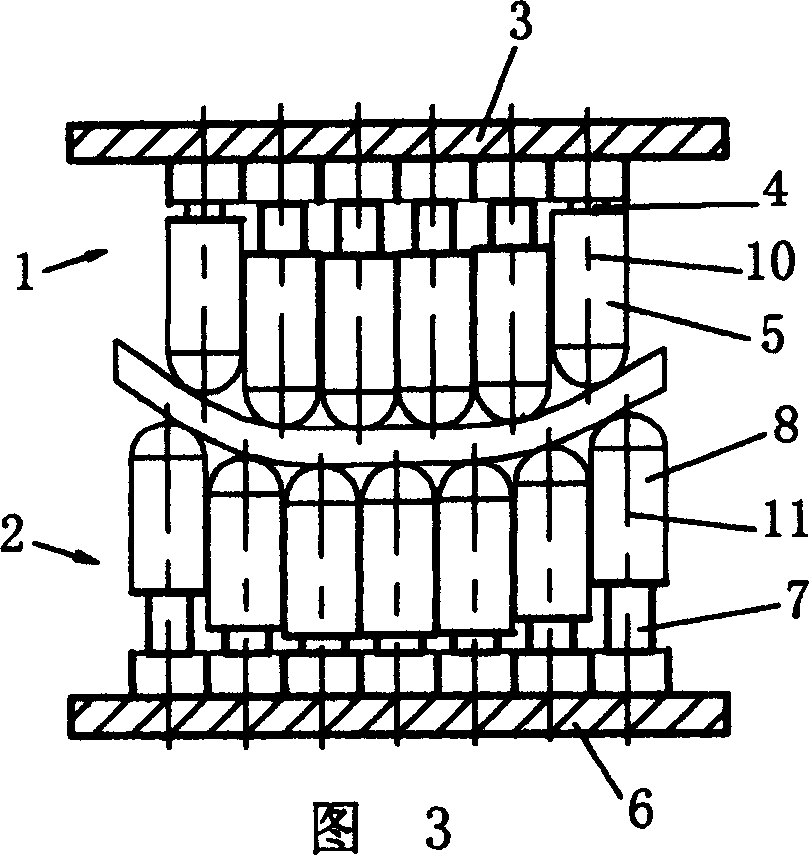

[0023] Example 2. See Figure 3. In this example, the punch on the upper die 1 and the corresponding punch on the lower die 2 are staggered and not on the same axis, that is, the axis 10 of the punch on the upper die 1 and the axis 11 of the corresponding punch on the lower die 2 Stagger each other. Others are with embodiment 1.

[0024] Figure 4 It is a top view schematic diagram of the corresponding punches on the same axis in the upper and lower dies in Fig. 1 and Fig. 2, the top view projections of the corresponding punches on the upper and lower dies overlap, and the center distance between each adjacent two punches in the upper and lower dies is D; Figure 5 and Figure 6 Respectively represent the form of the corresponding punch misalignment in the upper and lower dies, Figure 5 The solid line and dotted line in the figure represent the positions of the punches of the upper and lower dies respectively, indicating the relative displacement in the X and Y directions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com