Integrated Hydraulic Damper with Temperature Sensing Variable Ring Seam

An integrated technology of hydraulic damper, applied in the field of hydraulic damper, can solve the problem of temperature change sensitivity of hydraulic damper, and achieve the effect of large damping force, improved stability and sensitive response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

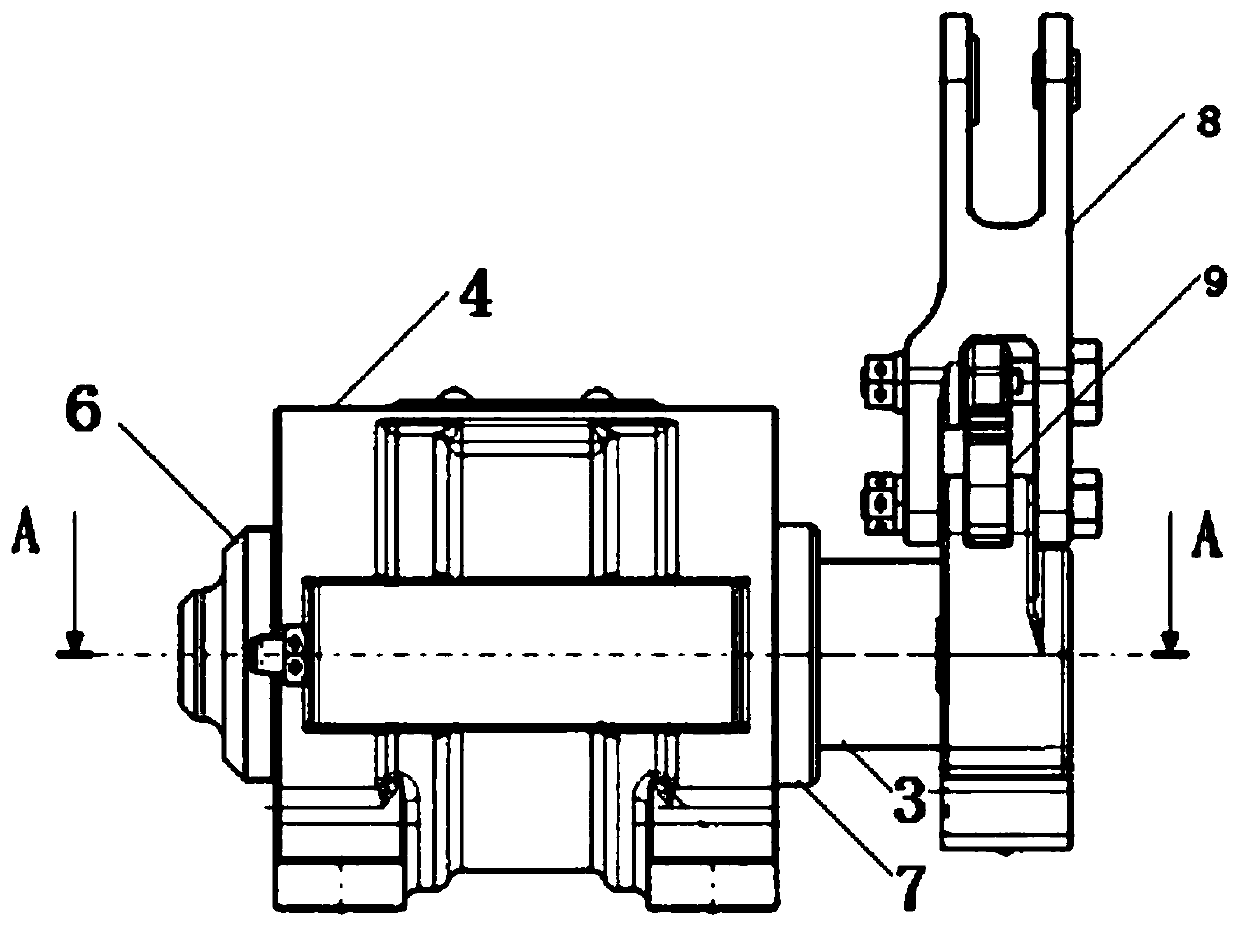

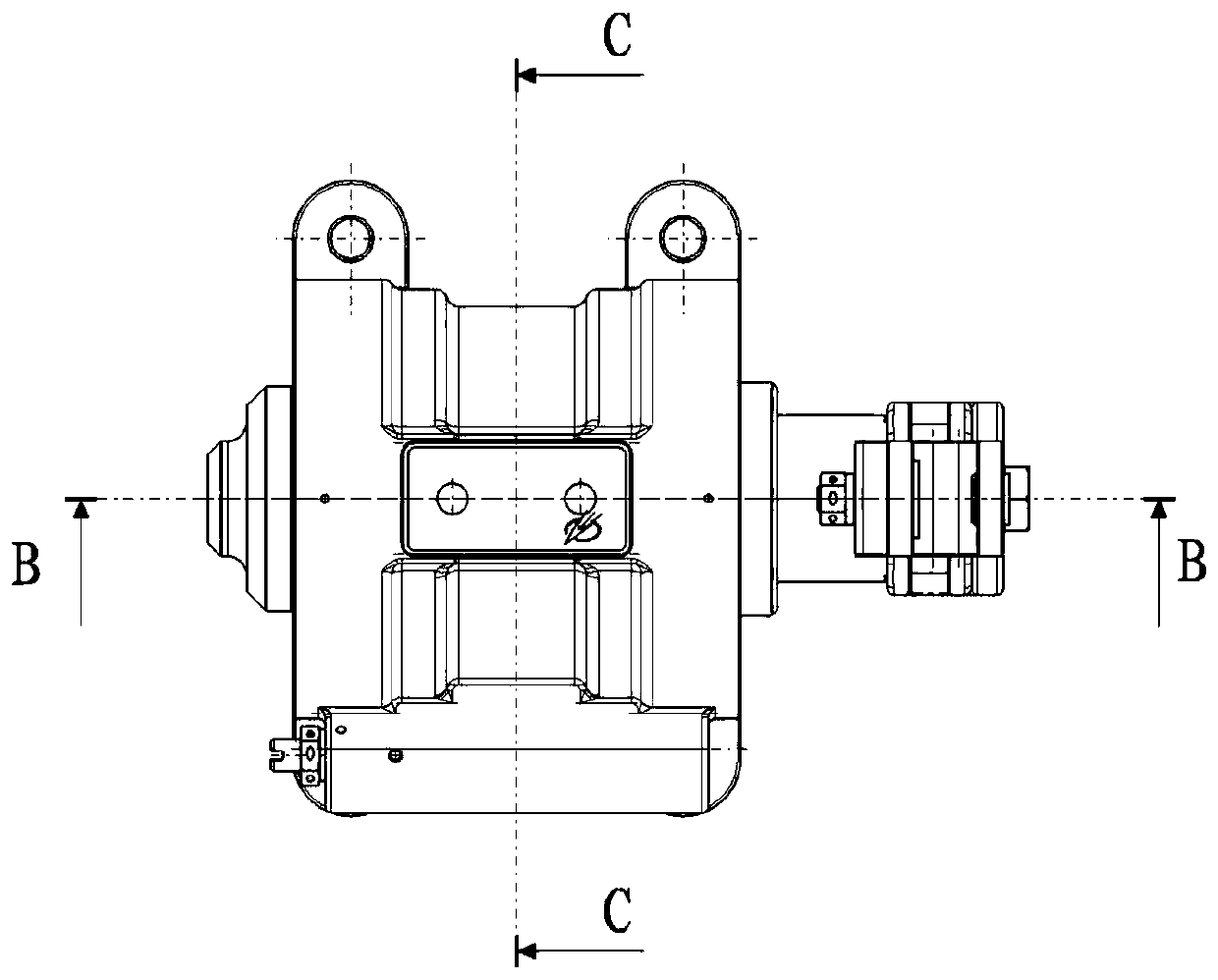

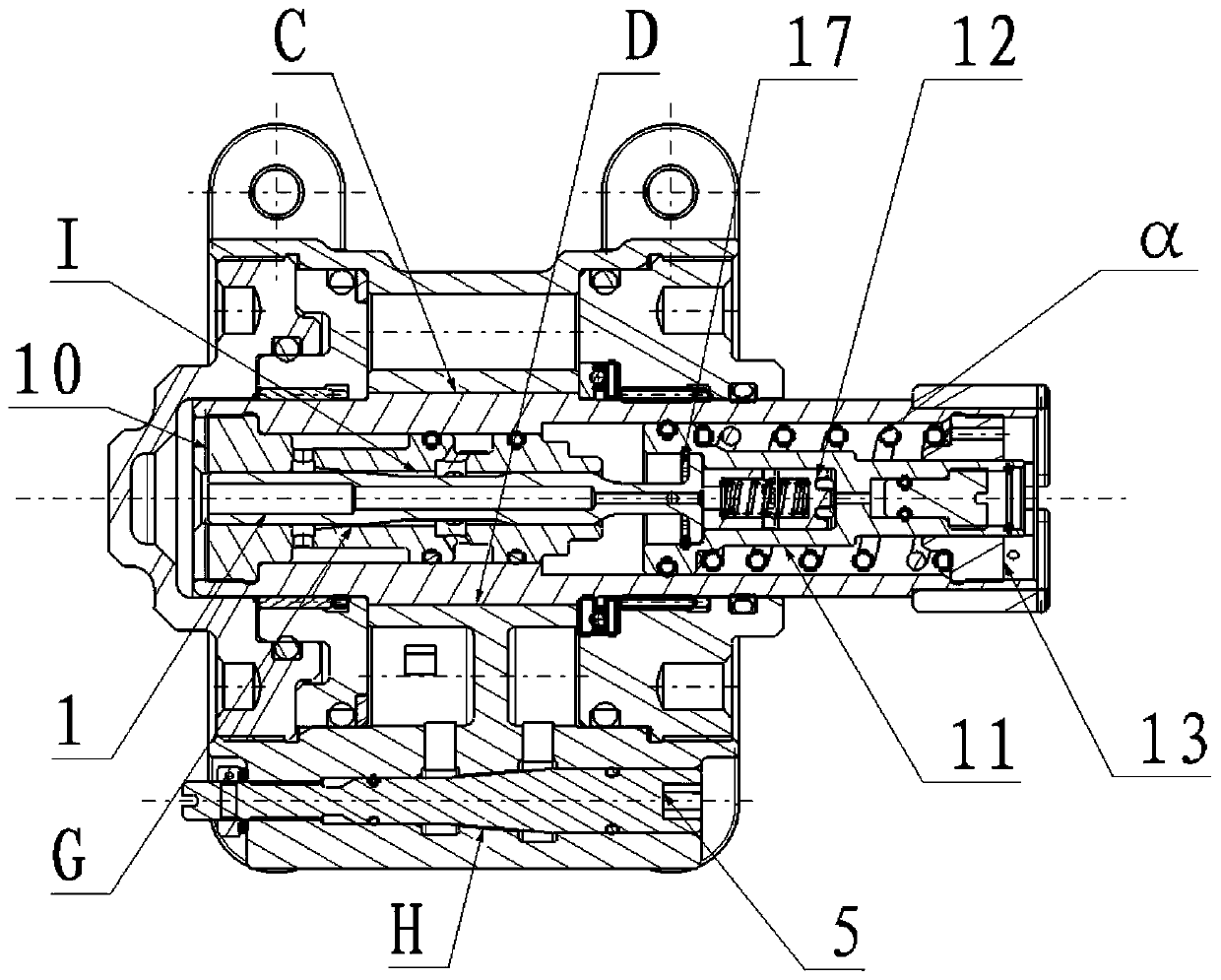

[0021] refer to Figure 2-Figure 5 . In the embodiment described below, a temperature-sensing variable annular gap integrated hydraulic damper includes: a hollow piston rod 3 that is assembled in the damping cylinder 4, and whose end is supported in the oil chamber by a rolling bearing, and is fixedly connected in the axial direction The plunger 10 in the hollow cavity of the piston rod 3, the temperature compensation piston 11 that reciprocates in the hollow cavity of the piston rod 3 and one end is fixed in the hollow cavity of the temperature compensation piston 11, and the other end is made through the inner hole of the plunger 10. The reciprocating temperature compensating valve core 1 is characterized in that: the piston rod 3 is formed with a radially symmetrical piston rod rotor blade 15, and a surrounding space is formed between the piston rod rotor blade 15 and the wall of the damping cylinder 4. The outer circle of the blade extends to both sides along the generatr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com