A kind of experimental device and experimental method for rotary dynamic sealing characteristics of sealing ring

A technology of rotary sealing and experimental device, which is used in the testing of machine sealing rings, measuring devices, and testing of machine/structural components, etc. problems, to achieve the effect of low friction, ensuring stability and certainty, and low starting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

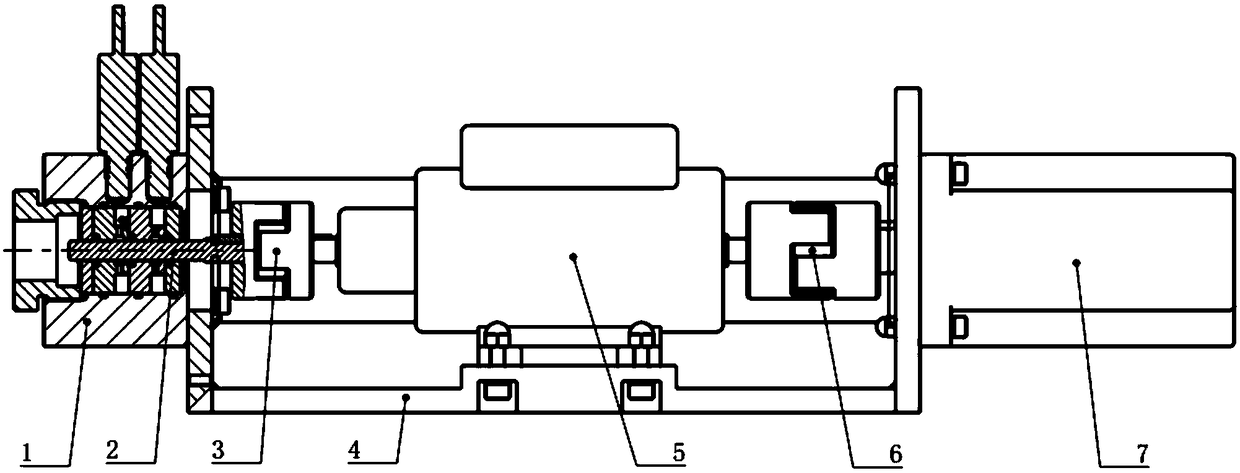

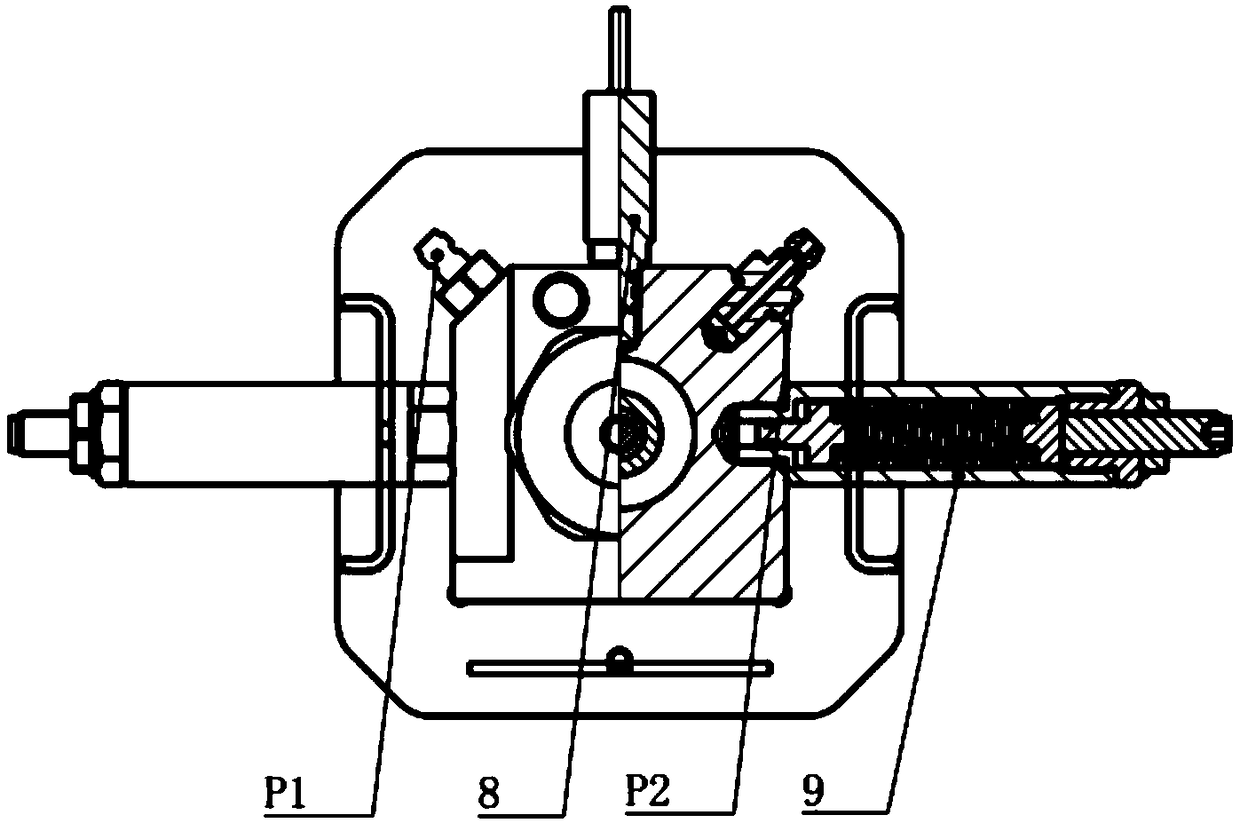

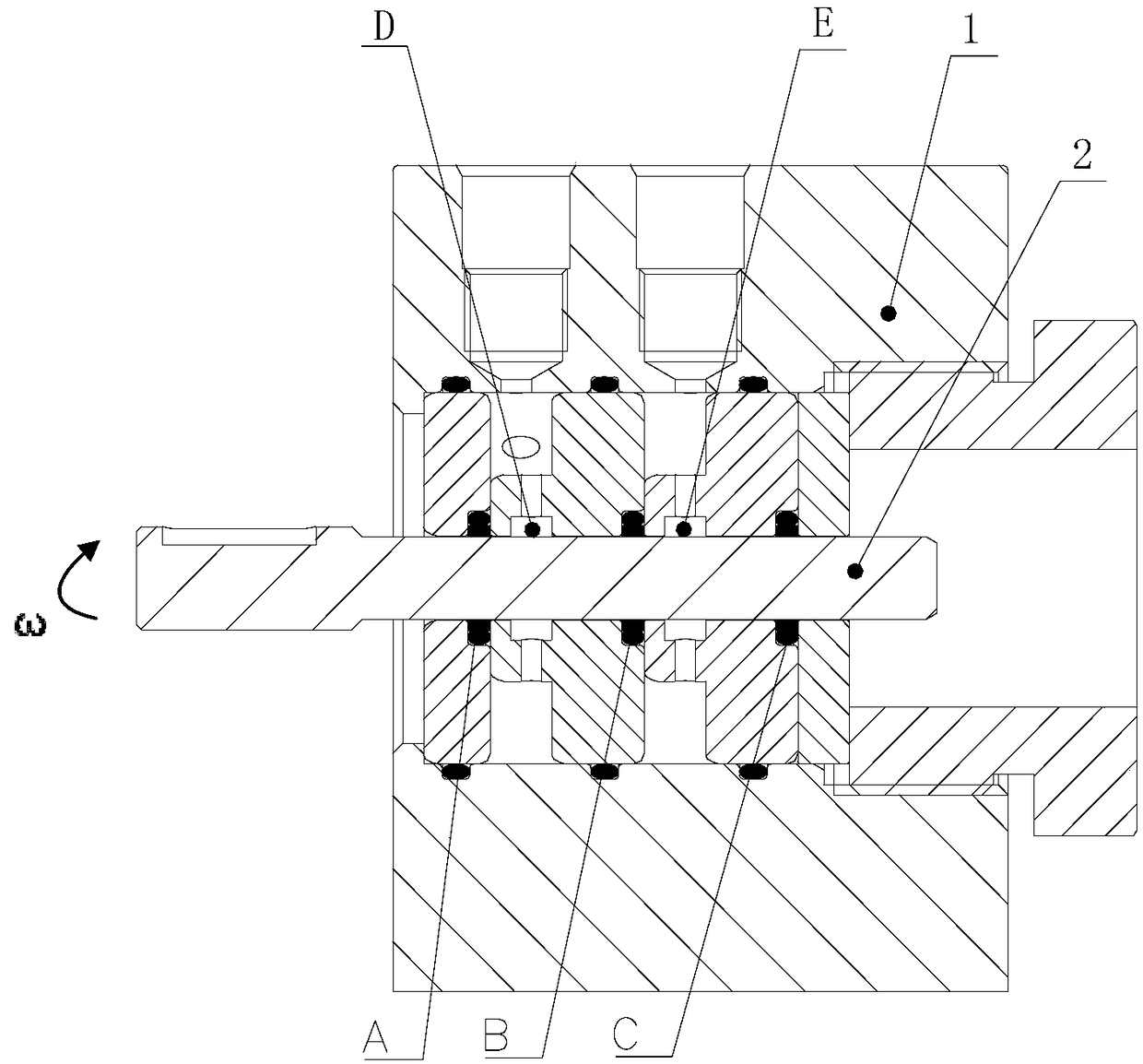

[0043] Example 1, such as figure 1 As shown, this embodiment discloses an experimental device for the rotating dynamic sealing characteristics of a sealing ring. The device includes a support 4 on which a torque speed sensor 5 is installed, and one end of the torque speed sensor 5 passes through a shaft coupling 6 It is connected with the output shaft of the motor 7, and the other end is connected with the shaft 2 through the shaft coupling 3, and a sleeve assembly 1 is set on the shaft 2, and the sleeve assembly 1 is fixedly connected with the support 4; as image 3 As shown, two gray ring installation parts A and C are arranged at intervals along the shaft 2 inside the sleeve assembly 1, and a sealing ring installation part B is arranged between the two gray ring installation parts A and C, and the gray ring and After the sealing ring is installed in the above-mentioned gray ring installation part A, C and sealing ring installation part B, the shaft 2 can pass through the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com