Reversing formwork for manufacturing cast-in-situ prestressed concrete cylindrical fan foundation

A wind turbine foundation and concrete technology, which is applied in the direction of basic structure engineering and construction, can solve the problems of high cost and poor bending resistance, and achieve the effect of large bending moment, sufficient application and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

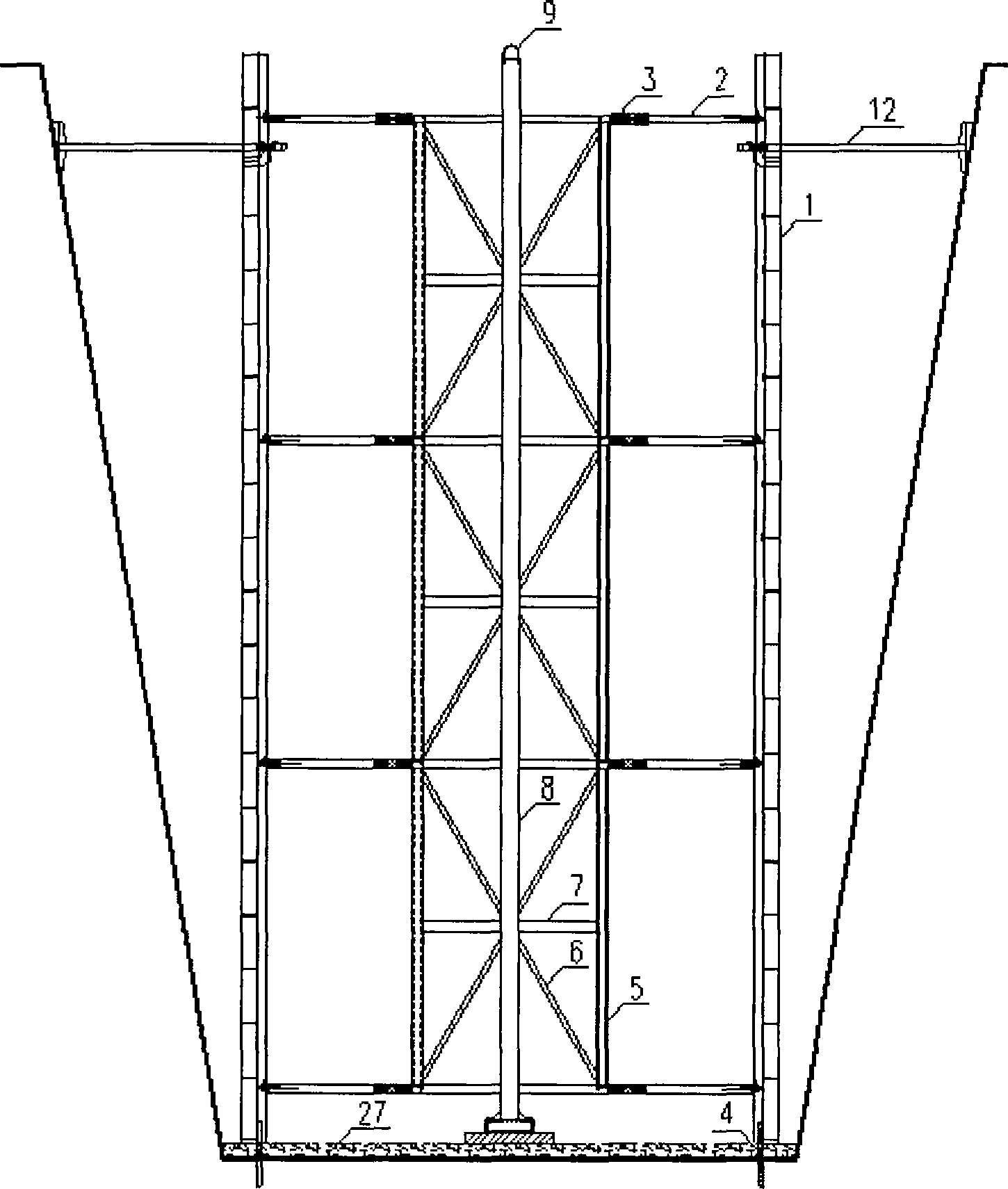

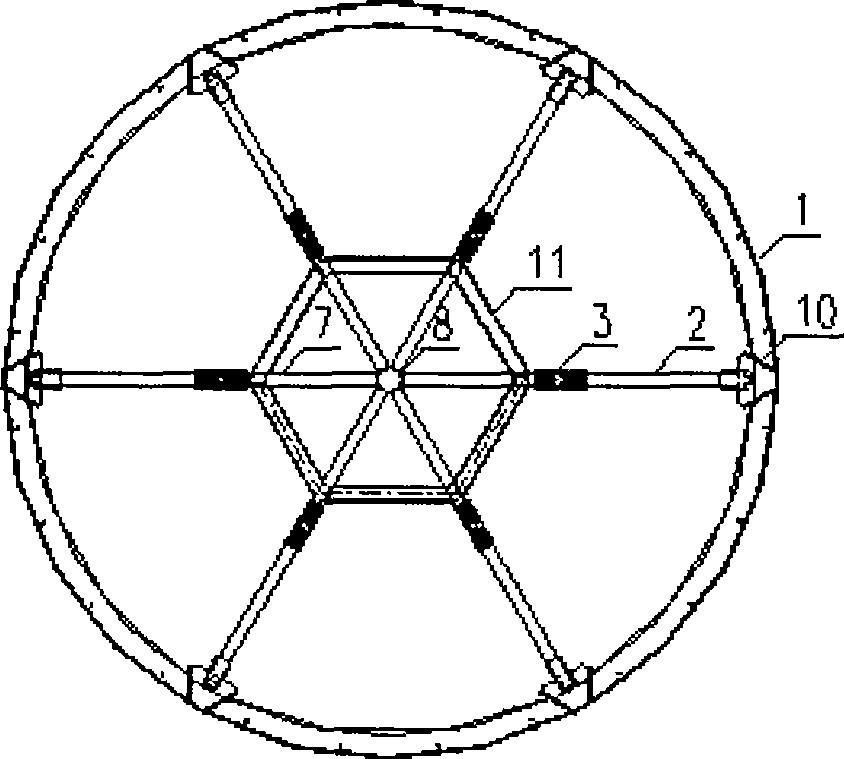

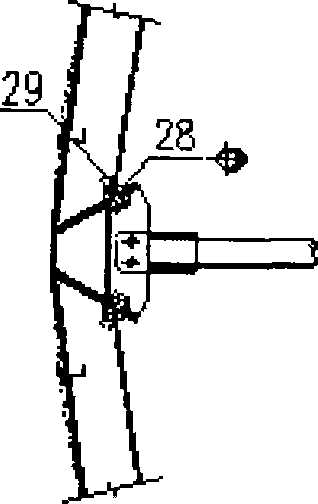

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the reverse formwork consists of the reverse formwork tube wall 1, the reverse formwork horizontal strut 2, the flower basket bolt 3, the bottom positioning pile 4, the inner truss column 5, the inner truss inclined bar 6, the inner truss cross bar 7, the inner vertical Center column 8, hook 9, reverse formwork special-shaped column 10, inner truss cross brace 11, outer strut 12, reverse formwork special-shaped column oval hole 28, reverse formwork connecting bolt 29 are formed. When in use, hoist the integrally assembled inverted formwork into the excavated foundation pit, pour plain concrete 26 in the space between the inverted formwork tube wall 1 and the foundation pit wall, and shrink the flower basket bolt 3 after the plain concrete 26 is cured. , the connecting bolt 29 between the special-shaped column 10 of the reversed formwork and the cylinder wall 1 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com