High-bending-moment carbon-fiber reinforced concrete pole and manufacturing method thereof

A carbon fiber reinforced concrete, carbon fiber technology, applied in the direction of manufacturing tools, ceramic molding machines, building types, etc., can solve the problems of separation of steel bars and concrete, increased weight of poles, difficult transportation and installation, etc., to save steel, reduce prices, and avoid duplication. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

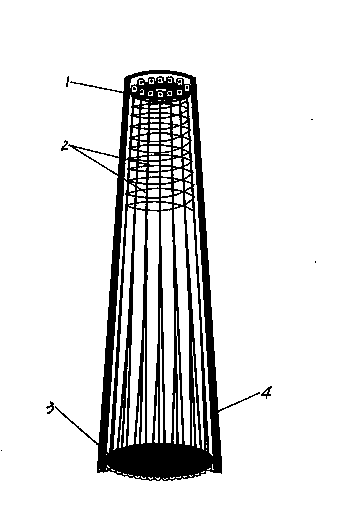

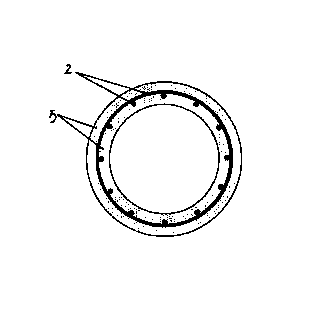

[0008] as attached figure 1 , 2 As shown, it is a wire rod whose frame is made of carbon fiber rope 2 and poured with high-grade concrete 5; The pier heads 1 and 3 are then poured with high-grade concrete and steam-cured using the traditional reinforced concrete pole centrifugal method to make full carbon fiber concrete poles.

[0009] Take the production of a commonly used slightly diameter of 190mm and a 15-meter round rod of 365 mm as an example.

[0010] Cut off one carbon rope of 15.1m, 10.1m and 5.1m first, and glue one end of the 10.05m and 5.05m carbon ropes to one-third and two-thirds of the 15.1m carbon rope respectively with epoxy glue , put one end through the upper pier head of the steel mold, and fix it with a wedge hinged C-shaped metal wire clamp, and the other three wires pass through the lower pier head of the steel mold, and fix it with a wedge hinged C-shaped metal wire clamp. One longitudinal tendon, like this, make a total of 16 longitudinal tendons to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com