Variable-inertia spring flywheel capable of automatically regulating rotational inertia

A moment of inertia and automatic adjustment technology, applied in the direction of vibration suppression adjustment, flywheel, spring/shock absorber, etc., can solve problems such as low reliability, complex structure, torque fluctuation, etc., achieve small starting force, reduce torque fluctuation, reduce Effect of Axial Vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

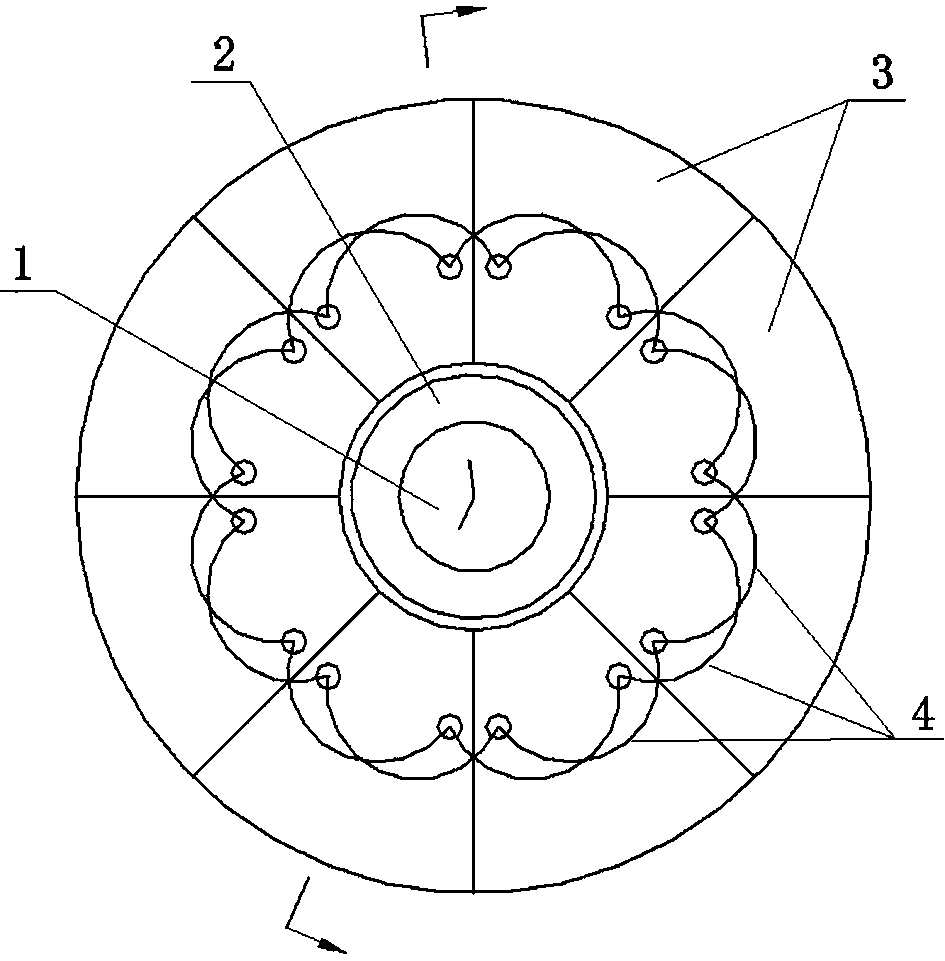

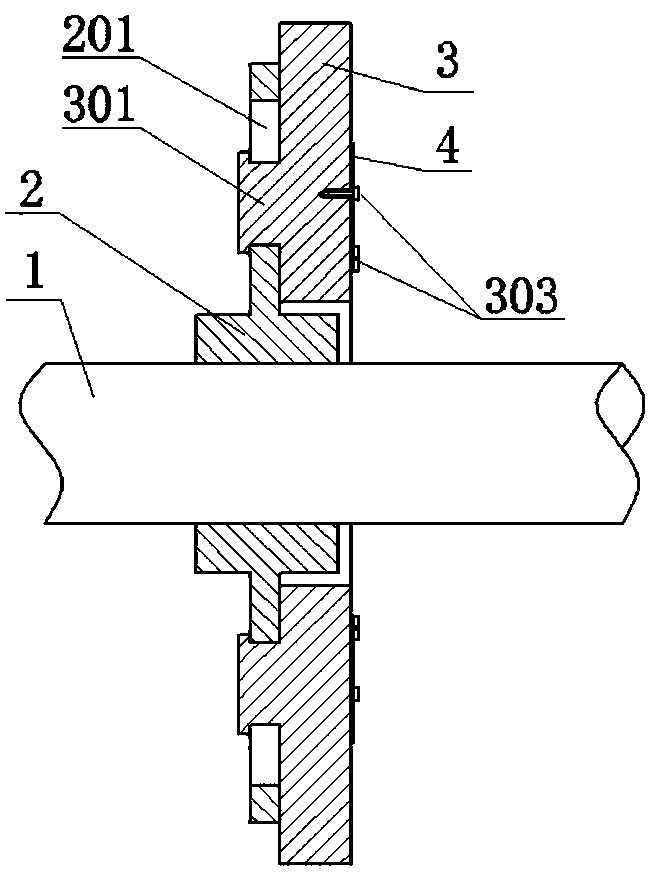

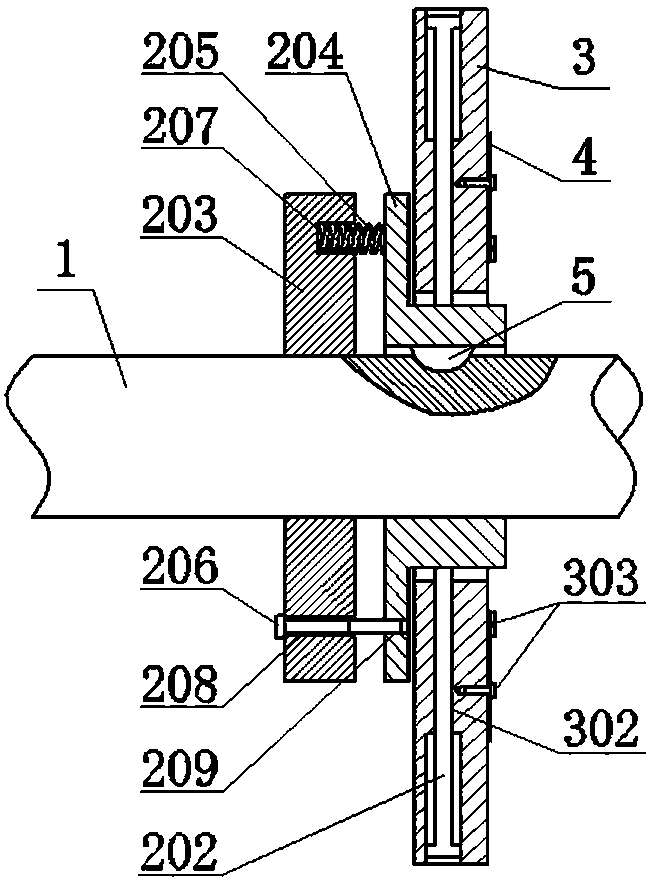

[0017] Such as figure 1 , 2 As shown in and 3, the present invention includes a flywheel shaft 1, a fixed disk 2, a flywheel sheet 3, and a connecting spring 4. The fixed disk 2 is coaxially fixedly connected with the flywheel shaft 1, and at least two A flywheel 3 is radially slidably connected to the fixed plate 2, and the two ends of the connecting spring 4 are respectively fixedly connected to the adjacent flywheel 3.

[0018] Such as figure 2 As shown, the fixed disk 2 is evenly distributed with the radially extending kidney holes 201 corresponding to the number of the flywheel pieces 3 along the circumferential direction, and one end of the flywheel piece 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com