A hydraulic variable diameter centralizer

A centralizer, a variable technology, applied in the direction of drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of short installation distance, large starting force of downhole variable diameter centralizers, etc., and achieve small starting force and simple mechanical structure Reliable, easy-to-drive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

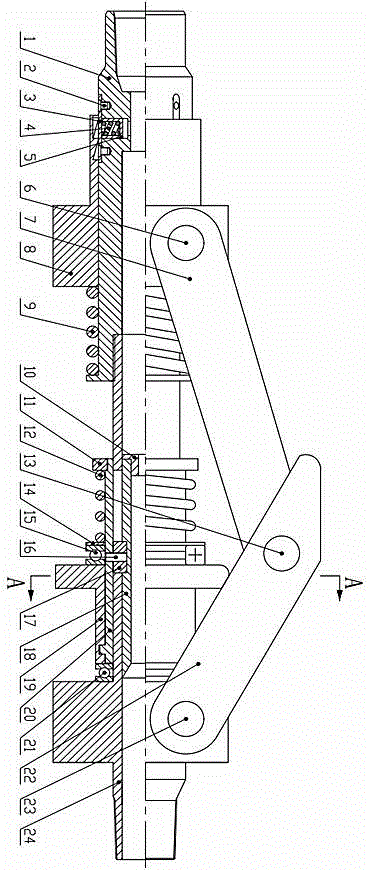

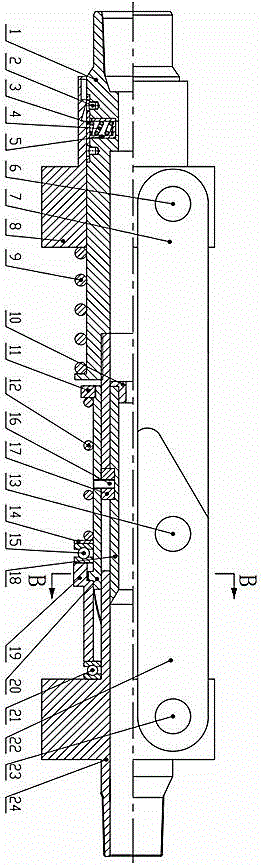

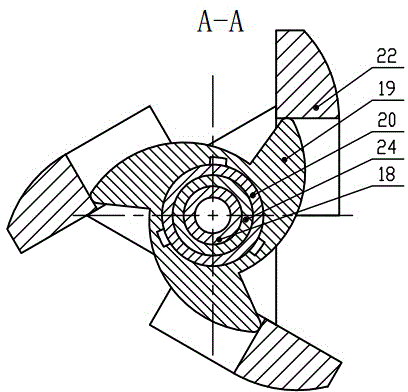

[0012] Such as figure 1 and figure 2 As shown, a hydraulic variable-diameter centralizer of the present invention includes an upper cylinder body 1, a screw a2, a pressure plate 3, a spring a4, a locking cylinder 5, a pin a6, a centralizing arm a7, a sliding sleeve 8, a spring b9, and a faucet 10. Stop ring 11, spring c12, pin b13, spacer ring 14, thrust bearing a15, screw b16, slider 17, inner central tube 18, rotating cylinder 19, outer central tube 20, thrust bearing b21, righting arm b22, The pin c23, the lower cylinder 24; the upper end of the upper cylinder 1 is provided with a standard threaded thread to connect with the upper drill string, the lower end is provided with a standard threaded thread to connect with the lower cylinder 24, and the upper cylinder 1 is radially processed with three through holes , there is a step at the inner end of the through hole, the three through holes are distributed at 120° in the circumferential direction, three grooves are processe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com