Patents

Literature

31results about How to "Small starting force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

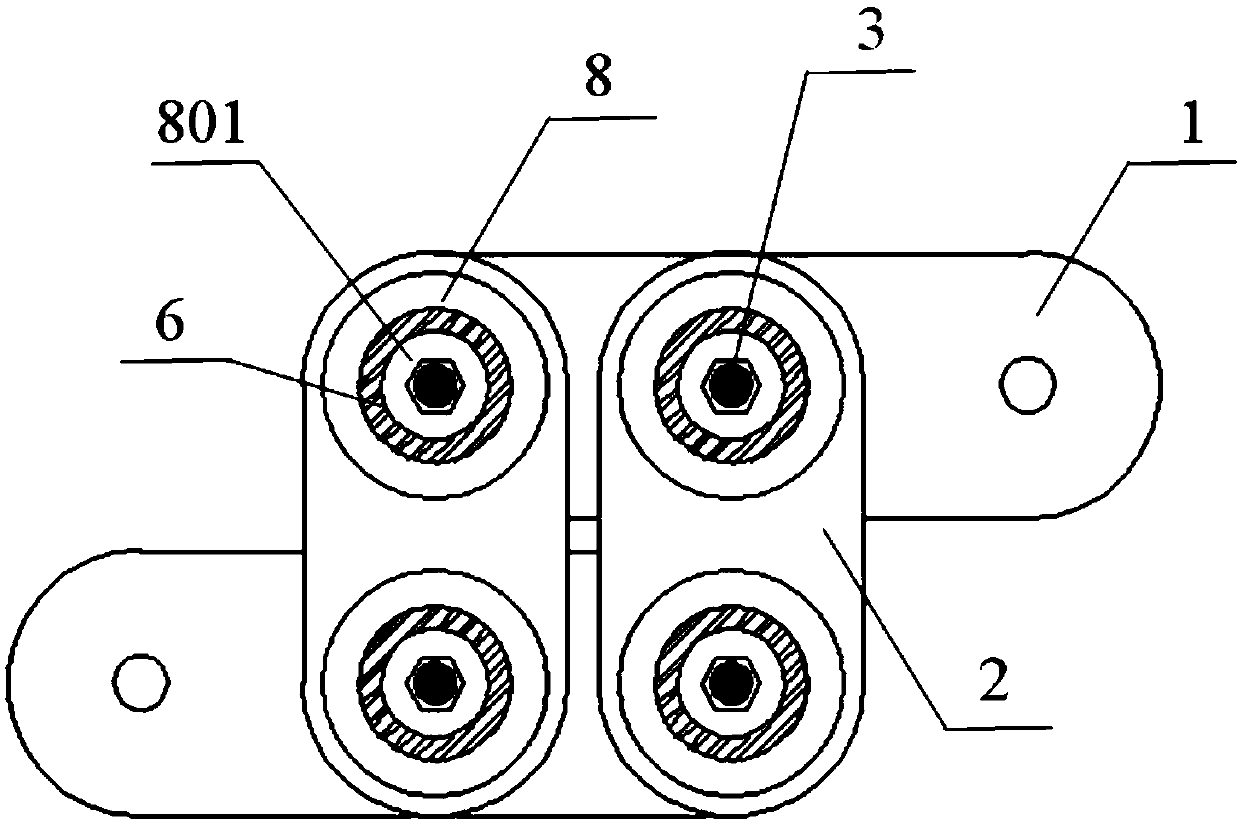

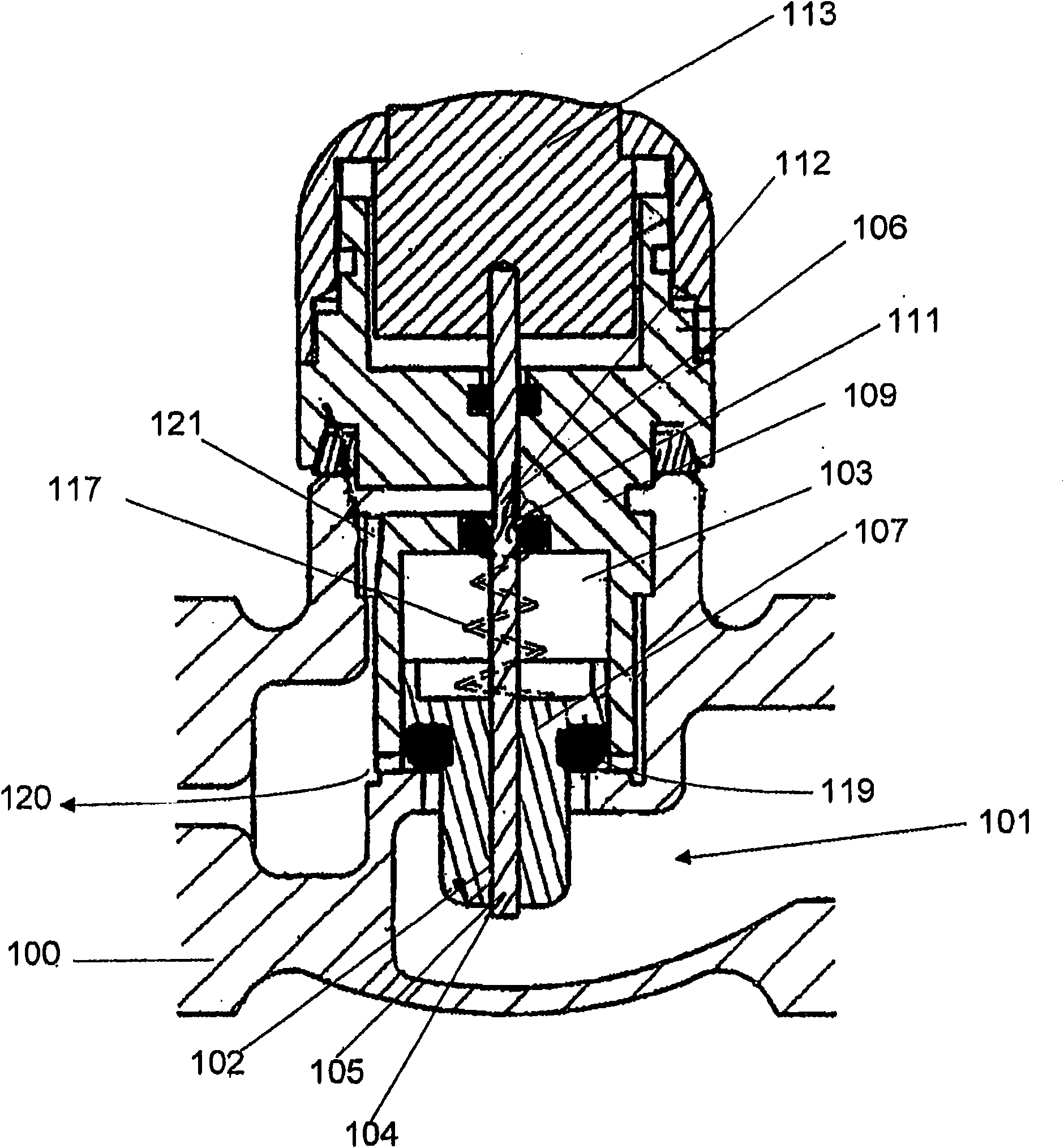

Hydraulic variable-diameter centralizer

InactiveCN103541666ASmall starting forceEasy to driveDrilling rodsDrilling casingsTriangular prismEngineering

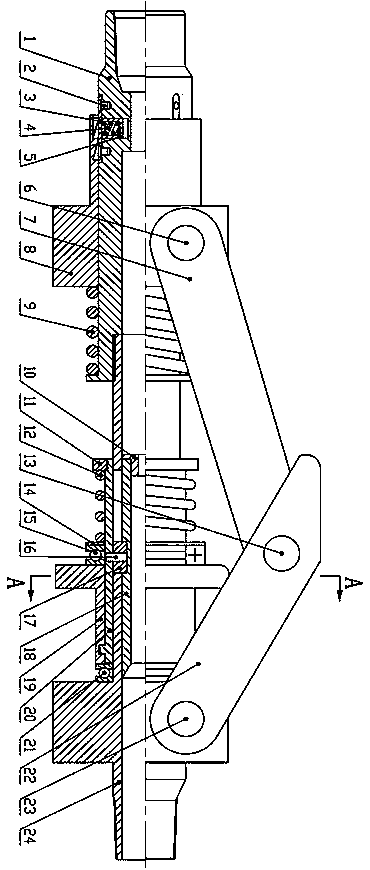

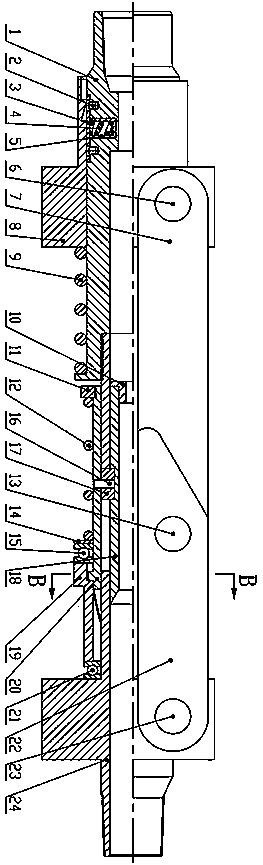

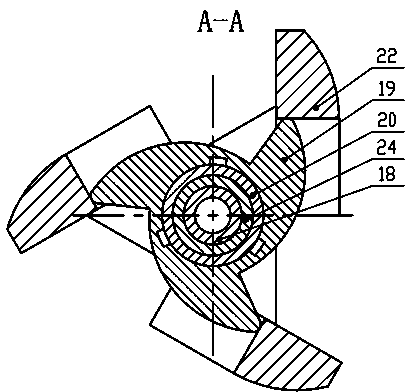

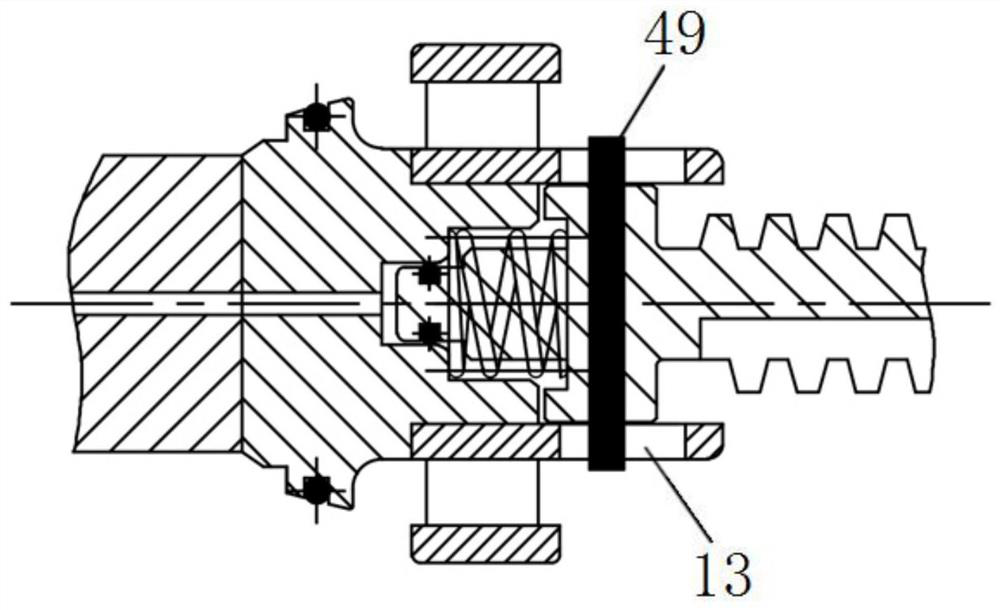

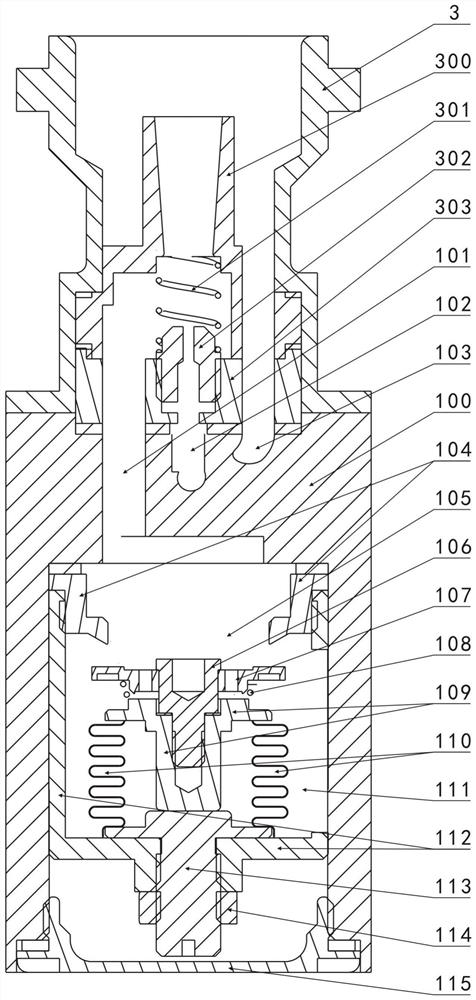

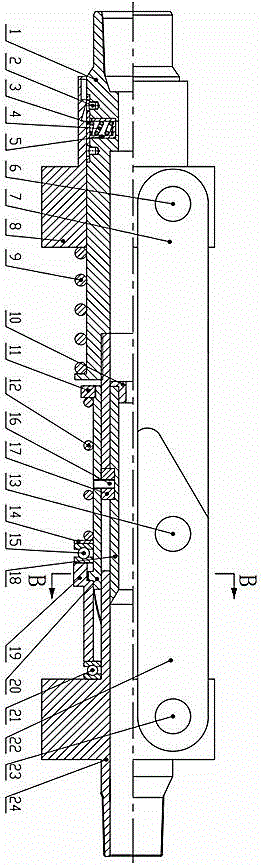

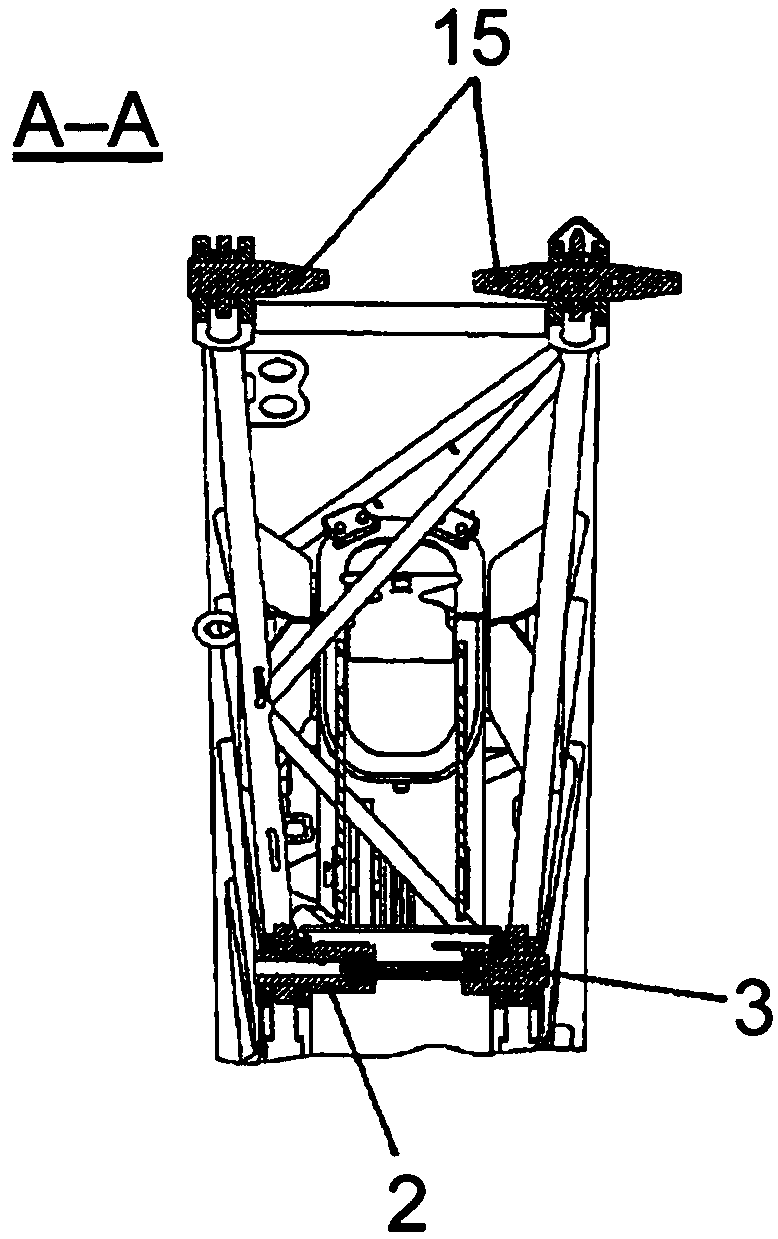

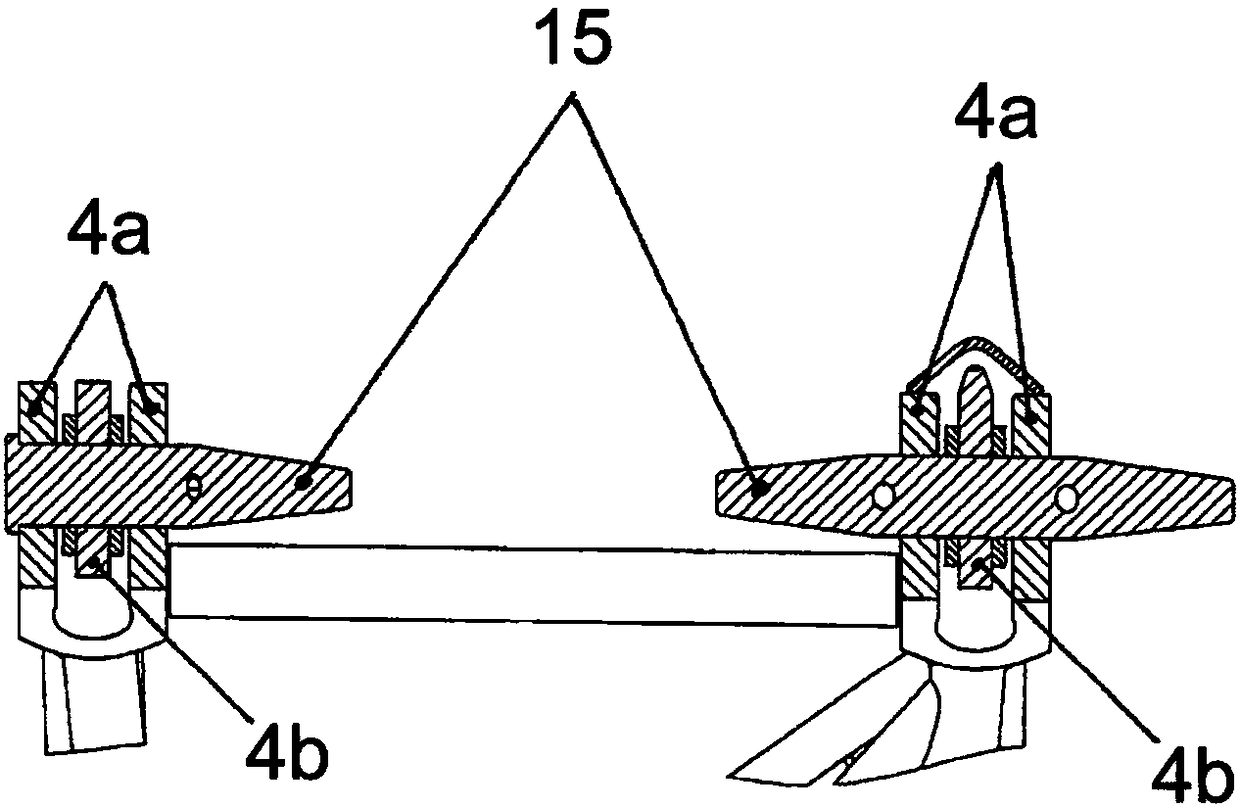

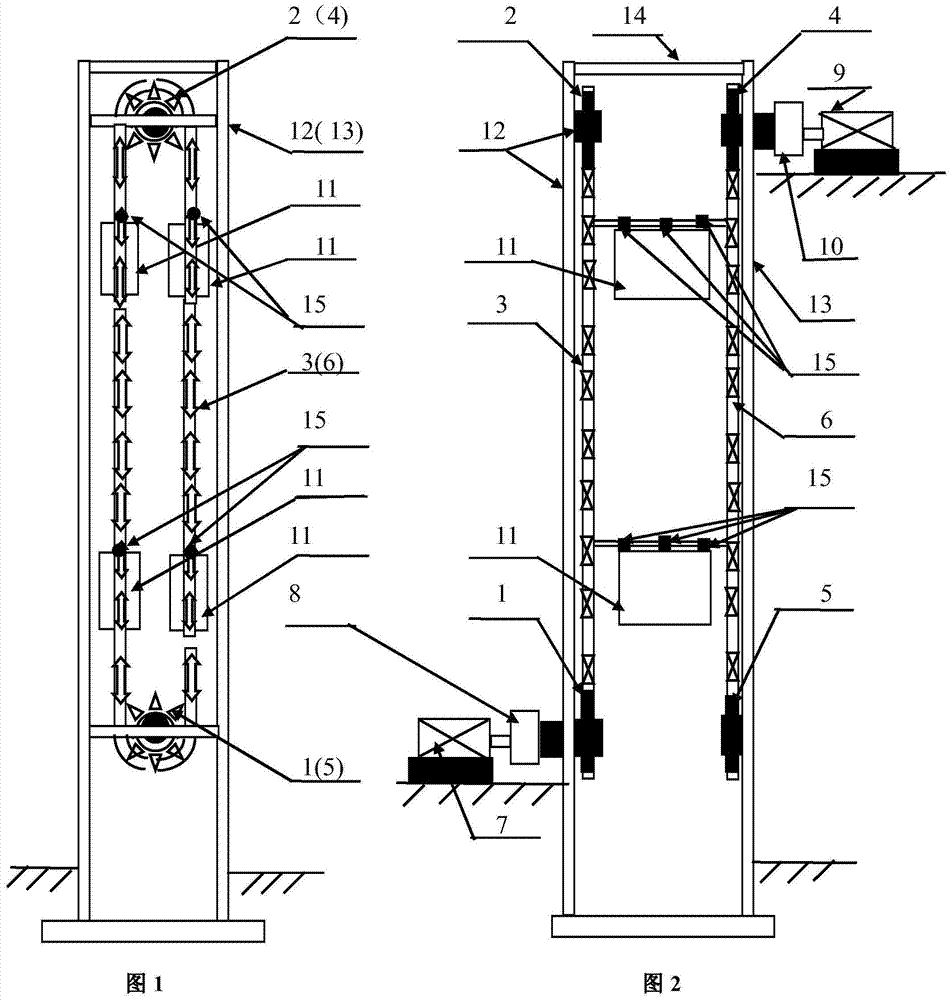

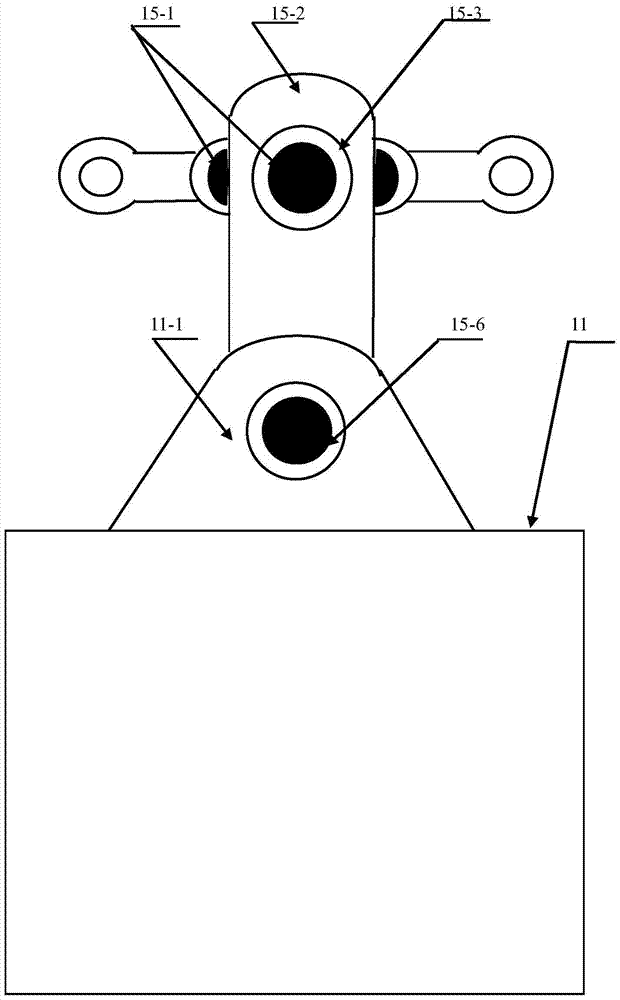

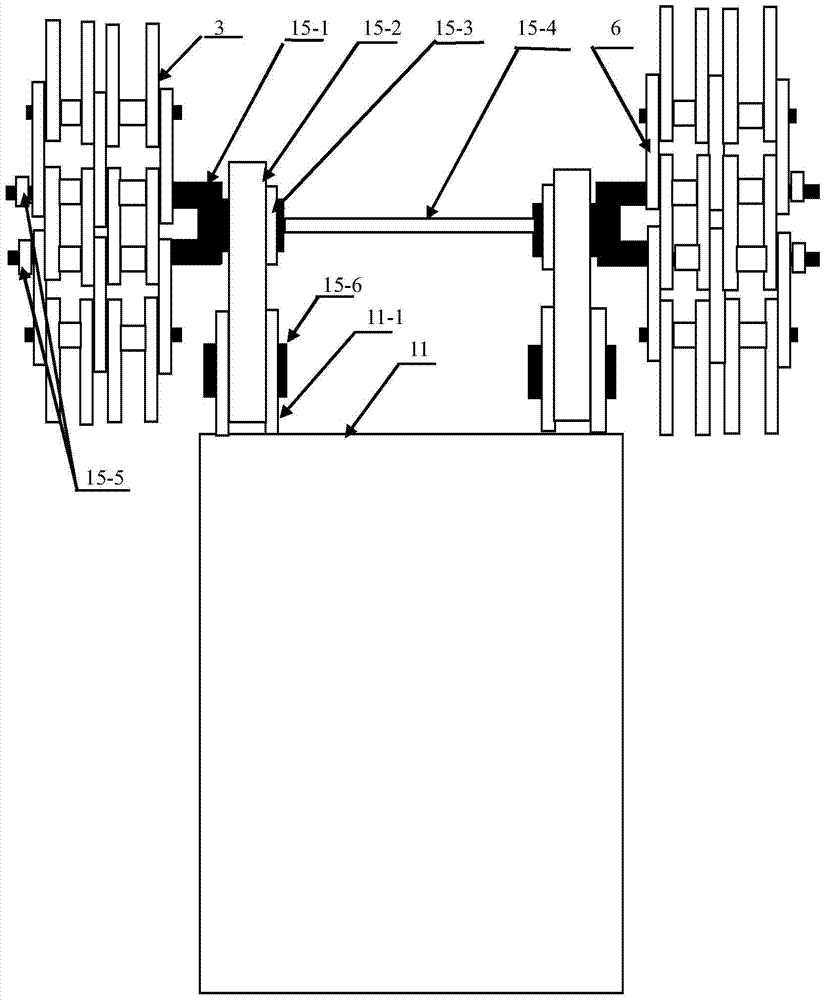

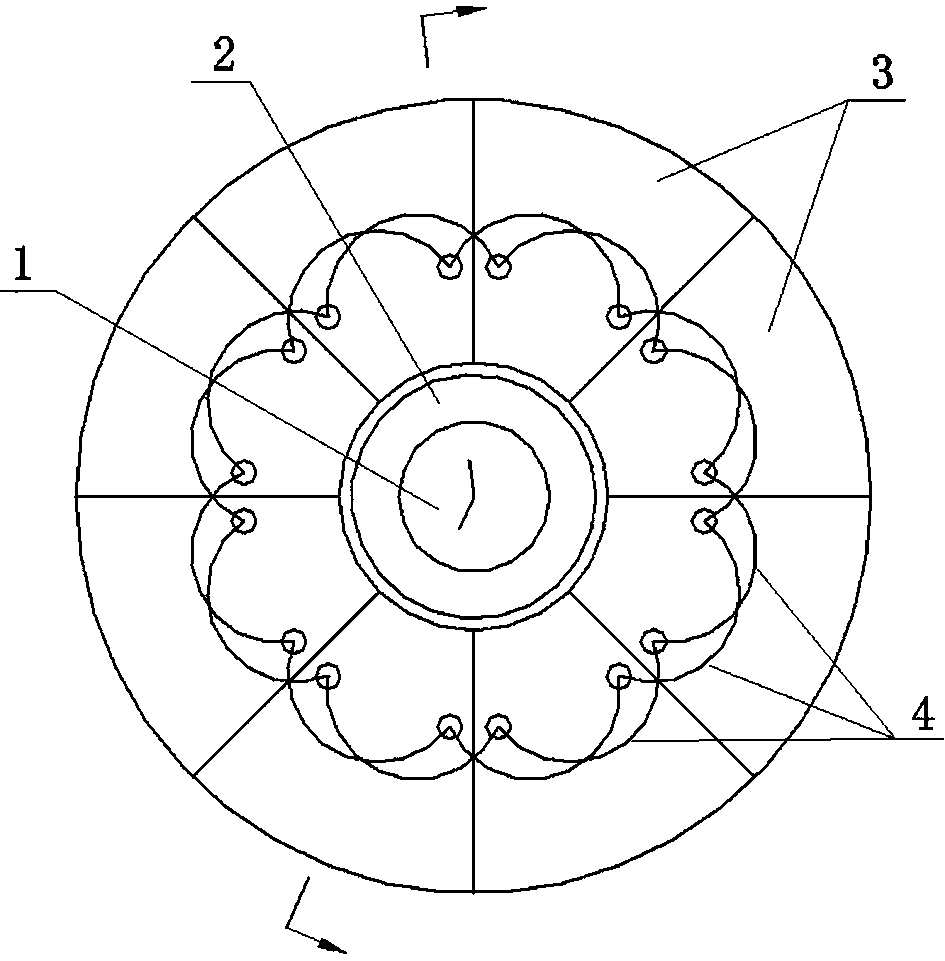

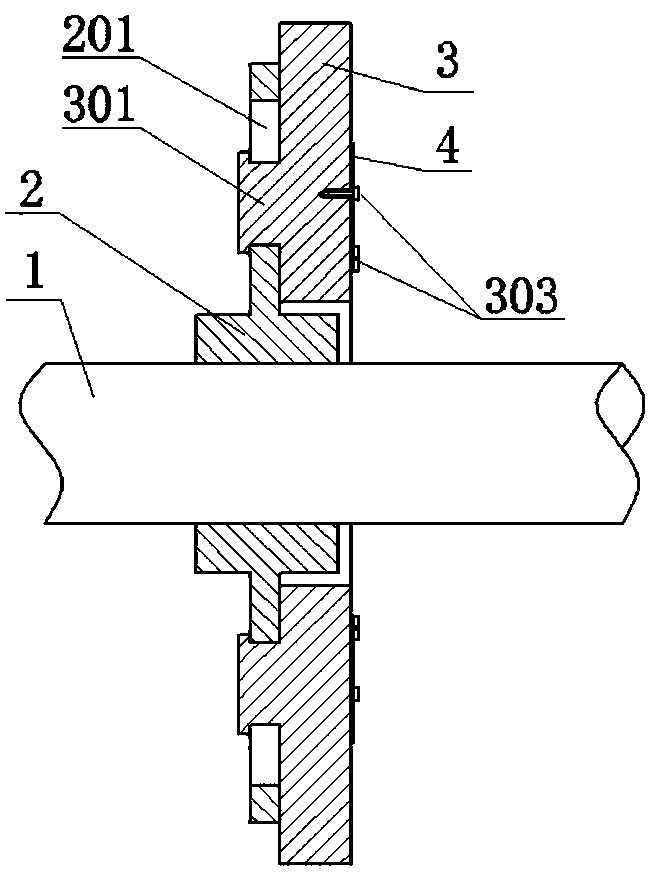

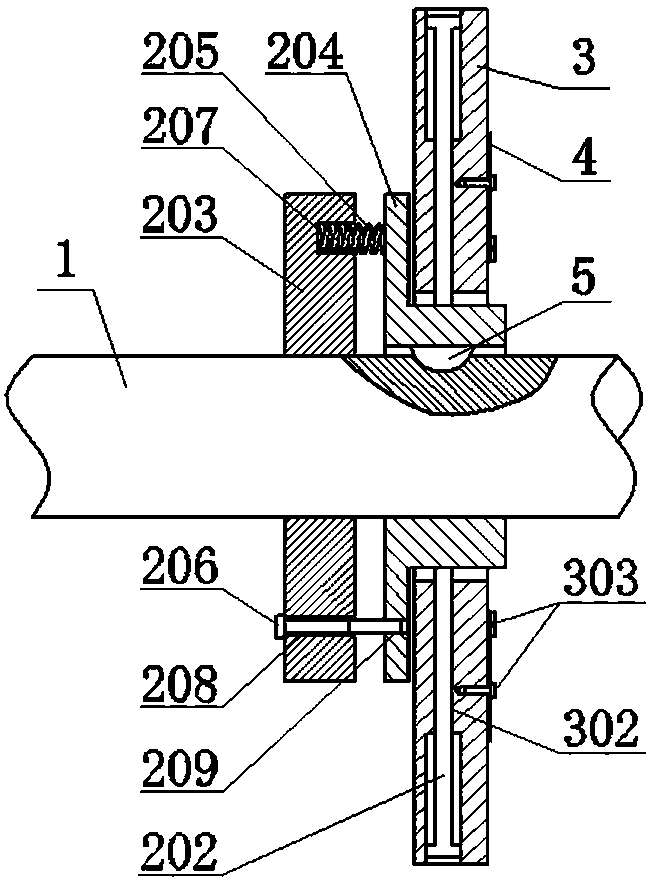

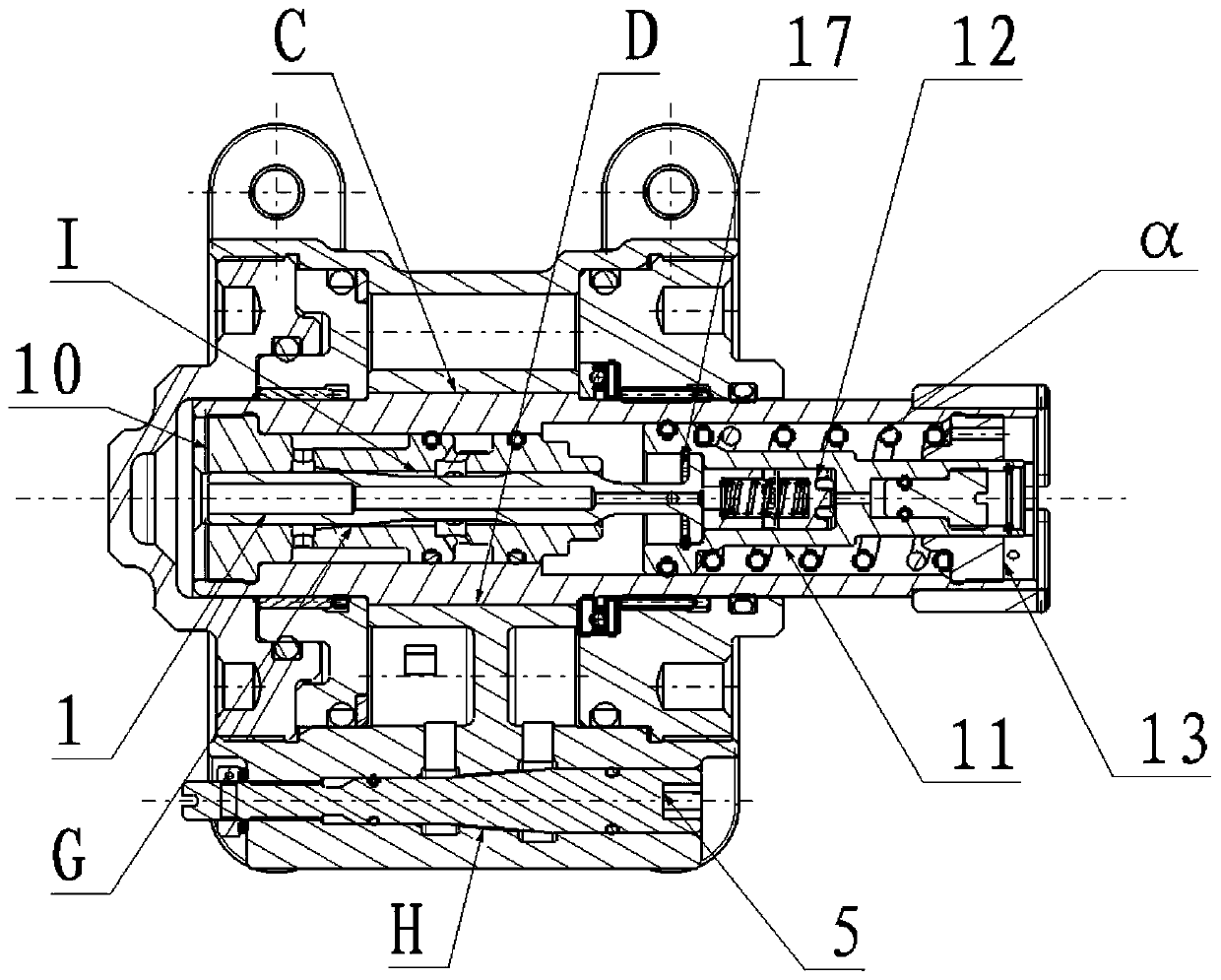

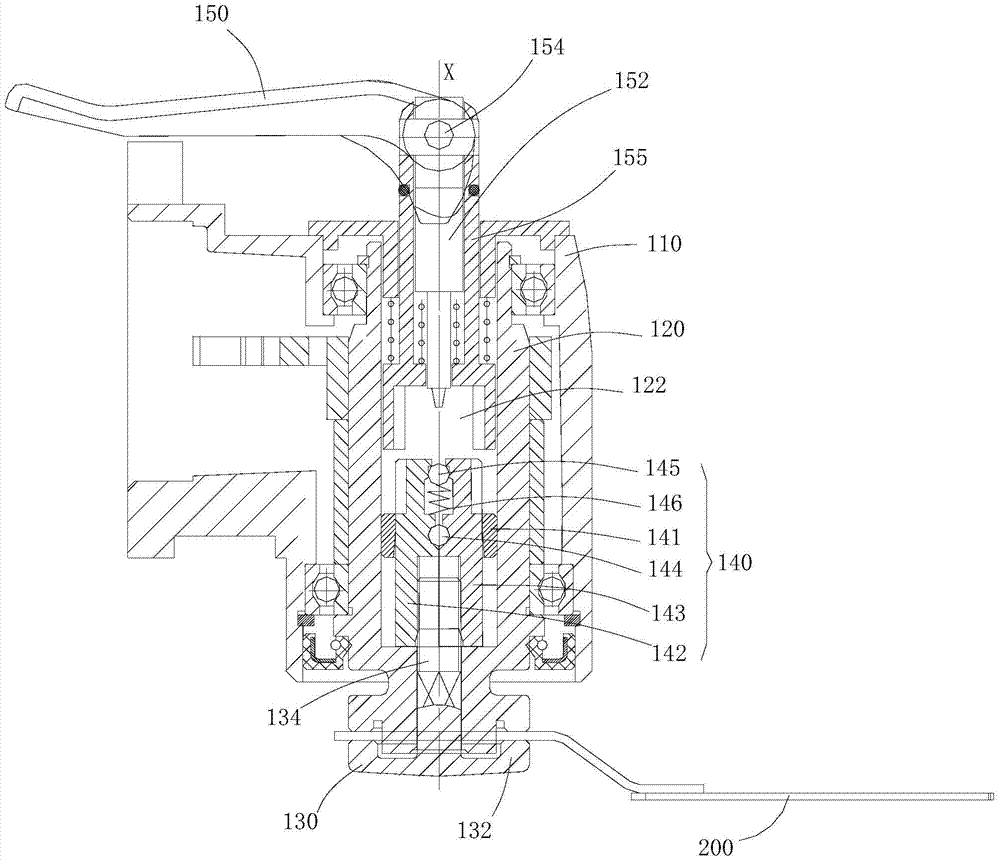

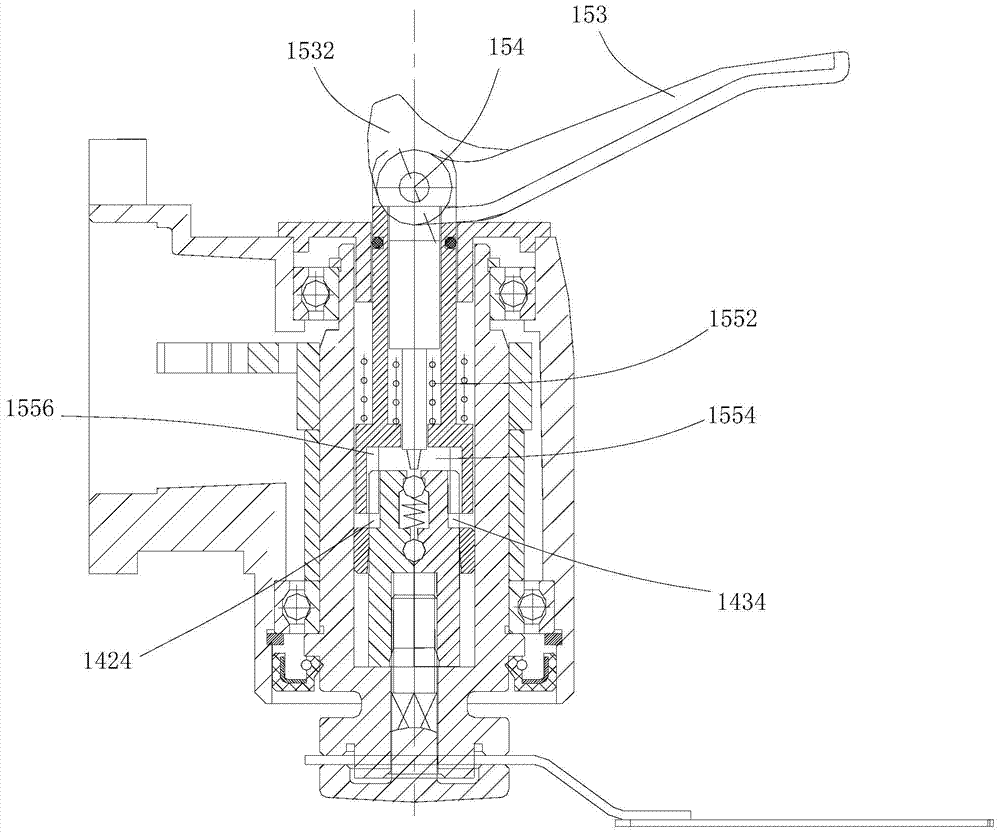

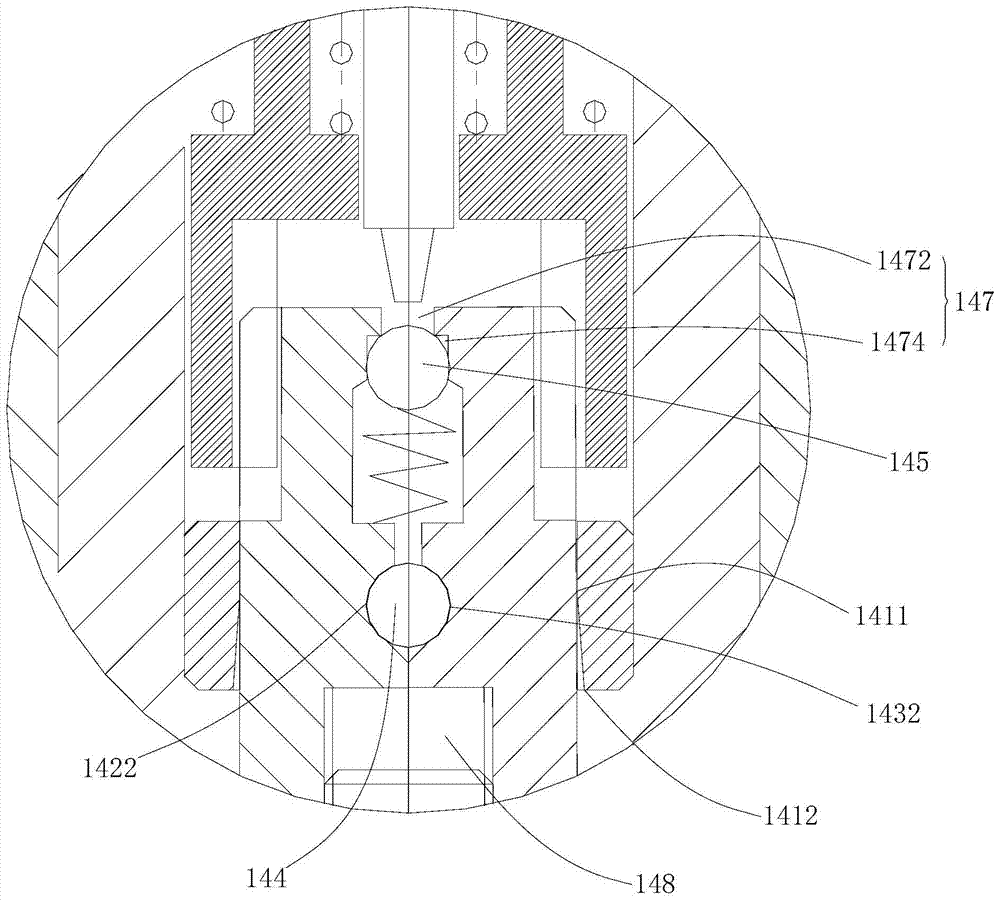

The invention relates to a hydraulic variable-diameter centralizer used for convention oil gas well drilling and solid mineral resource well drilling, and the hydraulic variable-diameter centralizer solves the problems that an underground variable-diameter centralizer is large in starting force and short in installation distance. According to the technical scheme, sliding blocks penetrate through lower cylindrical body through grooves and are embedded into inner central tube annular grooves, an outer central tube is arranged in a revolving cylindrical body in a sleeved mode, protrusive splines outside the outer central tube are embedded into spiral grooves in the revolving cylinder body, a spring c is arranged outside the outer central tube in a sleeved mode, an upper cylindrical body is in threaded connection with a lower cylindrical body, a spring b is arranged outside the upper cylindrical body in a sleeved mode, and a sliding sleeve is arranged in the upper cylindrical body in a sleeved mode. A centralizing arm a is hinged to the triangular prism surface of the sliding sleeve, a centralizing arm b is hinged to the triangular prism surface of the lower cylindrical body and hinged to the centralizing arm a, a locking cylinder is placed in an upper cylindrical body through hole, a spring a is put in the locking cylinder, and a press plate and the upper cylindrical body are fixed through screws a. The hydraulic variable-diameter centralizer converts axial motion of the inner central tube and the outer central tube into circumferential direction rotation of the revolving cylindrical body, converts axial thrust generated by hydraulic pressure into circumferential direction centralizing force, and is reliable in supporting and large in installation distance.

Owner:SOUTHWEST PETROLEUM UNIV

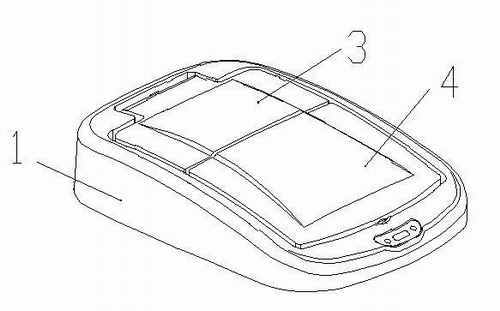

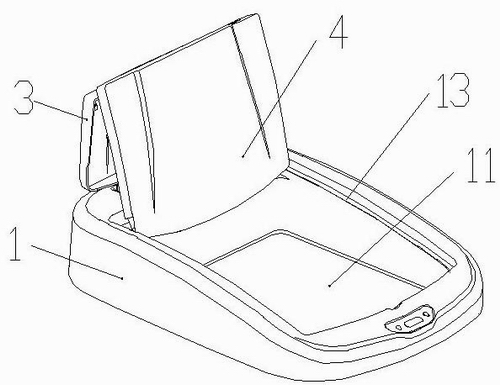

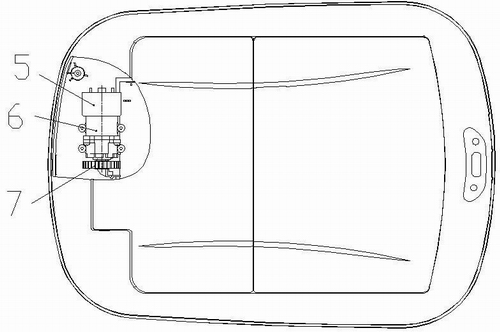

Upturning and folding barrel cover device

InactiveCN101891050AGravity does little workExtended service lifeRefuse receptaclesEngineeringFront cover

The invention relates to an upturning and folding barrel cover device, which comprises a barrel cover seat ring with a material feeding through hole. The device is characterized in than an opening of the barrel cover seat ring is provided with a folding cover plate which is formed by the articulation between a front cover and a back cover, the two sides at the front of the front cover are provided with matching parts which are restrained to run on tracks at the two sides of the seat ring, and a rotation part which is connected with the back side part of the back cover is arranged at the back side of the seat ring to control the back cover to be upward and downward overturned. The device can open and close the barrel cover, has smaller power for opening the cover, and does not occupy more space at the left part, the right part and the upper part of the barrel. The device is reasonable in design, energy-saving, and hard to break.

Owner:王昕

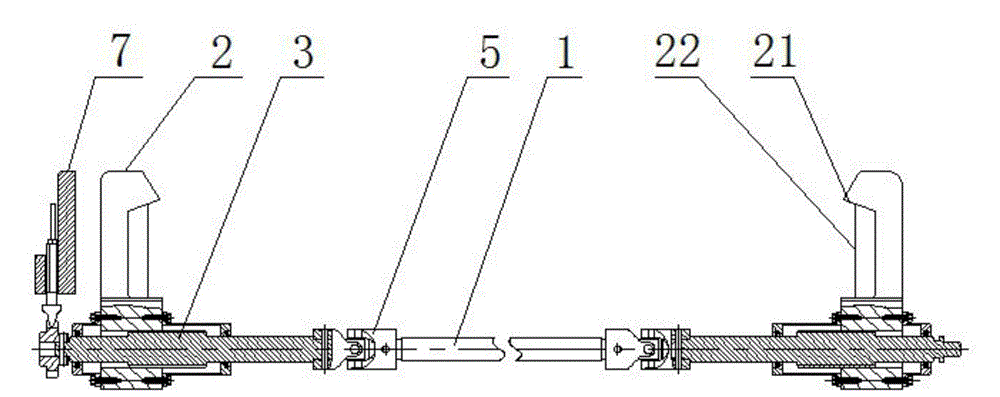

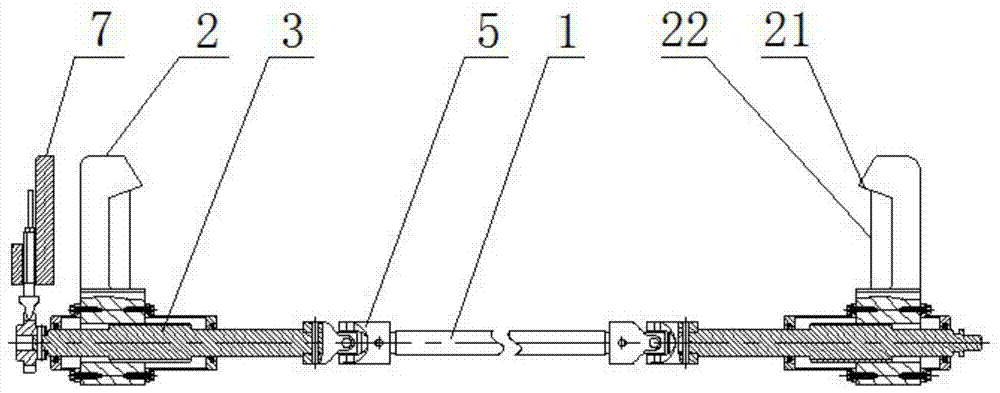

Labor-saving linkage positioning and locking structure

ActiveCN105090302AReliable locking and positioningAchieve reliable fastening effectBraking membersBrake actuating mechanismsPositional TechniqueLocking mechanism

The invention discloses a labor-saving linkage positioning and locking structure, and belongs to the technical field of positioning of machining equipment. The labor-saving linkage positioning and locking structure comprises a connecting rod, clamping jaws, screw rods, a frame, cross universal joints, a guide rail, a locking mechanism, a spring support base, a positioning groove and a steel plate spring, wherein the guide rail is horizontally mounted on the frame; the positioning groove is formed in the guide rail; the spring support base is arranged on the side surface of the frame, and is provided with the steel plate spring; the steel plate spring is parallel to the guide rail; the connecting rod is perpendicular to the guide rail, and is horizontally arranged below the guide rail; the screw rods are respectively connected to the two ends of the connecting rod; the cross universal joints are respectively arranged between the connecting rod and the screw rods; the clamping jaws are respectively matched and mounted on the screw rods at the two ends of the connecting rod; and the tail end of one screw rod is fixedly connected to the locking mechanism. Through the positioning of rollers and the linkage of the clamping jaws, mechanical loads with the rollers achieve a quick, stable and reliable positioning and locking effect on the guide rail for a long time; and the starting force in renewed starting is comparatively low and no scratches of the guide rail may be caused.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

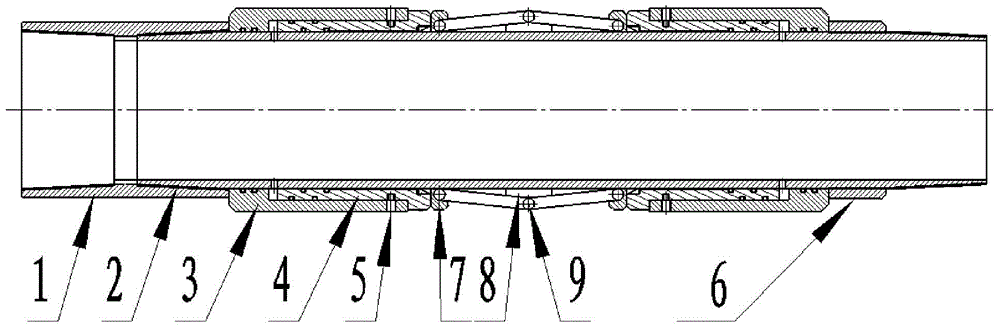

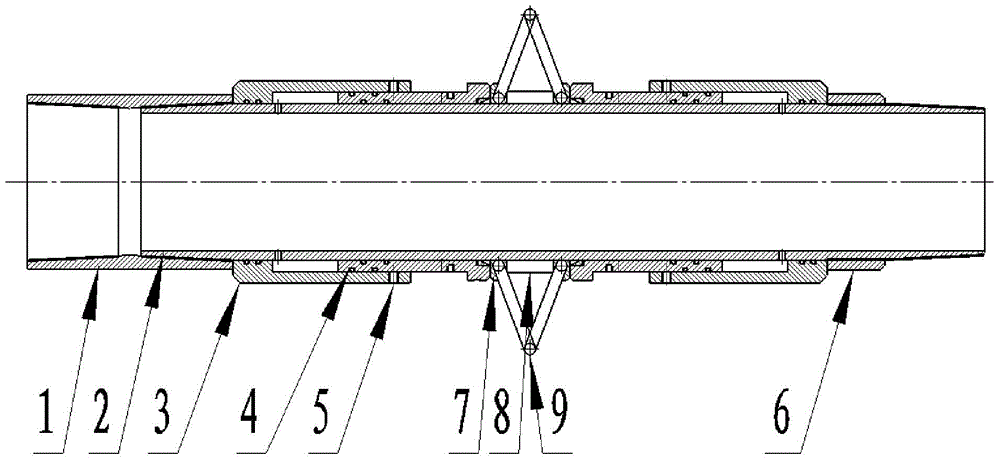

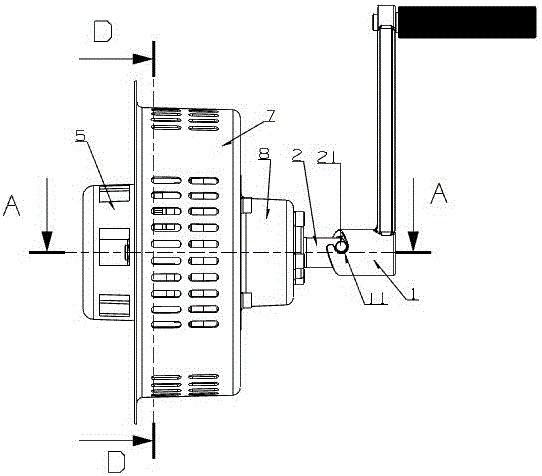

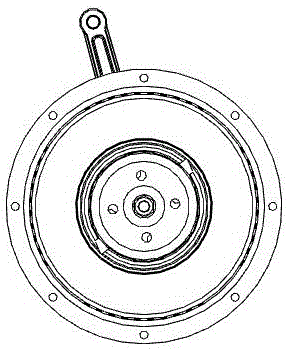

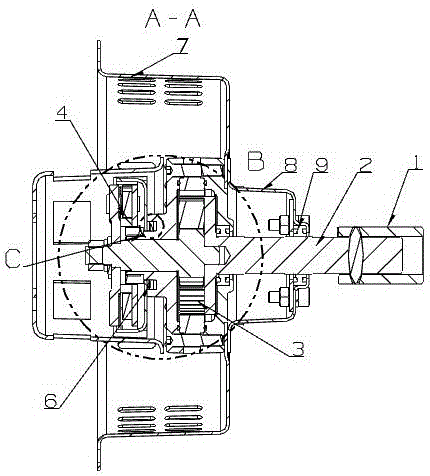

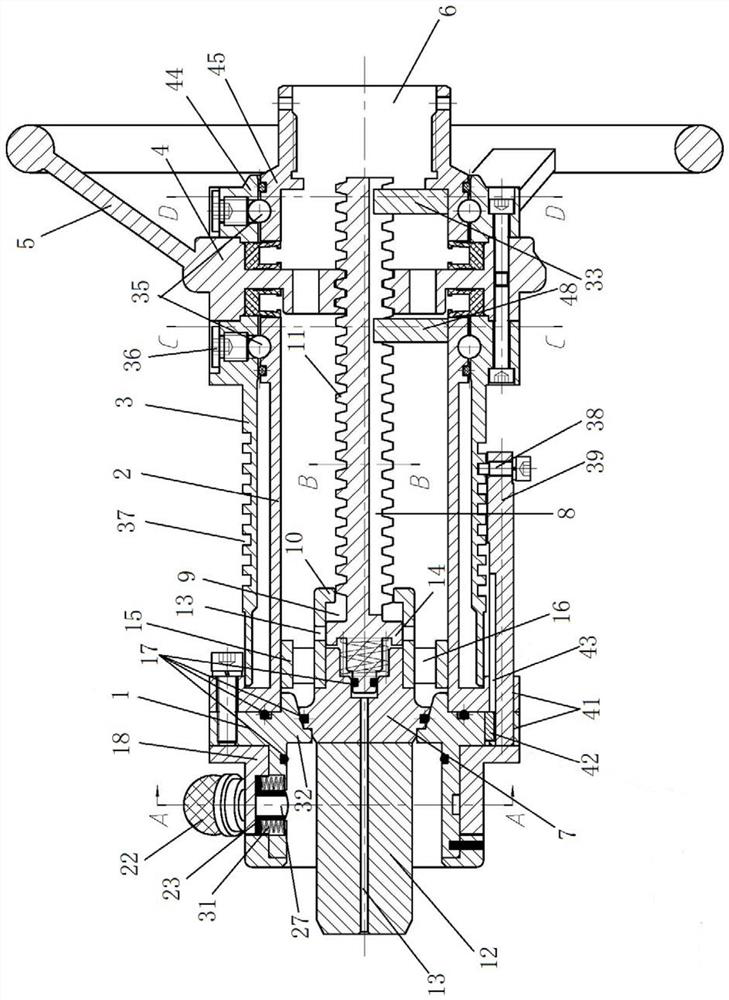

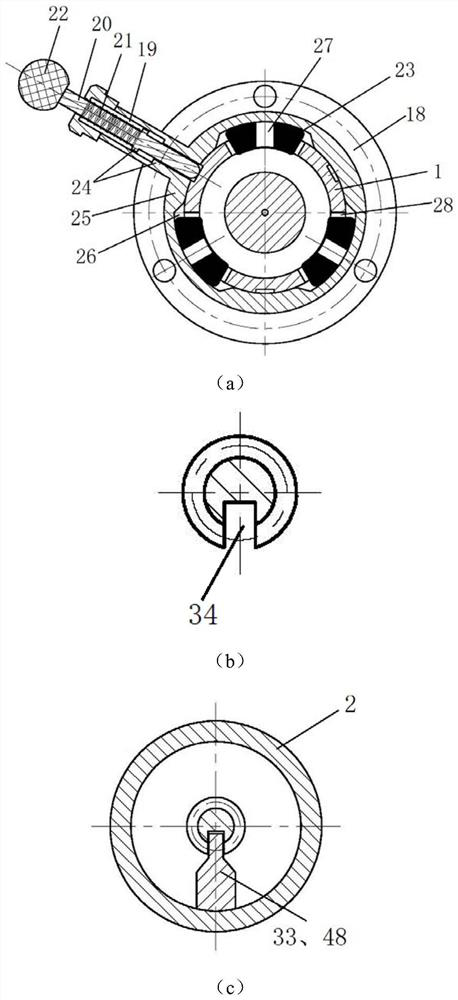

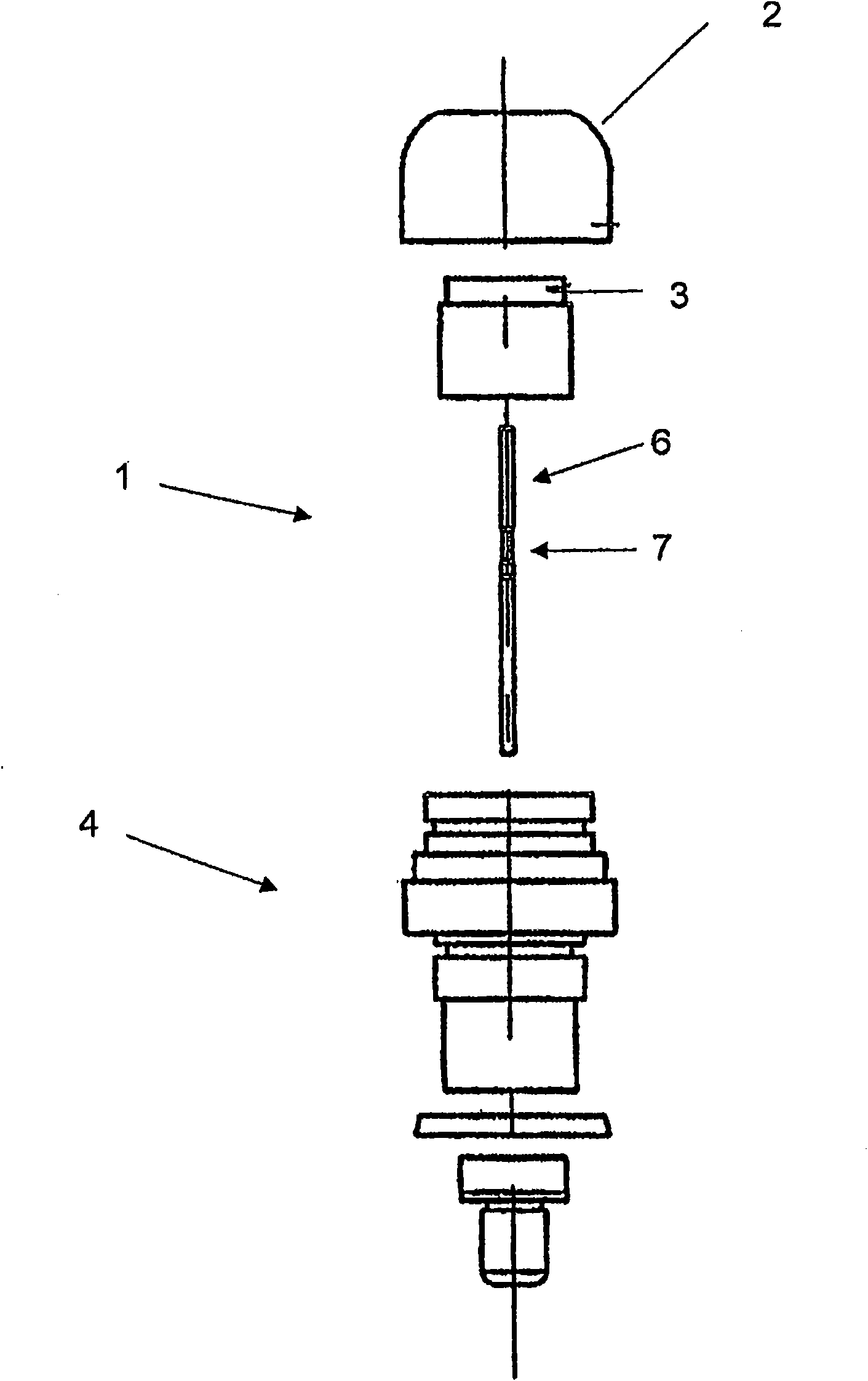

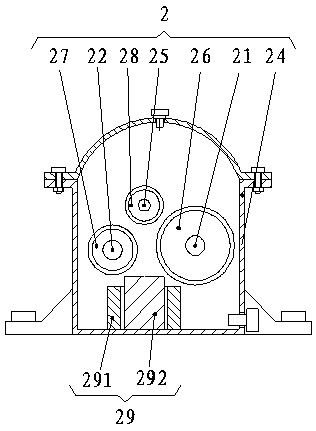

Power tool

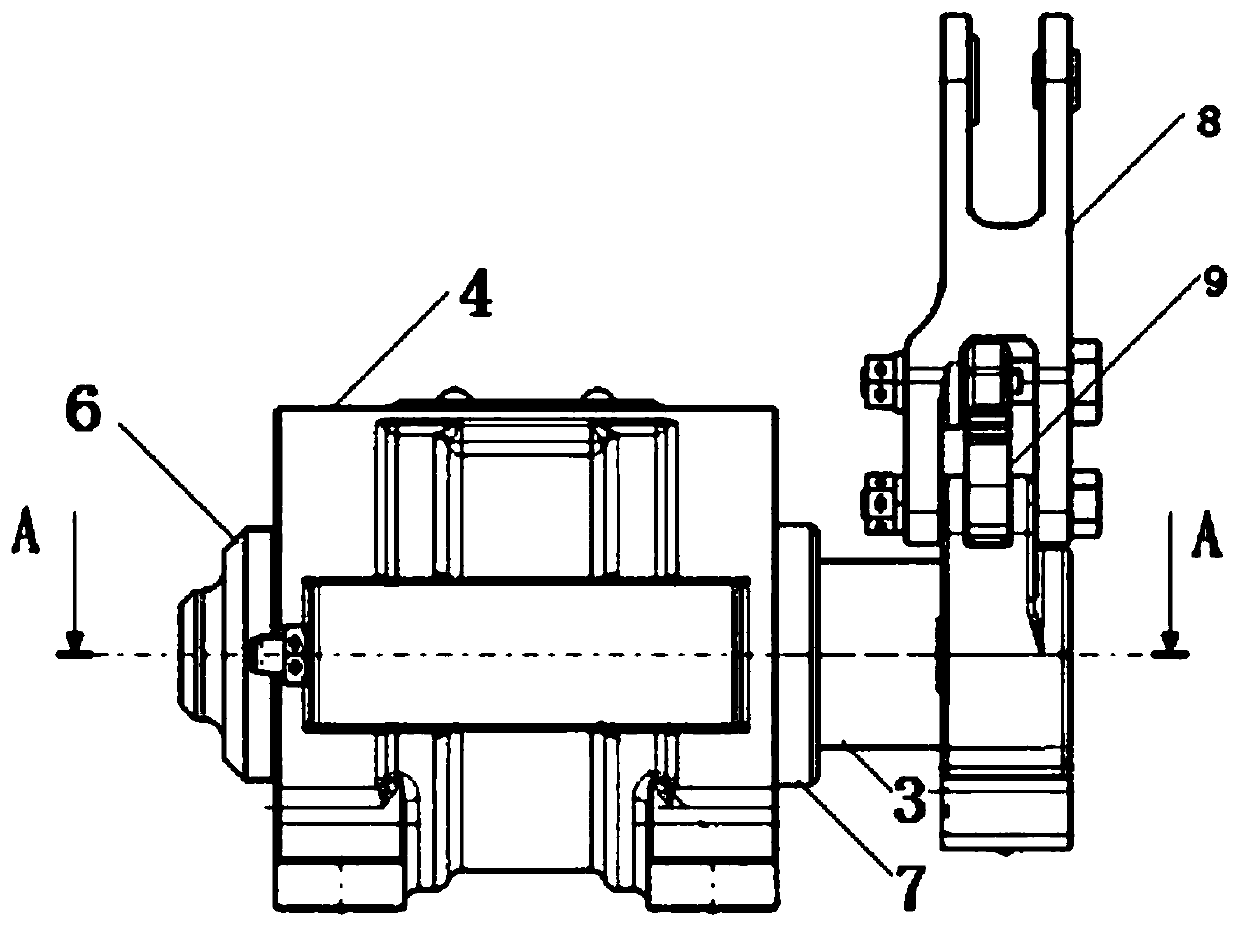

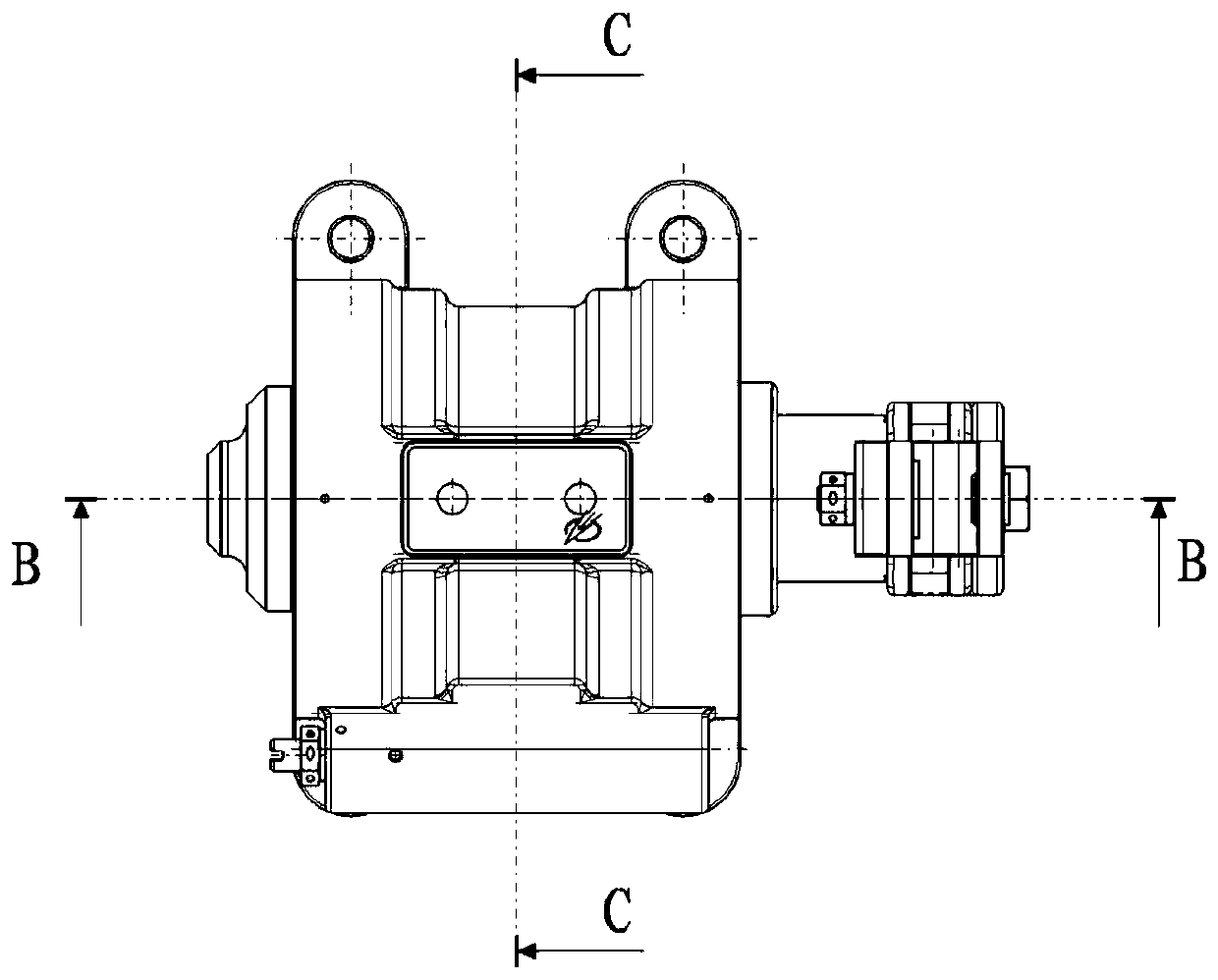

ActiveCN104690694AEasy to installSmall starting forcePortable power-driven toolsEngineeringPower tool

The invention relates to a power tool which comprises a shell, an output shaft, a fixing member for pressing a working head onto the output shaft, a locking assembly for locking the fixing member and a driving mechanism, wherein the locking assembly comprises a sleeve fixed in the output shaft, a first clamping member and a second clamping member contained in the sleeve, as well as a rotation shaft arranged between the first clamping member and the second clamping member; the first clamping member and the second clamping member can rotate by taking the rotation shaft as the center, so that the locking assembly is located at a locking position or a release position; a locking member for keeping the locking assembly at the locking position and a first elastic member for elastically supporting the locking member are further arranged between the first clamping member and the second clamping member; the driving mechanism comprises a push rod which is arranged in the output shaft and can move along the output shaft axially; the push rod can push the locking member to move when movement, so as to release restriction on the locking assembly. With adoption of the power tool, the detachment process can be completed conveniently through simple pressing action, without rotating a wrench for multiple turns; the starting force is small.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

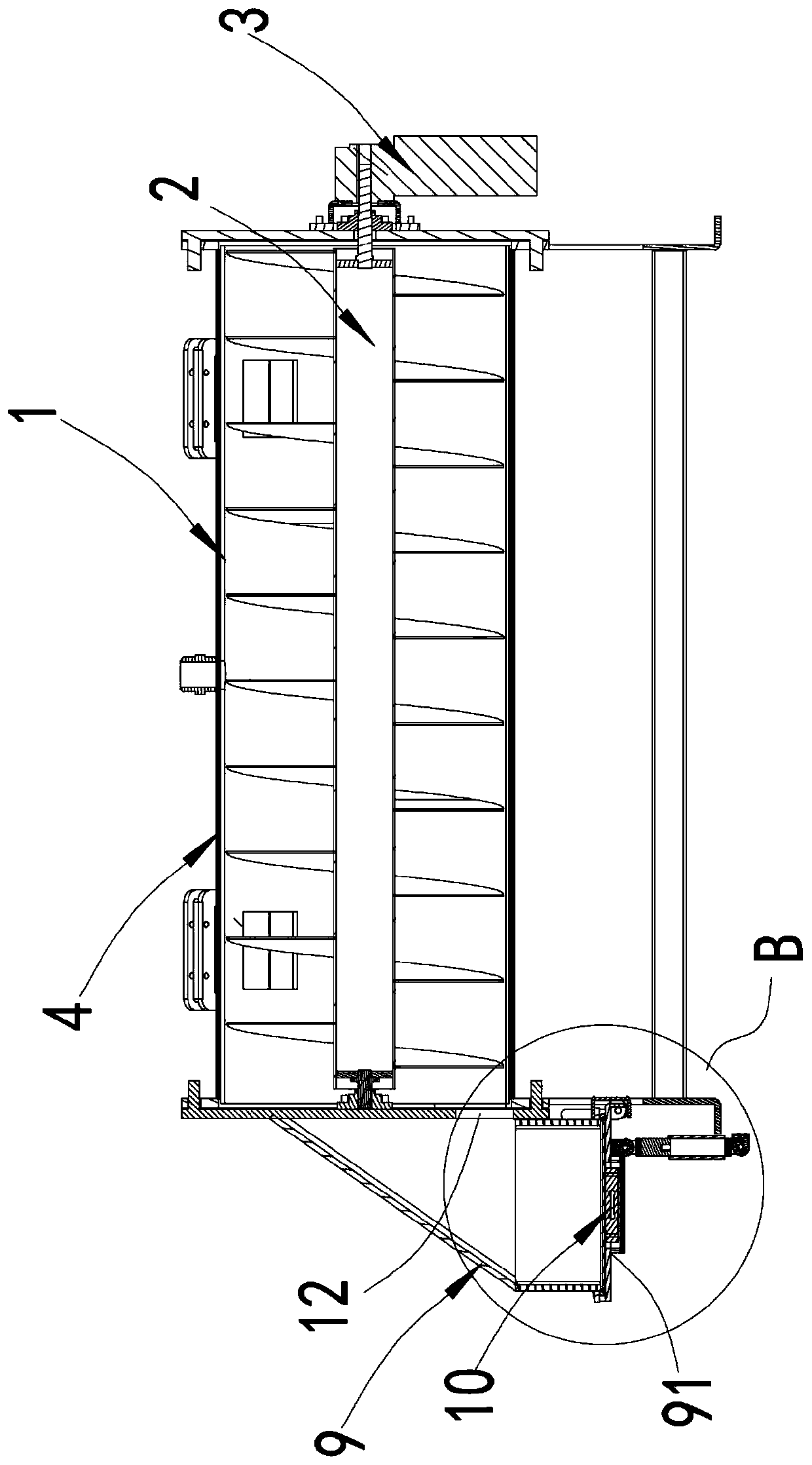

Quantitative discharging type fermentation equipment and fermentation method thereof

PendingCN111196741ARealize moving forwardImplement backDrying solid materials without heatClimate change adaptationProcess engineeringMechanical engineering

The invention discloses quantitative discharging type fermentation equipment and a fermentation method thereof. The quantitative discharging type fermentation equipment comprises a barrel, a spiral conveying shaft, a driving device, a heating device and a material receiving bin, wherein the barrel is provided with a feeding port and a discharging port which are located in the two ends; the spiralconveying shaft is arranged in the barrel body in the axis direction of the barrel body in a self-rotating mode; the driving device drives the spiral conveyor to rotate; the heating device is positioned on the barrel body; and the material receiving bin is arranged at the discharge port, a weighing sensor is integrated on a bottom plate of the material receiving bin, and the bottom plate of the material receiving bin can be opened and closed. According to the scheme, spiral horizontal conveying is adopted; forward movement and backward movement of materials can be realized; the standing time of the materials is controlled; the materials are turned over; the barrel body does not need an outlet capable of being automatically opened and closed, the internal structure is greatly simplified, the material receiving bin integrated with weighing equipment is arranged at the discharging port, a bottom plate of the material receiving bin can be opened, online quantitative discharging is effectively achieved, quantitative packaging is easy, and compared with the prior art, a feasible automatic weighing and discharging mode is provided.

Owner:SUZHOU HUANCHUAN ENERGY SAVING EQUIP CO LTD

Frictional energy dissipation damper

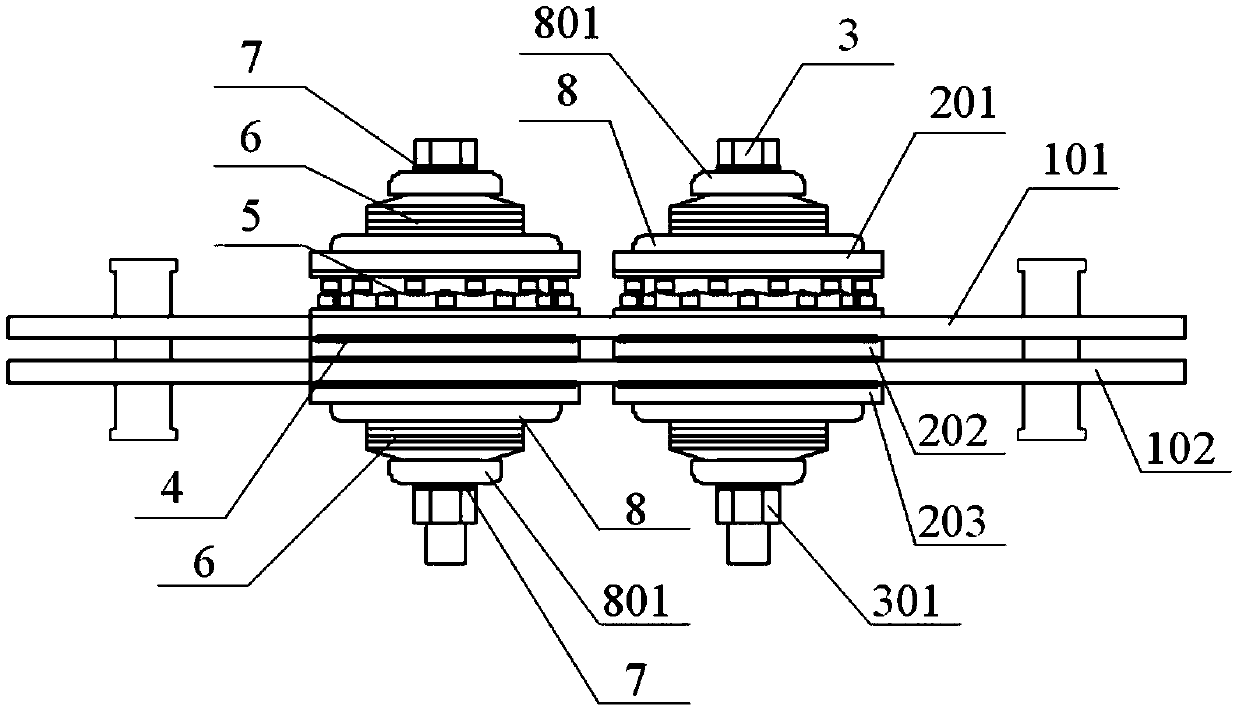

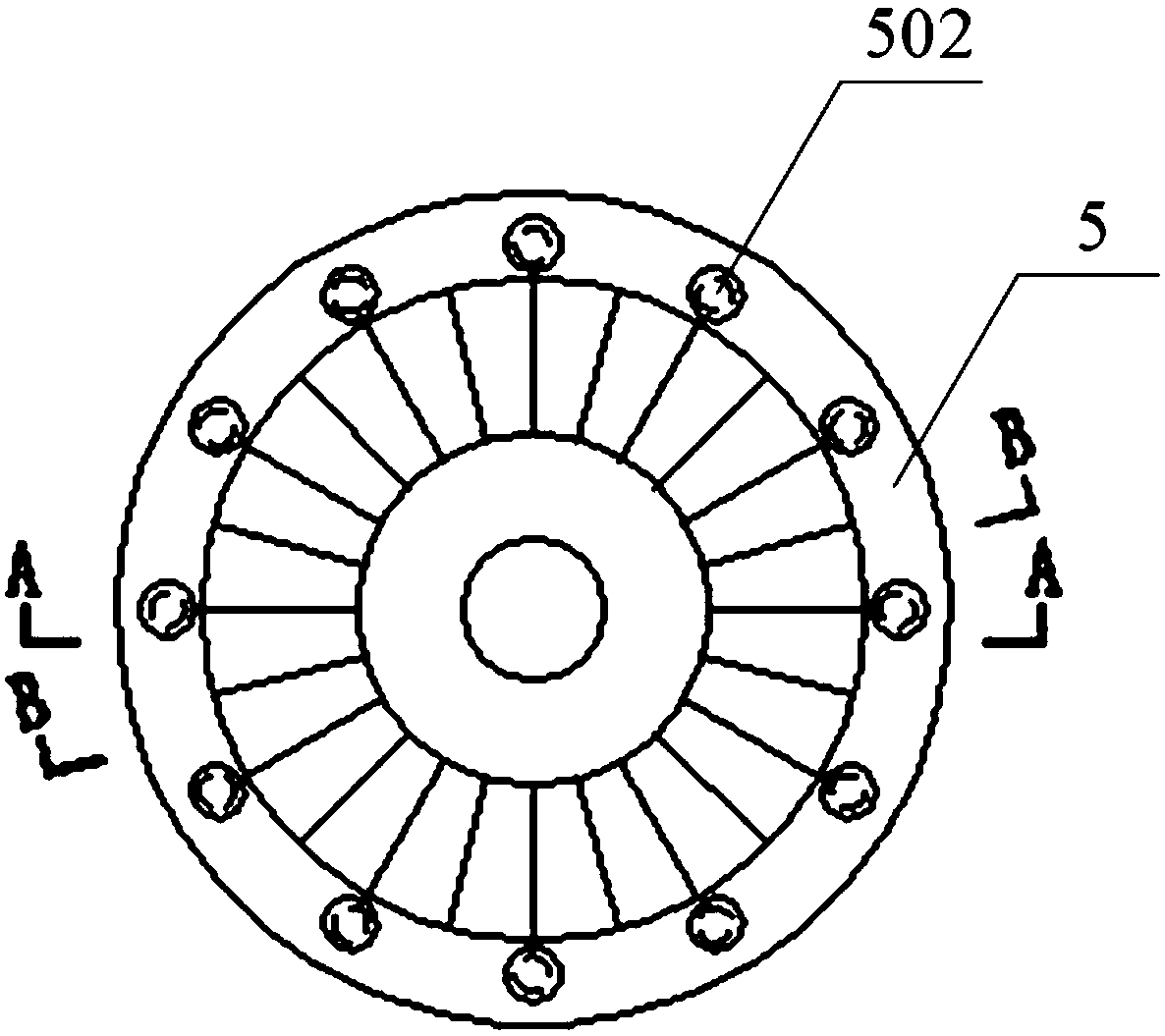

PendingCN109537971ASmall starting forceSmall structural deformationProtective buildings/sheltersShock proofingSnubberEngineering

The invention discloses a frictional energy dissipation damper which comprises a moving flat plate device and auxiliary clamping devices. The frictional energy dissipation damper is characterized in that the damper also comprises face gears, a horizontal plate group and a longitudinal plate group of the moving flat plate device are mutually connected; the face gears are arranged in pairs at the connection portions of the horizontal plate group and the longitudinal plate group, and the tooth surfaces of the face gears are in contact with each other and complementary; the auxiliary clamping devices are located at the upper portion and the lower portion of a face gear adjusting device. The damper has low starting power, and after starting, the generated damping force and energy dissipation capability can be adjusted according to the degree of deformation of the damper.

Owner:北京筑信润捷科技发展有限公司

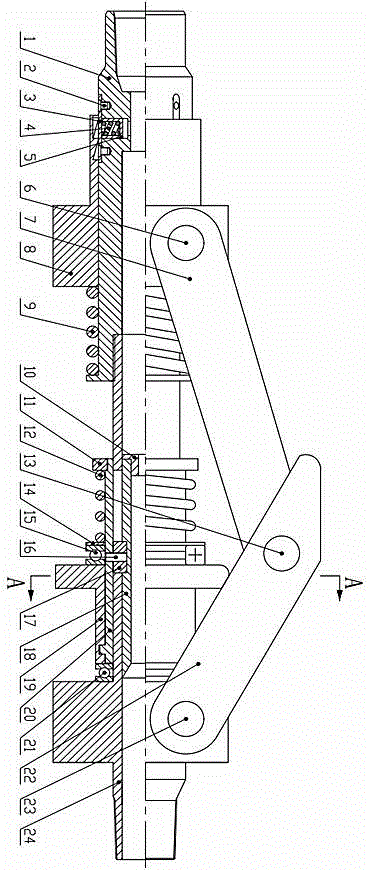

Temperature sensing variable annular gap integrated hydraulic damper

ActiveCN109578492ACompact structureReduce volumeSpringsLiquid based dampersHydraulic pumpEffective length

The invention provides a temperature sensing variable annular gap integrated hydraulic damper, which aims at solving the problem that the hydraulic damper is sensitive to temperature change and can maintain relative good stability in a larger temperature range. The invention is realized through the following technical scheme: a temperature compensation annular gap formed by a temperature compensation valve core movably assembled in a plunger hole is combined, a temperature compensation cavity formed by necking in middle part of the temperature compensation valve core, a pressure compensation cavity formed on the space of a plunger shaft end and a damping cavity of the pressure compensation cavity are communicated; the oil in a crossed damping cavity of a piston rod rotor blade generates intermolecular friction in the oil of the damping annular gap; when the temperature of the oil of a damping cylinder is changed, the hydraulic pressure thermal displacement generated by the oil in the temperature compensation cavity push an end drive head of the compensation valve core and the temperature compensation piston to drive the temperature compensation valve core to do reciprocating linearmotion, so that the effective length and height of the temperature compensation annular gap are continuously changed, and the kinematic viscosity of the working medium with temperature changes is balanced and compensated.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

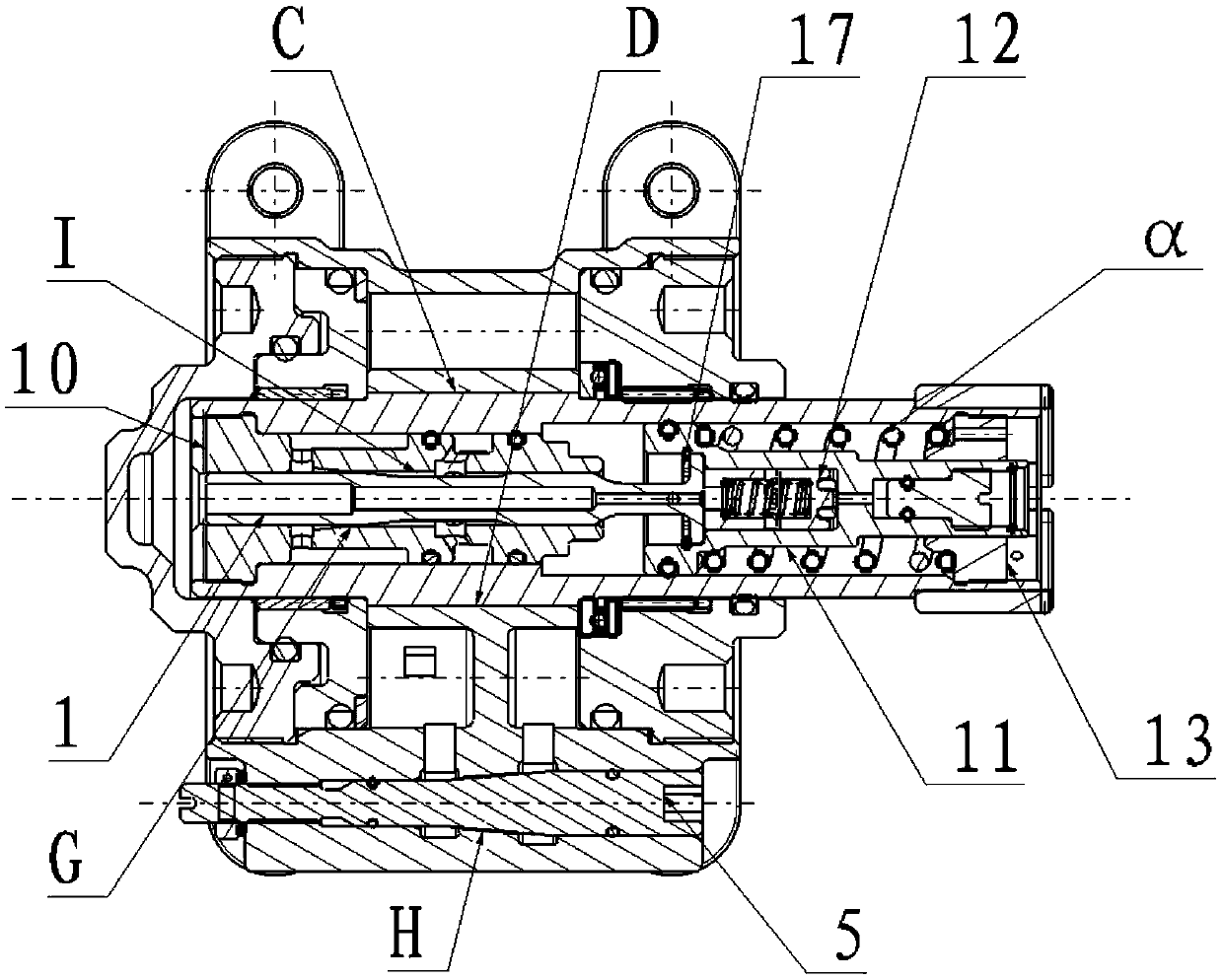

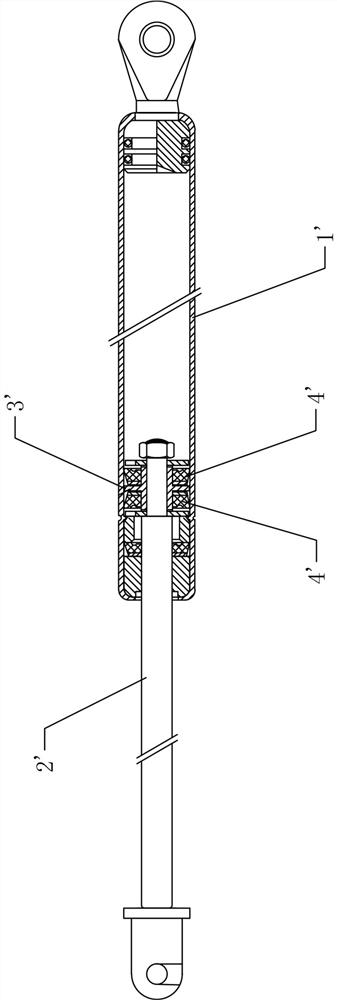

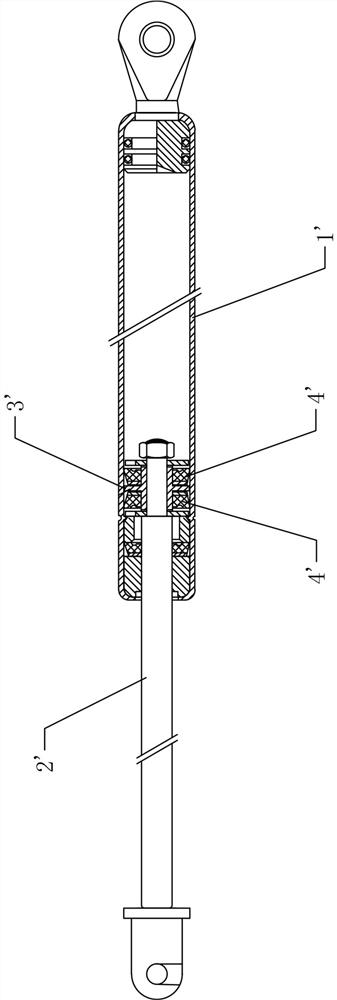

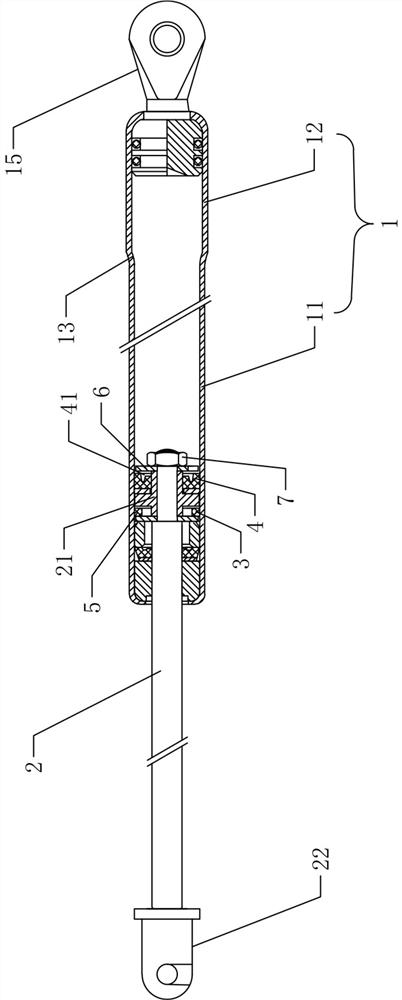

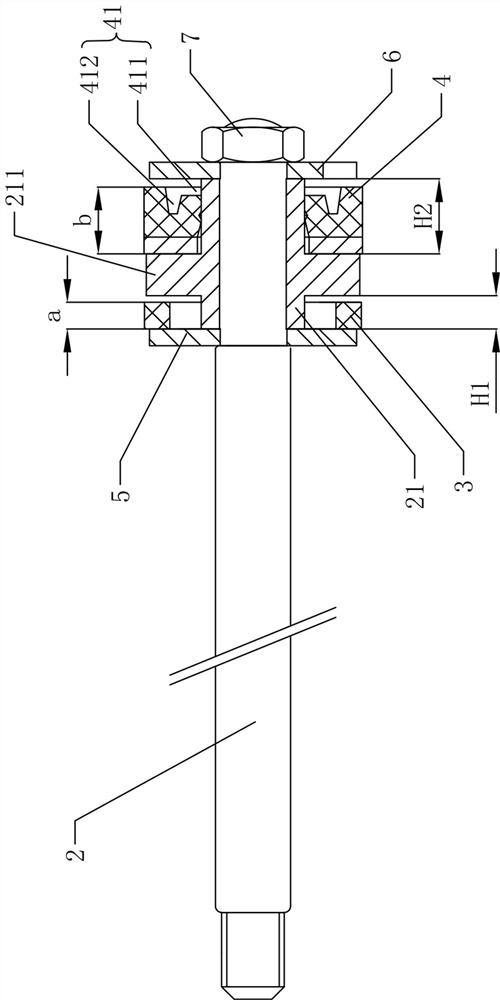

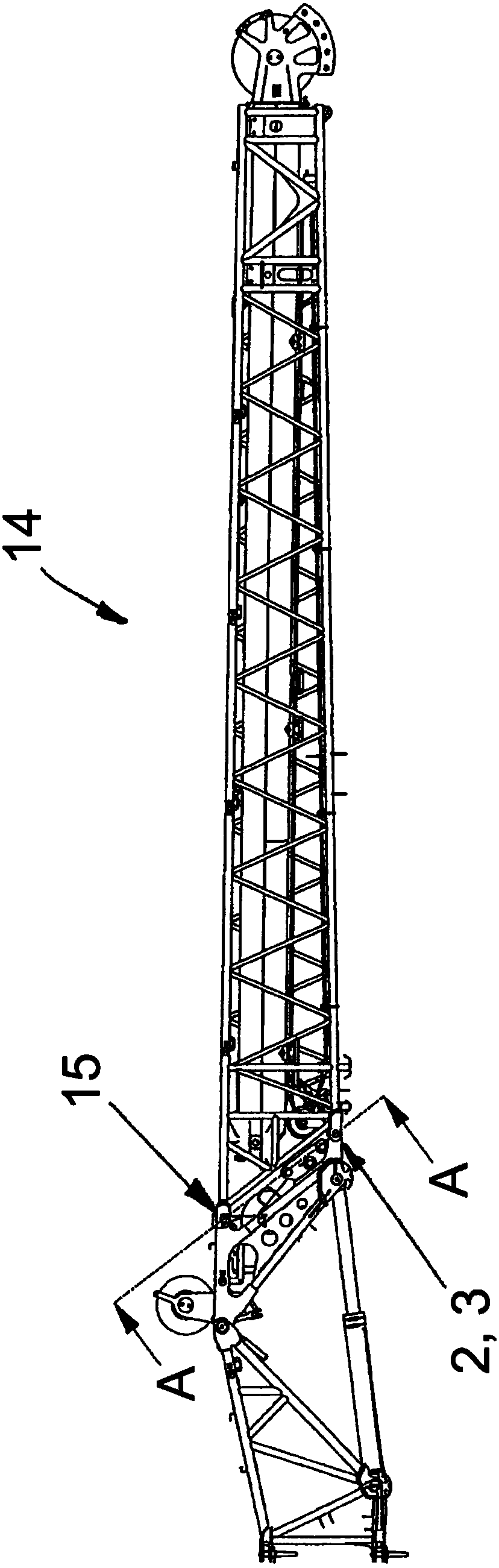

Elbow-type dual-thrust hydraulic centralizer

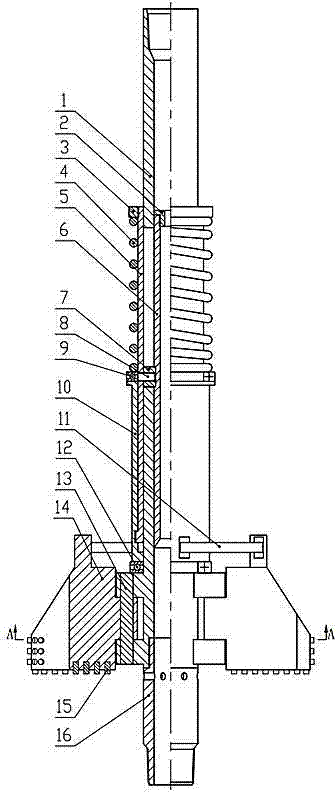

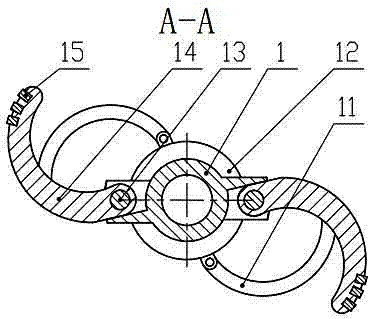

InactiveCN105178882ASmall outer diameterSmall starting forceDrilling rodsDrilling casingsAxial displacementHydraulic cylinder

The invention provides an elbow-type dual-thrust hydraulic centralizer. The elbow-type dual-thrust hydraulic centralizer comprises a hydraulic thrust system and a centering system, wherein the hydraulic thrust system comprises a main body, hydraulic cylinders and a retaining system; the hydraulic cylinders are arranged on the main body; a piston is arranged in each hydraulic cylinder; the hydraulic cylinders and the pistons act on the centering system through in-pipe pressure building to realize centering; the retaining system can realize permanent centering after in-pipe pressure relief; the centering system comprises a push ring, a positioning block and at least four groups of elbows uniformly distributed on the circumference of the main body; the push ring is connected with the pistons; the positioning block is fixed to the middle of the main body; one end of each elbow is fixed on the push ring, and the other end of each elbow is fixed on the positioning block; an included angle is formed between each elbow and the main body; and the centering system can be started up by an extremely small starting force. The bidirectional hydraulic system ensures no axial displacement of the centering system; owing to the unique pre-bending structural design, the starting force of the centering system becomes smaller; and the elbow-type dual-thrust hydraulic centralizer is suitable for centering casings of both horizontal wells and highly-deviated wells.

Owner:CNPC BOHAI DRILLING ENG

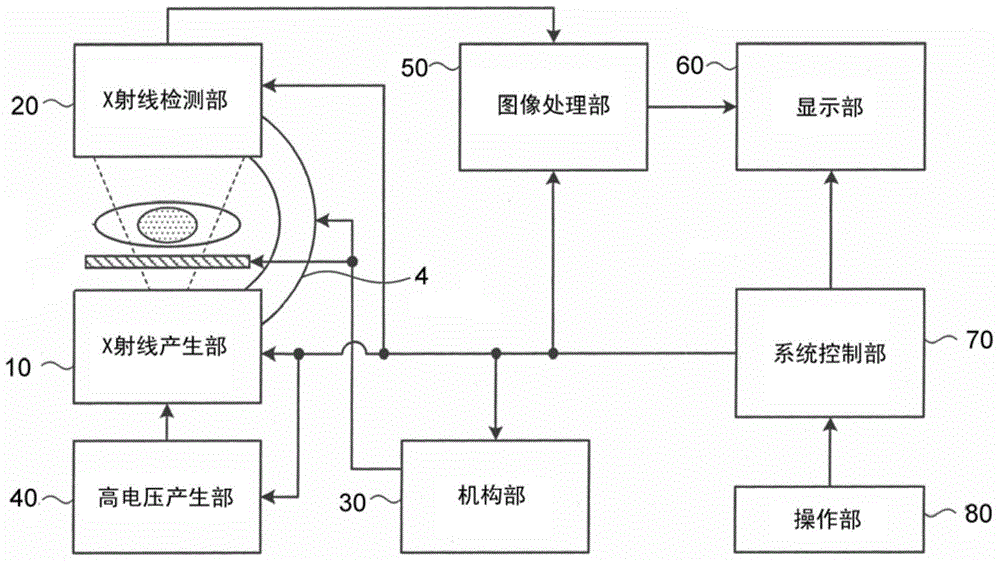

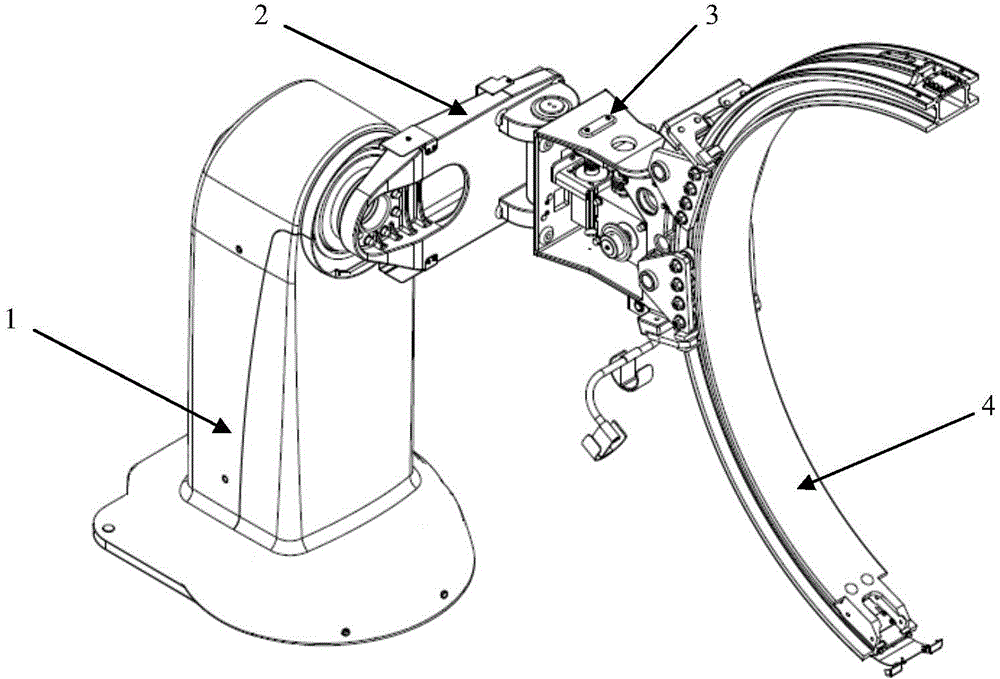

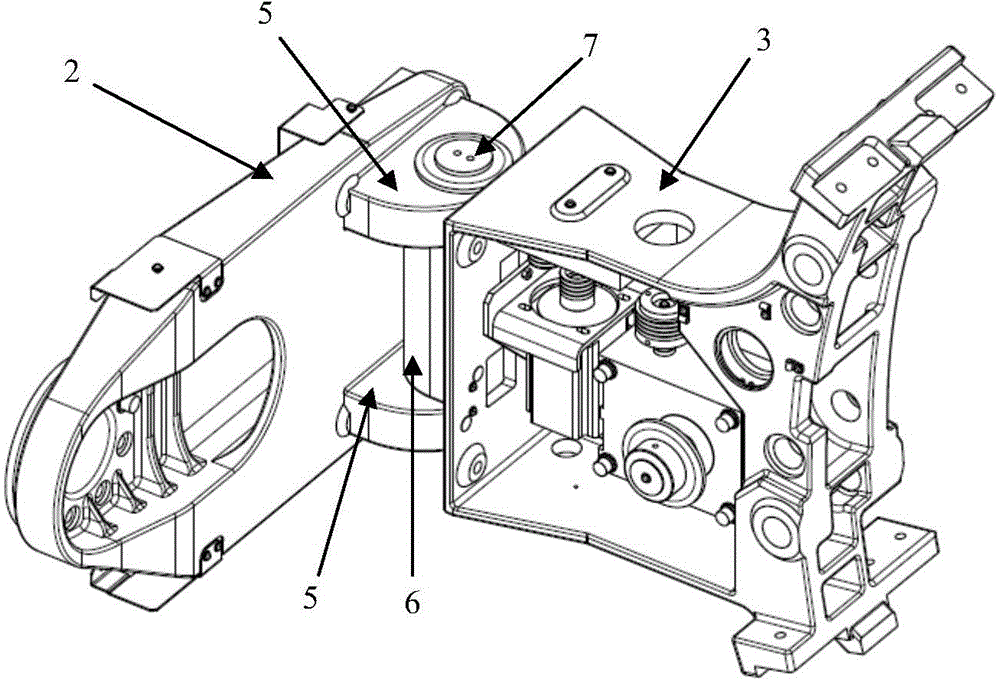

C-shaped arm device, C-shaped arm retraining device and X-ray diagnosis device

The present invention proposes a C-type arm device which has improved operational and rotational performance, a relevant C-type arm holding device and an X-ray diagnostic device employing said C-type arm holding device. The inventive C-type arm device comprises a base, a cantilever bracket, a C-type arm holding part and a C-type arm. The cantilever bracket is provided on the base at one end. The C-type arm holding part is provided on the other end of the cantilever bracket and is connected to it in such a way that the part is rotatable about a vertical axis. Said C-type arm and said C-type arm holding part are connected to each other in such a way that the arm is slidable along a circular arc of itself.

Owner:TOSHIBA MEDICAL SYST CORP

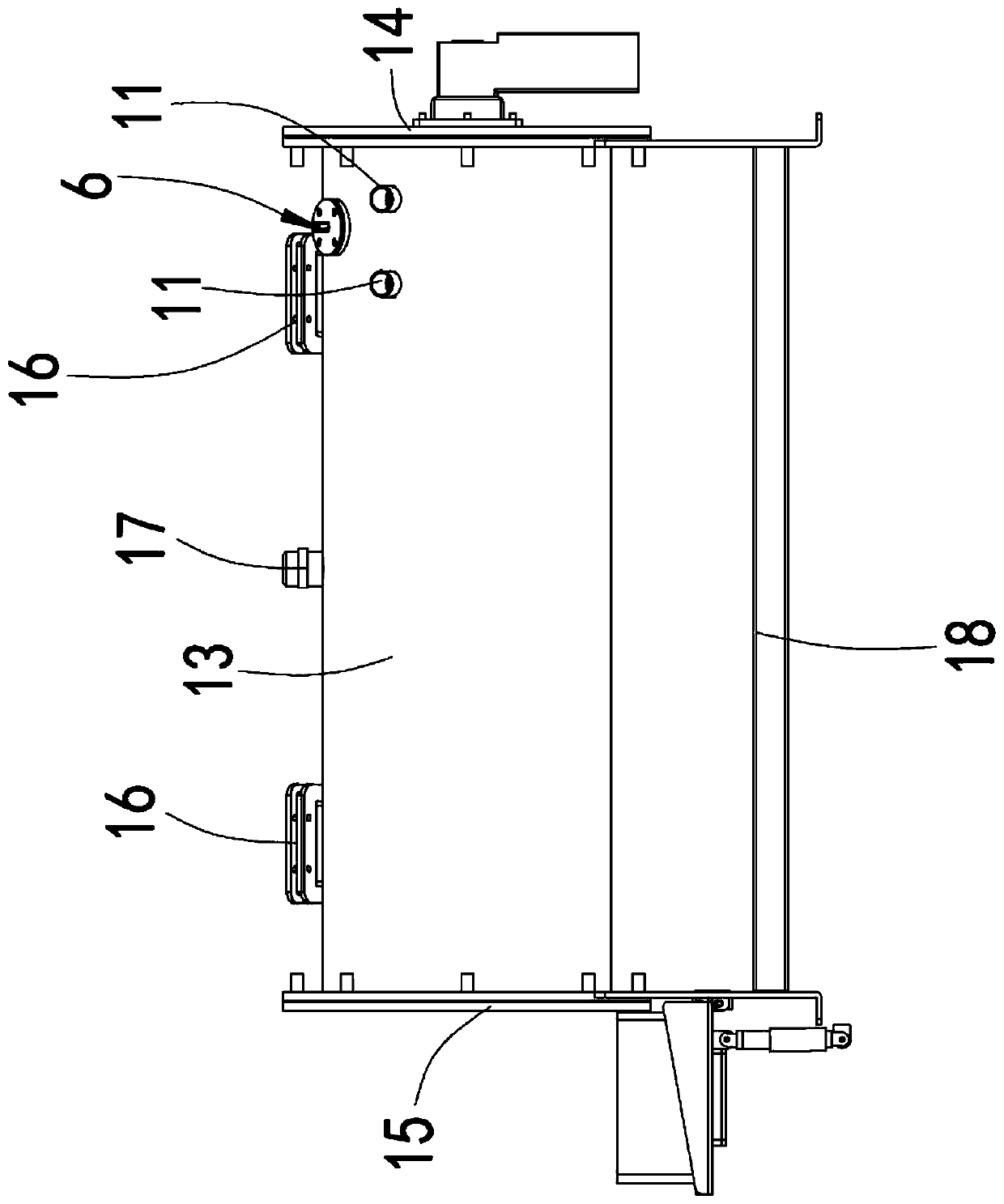

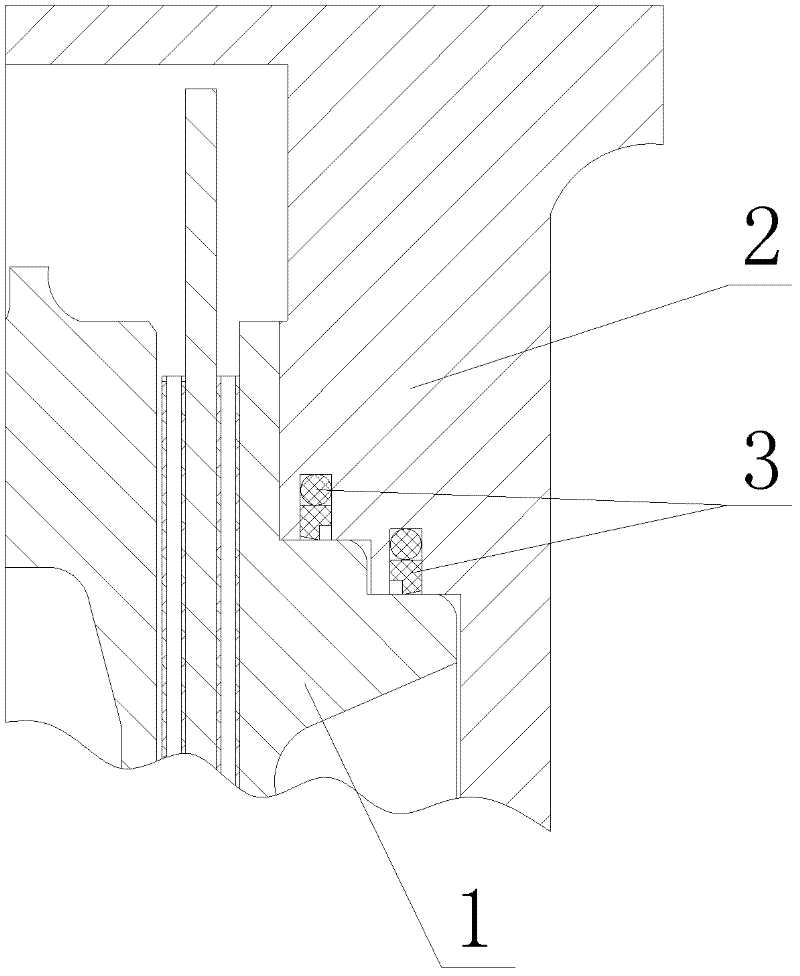

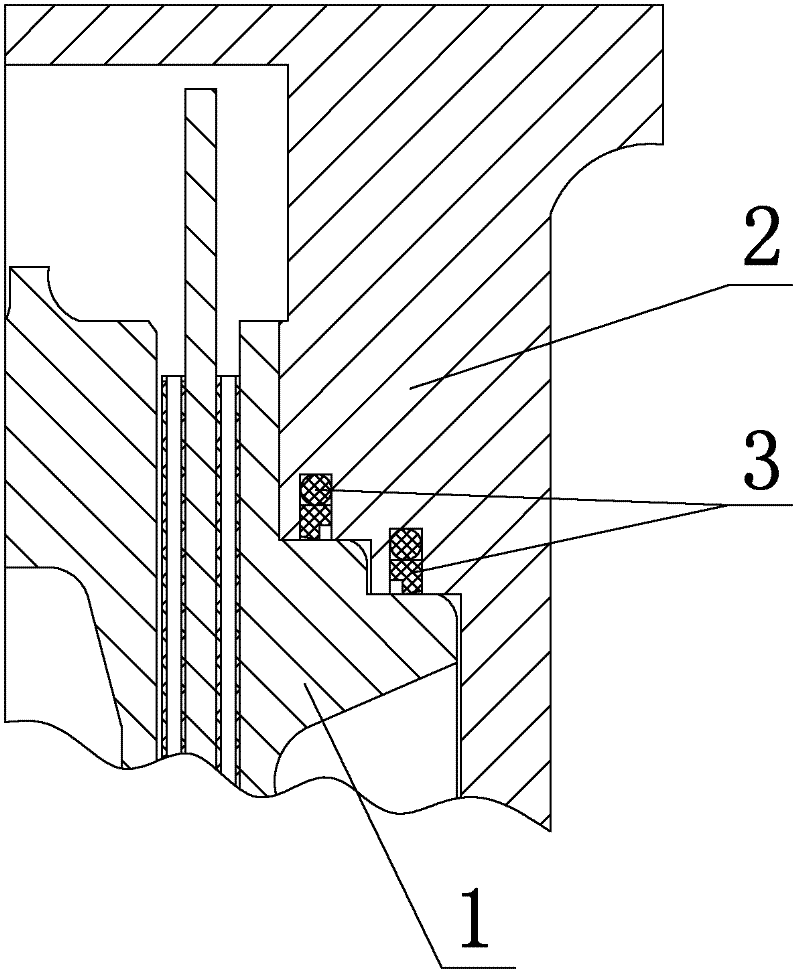

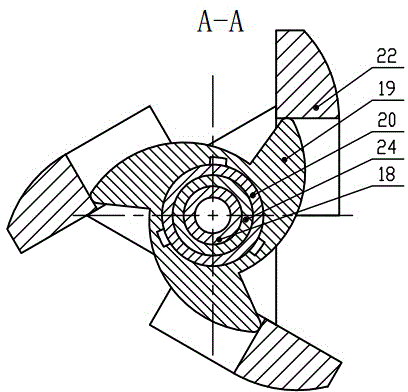

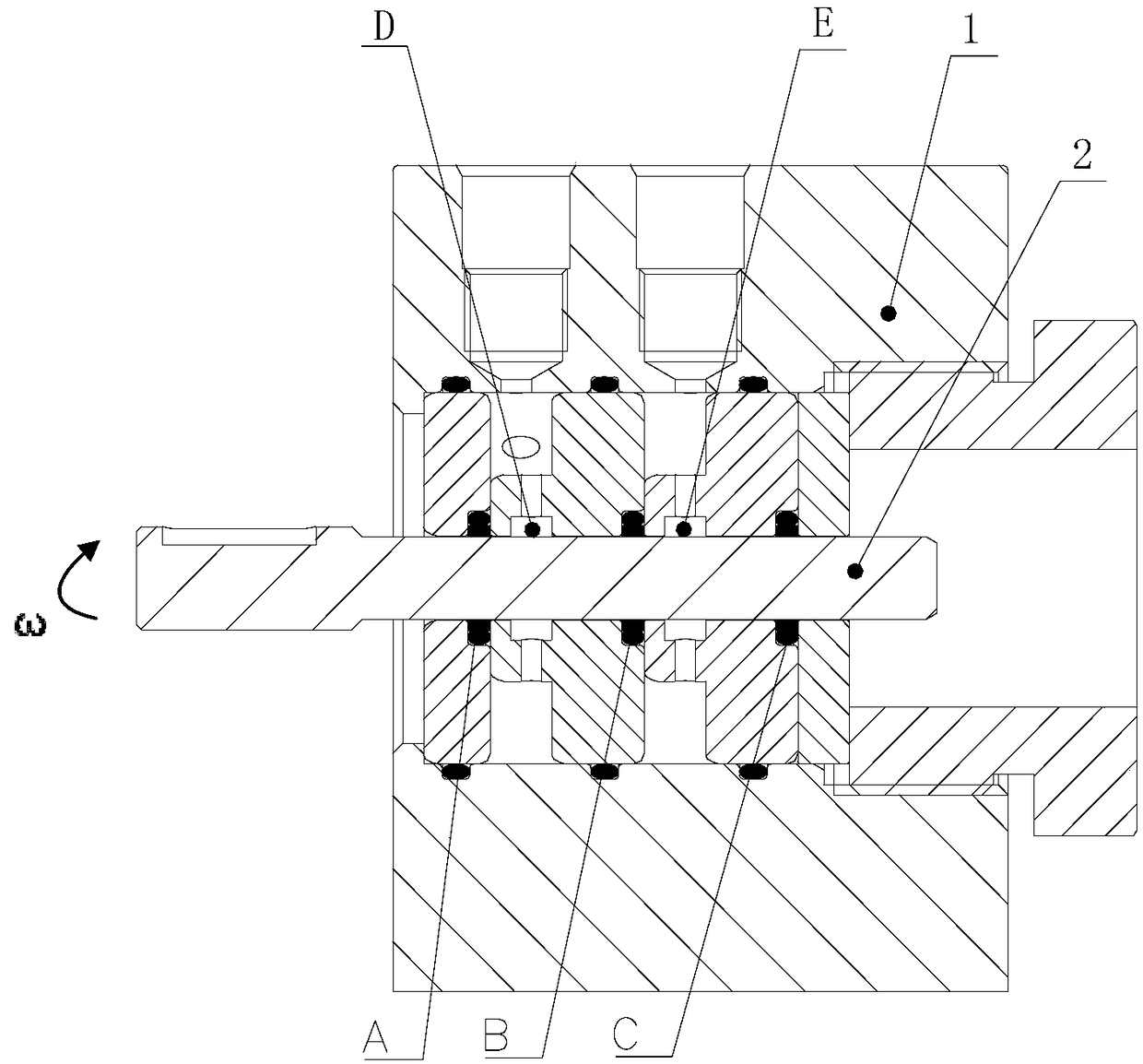

Wet brake with step sealing structure

InactiveCN102401134AReduce coefficient of frictionImprove braking effectEngine sealsBrake actuating mechanismsEngineeringWear resistance

The invention discloses a wet brake with a step sealing structure. The wet brake comprises a piston (1) and a shell (2), wherein a sealing element is arranged at the cooperating part of the shell (2) with the outer diameter of the piston (1), and the sealing element is a step sealing element (3); the step sealing element (3) comprises a rubber O-ring and a wear-resisting ring. In the wet brake provided by the invention, the O-ring is a force application element, provides a sufficient sealing force and compensates the wear-resisting ring, and the wear-resisting ring plays the action of wear resistance in the use process so as to reduce wearing, therefore, the sealing property is enhanced, the service life is prolonged, and the braking effect of the wet brake is improved.

Owner:SICHUAN CHENGDU CHENGGONG CONSTR MACHINERY

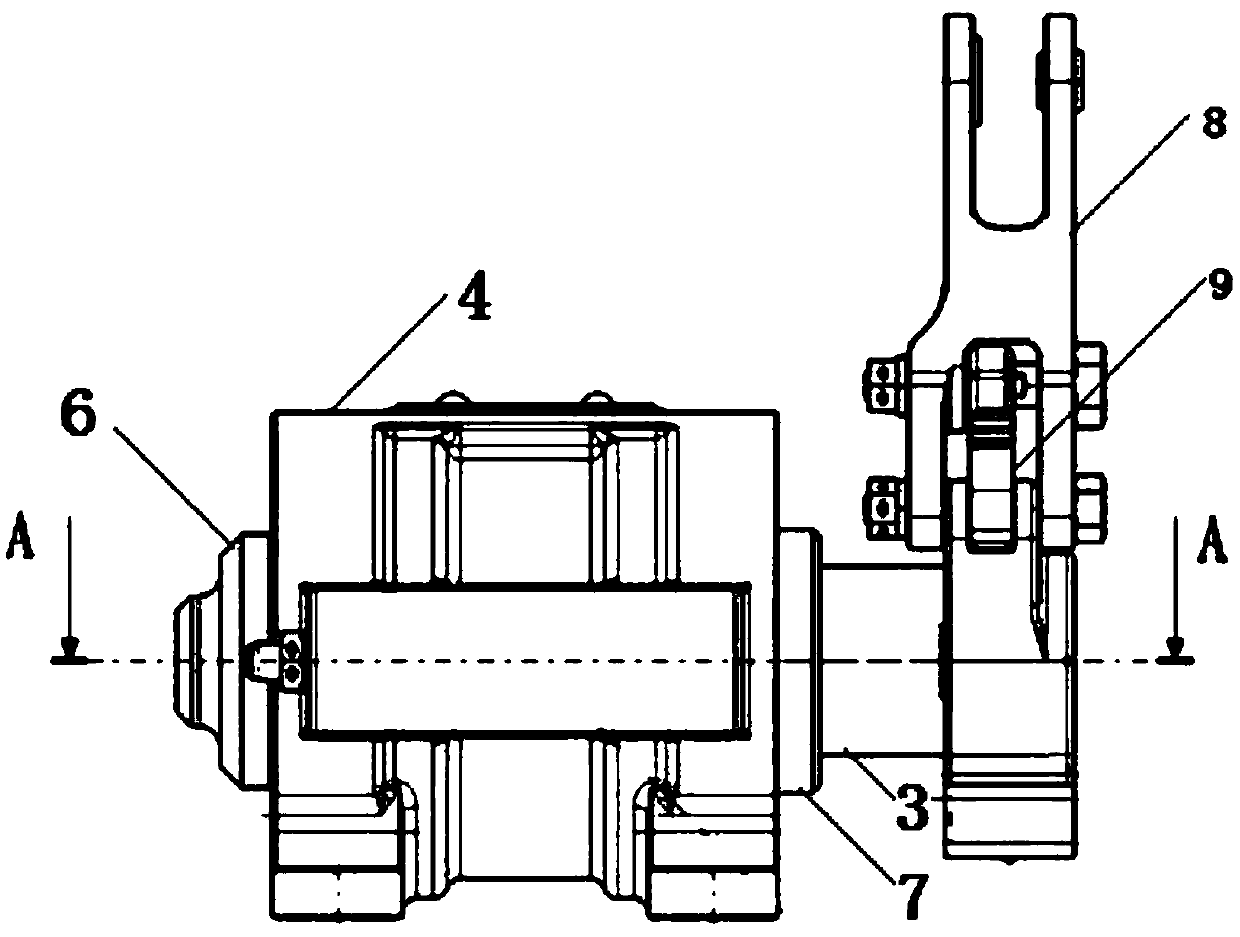

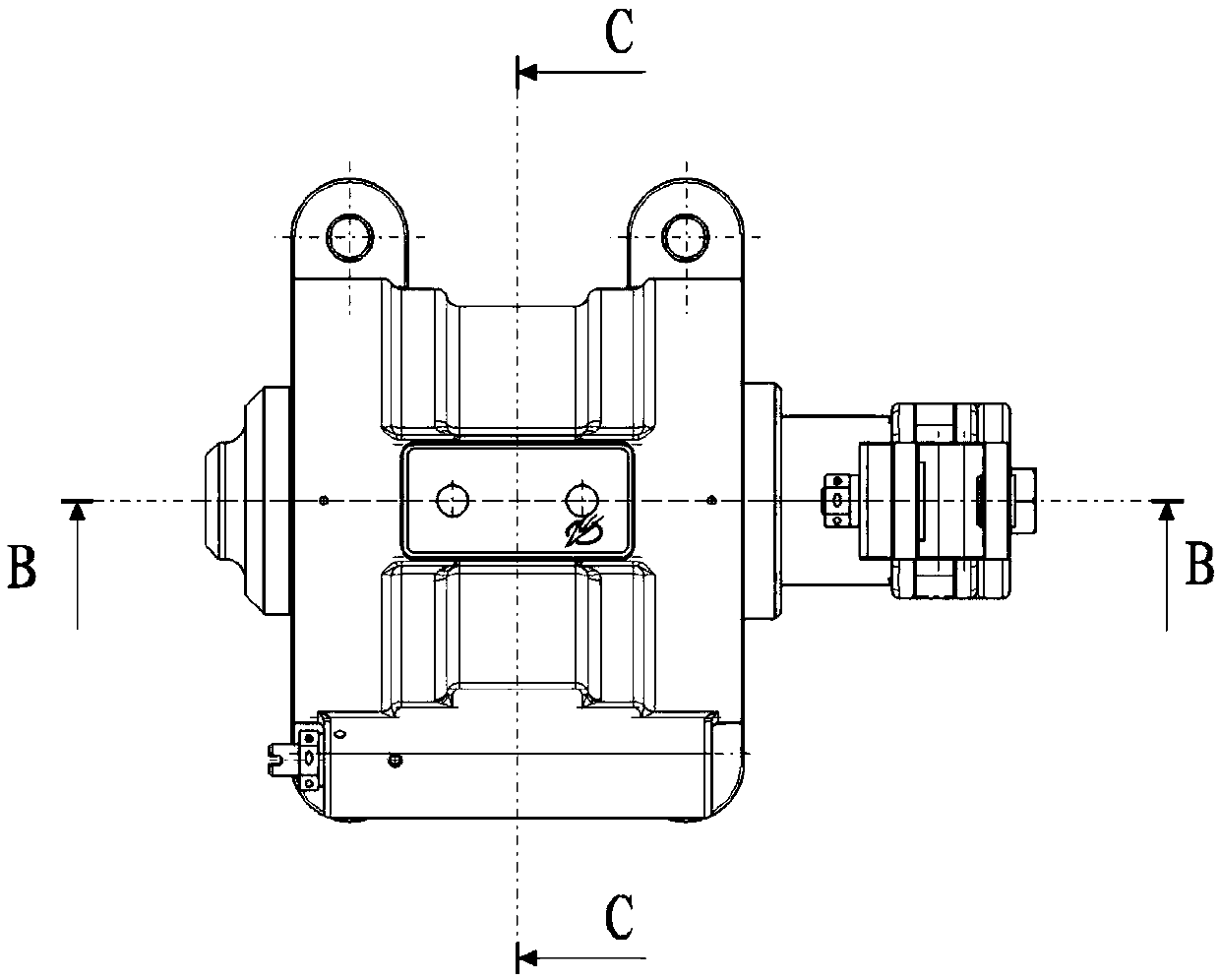

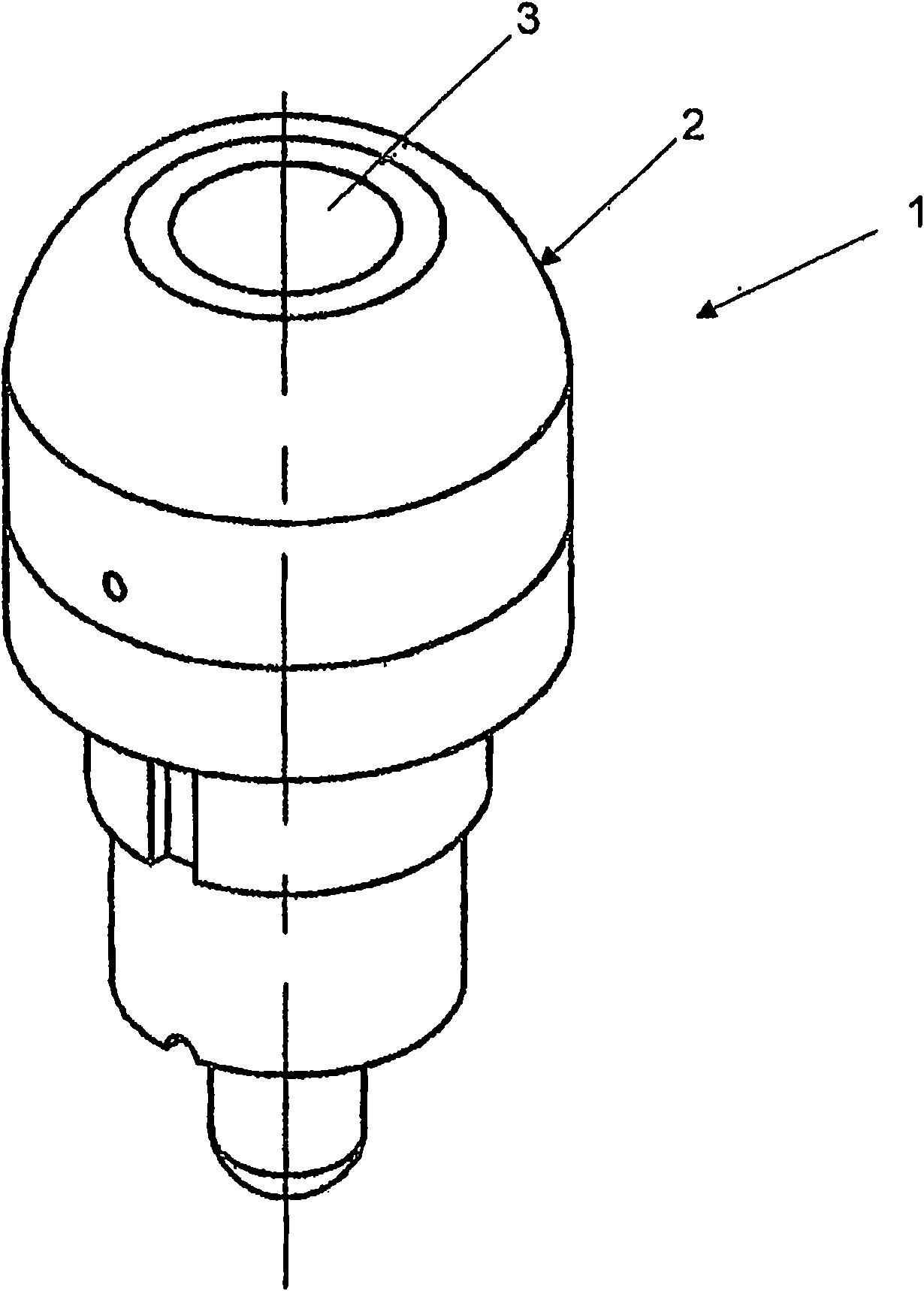

Hand-operated starter and mini-tiller

InactiveCN106762321AExtended service lifeLow costPower operated startersMachines/enginesEngineeringRocker arm

The invention discloses a hand-operated starter. The hand-operated starter comprises a rocker arm (1) and a rockshaft (2) connected with the rocker arm (1). The hand-operated starter is characterized in that the rockshaft (2) is connected with a speed increasing mechanism (3), the speed increasing mechanism (3) is connected with a flail block mechanism (4); and the flail block mechanism (4) drives a starting cup (5) of an engine. By the hand-operated starter, high starting speed can be guaranteed, and the service life is long.

Owner:CHONGQING WANHU MECHANICAL & ELECTRICAL PROD CO LTD

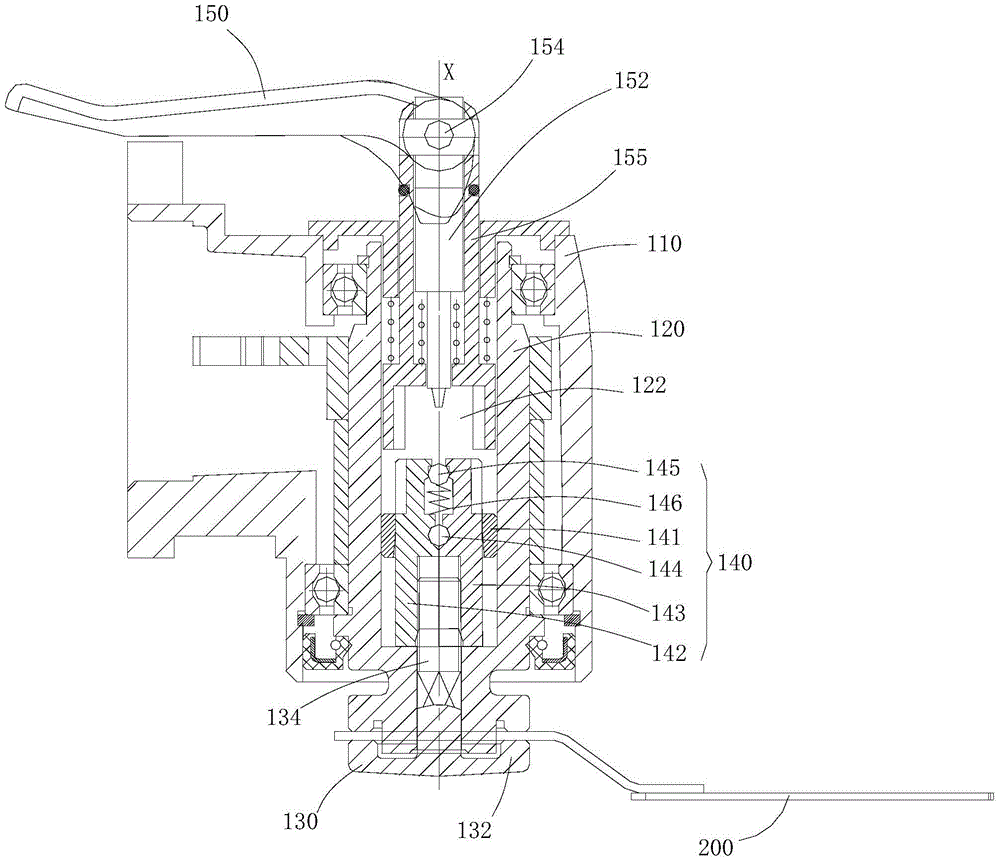

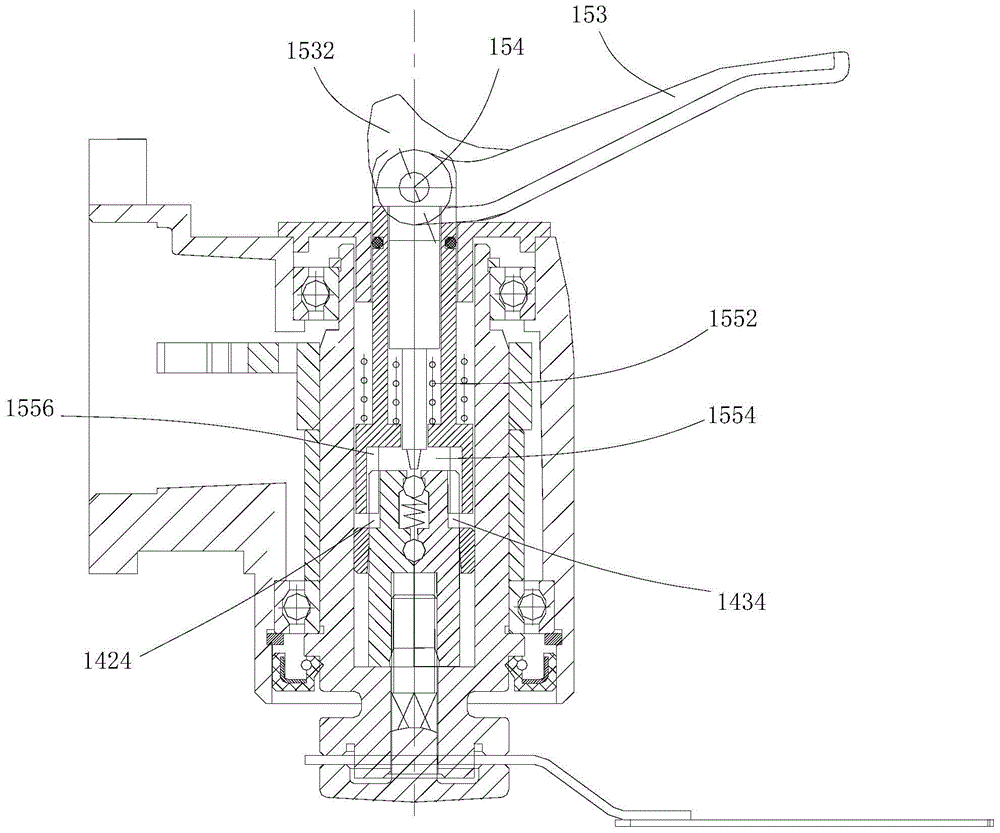

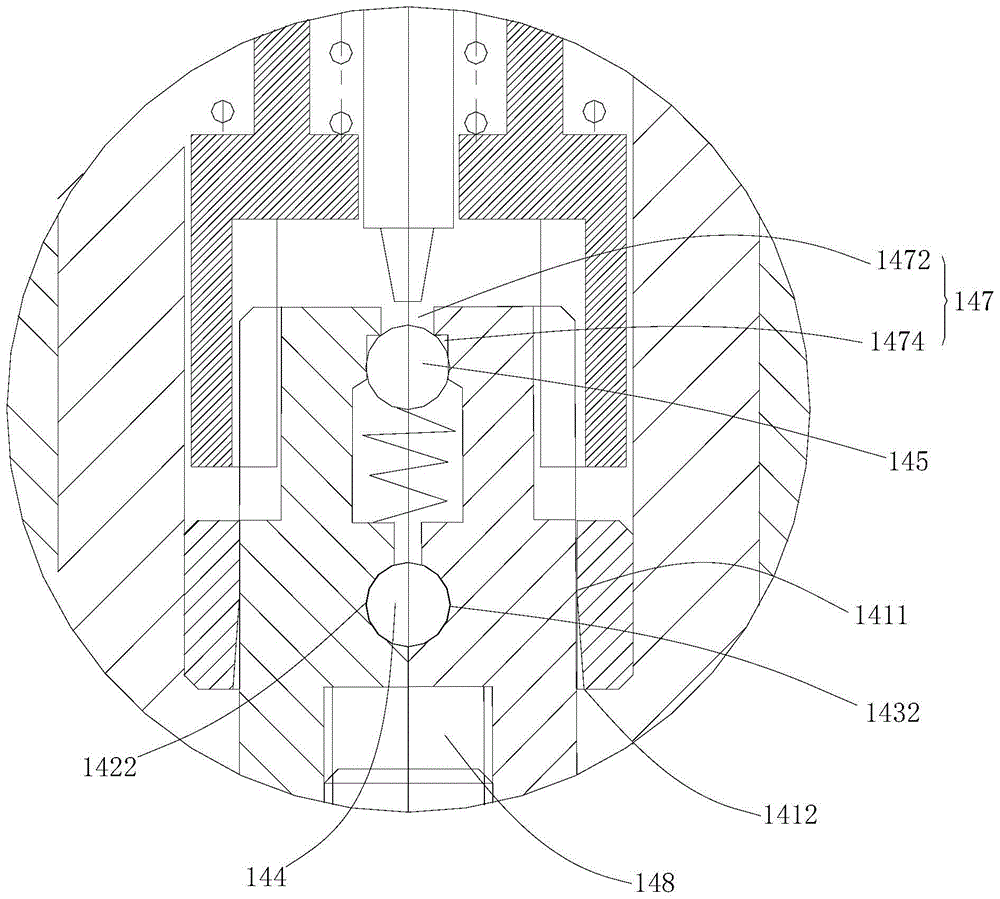

Quick coupling for fluid loading and unloading

PendingCN112393044ANo accidental disengagementShorten retrofit timeLiquid transferring devicesCouplingsPilot holeCoupling

The invention provides a quick coupling for fluid loading and unloading. The quick coupling comprises a valve, a fixed inner ring, a guide inner ring, an outer ring, a nut flange and a hand wheel, wherein the valve is arranged in the guide inner ring, the guide inner ring is connected with the fixed inner ring, and the outer ring and the hand wheel are respectively connected with the nut flange; the rear end of the valve is of a screw structure, and thread is arranged in the nut flange and matched with a thread on the screw structure; guide holes are formed in the edge of the end surface of the fixed inner ring, or guide holes are correspondingly formed in the edge of the end surface of the fixed inner ring and the edge of the end surface of the guide inner ring; an interlocking limiting guide rod is arranged in each guide hole; a guide centre is fixed to the rear end of each interlocking limiting guide rod, a spiral groove is formed in the outer surface of the outer ring, and the guide centres are located in the spiral groove; the thread of the spiral groove is opposite to the thread of the screw structure in rotating direction; a sliding-moving device is fixed to the valve and can drive the valve to slide in the guide inner ring along the axis. and a limiting structure is arranged on the fixed inner ring. The quick coupling has the advantages that a tank car does not need tobe transformed, and operation is easy.

Owner:连云港天邦科技开发有限公司

Portable breathing air supply device capable of realizing self-adaptive adjustment

The invention discloses a portable breathing air supply device capable of realizing self-adaptive adjustment. The portable breathing air supply device is characterized in that a lung type valve is mounted in an inner cavity of a first shell and divides the inner cavity into an oxygen inlet inner cavity, an oxygen outlet inner cavity and an oxygen transfer inner cavity which are independent of oneanother, the oxygen inlet inner cavity is used for being connected with an oxygen source, the oxygen outlet inner cavity communicates with an oxygen inlet in an air suction pipe connector, the oxygentransfer inner cavity communicates with a mixed gas outlet in the air suction pipe connector, a corrugated pipe flow adjusting mechanism is mounted in an inner cavity of a second shell, and an air inlet and an air outlet of the corrugated pipe flow adjusting mechanism communicate with outside air and an air inlet in the air suction pipe joint respectively. The portable breathing air supply devicehas the advantages of facilitating self-adaptive adjustment of oxygen and air flow, being high in integration level, small in size, light in weight and convenient to carry, is suitable for providing oxygen supply protection for plateau operators, and can be widely applied to oxygen demand places such as plateau and mountainous regions and oxygen scenes for teaching tests.

Owner:CHENGDU KANGTUO XINGYE TECH CO LTD

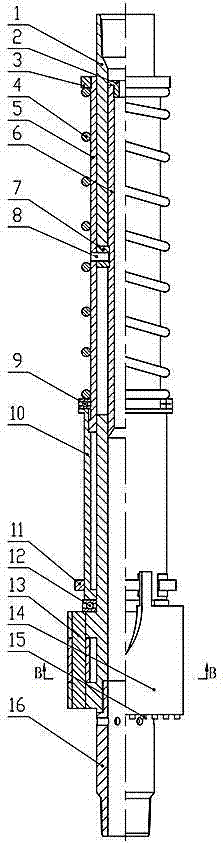

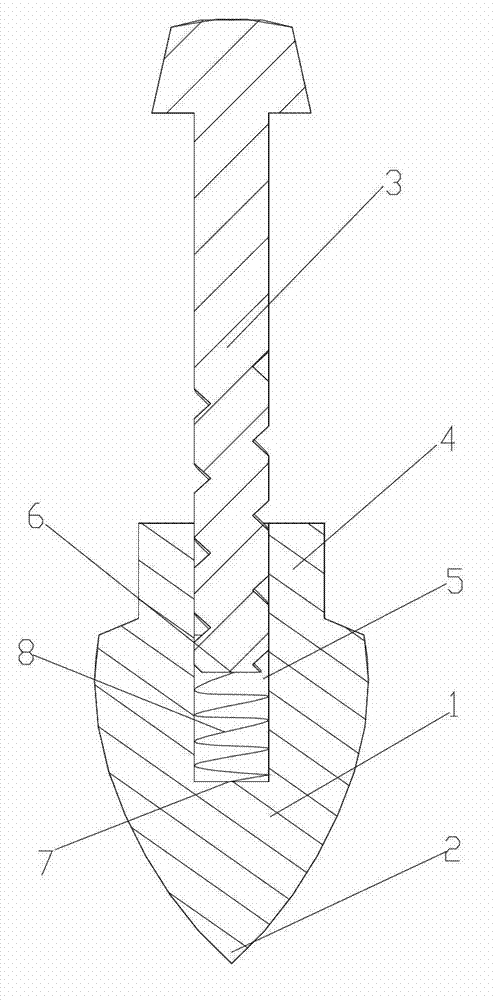

Large changing diameter double-drag-blade hole reaming drill

InactiveCN103556950BWide range of variable diameterSmall starting forceDrill bitsThrust bearingEngineering

The invention relates to a large changing diameter double-drag-blade hole reaming drill for deep stratum mineral exploitation and oil gas well underground hole reaming, and solves the problem that a conventional drill cannot change diameter, or the diameter changing range is too small. The technical scheme is that a main cylinder body is in screw thread connection with a lower joint; two drag blades are hinged to hinge supports of the main cylinder body through pin bolts; a rotary cylinder body is sleeved in the main cylinder body; an outer central pipe is sleeved in the main cylinder body; bulge splines at the outer part of the outer central pipe are embedded into a screw groove in the inner part of the rotary cylinder body; three sliding blocks respectively penetrate through three through grooves of the main cylinder body, and are embedded in a ring-shaped groove in the outer part of an inner central pipe; the outer central pipe is connected with the sliding blocks through bolts; the upper part of the inner central pipe is in screw thread connection with a water nozzle; a thrust bearing a is sleeved in the outer central pipe, and is contacted with the rotary cylinder body; a reset spring is mounted on the upper end surface of the thrust bearing a; a baffle ring is in screw thread connection with the outer central pipe; one ends of arch connecting rods are hinged to the rotary cylinder body, and the other ends of the arch connecting rods are hinged to the drag blades; cutting teeth are embedded on the drag blades. The drill is large in diameter changing range, simple to control and reliable in structure, and can be used for the hole reaming operation.

Owner:SOUTHWEST PETROLEUM UNIV

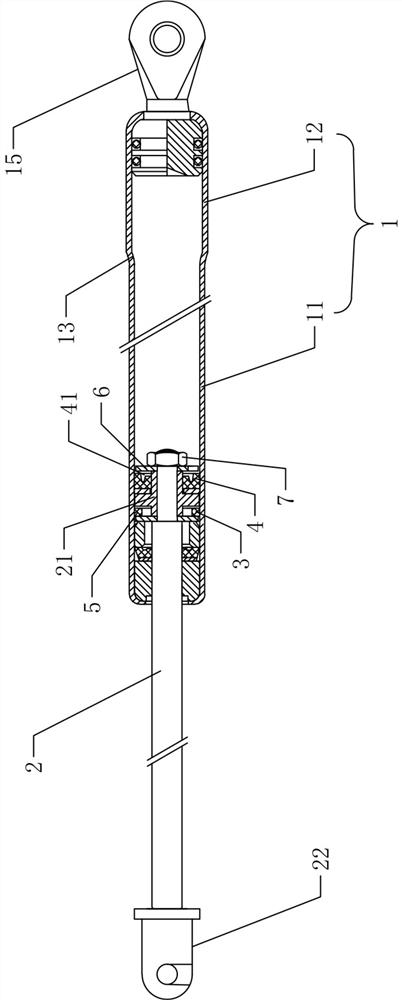

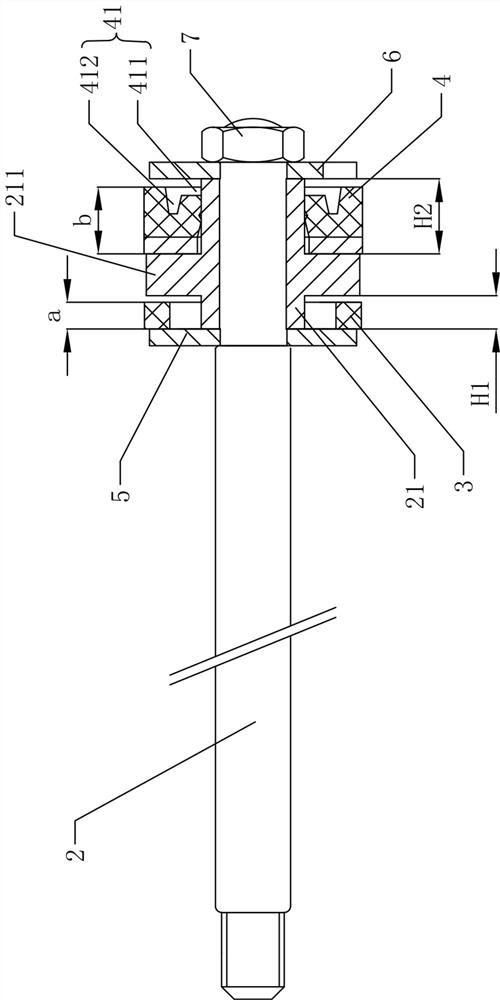

Damping type gas spring

ActiveCN113565914AReduce the degree of expansionAvoid high static locking forcesSpringsGas based dampersGas springEngineering

The invention discloses a damping type gas spring. The damping type gas spring. comprises a cylinder barrel and a piston rod arranged on the cylinder barrel in a telescopic mode, the piston rod is provided with a piston assembly, the piston assembly comprises a piston framework, a rectangular ring, a bowl-shaped ring, a piston flat gasket and a piston fancy gasket, and the piston framework is fixedly installed on the piston rod; the rectangular ring and the bowl-shaped ring are both arranged on the piston framework in a sleeving mode, the piston flat gasket abuts against the rectangular ring for limiting, the piston fancy gasket abuts against the bowl-shaped ring for limiting, and the outer side wall of the bowl-shaped ring is arranged to be a cylindrical surface; and a long-strip-shaped thin groove is formed in the inner wall of the cylinder barrel in the axial direction of the cylinder barrel, and air in the cylinder barrel circulates through the thin groove. The damping type gas spring has the following advantages and effects that a new mechanical structure is utilized for the scheme, the mode that the single bowl-shaped ring is matched with the rectangular ring is adopted, friction resistance with the inner wall of the cylinder barrel during movement can be reduced to a certain extent, accordingly, large static locking force is prevented from being generated during starting, the outward expansion degree of the bowl-shaped ring can be reduced through the cylindrical surface, and elastic restoring force is reduced, so that starting force is reduced, and starting is more convenient.

Owner:FENGHUA RENLONG MACHINERY

A hydraulic variable diameter centralizer

InactiveCN103541666BSmall starting forceConvenient hydraulic driveDrilling rodsDrilling casingsWell drillingAxial thrust

The invention relates to a hydraulic variable-diameter centralizer used for convention oil gas well drilling and solid mineral resource well drilling, and the hydraulic variable-diameter centralizer solves the problems that an underground variable-diameter centralizer is large in starting force and short in installation distance. According to the technical scheme, sliding blocks penetrate through lower cylindrical body through grooves and are embedded into inner central tube annular grooves, an outer central tube is arranged in a revolving cylindrical body in a sleeved mode, protrusive splines outside the outer central tube are embedded into spiral grooves in the revolving cylinder body, a spring c is arranged outside the outer central tube in a sleeved mode, an upper cylindrical body is in threaded connection with a lower cylindrical body, a spring b is arranged outside the upper cylindrical body in a sleeved mode, and a sliding sleeve is arranged in the upper cylindrical body in a sleeved mode. A centralizing arm a is hinged to the triangular prism surface of the sliding sleeve, a centralizing arm b is hinged to the triangular prism surface of the lower cylindrical body and hinged to the centralizing arm a, a locking cylinder is placed in an upper cylindrical body through hole, a spring a is put in the locking cylinder, and a press plate and the upper cylindrical body are fixed through screws a. The hydraulic variable-diameter centralizer converts axial motion of the inner central tube and the outer central tube into circumferential direction rotation of the revolving cylindrical body, converts axial thrust generated by hydraulic pressure into circumferential direction centralizing force, and is reliable in supporting and large in installation distance.

Owner:SOUTHWEST PETROLEUM UNIV

Time Flow Valve

InactiveCN101965472ACompact designSmall pressure chamberFluid-delivery valvesThin material handlingControl roomEngineering

Owner:MICROFLOW INTERNATIONAL PTY LTD

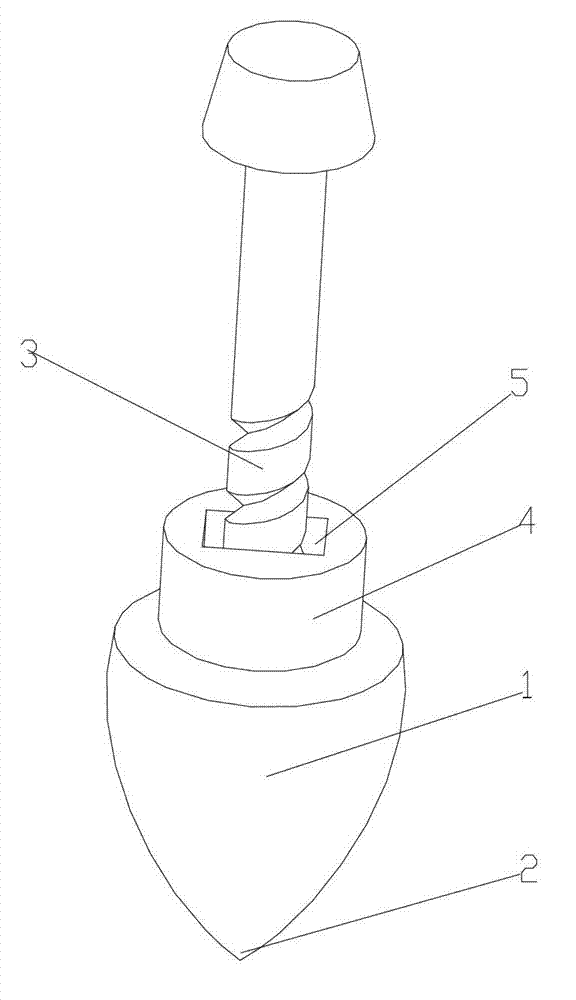

Driven gyro

The invention discloses a driven gyro which comprises a gyro body and a screw rod, a touchdown rotating head is arranged at the bottom of the gyro body, a boss is arranged at the upper end of the gyro body, an opening matched with the screw rod is arranged in the boss, the cross section of the opening is rectangular, and the screw rod is inserted into the opening and capable of moving up and down along the opening to drive the gyro body to rotate. The driven gyro in the scheme is simple in structure and only needs to be placed on the ground or on other table tops when played, and a hand holds the screw rod to apply downward action force and the screw rod moves downwards in the opening so as to drive the gyro to rotate. The driven gyro is extremely simple to operate, small in starting force, long in continuous rotation time and particularly suitable for children to play.

Owner:朱兴生

A labor-saving linkage positioning and locking structure

ActiveCN105090302BReliable locking and positioningAchieve reliable fastening effectBraking membersBrake actuating mechanismsStart timeLocking mechanism

The invention discloses a labor-saving linkage positioning and locking structure, which belongs to the technical field of mechanical processing equipment positioning and includes connecting rods, claws, screw rods, racks, cross universal joints, guide rails, locking mechanisms, spring support seats, positioning Groove and leaf spring; the guide rail is horizontally installed on the frame, and the guide rail is provided with a positioning groove; the side of the frame is provided with a spring support seat, and a leaf spring is arranged on the spring support seat, and the leaf spring is parallel to the guide rail; The connecting rod is horizontally arranged below the guide rail perpendicular to the guide rail, the screw rods are respectively connected to both ends of the connecting rod, and cross universal joints are arranged between the connecting rod and the screw rod; the claws are respectively matched and installed on both ends of the connecting rod. On the screw rods at the end, one of the screw rod ends is fixedly connected with a locking mechanism. The technical solution uses the positioning of the rollers and the linkage of the claws, so that the mechanical load with rollers can be positioned and locked quickly, stably and reliably for a long time on the guide rail, and the starting force is small when restarting, and there is no scratch on the guide rail.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

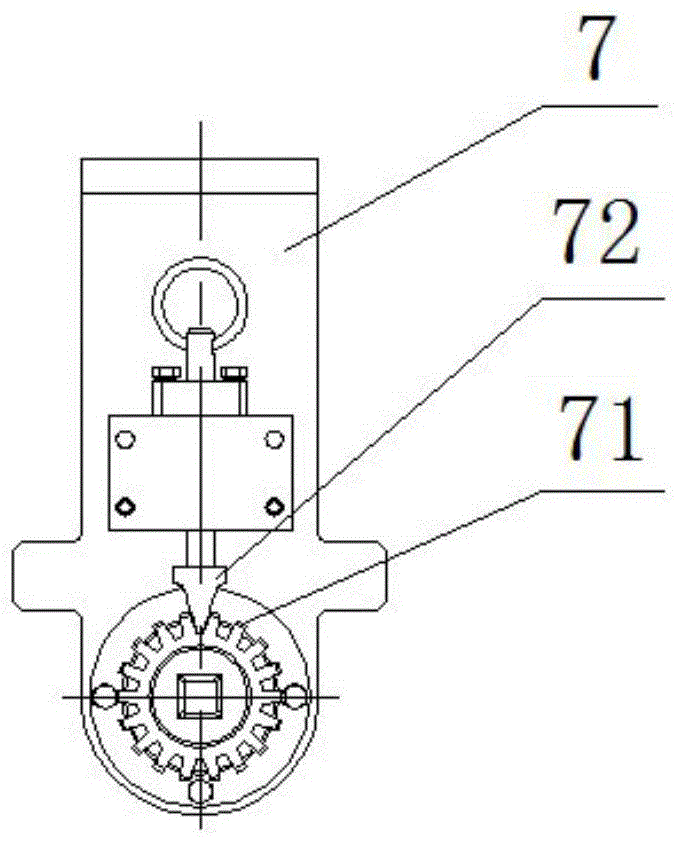

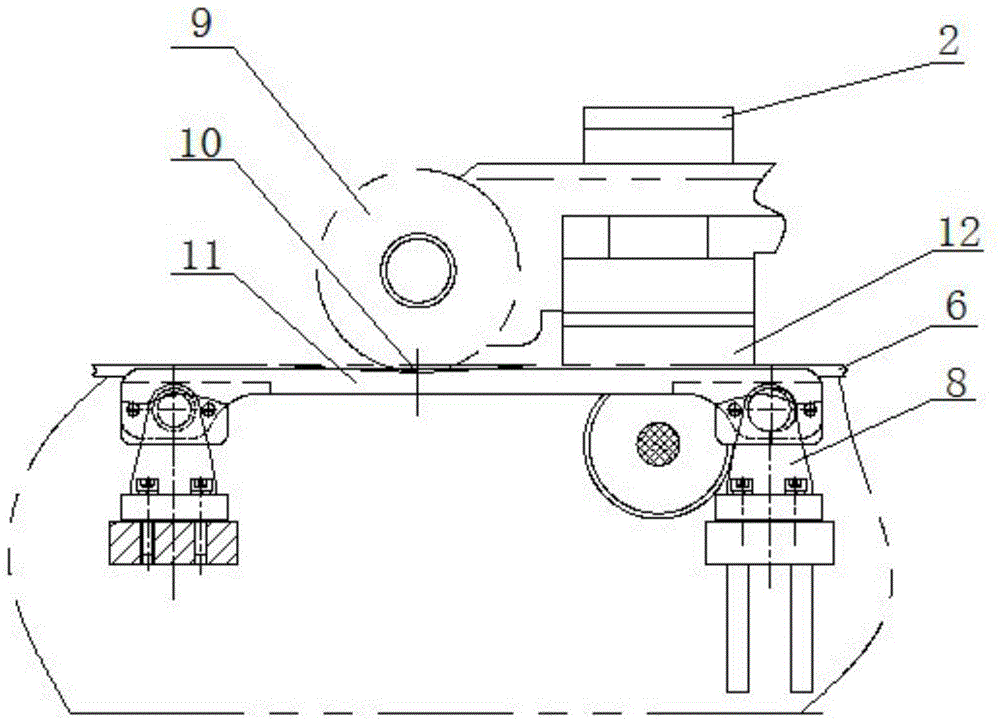

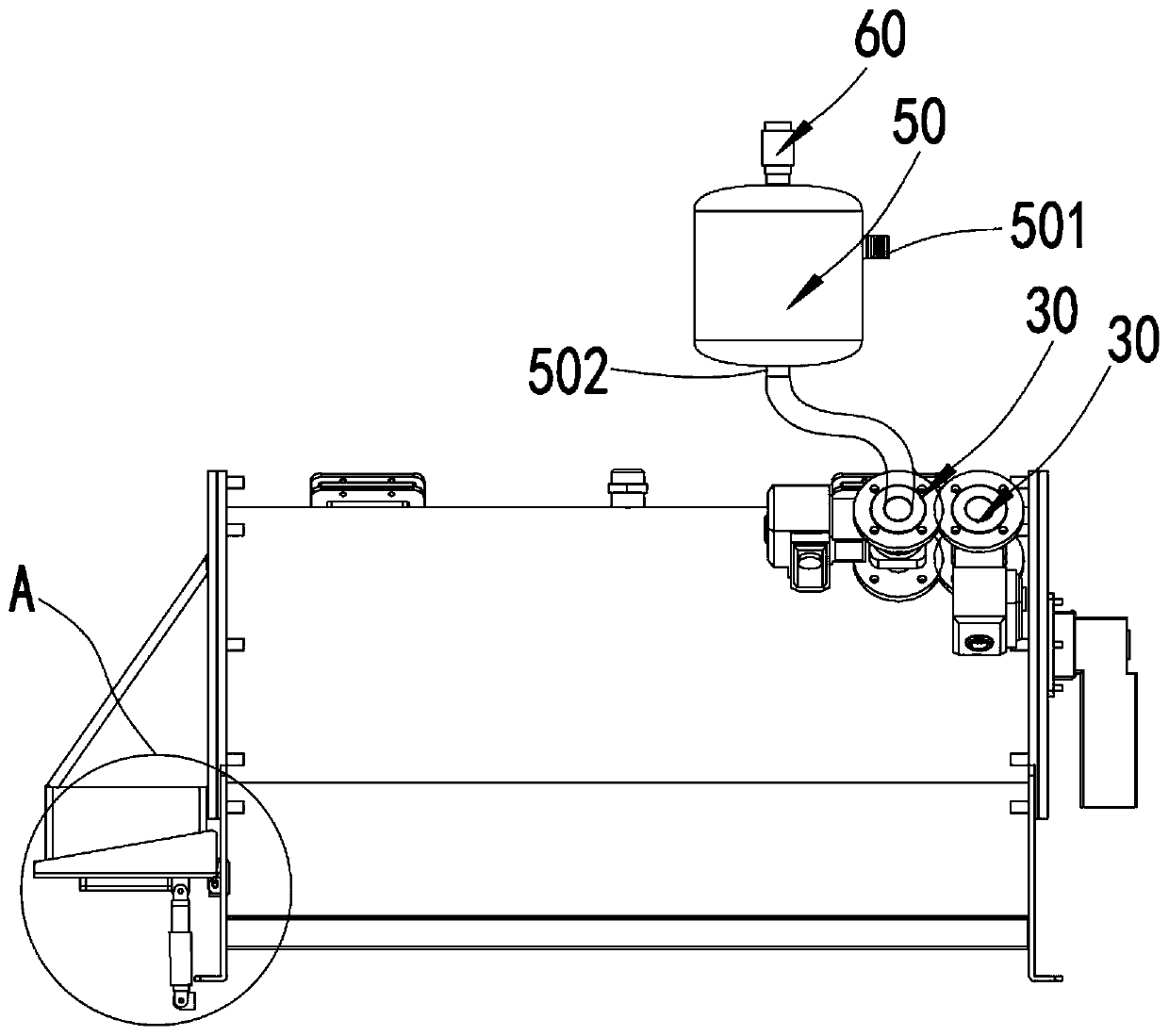

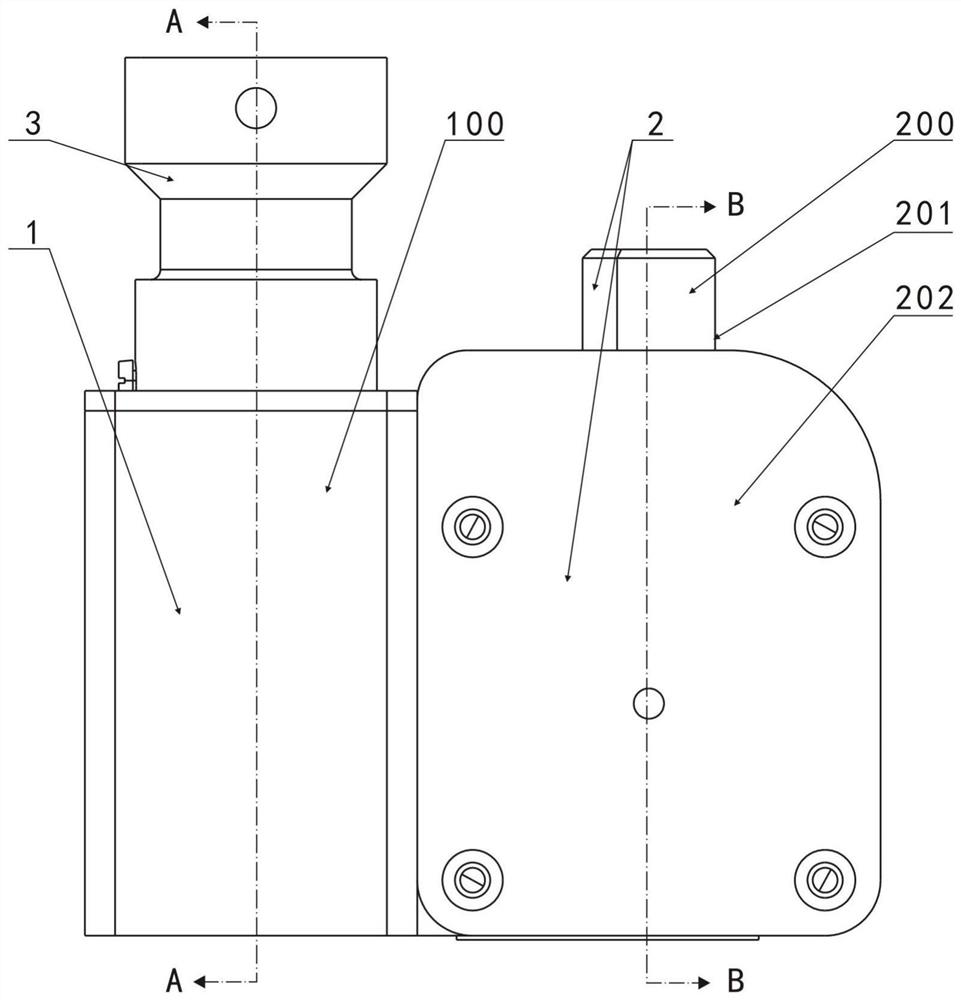

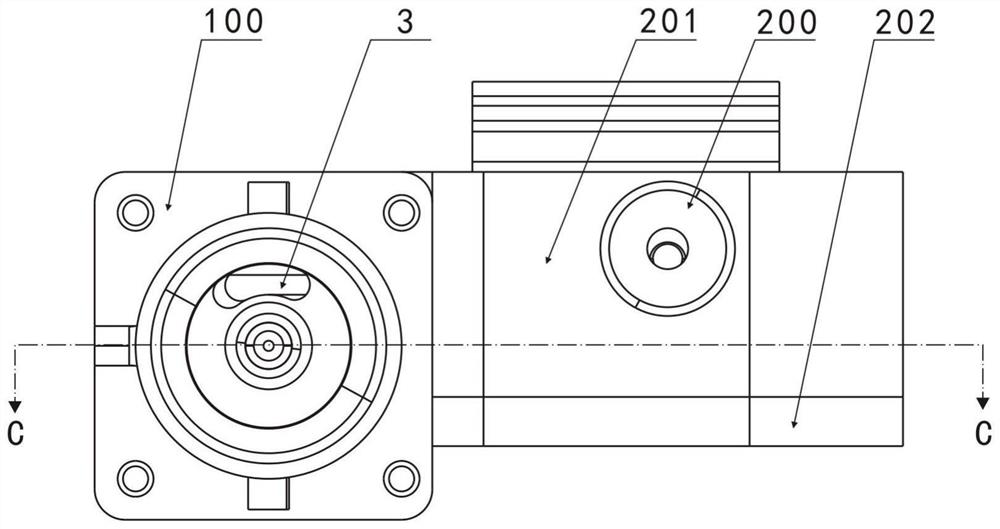

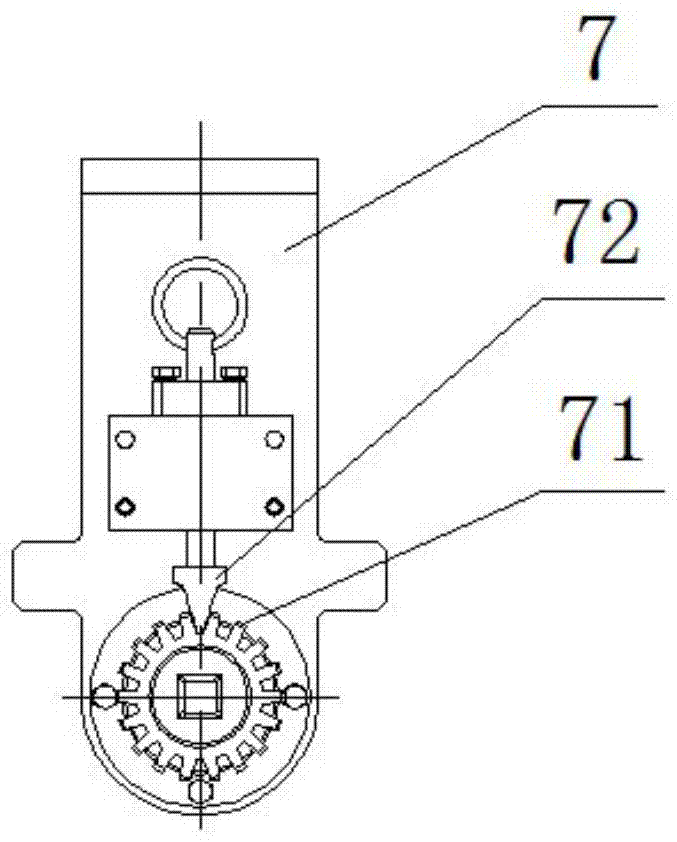

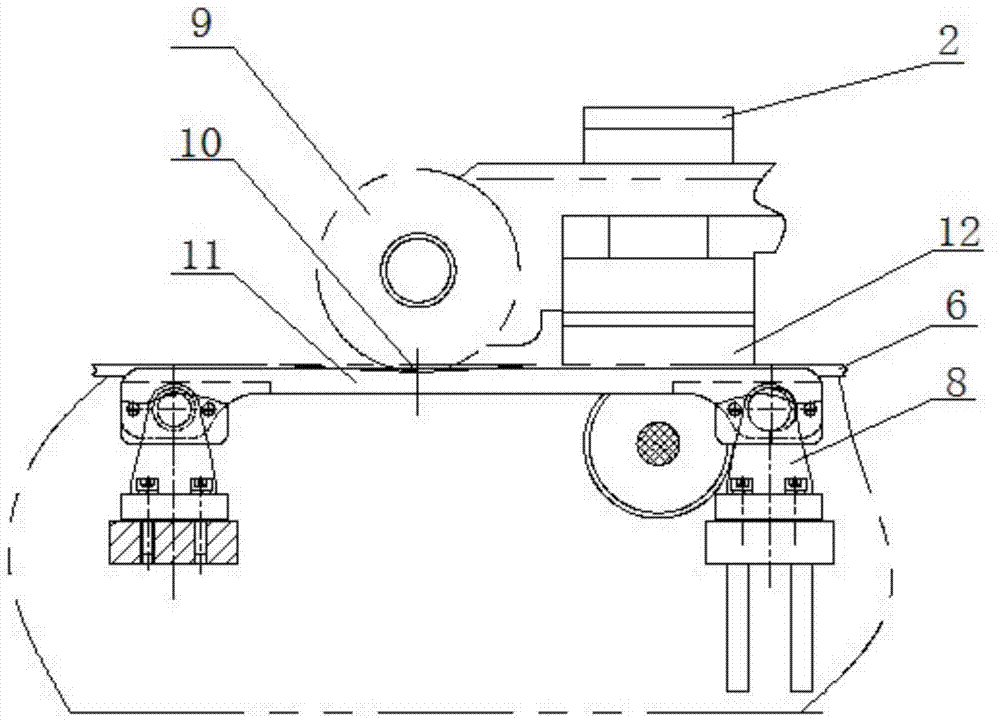

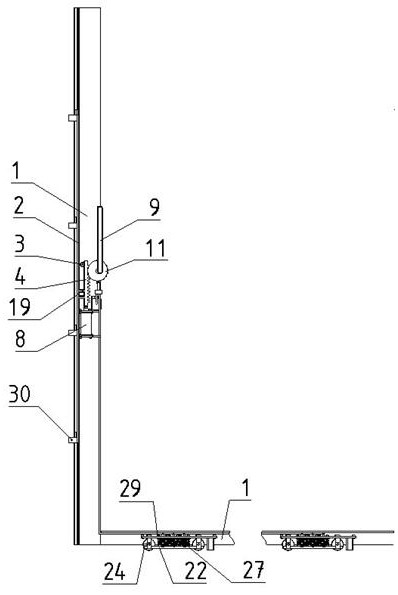

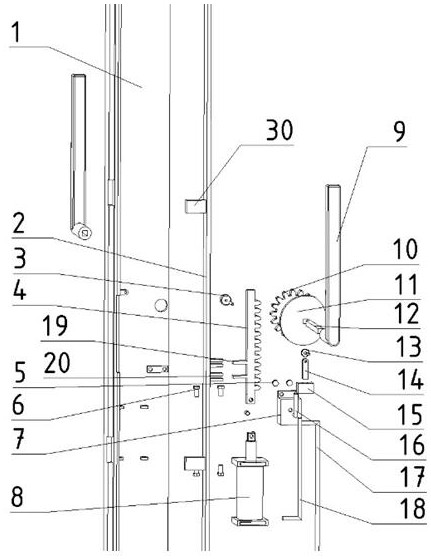

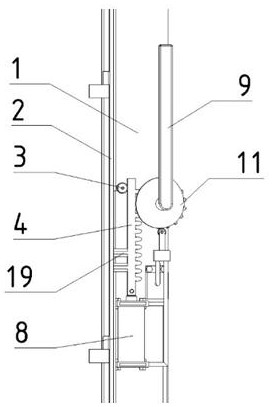

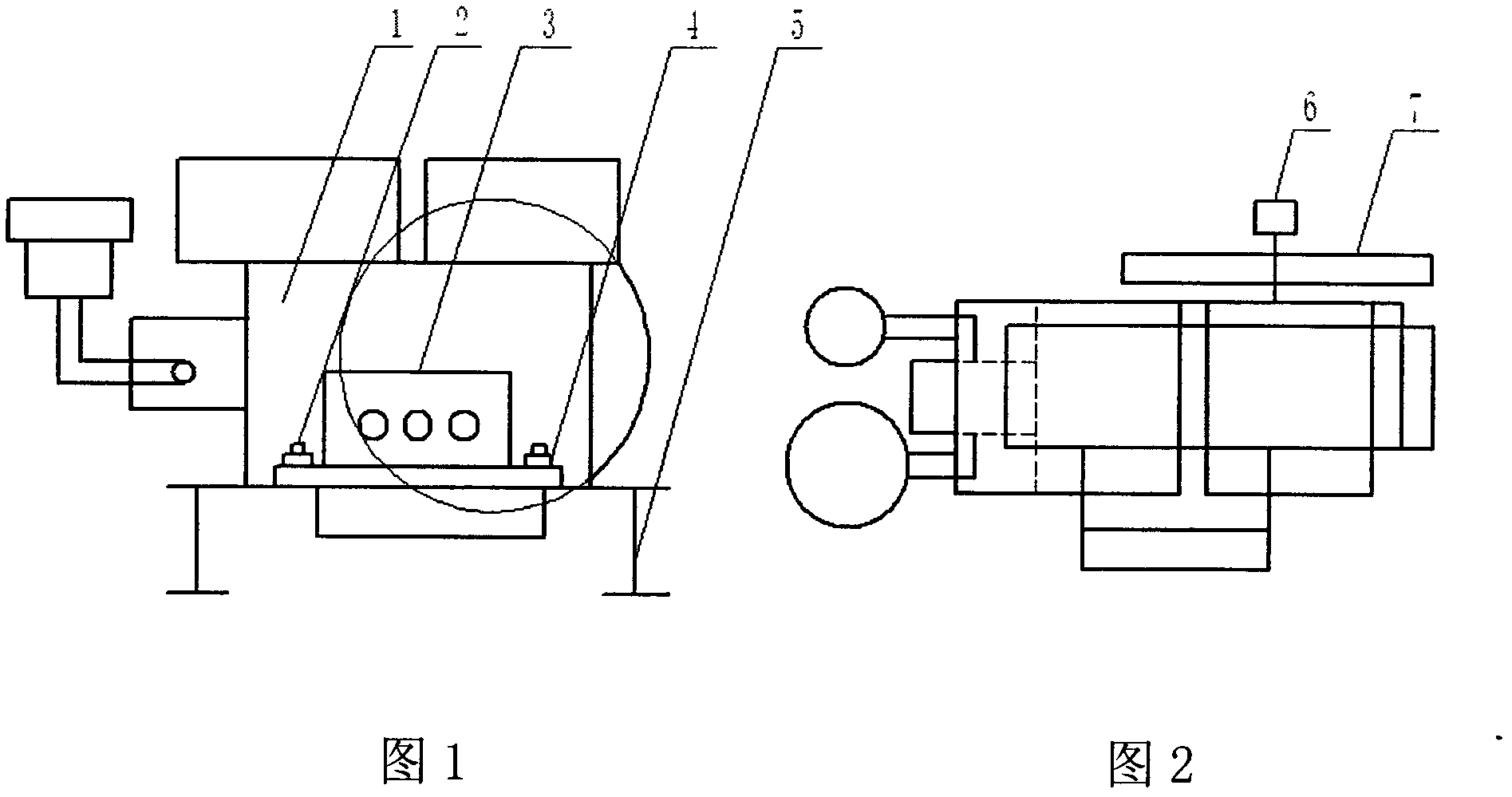

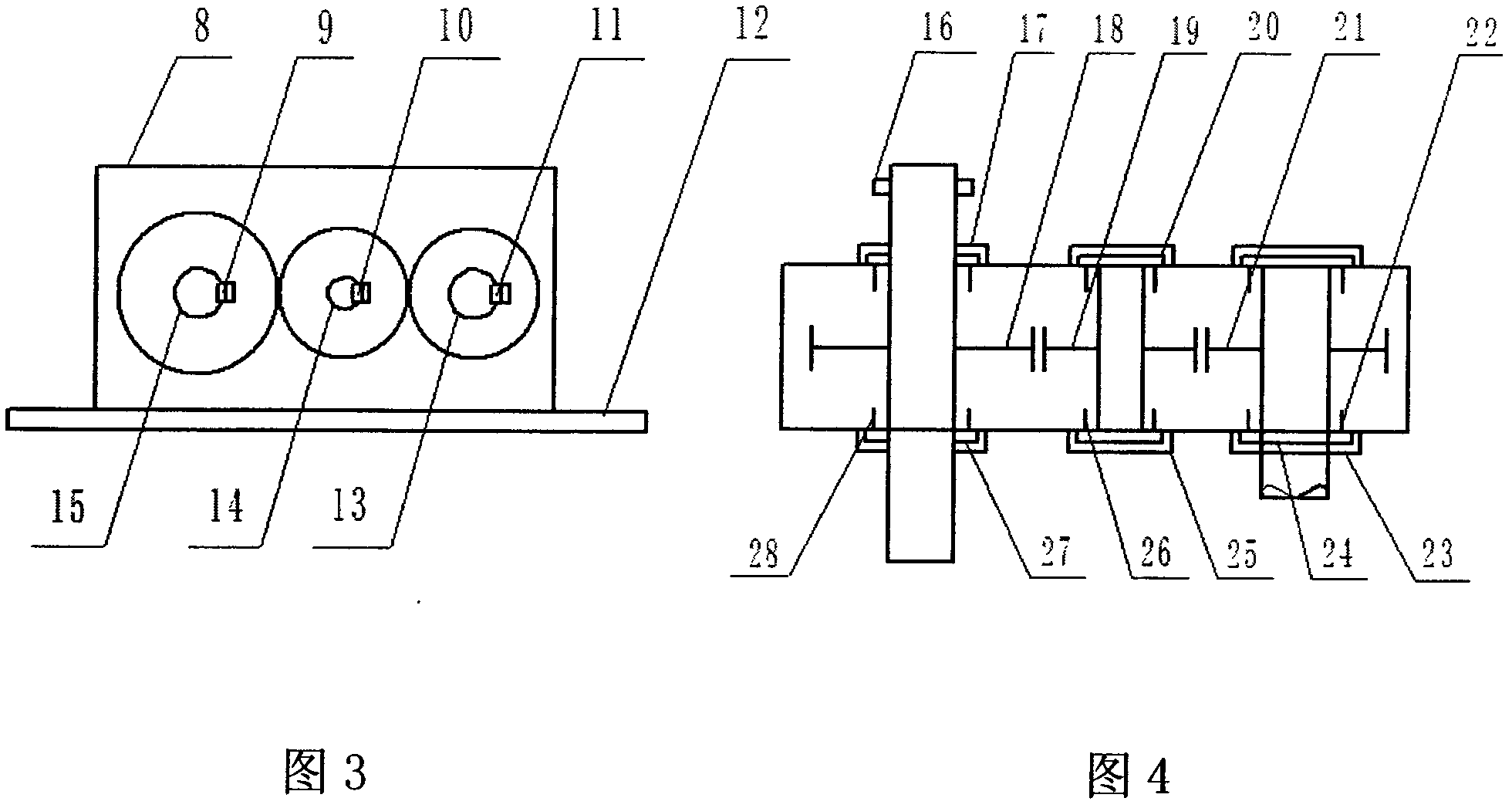

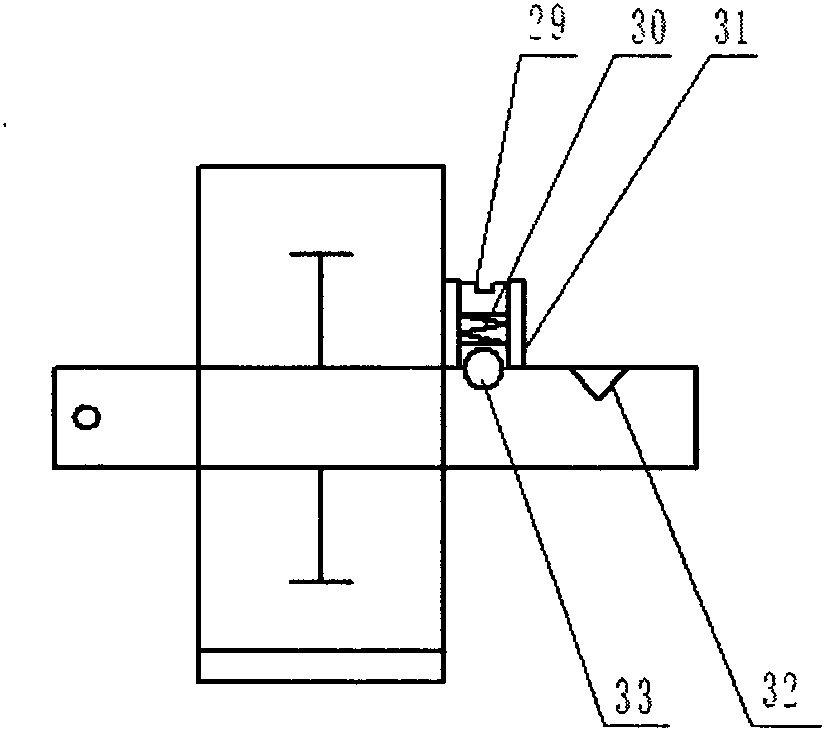

Hydraulic force increasing and transmission system for lifting sliding door

ActiveCN113073916ASolve CatonSmall starting forcePower-operated mechanismWing suspension devicesHydraulic cylinderGear wheel

The invention provides a hydraulic force increasing and transmission system for lifting a sliding door. The hydraulic force increasing and transmission system comprises a handle mechanism arranged on the vertical edge of a door leaf, a pulley mechanism arranged on the bottom edge of the door leaf and a hydraulic control mechanism which drives the pulley mechanism to lean on through the handle mechanism; the hydraulic control mechanism is connected with the handle mechanism and the pulley mechanism through a locking hydraulic cylinder and a lifting hydraulic cylinder; the locking hydraulic cylinder is fixed to the door leaf; the lifting hydraulic cylinder is fixed to the pulley mechanism; the handle mechanism is used for locking the door leaf and driving the hydraulic control mechanism; the hydraulic control mechanism is used for driving the pulley mechanism; the pulley mechanism is used for lifting and pushing the door leaf; and the handle mechanism and the pulley mechanism are provided with different hydraulic cylinders, a handle drives a gear and a rack to move so that the hydraulic cylinders can move, and the door leaf can be lifted and lowered. By means of the system, torque needed for lifting the door leaf can be effectively reduced, and the phenomena of jamming and jamming which are extremely prone to happening in a traditional mechanical transmission manner are avoided.

Owner:SHANDONG JIANZHU UNIV

Labor-saving starter of diesel engine

InactiveCN103032233AImprove work efficiencyReduce labor intensityMuscle operated startersMachines/enginesEngineeringDiesel engine

The invention discloses a labor-saving starter of a diesel engine. The labor-saving starter is connected with a diesel engine installing frame, a labor-saving starter box body is connected with a starter base plate, a starting shaft key is connected with a starting shaft and a starting gear, a middle shaft key is connected with a middle shaft and a middle gear, a crank shaft key is connected with a crank shaft and a crank gear, the middle gear is connected with the middle shaft and is meshed with the starting gear, the crank gear is connected with the crank shaft and is meshed with the middle gear, a set screw is connected with a rolling ball pressure spring and a rolling ball, the rolling ball pressure spring is connected with the rolling ball, the rolling ball is connected with the rolling ball pressure spring and the inclined surface of the rolling ball, a diesel engine starting pipe shaft is connected with a diesel engine body, and a starting pin shaft is connected with the starting shaft.

Owner:许飞

A damping gas spring

ActiveCN113565914BReduce the degree of expansionAvoid high static locking forcesSpringsGas based dampersGas springEngineering

The invention discloses a damping gas spring, which comprises a cylinder, a telescopic piston rod arranged on the cylinder, the piston rod is provided with a piston assembly, and the piston assembly includes a piston skeleton, a rectangular ring, a bowl ring, a piston flat washer and a piston The flower pad, the piston frame is fixedly installed on the piston rod; the rectangular ring and the bowl ring are both sleeved on the piston frame, the piston flat pad and the rectangular ring are offset to limit, the piston flower pad and the bowl ring are offset to limit, and the bowl ring The outer wall of the cylinder is set as a cylinder; the inner wall of the cylinder is provided with a long thin groove along the axial direction of the cylinder, and the thin groove is used for the gas circulation in the cylinder. The present invention has the following advantages and effects: the scheme utilizes a new mechanical structure and adopts a single bowl-shaped ring and a rectangular ring to cooperate to a certain extent, which can reduce the frictional resistance between the inner wall of the cylinder during movement, thereby avoiding the Larger static locking force is generated when starting, and the cylindrical surface can reduce the degree of expansion of the bowl-shaped ring and reduce the elastic recovery force, thereby reducing the starting force and making it easier to start.

Owner:FENGHUA RENLONG MACHINERY

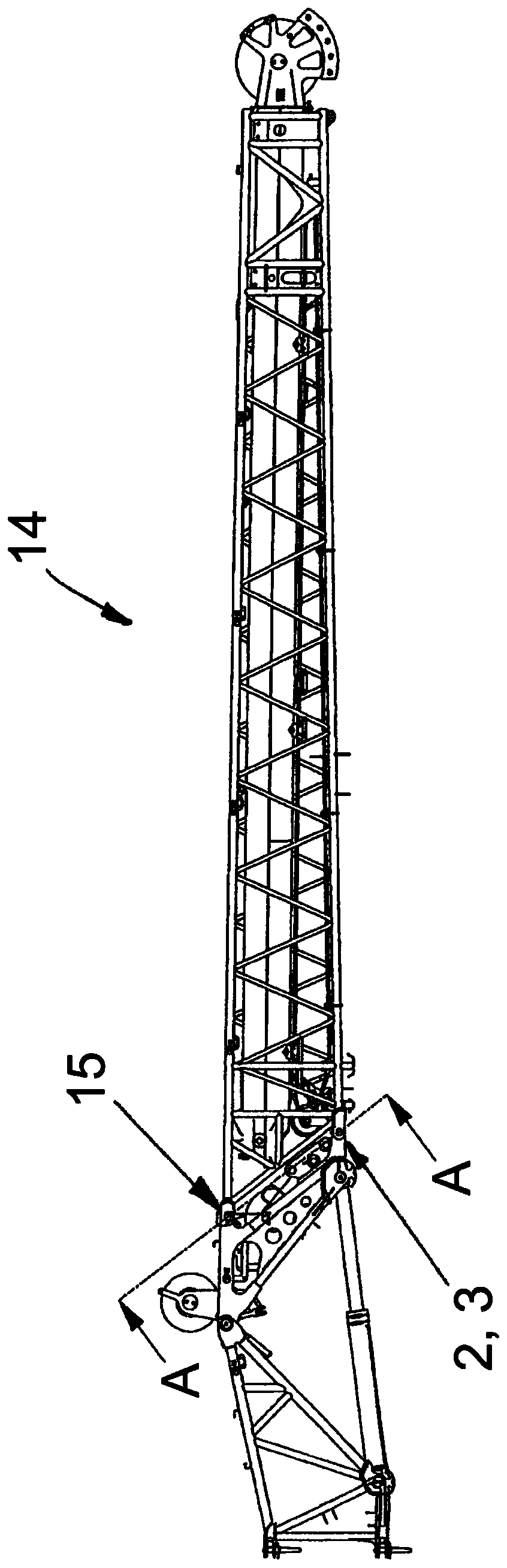

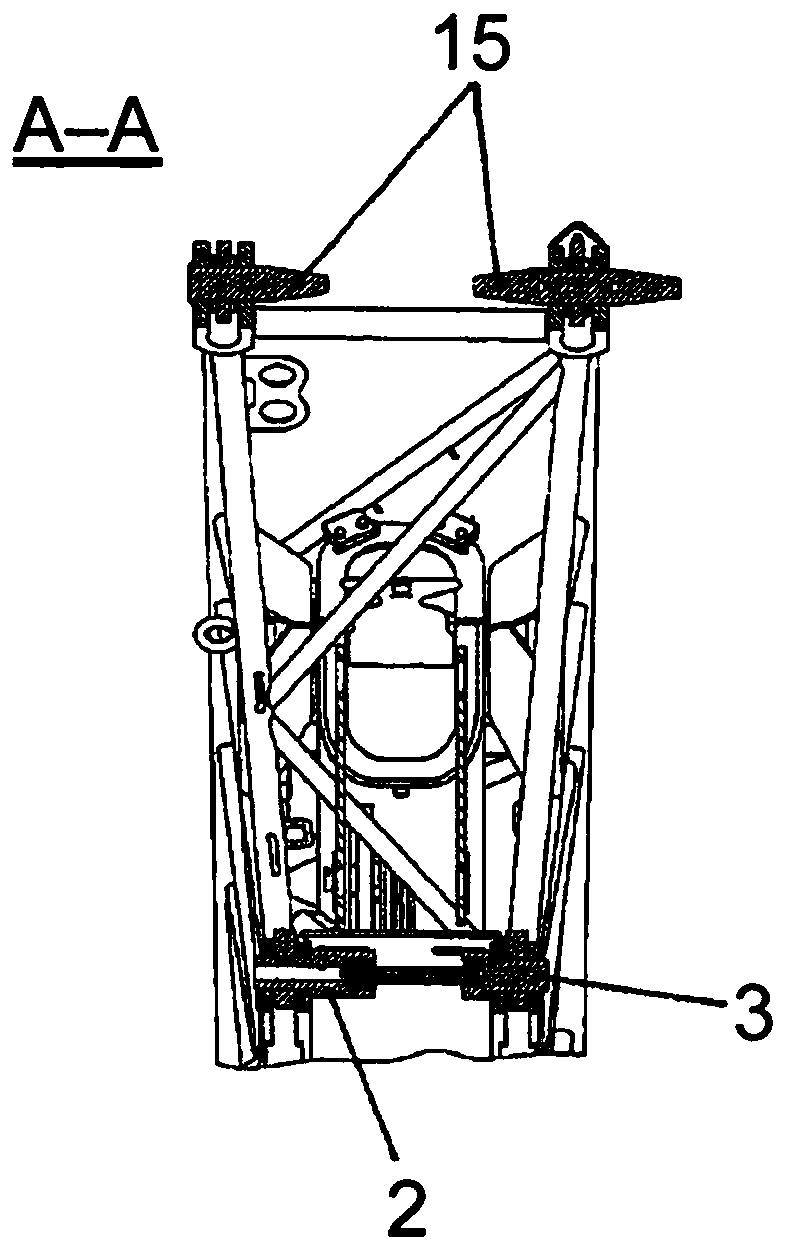

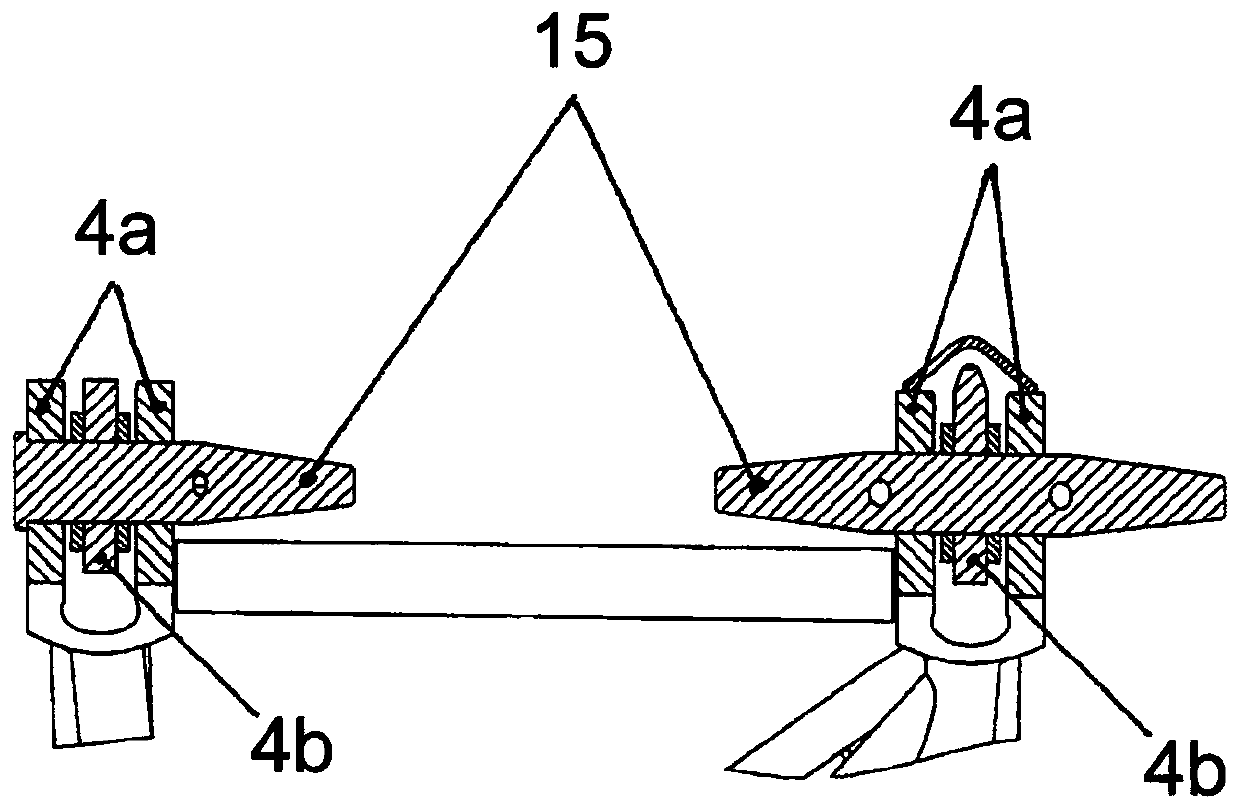

Bolting Device

ActiveCN108502751AAchieving Symmetrical MovementScheduled revolutions halvedRod connectionsCranesScrew threadBolt connection

The invention relates to a bolting device having two bolts which are held rotationally secure and coupled to each other via a spindle element, wherein: a first bolt is connected via a threaded engagement to a corresponding thread of the spindle element; rotating the spindle element about its central longitudinal axis causes the first bolt to move along the longitudinal axis; and a second bolt is rotationally mounted on the spindle element in a fixed axial position. The invention also relates to a crane jib head comprising such a bolting device, for bolting a lattice masthead to a head adaptor.

Owner:MANITOWOC CRANE GROUP FRANCE

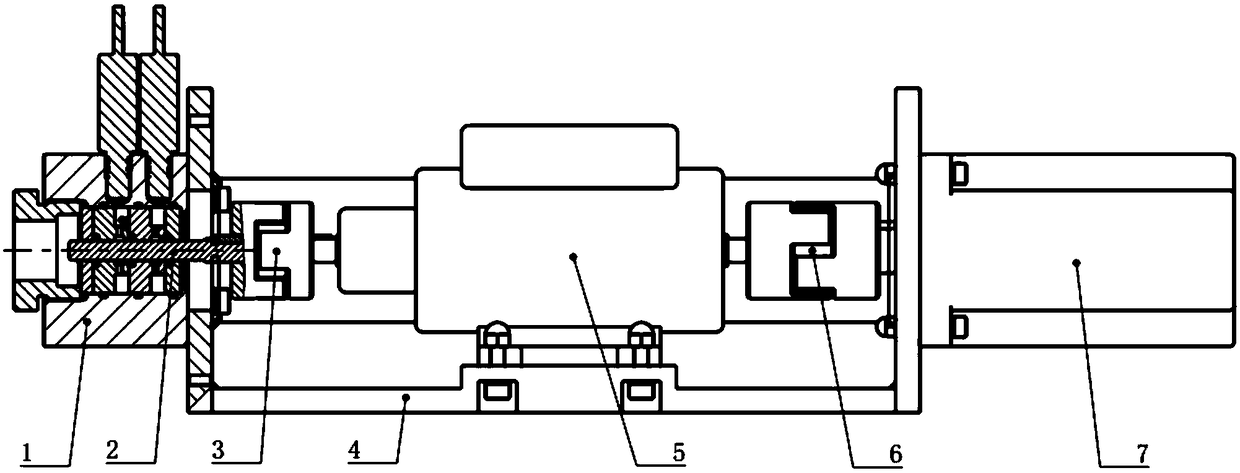

A low starting force water pump device and its control method

InactiveCN105937498BExtended service lifeAchieve conversionRotary/oscillating piston combinations for elastic fluidsMagnetically actuated clutchesElectric machineEngineering

Provided are a low-starting-force water pump device and a control method of the low-starting-force water pump device. The low-starting-force water pump device comprises a drive motor. One end of each rotating shaft of the drive motor is connected with a corresponding power input shaft of a first clutch device. A power output shaft of the first clutch device is connected with an input shaft of an energy storing device. The other end of one rotating shaft of the drive motor is connected with a power input shaft of a second clutch device. The power output shaft of the second clutch device is connected with a pump body. The control method of the low-starting-force water pump device comprises the steps that the first clutch device engages, and the second clutch device disengages; a first motor and a second motor start simultaneously and drive a flywheel of the energy storing device to rotate through the first clutch device; after the flywheel rotates stably, the first clutch device disengages, the second clutch device is kept in the disengaged state, and meanwhile the second motor stops; and the second clutch device engages, the first clutch device is kept in the disengaged state, and the pump body is driven to start and operate through the first motor and the energy storing device together. By the adoption of the low-starting-force water pump device and the control method of the low-starting-force water pump device, the starting force of the water pump device is low, electric energy loss is reduced, and production cost is reduced.

Owner:李丽容

Bolt connection

ActiveCN108502751BAchieving Symmetrical MovementScheduled revolutions halvedRod connectionsCranesClassical mechanicsScrew thread

The invention relates to a bolt connection device comprising two bolts which are rotationally fixed and connected to each other by a spindle element, wherein: a first bolt is connected by a threaded engagement with a corresponding thread of the spindle element; Rotation of the spindle member about its central longitudinal axis causes said first bolt to move along said longitudinal axis; and a second bolt is rotatably mounted on said spindle member in a fixed axial position. The invention also relates to a crane jib head comprising such a bolting arrangement for bolting a lattice masthead to a head adapter.

Owner:MANITOWOC CRANE GROUP FRANCE

Variable-inertia spring flywheel capable of automatically regulating rotational inertia

The invention discloses a variable-inertia spring flywheel capable of automatically regulating the rotational inertia. The variable-inertia spring flywheel comprises a flywheel shaft, a fixed disc, flywheel plates and a connecting spring; the fixed disc is coaxially and fixedly connected with the flywheel shaft; at least two flywheel plates are uniformly distributed in the circumferential direction of the fixed disc; the flywheel plates are slidably connected with the fixed disc in the radial direction; and the two ends of the connecting spring are correspondingly fixedly connected with the adjacent flywheel plates. The flywheel disclosed by the invention is simple to mount, dismount and transfer; when at a low speed, the flywheel plates are difficult to move out due to limitation of the connecting spring so as to maintain a relatively low rotational inertia; when at a high speed, the flywheel plates move out because the limitation of the connecting spring is overcame by the centrifugal force so as to obtain a relatively high rotational inertia; the flywheel has the characteristics of small start force and high energy storage; each independently moving flywheel can realize automatic regulation by automatically sensing the quality unevenness of the flywheel and the torque fluctuation of an input end and an output end, and thus abnormal vibration and torque fluctuation are reduced.

Owner:凌飞

Integrated Hydraulic Damper with Temperature Sensing Variable Ring Seam

ActiveCN109578492BCompact structureReduce volumeSpringsLiquid based dampersEngineeringThermal displacement

The invention provides a temperature sensing variable annular gap integrated hydraulic damper, which aims at solving the problem that the hydraulic damper is sensitive to temperature change and can maintain relative good stability in a larger temperature range. The invention is realized through the following technical scheme: a temperature compensation annular gap formed by a temperature compensation valve core movably assembled in a plunger hole is combined, a temperature compensation cavity formed by necking in middle part of the temperature compensation valve core, a pressure compensation cavity formed on the space of a plunger shaft end and a damping cavity of the pressure compensation cavity are communicated; the oil in a crossed damping cavity of a piston rod rotor blade generates intermolecular friction in the oil of the damping annular gap; when the temperature of the oil of a damping cylinder is changed, the hydraulic pressure thermal displacement generated by the oil in the temperature compensation cavity push an end drive head of the compensation valve core and the temperature compensation piston to drive the temperature compensation valve core to do reciprocating linearmotion, so that the effective length and height of the temperature compensation annular gap are continuously changed, and the kinematic viscosity of the working medium with temperature changes is balanced and compensated.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

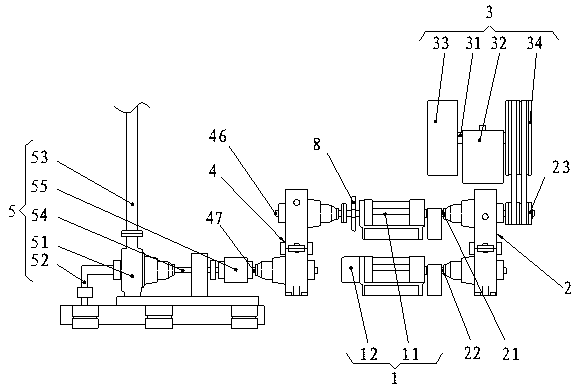

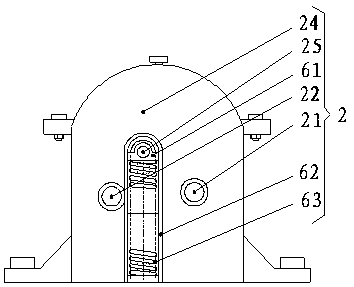

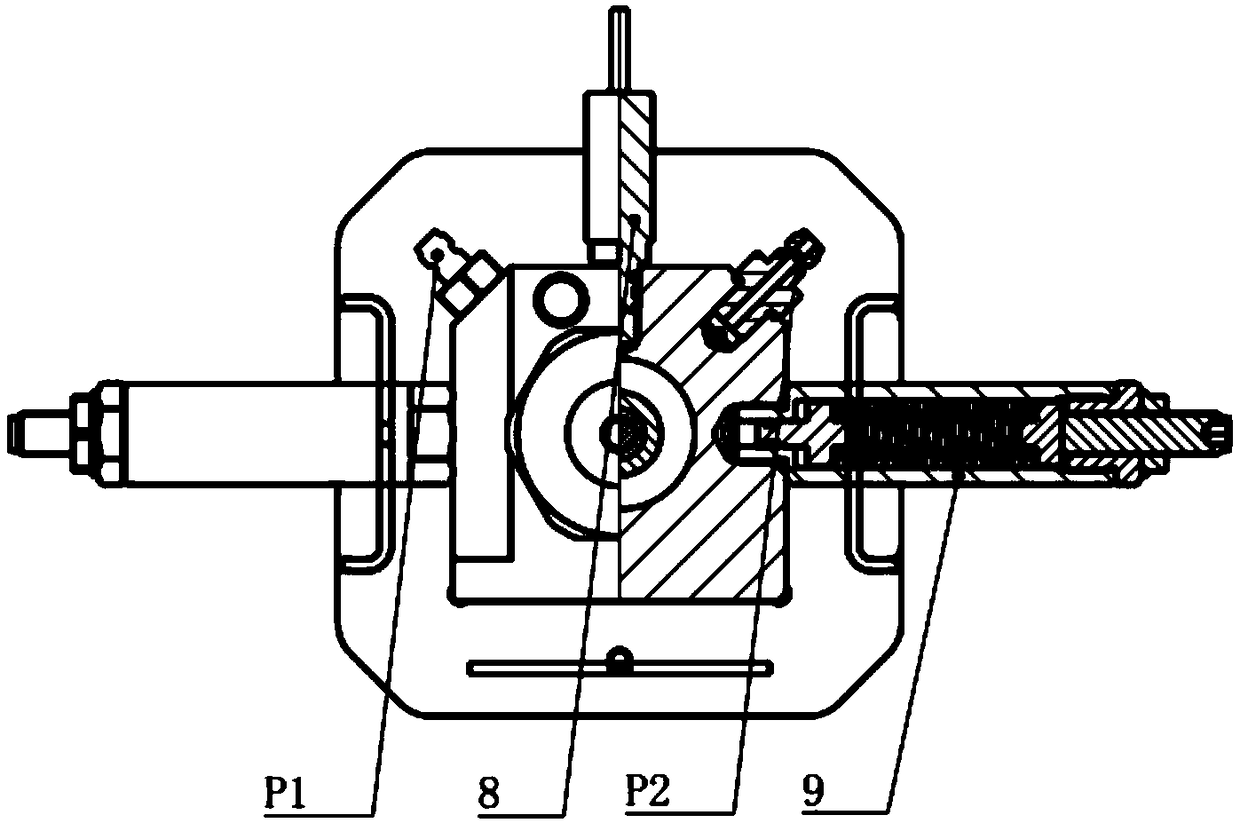

A kind of experimental device and experimental method for rotary dynamic sealing characteristics of sealing ring

ActiveCN106092562BGuaranteed certaintyGuaranteed stabilityMachine sealing rings testingExperimental methodsMotor drive

The invention discloses an experimental device and an experimental method for the rotation dynamic sealing characteristics of a sealing ring. The device comprises a support. A torque rotation speed sensor is installed on the support and a sleeve assembly is sleeved on a shaft thereof. The sleeve assembly is fixedly connected with the support. Two Glyd ring mounting parts are arranged in the sleeve assembly at intervals in the axial direction. A sealing ring mounting part is provided between the two Glyd ring mounting parts. After a Glyd ring and a sealing ring are loaded into the Glyd ring mounting parts and the sealing ring mounting part, the shaft can pass through the Glyd ring and the sealing ring to rotate in the Glyd ring and the sealing ring. A containing cavity for the shaft to pass through is arranged inside each of the Glyd ring mounting parts and the sealing ring mounting part respectively inside the sleeve assembly. According to the experimental device for the rotation dynamic sealing characteristics of the sealing ring, a motor driving shaft is rotated inside the sleeve assembly. After a sealing ring is arranged inside a sealing ring mounting part B, the shaft can pass through the sealing ring to rotate in the sealing ring. In this way, the working state of the sealing ring during rotating can be simulated, so that the experiment on the rotation dynamic sealing characteristics of the sealing ring can be conducted.

Owner:OCEAN UNIV OF CHINA

power tool

ActiveCN104690694BEasy to installSmall starting forcePortable power-driven toolsEngineeringPower tool

The invention relates to a power tool which comprises a shell, an output shaft, a fixing member for pressing a working head onto the output shaft, a locking assembly for locking the fixing member and a driving mechanism, wherein the locking assembly comprises a sleeve fixed in the output shaft, a first clamping member and a second clamping member contained in the sleeve, as well as a rotation shaft arranged between the first clamping member and the second clamping member; the first clamping member and the second clamping member can rotate by taking the rotation shaft as the center, so that the locking assembly is located at a locking position or a release position; a locking member for keeping the locking assembly at the locking position and a first elastic member for elastically supporting the locking member are further arranged between the first clamping member and the second clamping member; the driving mechanism comprises a push rod which is arranged in the output shaft and can move along the output shaft axially; the push rod can push the locking member to move when movement, so as to release restriction on the locking assembly. With adoption of the power tool, the detachment process can be completed conveniently through simple pressing action, without rotating a wrench for multiple turns; the starting force is small.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com