Patents

Literature

32results about How to "Reduce abnormal vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

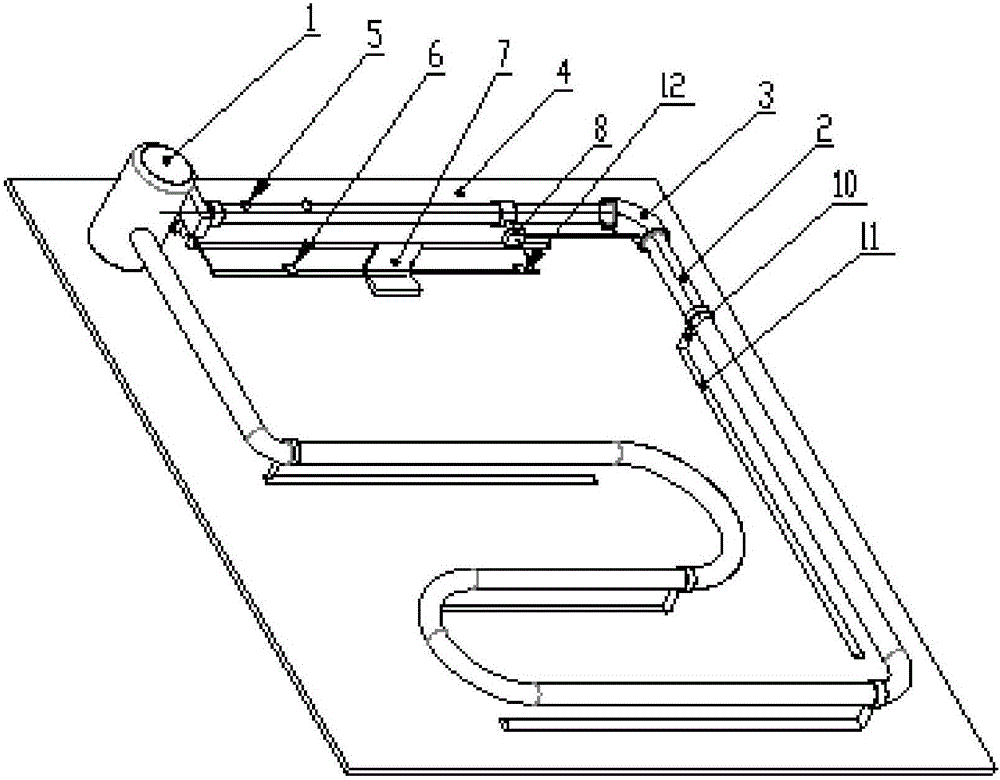

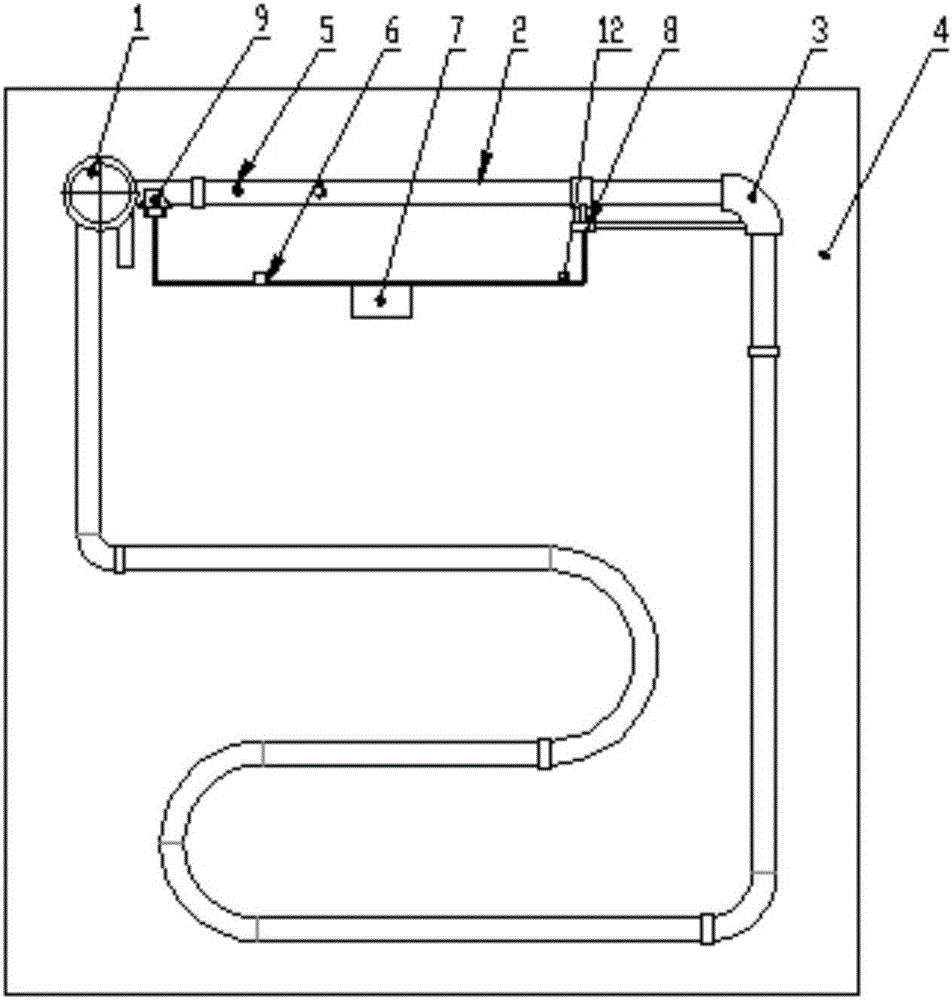

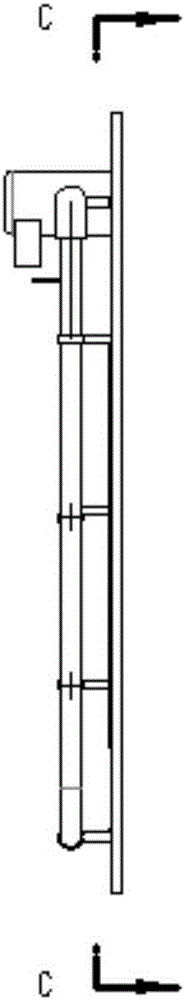

Pipeline vibration test platform based on fault diagnosis and automatic processing, and control method thereof

InactiveCN105910785AReduce abnormal vibrationAchieve imprisonmentVibration testingElectric machineryWater flow

The invention discloses a pipeline vibration test platform based on fault diagnosis and automatic processing, and a control method thereof. The pipeline vibration test platform comprises a pressure tank, a pipeline, a substrate and a signal analysis processing system. The pressure tank is arranged on the substrate and controls and adjusts the flow speed and pressure of a water flow in a pipeline. A plurality of supports sleeve the pipeline. The pipeline is arranged on the substrate through the supports. The substrate is provided with a track, and the support can move along the track. The signal analysis processing system comprises an acceleration sensor and a micro-processor. The acceleration sensor is connected with the micro-processor through a data collection card. The acceleration sensor is arranged on the pipeline. The micro-processor controls a motor to drive the supports to move along the track and controls the on-off degree of a valve. The analysis of pipeline abnormal vibration due to a plurality of factors is realized, the pipeline vibration is automatically adjusted, the method for reducing the pipeline abnormal vibration is explored, and various kinds of emergency processing means are assessed and optimized.

Owner:WUHAN UNIV OF TECH

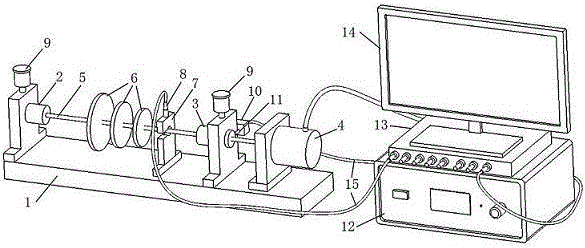

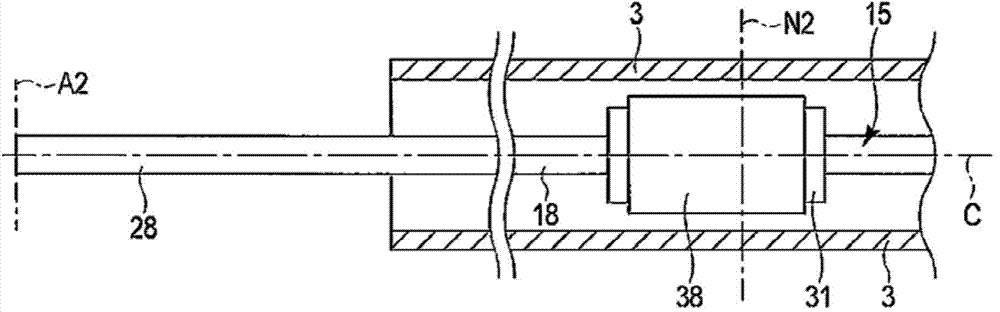

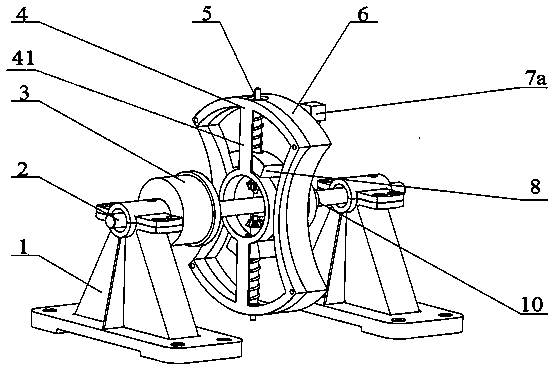

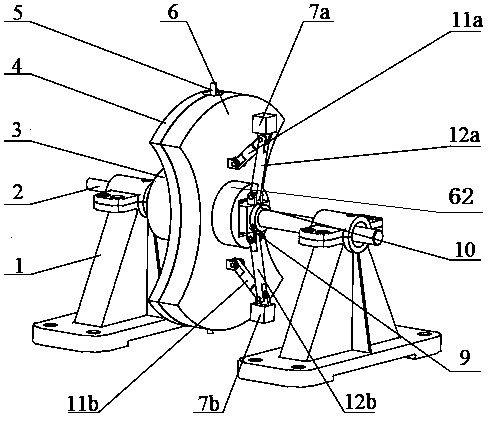

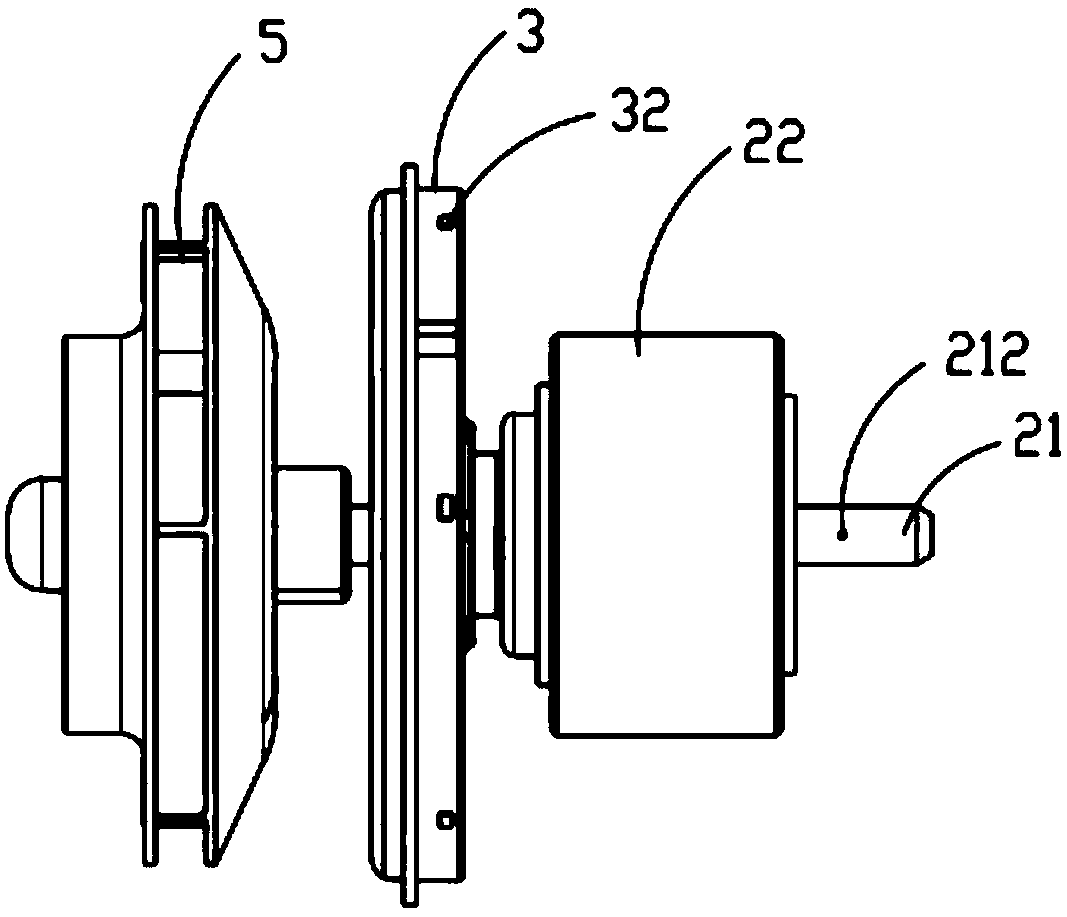

Experimental method for measuring critical speed influencing factors for steam turbine rotor

InactiveCN105806622ACritical speed avoidanceAchieve regulationEngine testingLinear/angular speed measurementExperimental methodsEngineering

An experimental method for measuring critical speed influencing factor for a steam turbine rotor relates to an experimental apparatus and method for measuring critical speed related influencing factors for a steam turbine rotor. A first sliding bearing (2), a second sliding bearing (3), a drive motor (4), a displacement sensor support (7) and a speed sensor support (10) are mounted on a carriage (1), a steam turbine rotor simulation spindle (5) and a steam turbine rotor simulation wheel (6) are mounted on the above-mentioned two bearings, a displacement sensor (8) and a speed sensor (11) are fixed on a support, a measurement signal is processed in a vibration data analyzer (13) and input to a computer and test software (14), and a speed regulator (12) controls output speed of the drive motor (4) through a connecting wire (15). It is possible to measure changes in the critical speed of the rotor by changing structural rigidity and quality of the steam turbine simulation rotor, thus acquiring main factors that influence the critical speed of the steam turbine rotor and their effect.

Owner:SHENYANG INST OF ENG

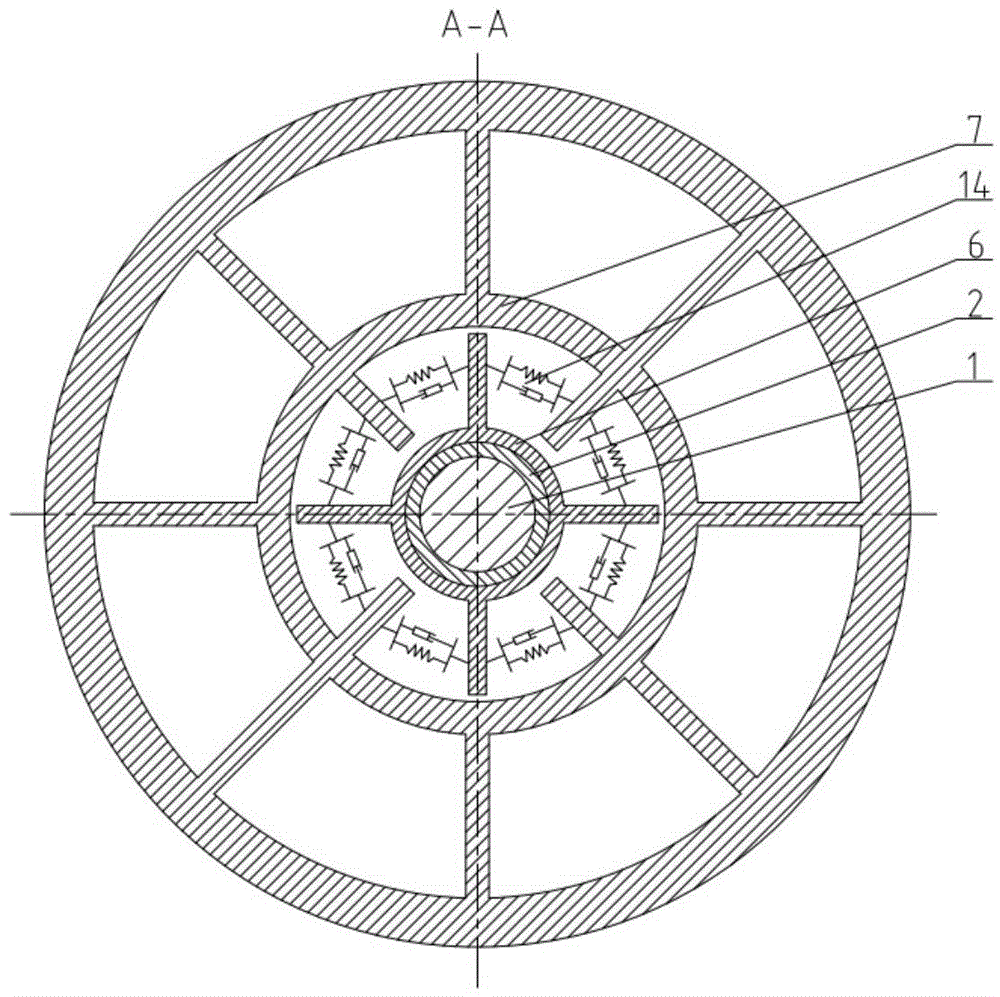

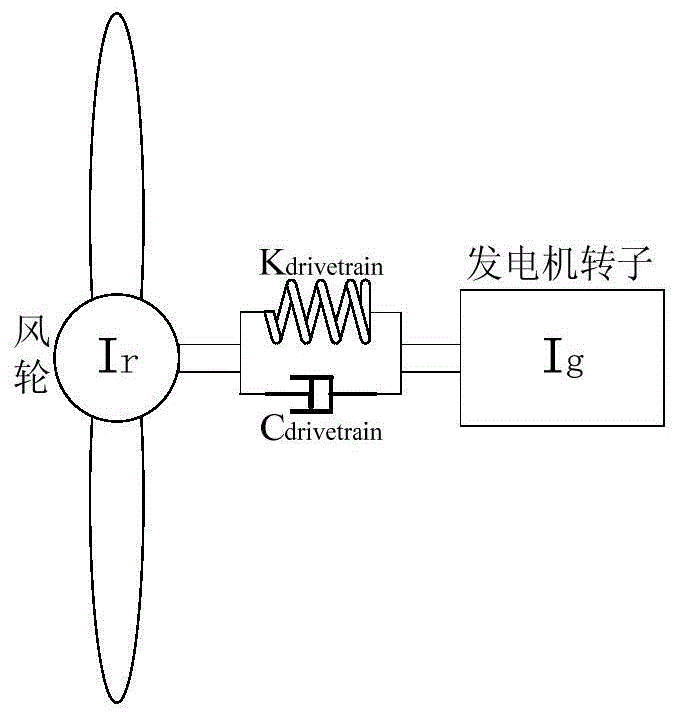

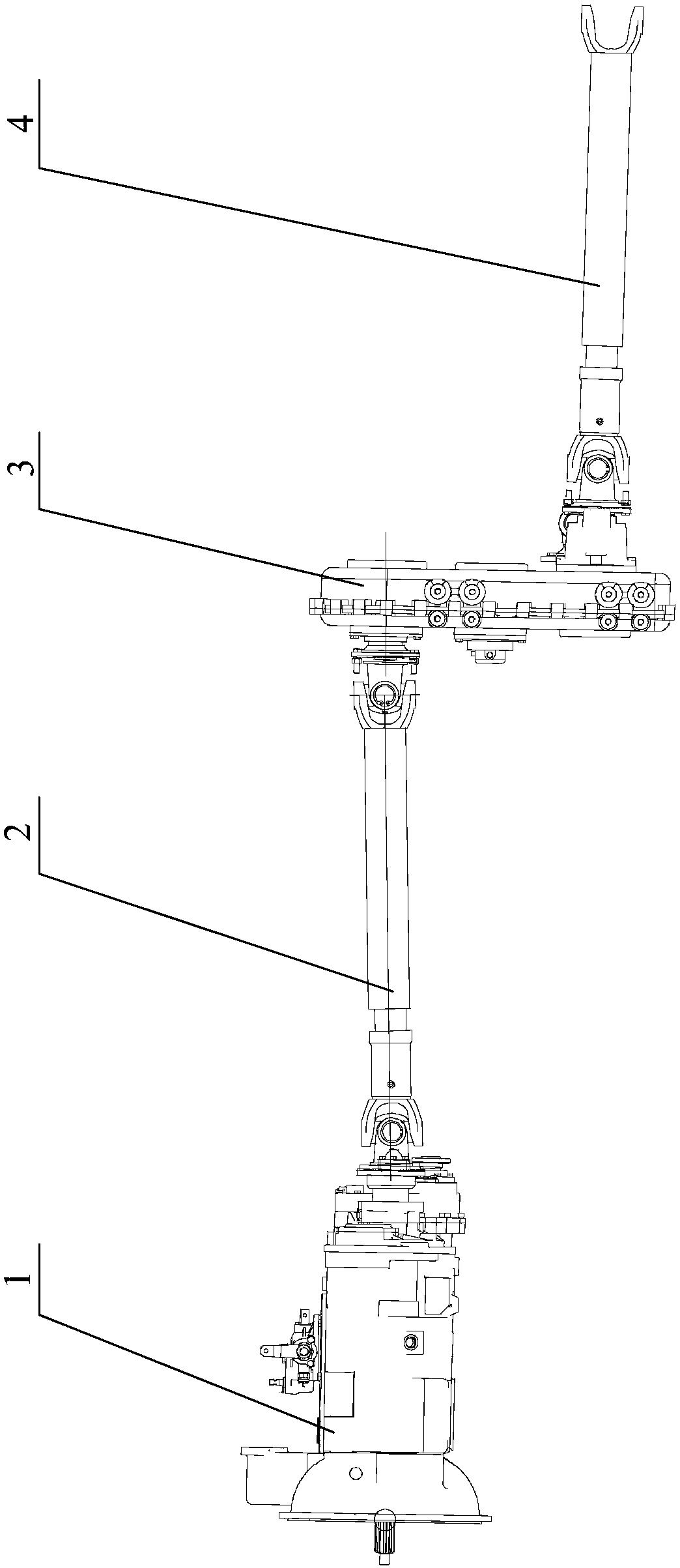

A transmission system torsional vibration reducing method and application thereof

ActiveCN104896007AReduce high frequency vibrationReduce vibrationVibration dampersSpringsWind forceTransmission system

The invention provides a transmission system torsional vibration reducing method and application thereof. The method is characterized in that a torsional vibration damper, which is a tuned rotary inertia damper, is added on a transmission shaft in a parallel connection manner, and the torsional rotation movement around the transmission shaft is used for reducing the vibration level of a certain first order torsional mode frequency. The method is flexible, can effectively reduce vibration without damage to the original structure of the transmission system, and can be used for later repair of the transmission system. The method can be applied to wind energy / tidal current energy generator sets; the torsional vibration damper is installed on a shaft, connected with a generator, of a high speed shaft coupler to greatly reduce a first-order mode component in the torsional vibration, so that a transmission system can operate more stably, the reliability of the structure can be improved and the service life can be prolonged.

Owner:国能联合动力技术(保定)有限公司

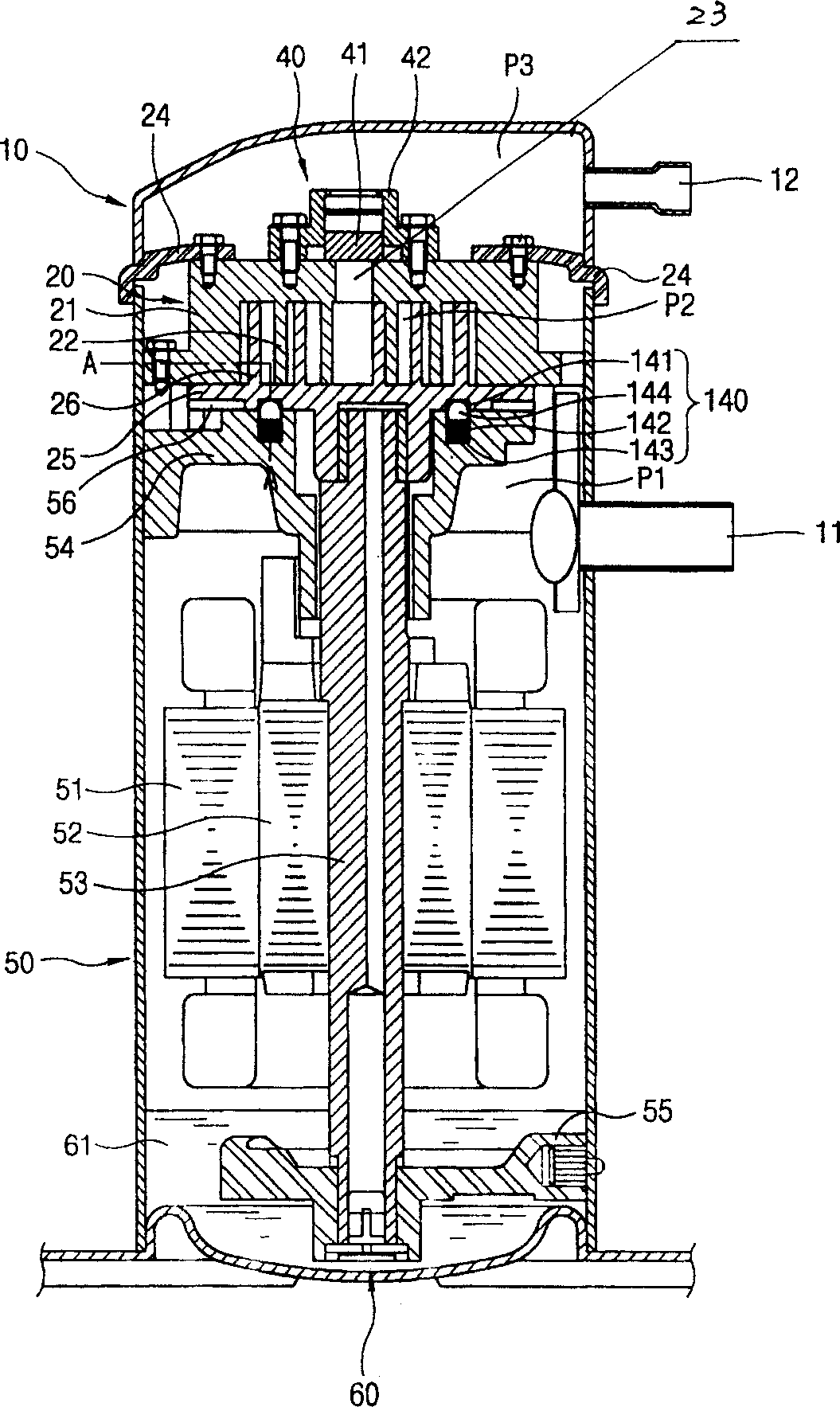

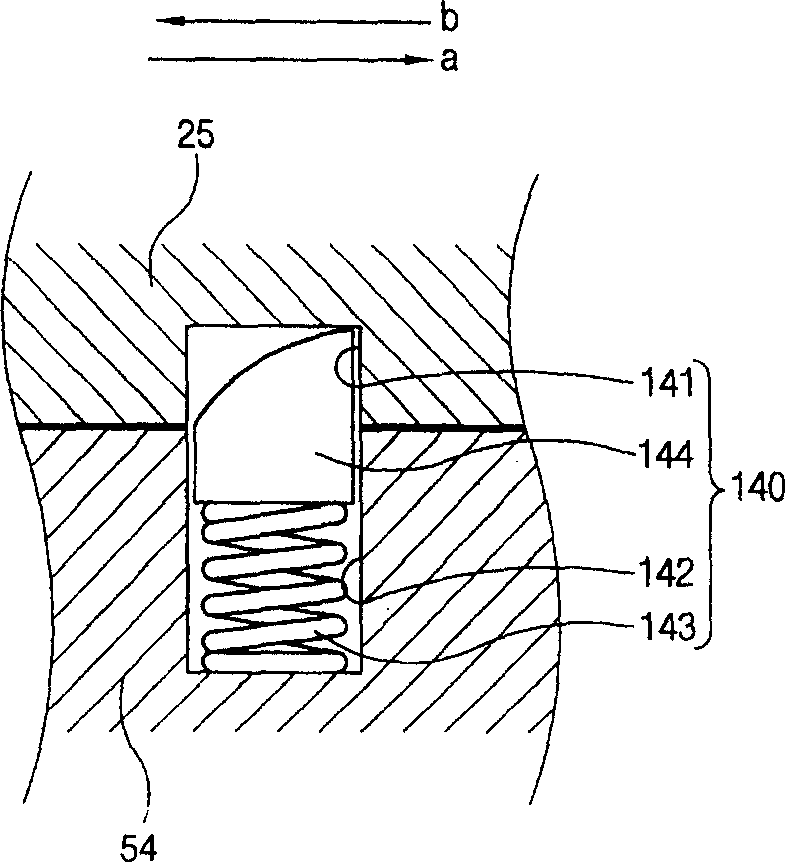

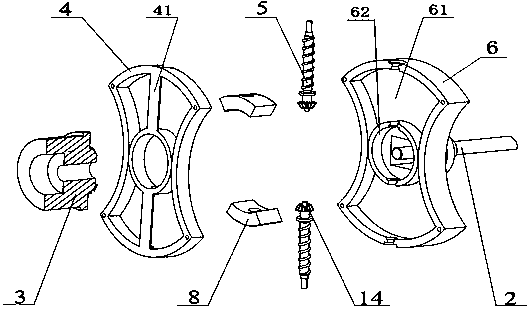

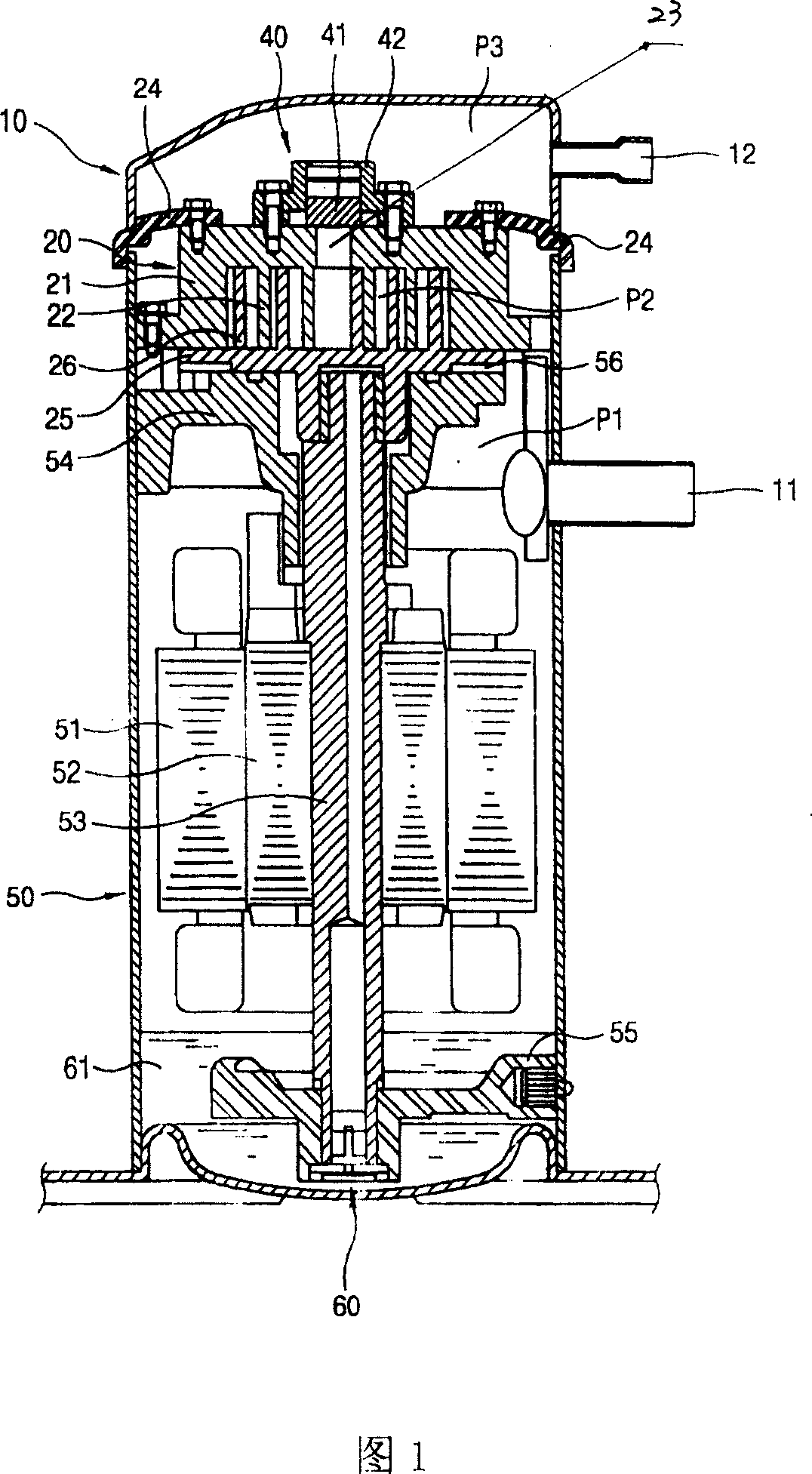

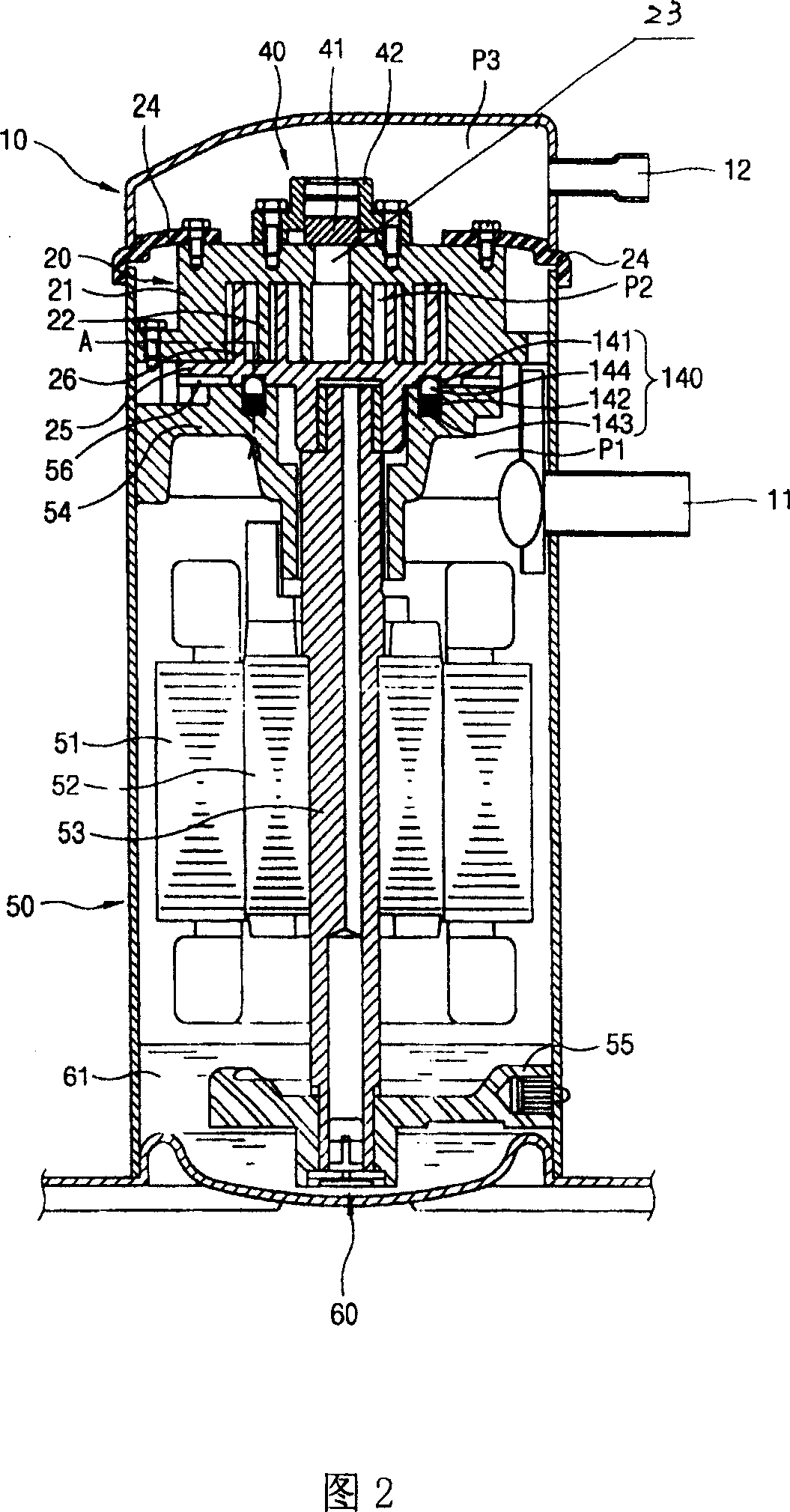

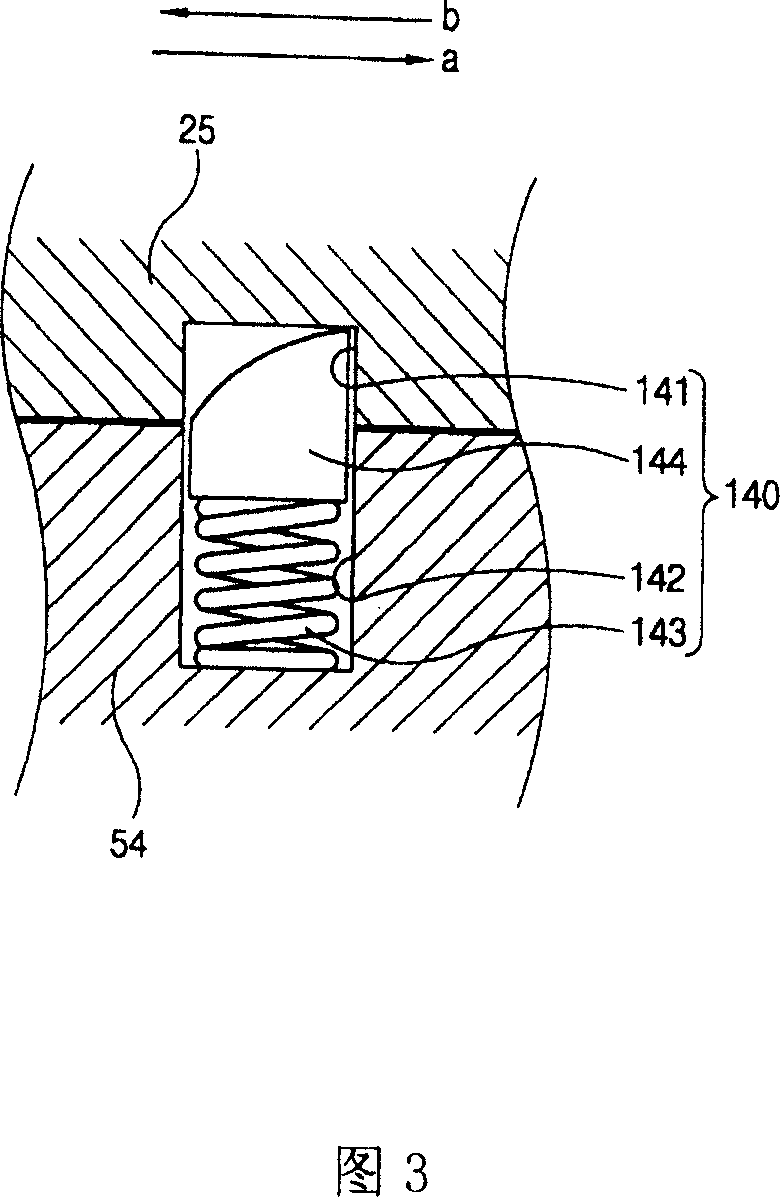

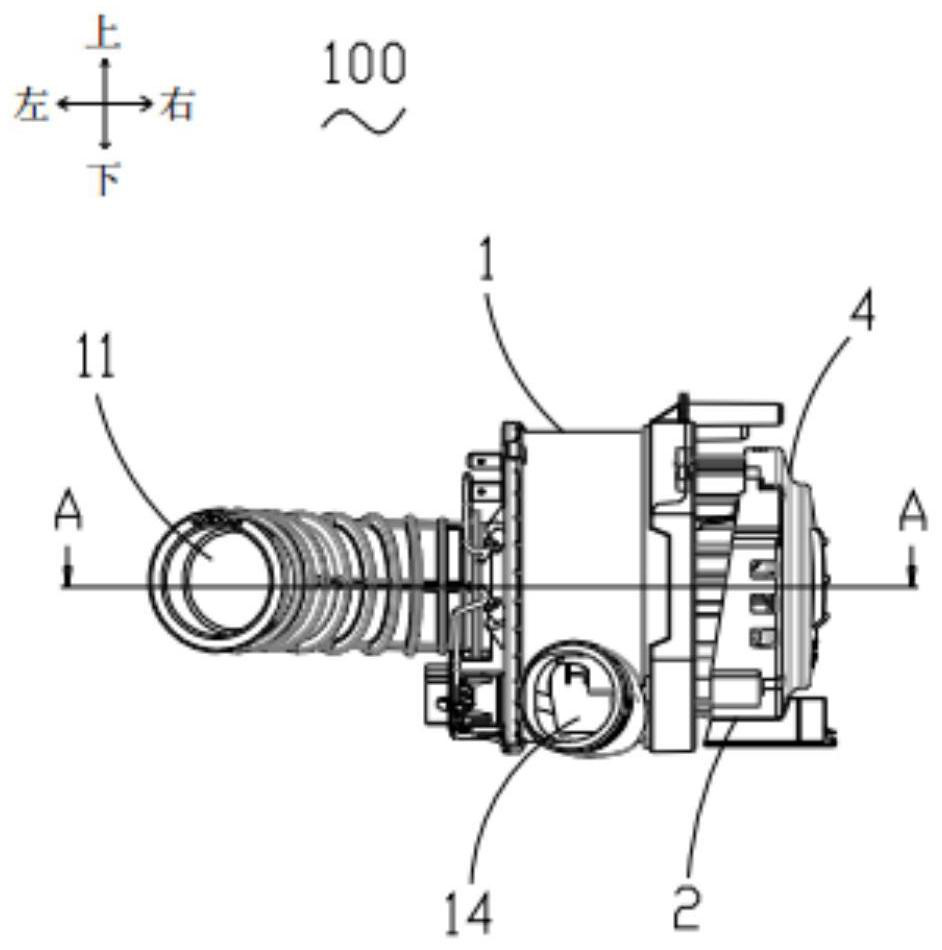

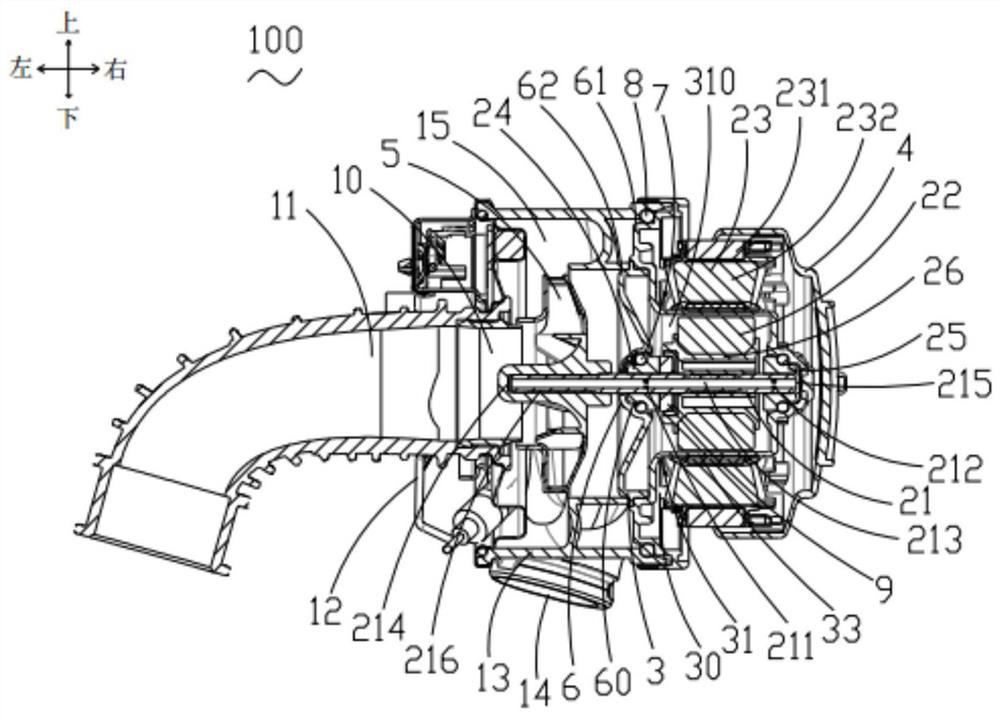

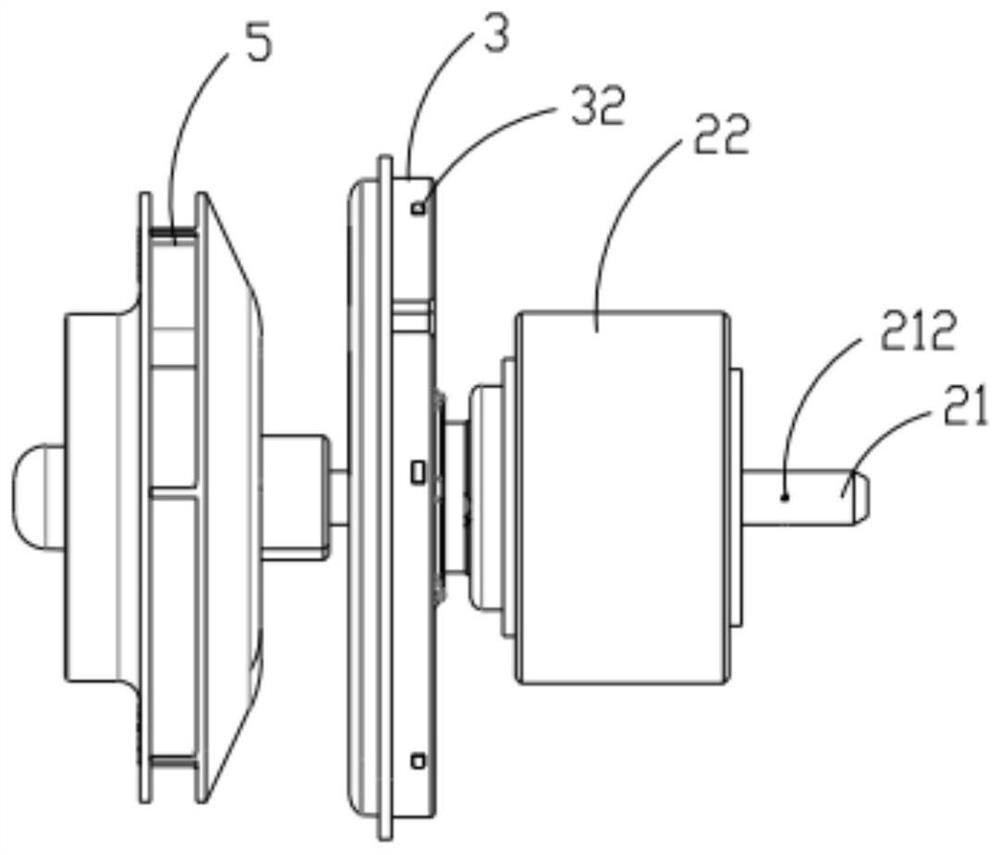

Anti-reverse device of vortex compressor

InactiveCN1510298AOvercoming noiseReduce abnormal vibrationRotary piston pumpsRotary piston liquid enginesEngineeringGenerating unit

A unit for preventing reverse rotation of vortex compressor, which has a rotary shaft with moving vortex disk, the compression unit composed of moving and static vortex disks, power generating unit, lubricating unit and reverse rotation preventer, features that it is arranged on main frame and moving vortex disk. When said moving vortex is going to rotate reverse, an elastic limiting pin moves upward and is hooked by a slot only main frame, so preventing the reverse rotation of moving vortex disk.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Method of regulating and controlling air volume of sintering machine by using main ventilation valve and rotating speed in combined mode

The invention provides a method of regulating and controlling the air volume of a sintering machine by using a main ventilation valve and the rotating speed in a combined mode, and belongs to the field of metallurgical production. The opening degree of an inlet baffle of a draught fan is regulated to 14%-65%, and the rotating speed of the draught fan is regulated to 700-1000rpm. By means of the method, the temperature of sintering flue gas can be effectively stabilized, the frequency of abnormal vibration, caused by the excess temperature of the flue gas, of a main ventilation draught fan is reduced, and threats to operation of a flue gas desulfurization and denitrification system caused by the excess temperature of the flue gas can be reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

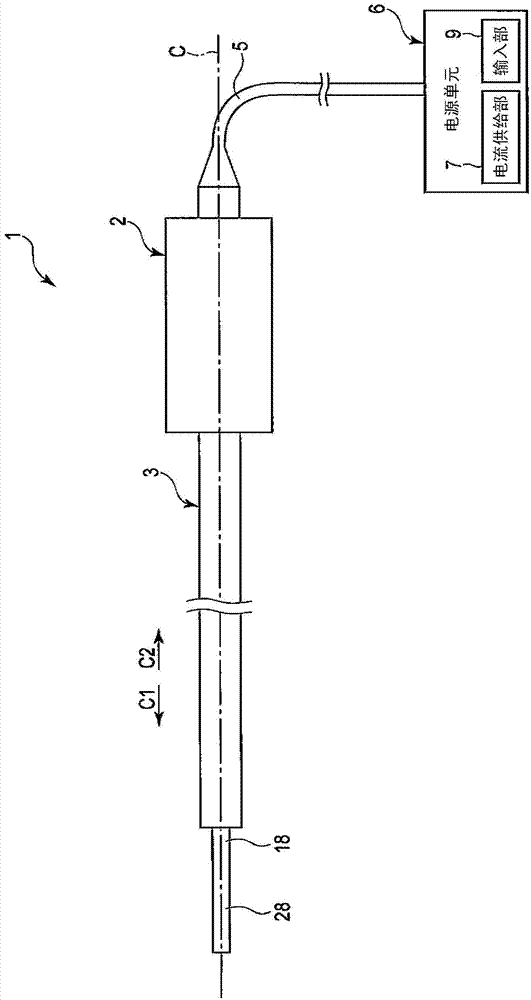

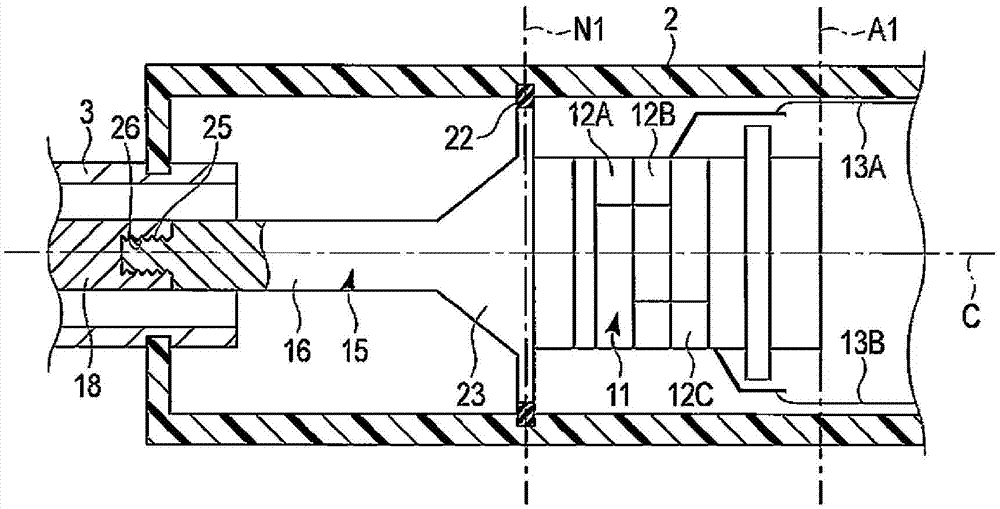

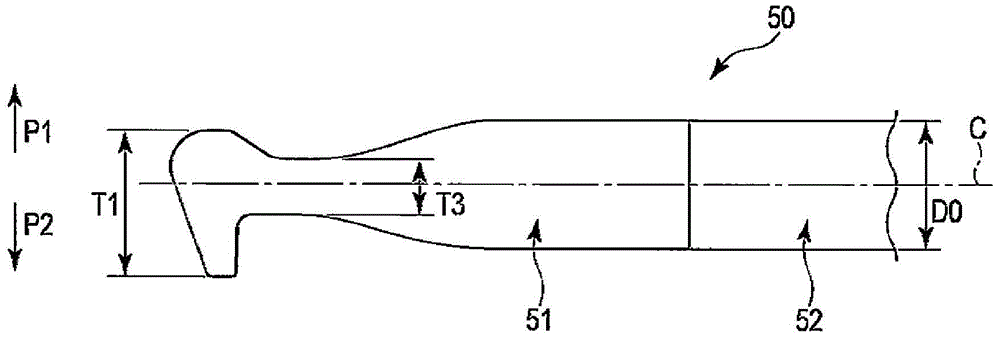

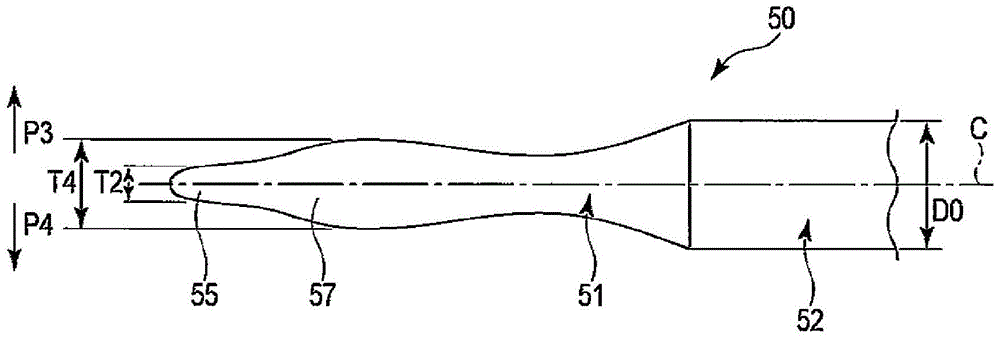

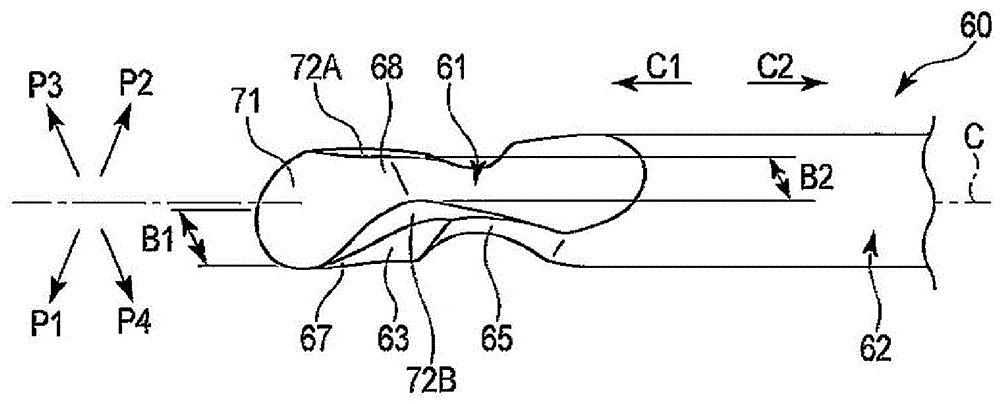

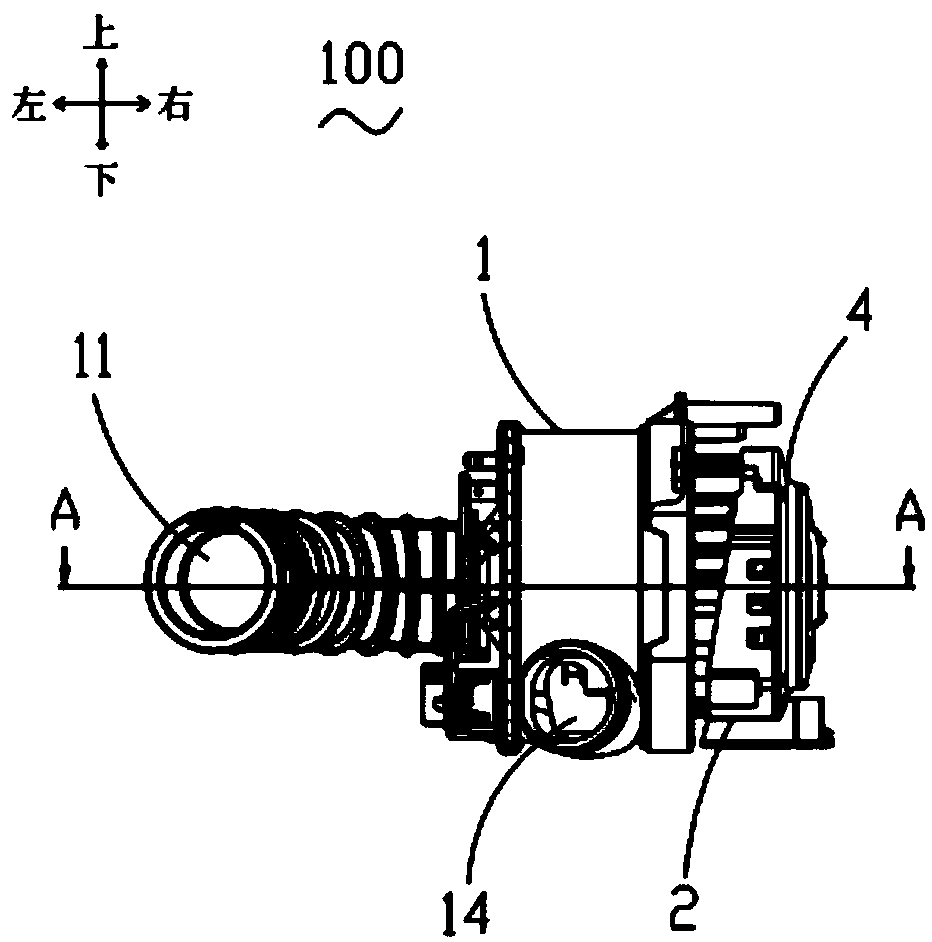

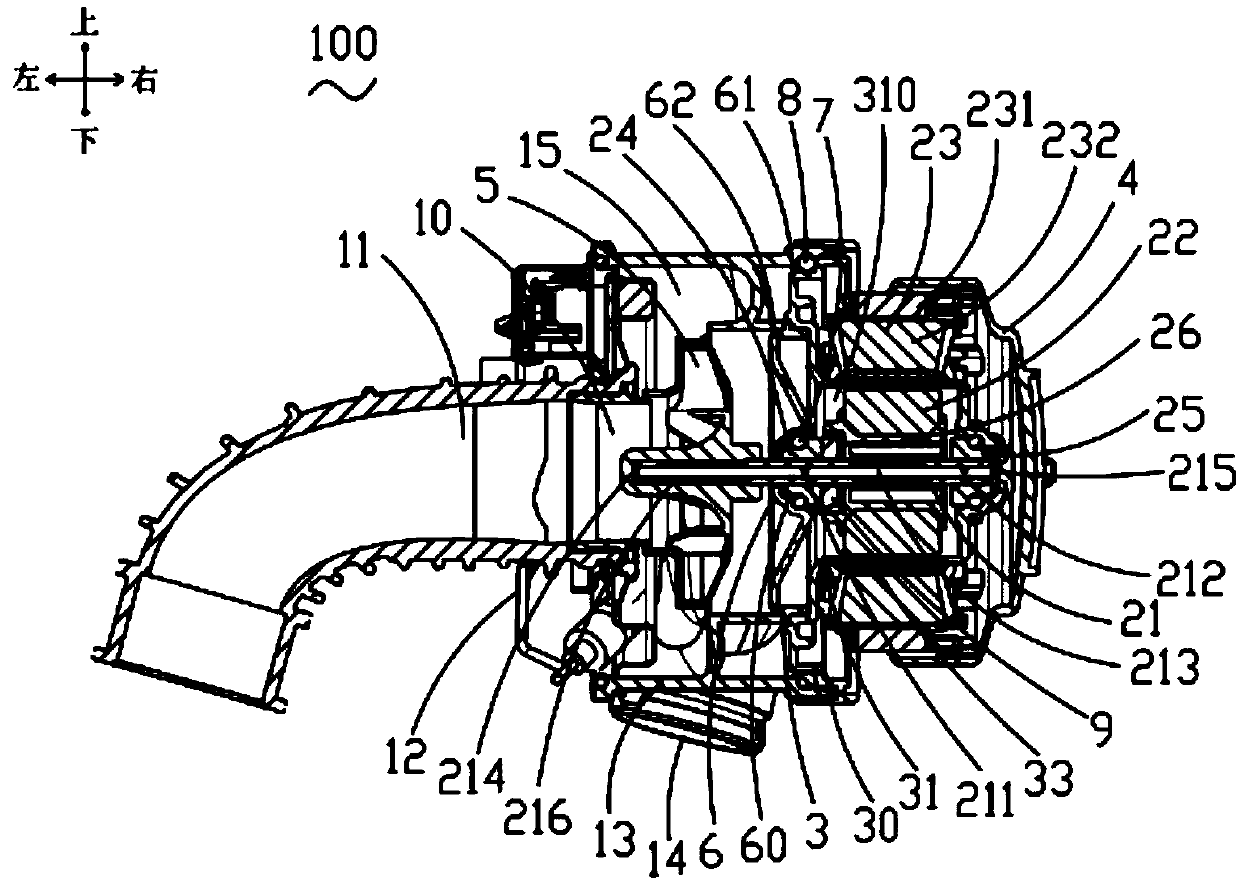

Ultrasonically-actuated unit and ultrasonic processing device

ActiveCN104334103AReduce abnormal vibrationDiagnosticsSurgical instrument detailsWave transmissionLongitudinal vibration

This ultrasonically-actuated unit is provided with: an ultrasonic wave transmission unit that is provided along the lengthwise axis and transmits ultrasonic vibrations; a relay unit that, at a node position of longitudinal vibrations, is contiguous with the ultrasonic wave transmission unit or is connected to the ultrasonic wave transmission unit; and a non-contact vibration unit that can transmit improper vibrations, is provided along a direction parallel to the lengthwise axis in the state of not contacting the ultrasonic wave transmission unit, and to which improper vibrations are transmitted from the ultrasonic wave transmission unit via the relay unit. The ultrasonically-actuated unit is provided with a vibration absorbing unit that absorbs the improper vibrations transmitted to the non-contact vibration section.

Owner:OLYMPUS CORP

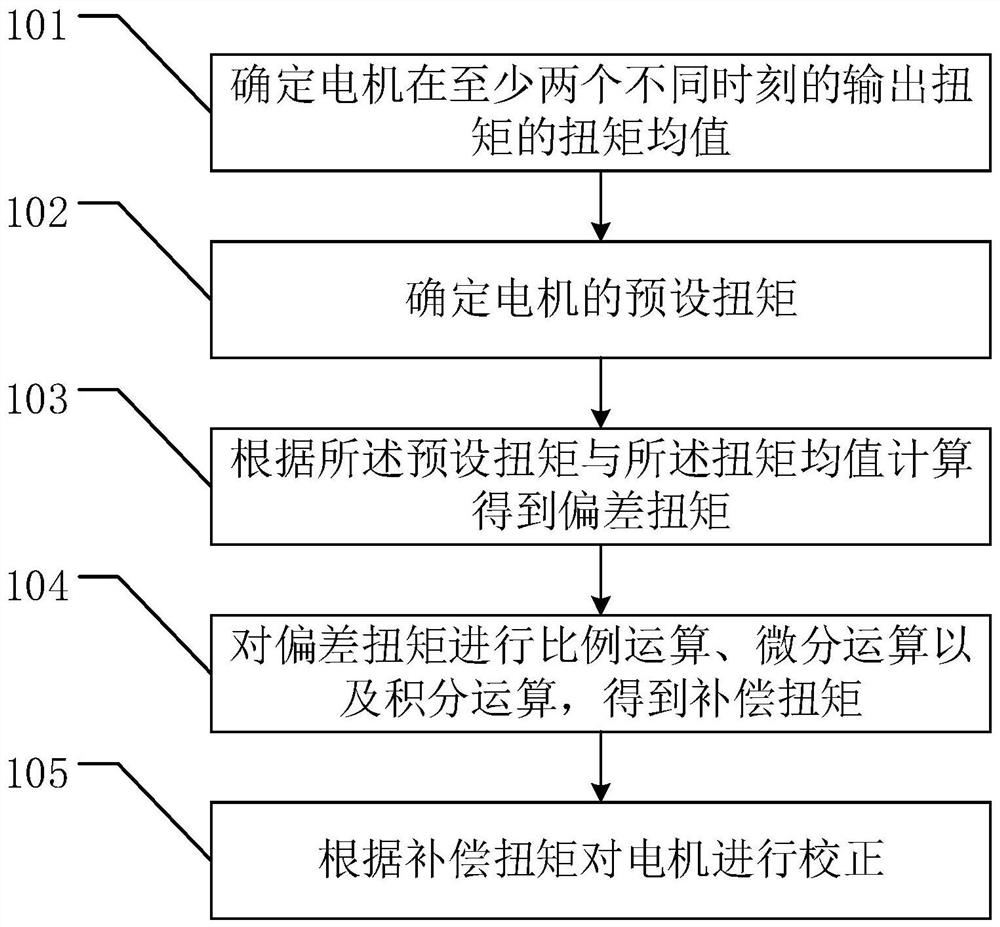

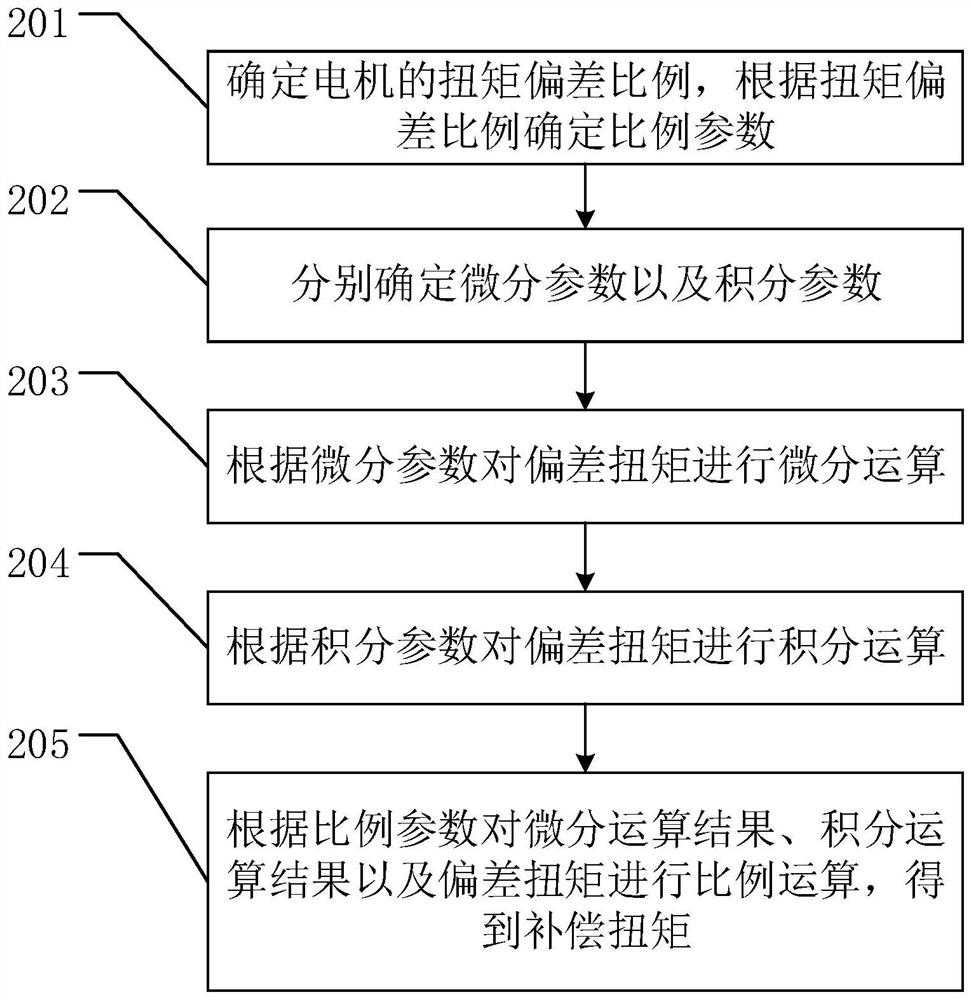

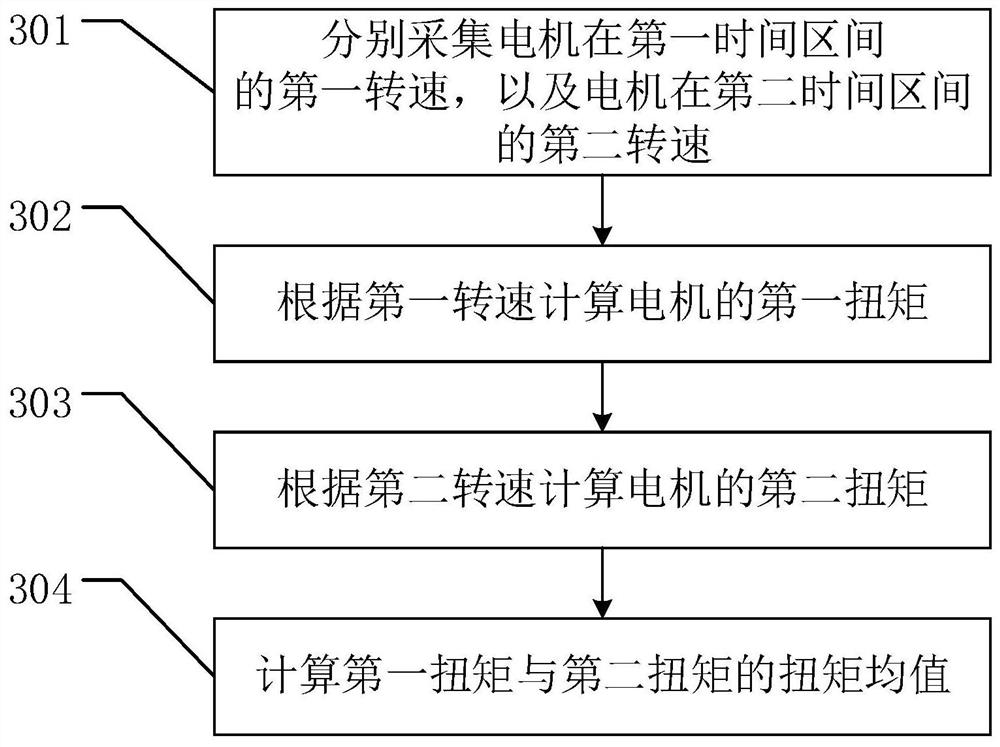

Motor control method and device, and storage medium

ActiveCN113489405ASmooth and stable running speedReduce abnormal vibrationElectronic commutation motor controlVector control systemsClassical mechanicsElectric machinery

The invention discloses a motor control method and device, and a storage medium, so that the operation rotating speed of a motion motor is smoother and more stable, and the operation efficiency of a robot is improved. The method comprises the following steps of: acquiring a torque mean value of output torque of the motor at at least two different moments; determining preset torque of the motor; calculating deviation torque according to the preset torque and the torque mean value; performing proportional operation, differential operation and integral operation on the deviation torque to obtain compensation torque; and correcting the motor according to the compensation torque.

Owner:深圳鹏行智能研究有限公司

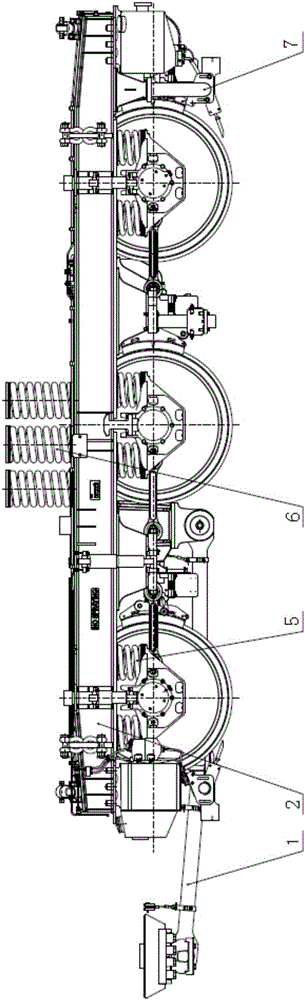

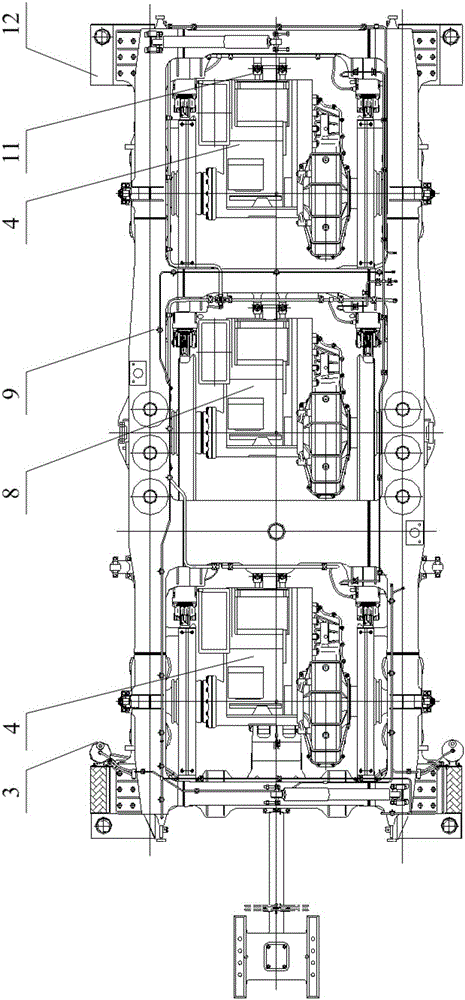

Transportation equipment and bogie thereof

The invention discloses a bogie. The bogie comprises a framework, a traction device, a primary suspension device and a secondary suspension device. The traction device comprises a first traction rod used for being hinged to the framework, a triangular supporting rod used for being connected with a framework front-end beam and a second traction rod used for being hinged to an adjacent vehicle body. The first traction rod and the second traction rod are located in the same vertical plane and both hinged to the triangular supporting rod. The first traction rod is horizontally arranged, and the end, used for being connected with the vehicle body, of the second traction rod is higher than the end, connected with the triangular supporting rod, of the second traction rod. According to the device, the combination of the double traction rods and the triangular supporting rod which are low in rate of wheel load reduction and high in adhesion utilization rate is adopted, so that a low-position traction structure is formed, and thus the vehicle body is connected with the bogie. Braking force and traction force are transmitted, and the overall adhesive property is good. Moreover, the stability of the vehicle body in the turning process can be improved. The invention further discloses transportation equipment including the bogie. Abnormal vibration is reduced, and safety and comfort are improved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

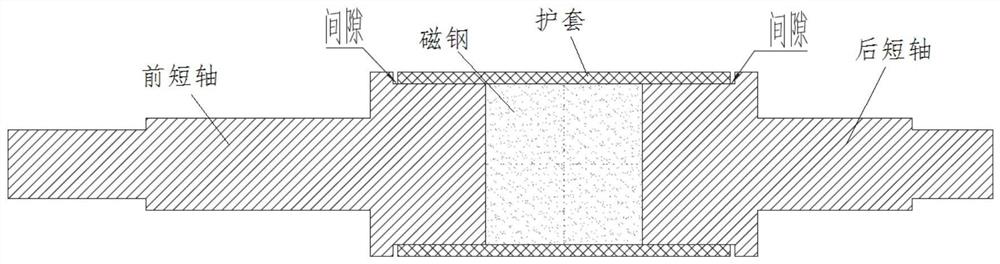

Motor rotor and magnetic suspension motor

PendingCN112803642AHigh precisionImprove stabilityMagnetic circuit rotating partsMechanical energy handlingInterference fitElectric machinery

The invention provides a motor rotor and a magnetic suspension motor. The motor rotor comprises a rotating shaft, the rotating shaft is provided with a hollow cylinder section, the peripheral side of the cylinder wall of the hollow cylinder section is sleeved with a sheath in an interference manner, the inner side of the cylinder wall of the hollow cylinder section is connected with magnetic steel in an interference manner, and a first cooling pipeline is arranged between the sheath and the cylinder wall of the hollow cylinder section. According to the invention, the temperature rise of the sheath is effectively reduced, so that the deformation of the sheath and the eccentricity and vibration of the rotor are reduced; and meanwhile, a double-layer interference fit mode is adopted, the stress of the sheath is dispersed to the rotating shaft, the equivalent stress of the sheath can be effectively reduced, the deformation degree of the sheath can be effectively reduced, abnormal vibration caused by eccentricity of the rotor is reduced, and the suspension precision and stability of the motor rotor are improved.

Owner:GREE ELECTRIC APPLIANCES INC +1

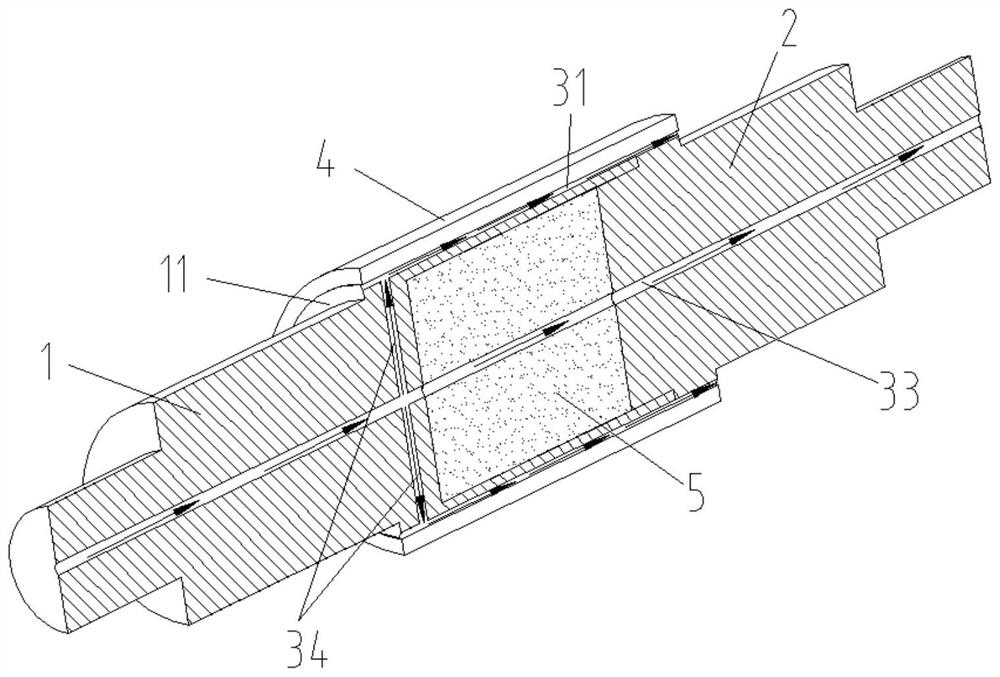

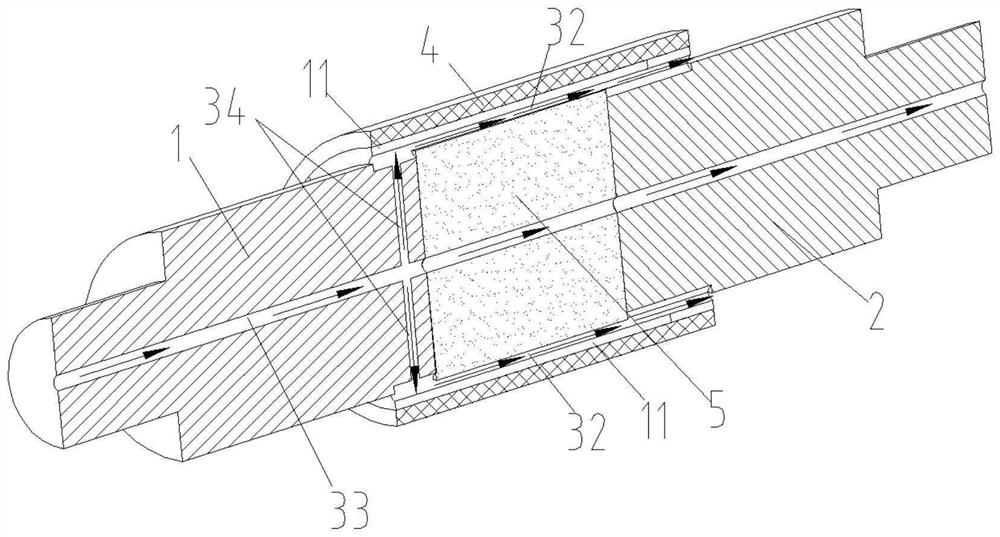

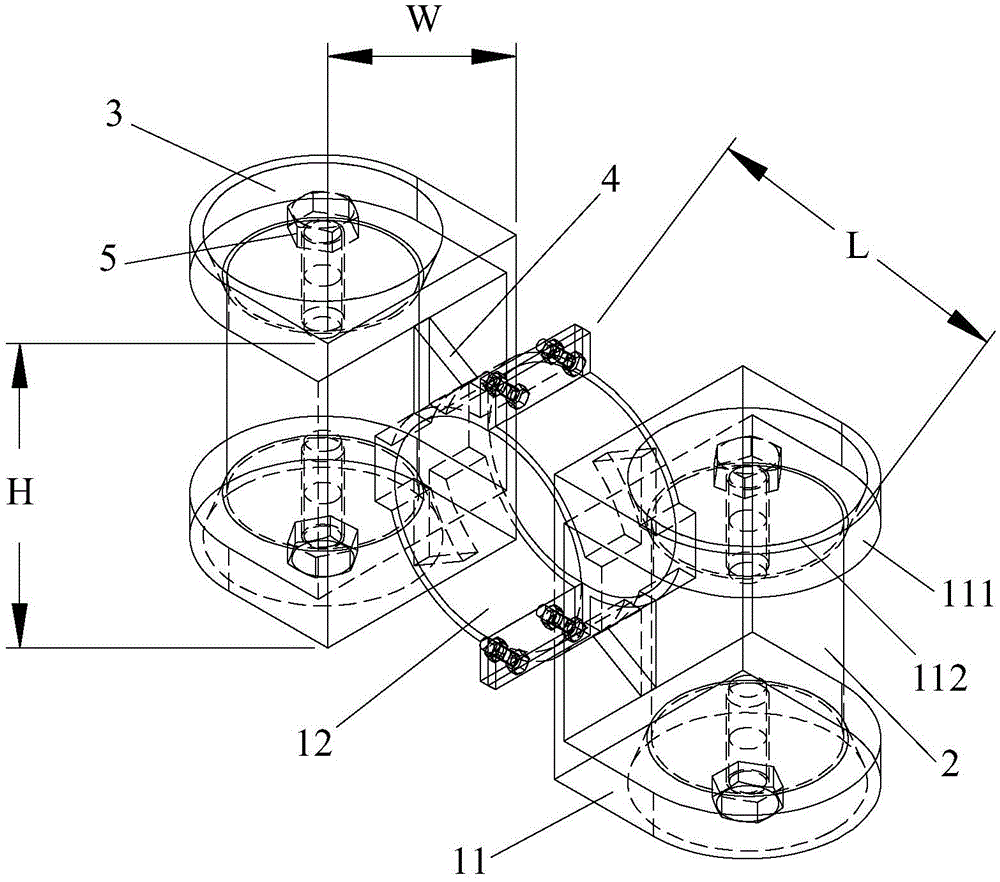

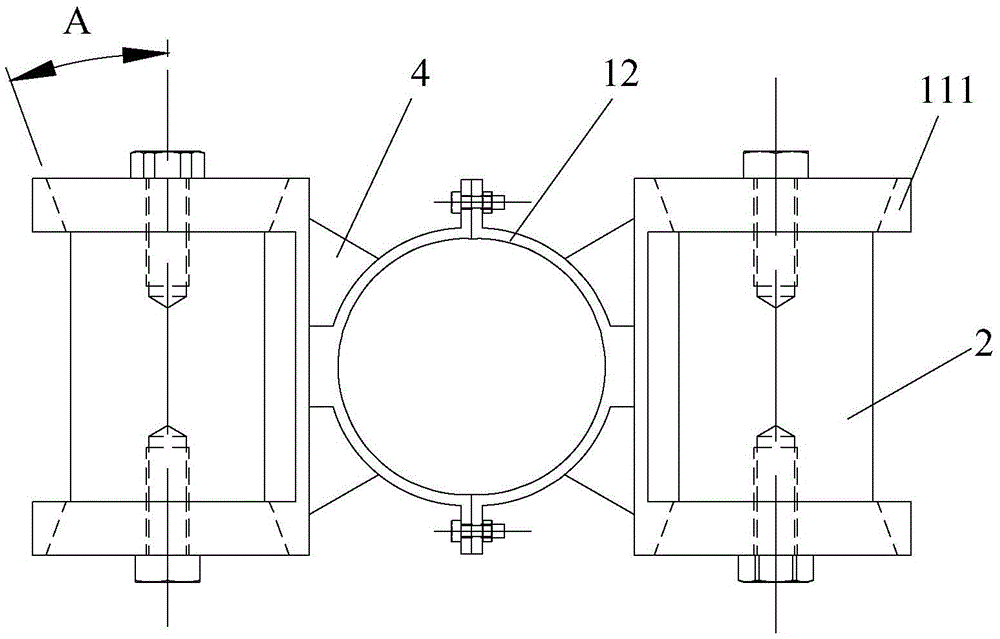

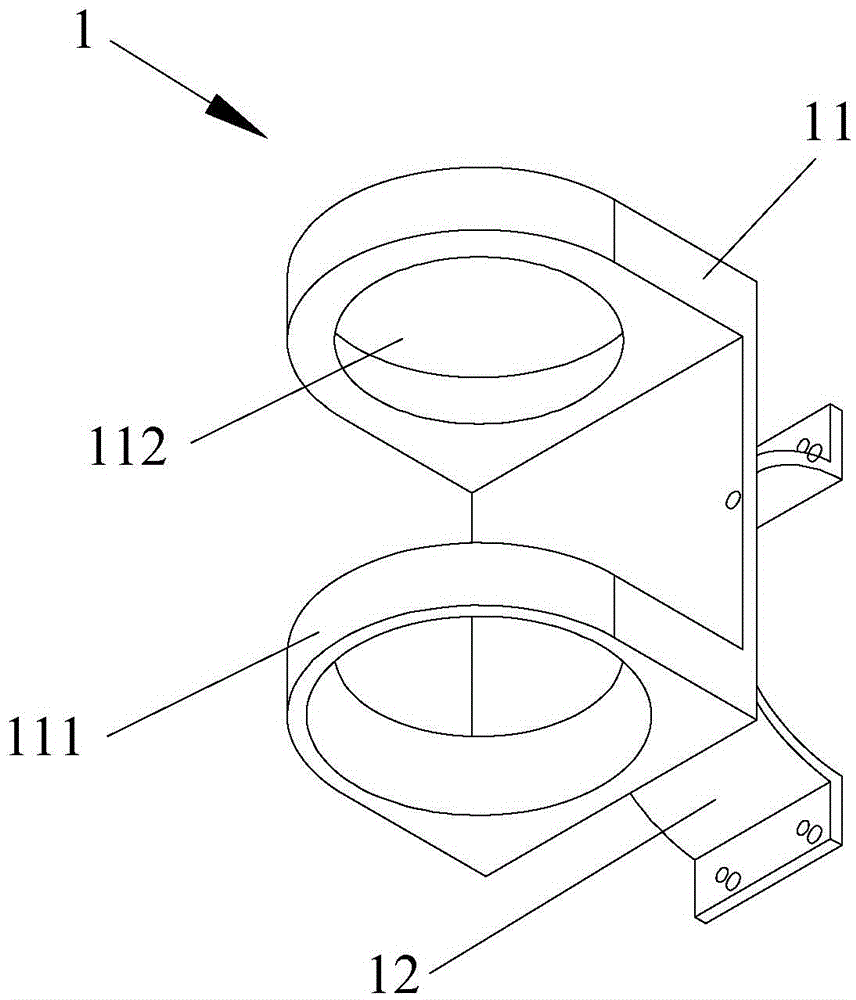

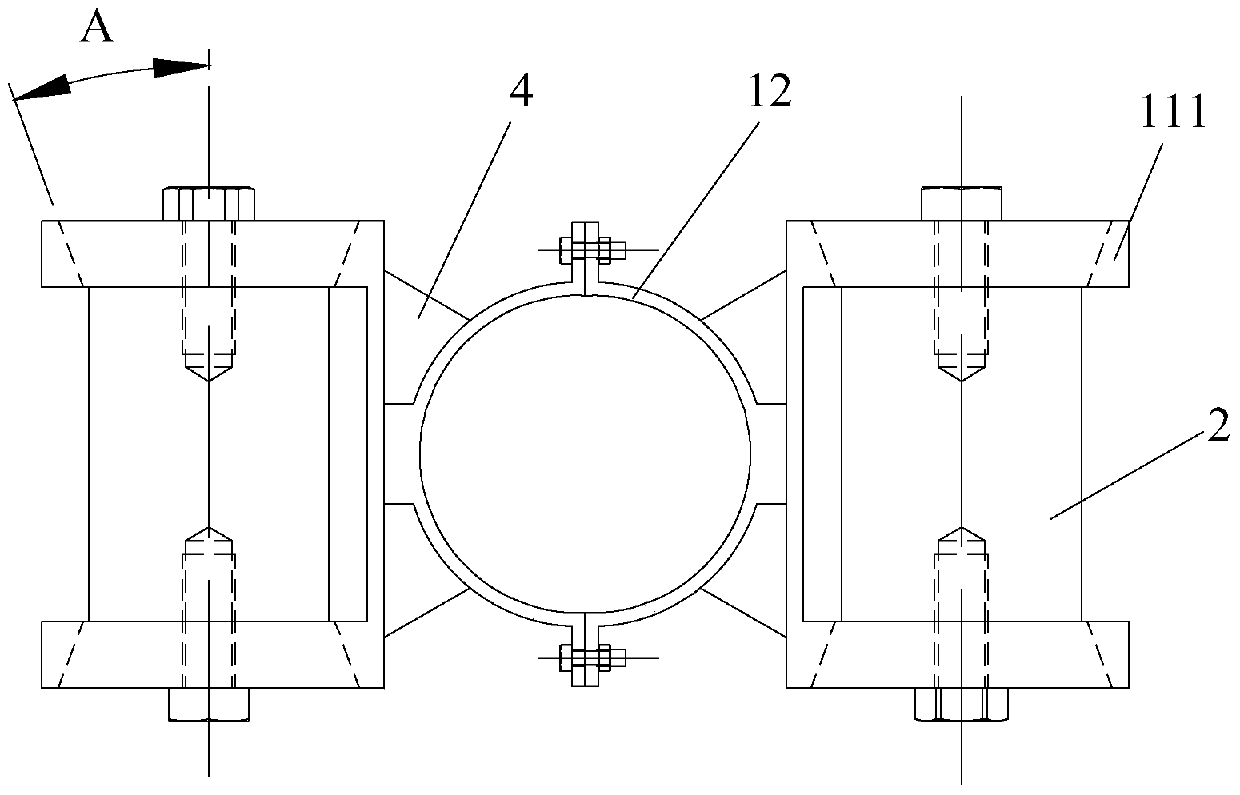

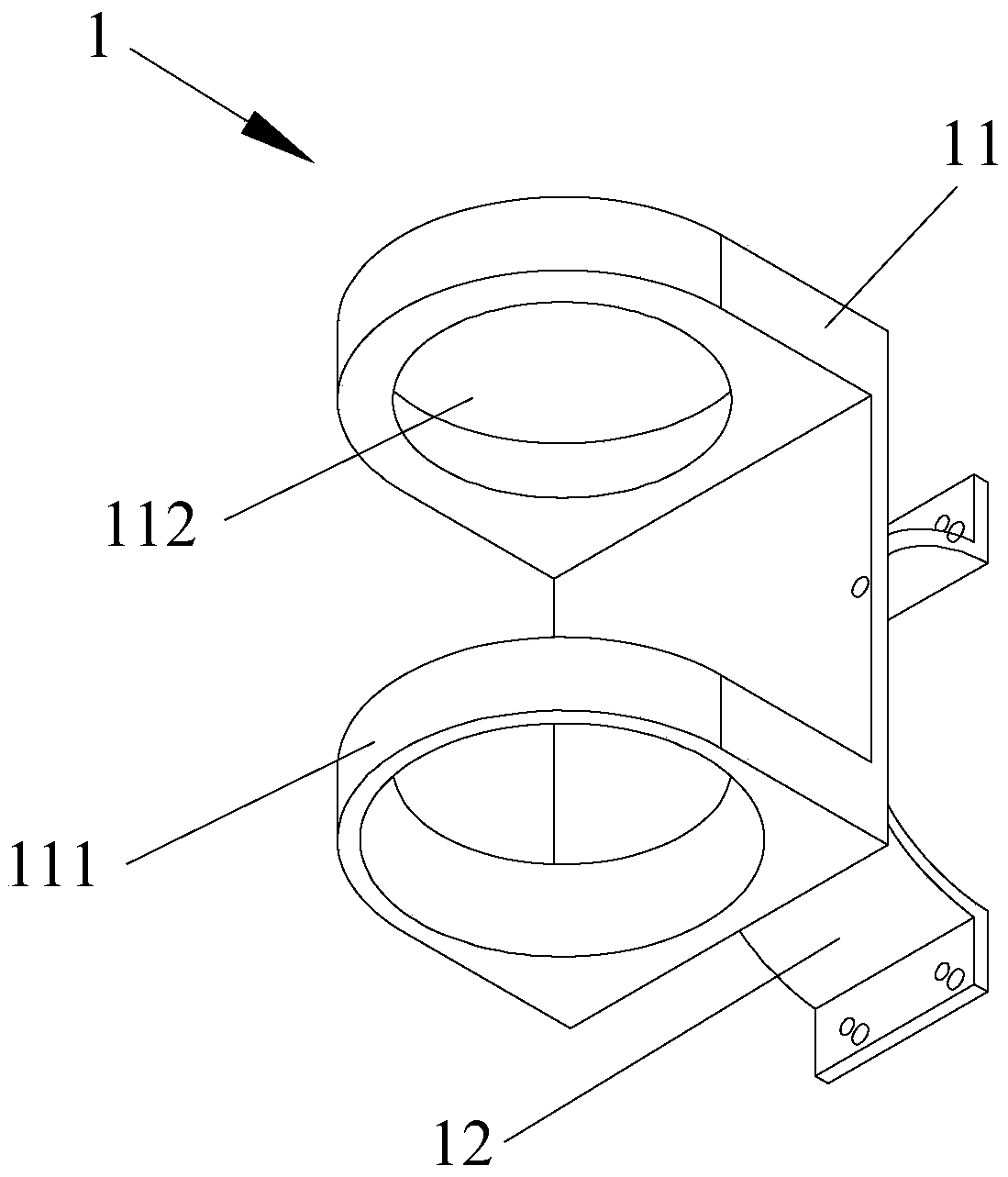

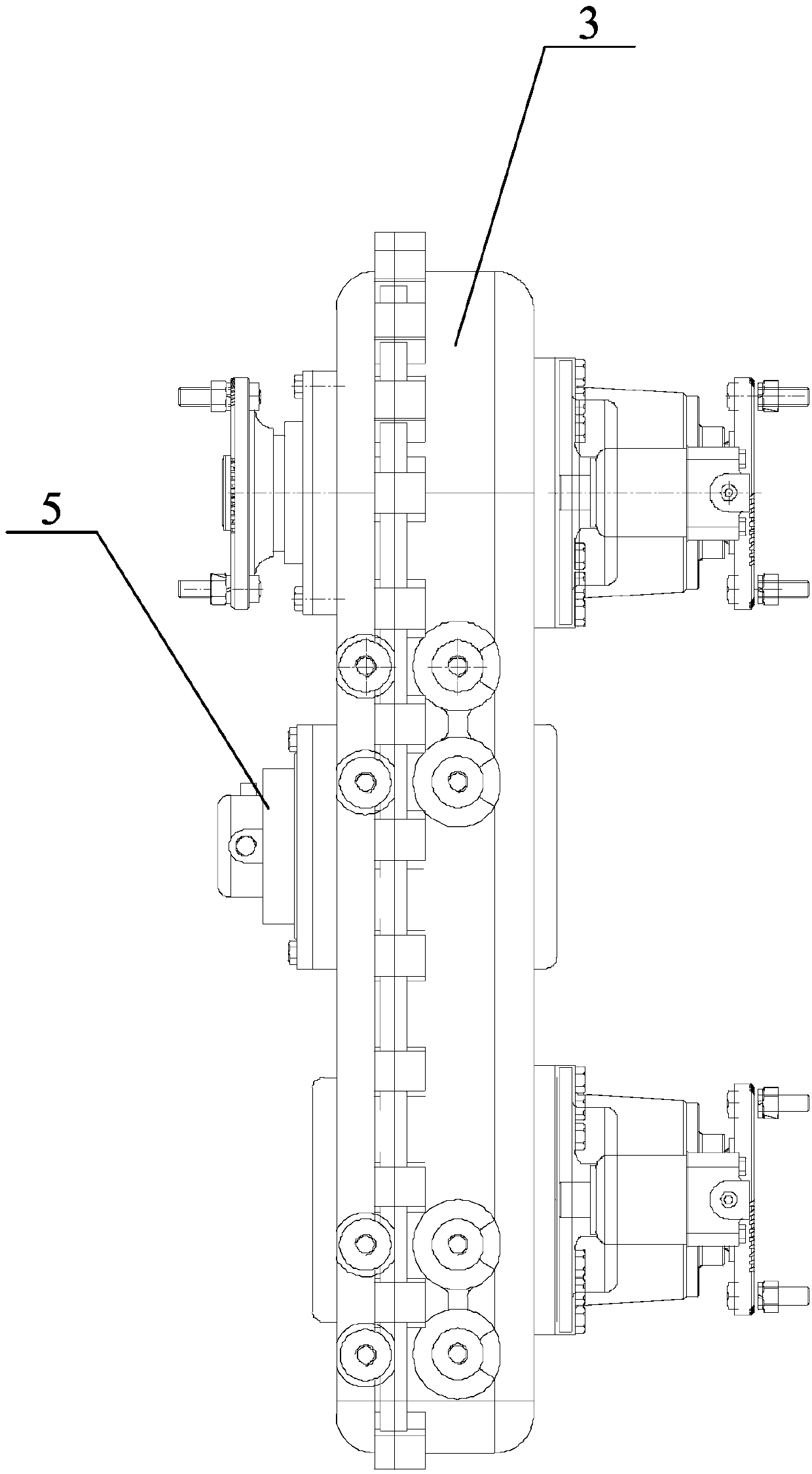

Dynamic vibration absorber for industrial pipeline

ActiveCN105570545AReduce vibrationTo achieve the effect of vibration reductionPipe supportsNon-rotating vibration suppressionEngineeringVibration absorption

The invention provides a dynamic vibration absorber for an industrial pipeline. The dynamic vibration absorber comprises two brackets and two mass blocks. The two brackets can be symmetrically clamped on the outer wall of the pipeline, and can be butted and fixed. The two mass blocks are respectively and detachably mounted on the two brackets. When the pipeline vibrates, the dynamic vibration absorber for the industrial pipeline is driven to vibrate, and an inertia force generated due to the vibration of the dynamic vibration absorber for the industrial pipeline reacts on the pipeline, so as to achieve the effect of effectively inhibiting the vibration of the pipeline. When the dynamic vibration absorber for the industrial pipeline is mounted, proper mass blocks are selected according to the vibration characteristics of the pipeline, and through the adjustment of the weights of the mass blocks, the optimal vibration absorption effect of the pipeline is achieved, and the vibration absorption purpose of the pipeline is achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

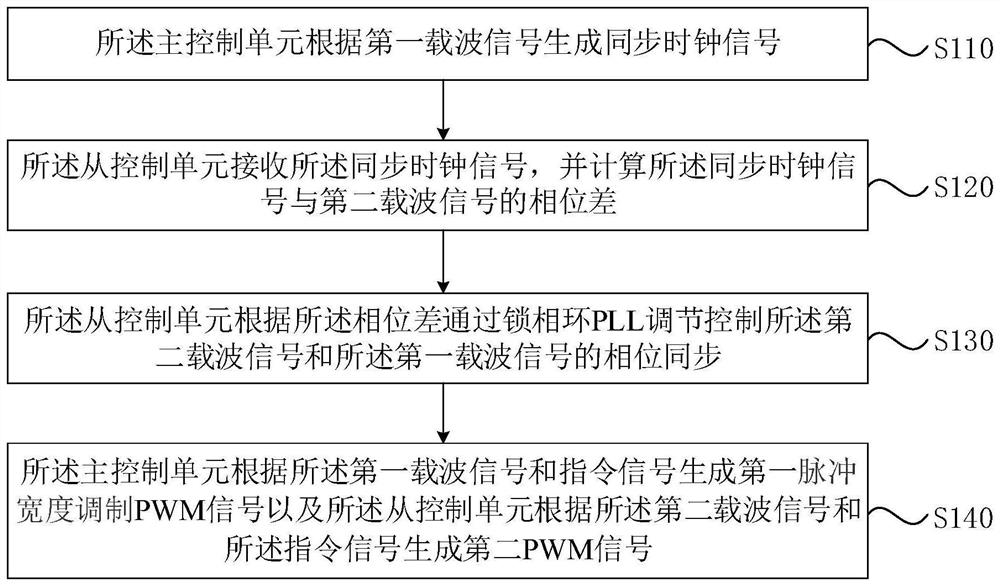

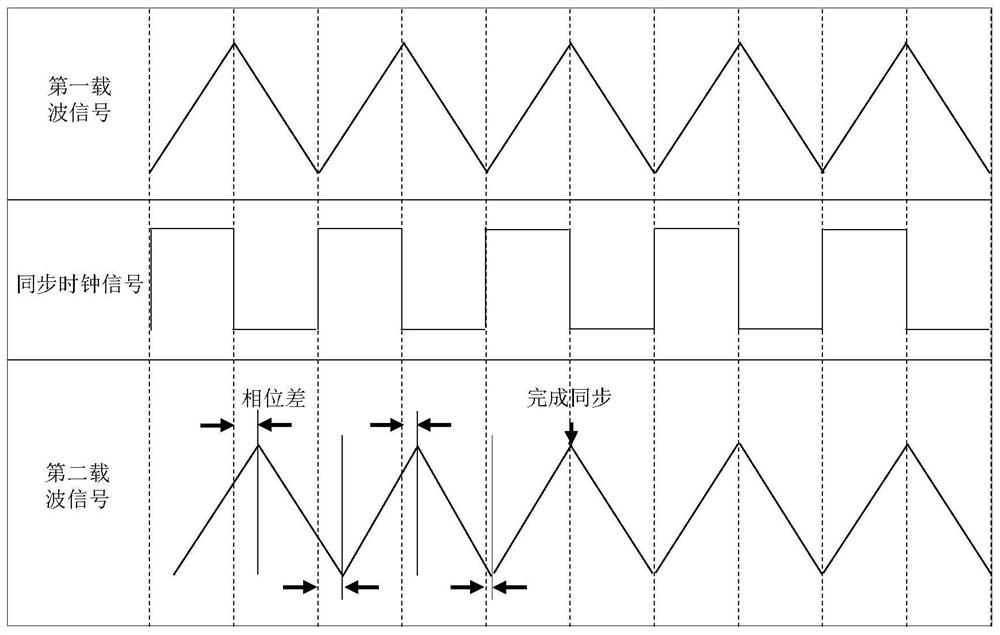

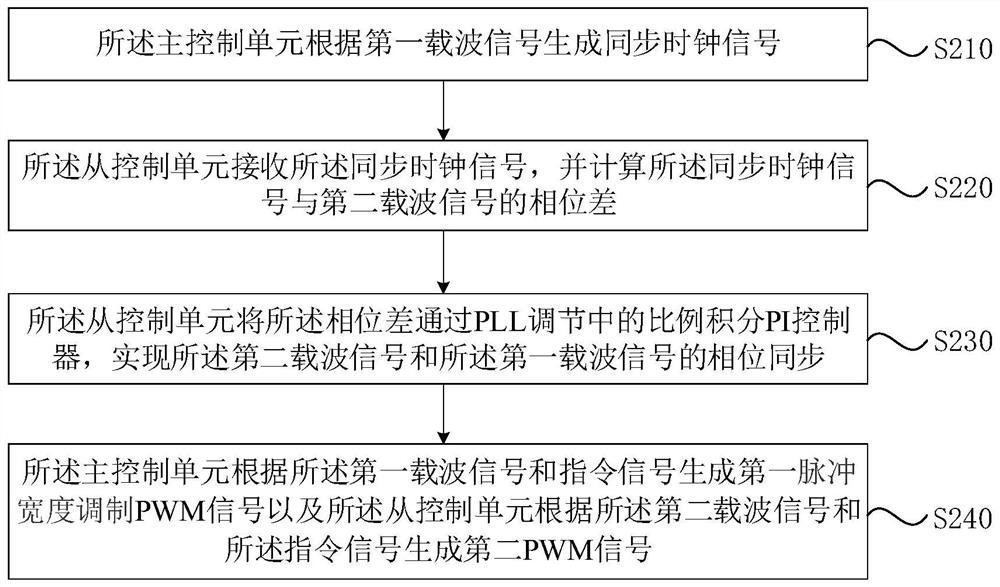

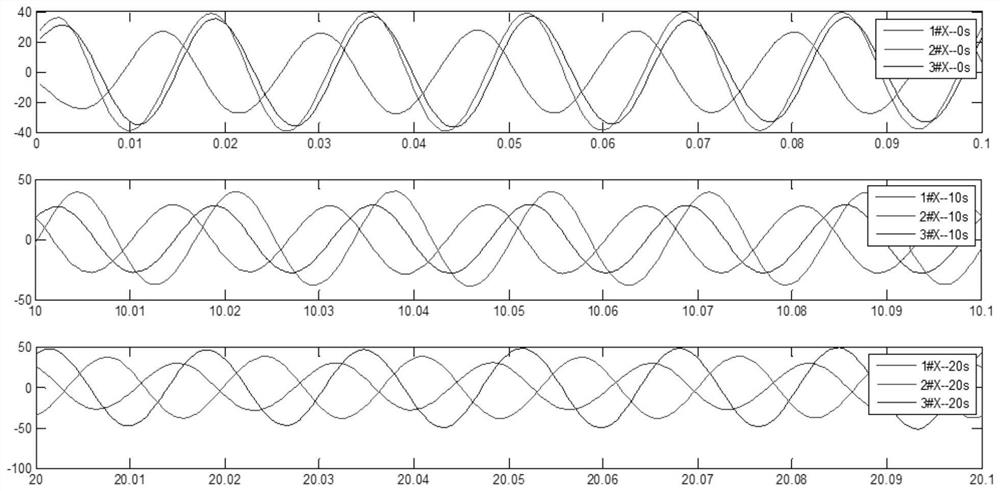

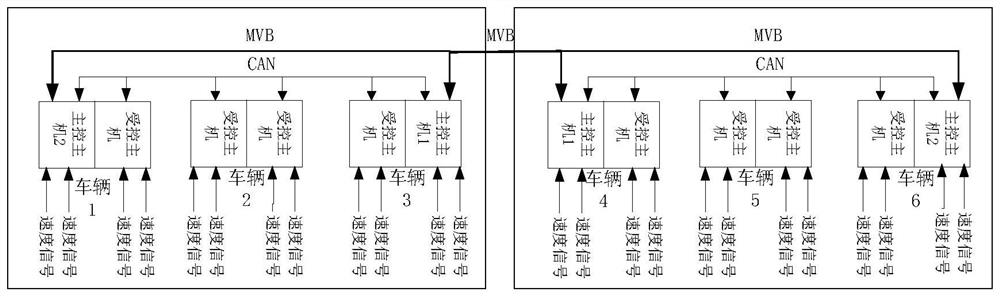

Control signal synchronization method, device and system, vehicle and storage medium

PendingCN112152612AImprove comfortAchieve synchronizationPulse automatic controlPulse duration/width modulationControl signalControl cell

The embodiment of the invention discloses a control signal synchronization method, device and system, a vehicle and a storage medium. The method comprises: the main control unit generating a synchronous clock signal according to a first carrier signal; the slave control unit receiving the synchronous clock signal and calculating the phase difference between the synchronous clock signal and a second carrier signal; the slave control unit adjusting and controlling phase synchronization of the second carrier signal and the first carrier signal through a phase-locked loop PLL according to the phase difference; the master control unit generating a first pulse width modulation (PWM) signal according to the first carrier signal and the command signal, and the slave control unit generating a second PWM signal according to the second carrier signal and the command signal. According to the technical scheme provided by the embodiment of the invention, synchronization of the PWM signals can be realized, so that abnormal vibration generated in a vehicle driving process is reduced.

Owner:CHINA FIRST AUTOMOBILE

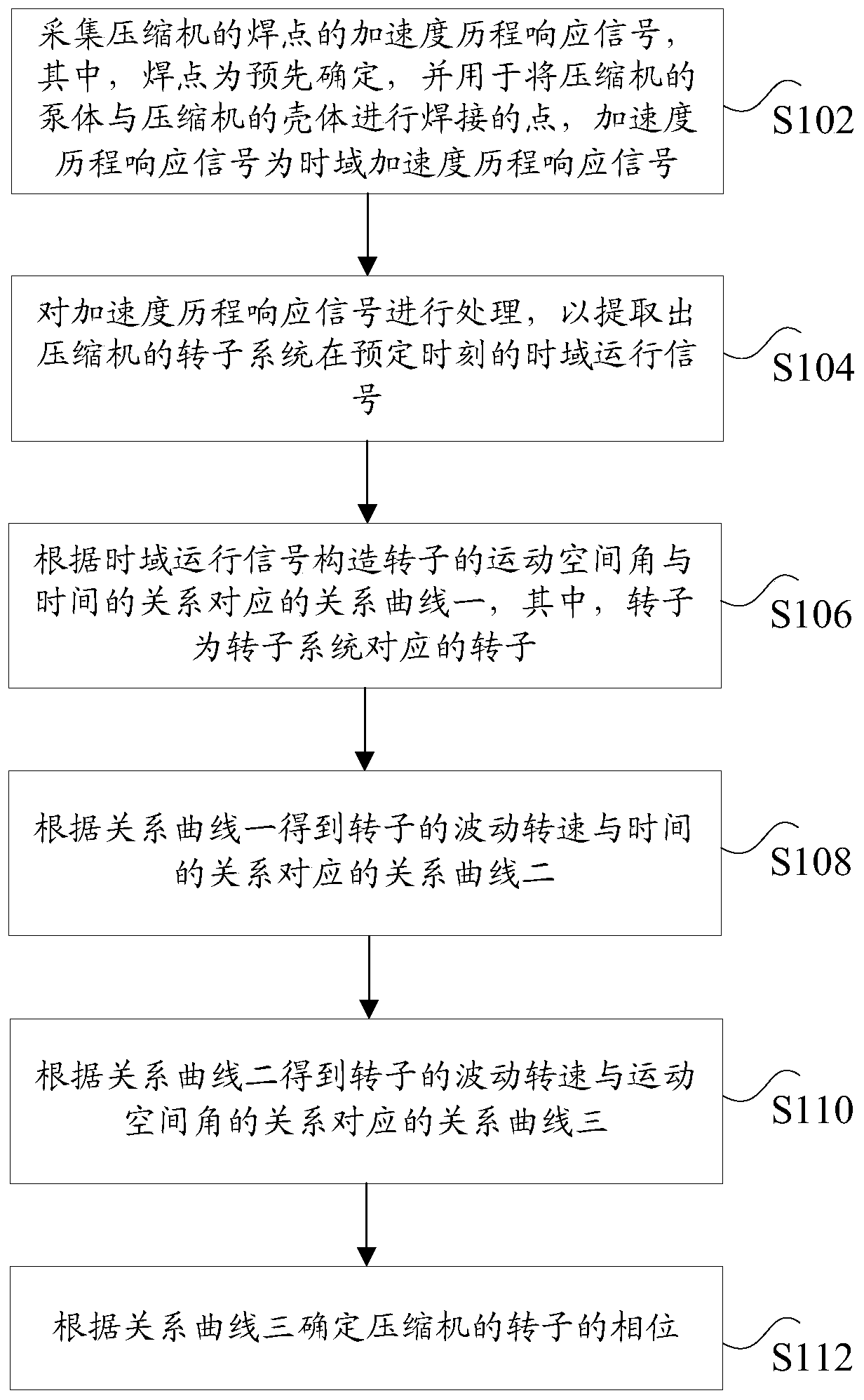

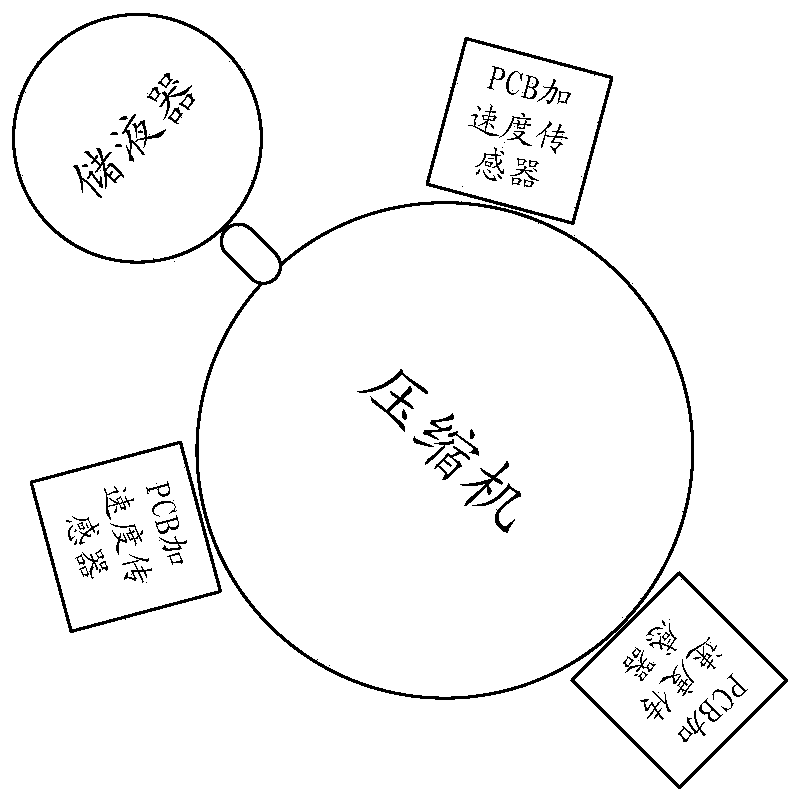

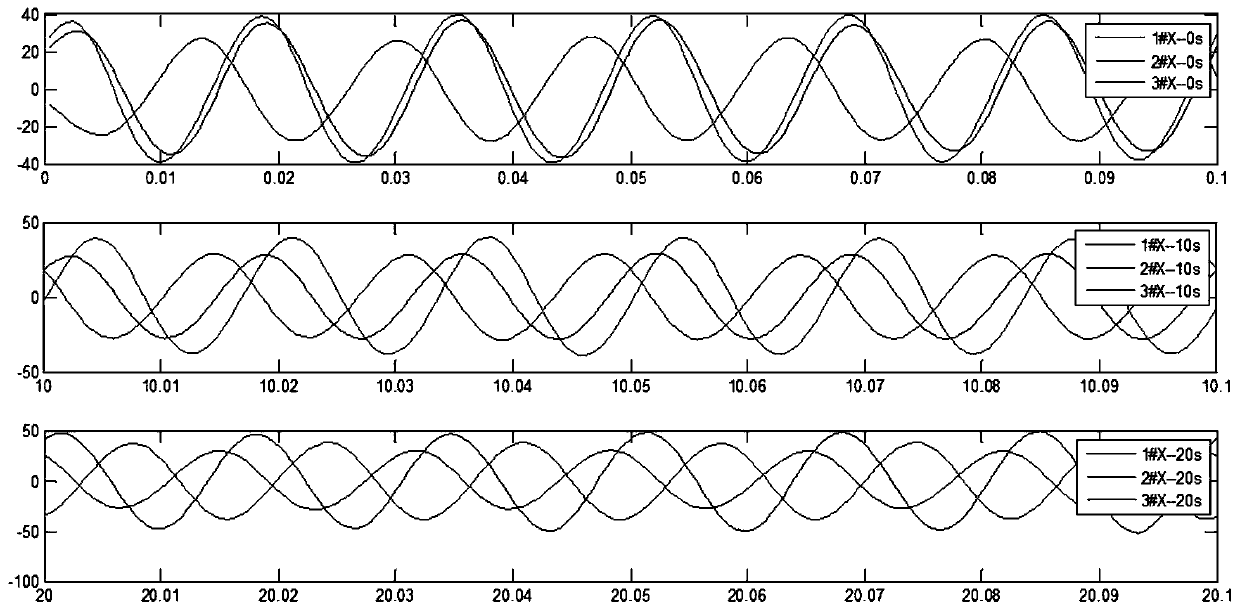

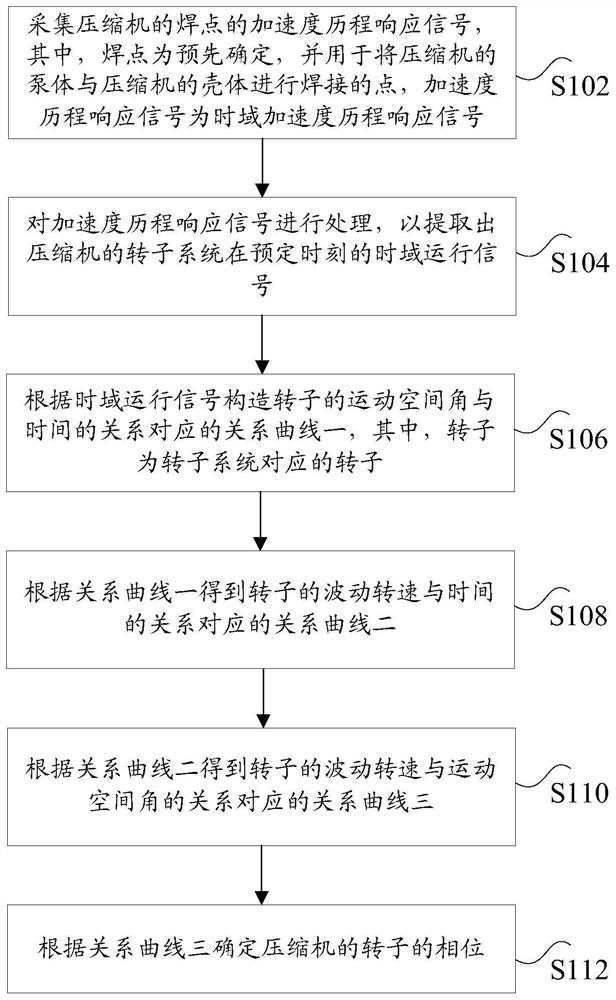

Determining method and device for rotor phase of compressor and compressor

ActiveCN111237191AImprove accuracyReduce abnormal vibrationMachines/enginesTime domainClassical mechanics

The invention discloses a determining method and device for a rotor phase of a compressor and the compressor. The method comprises the following steps: acquiring an accelerated speed course response signal of a welding spot of the compressor; processing the accelerated speed course response signal to extract a time domain operation signal, at a predetermined moment, of a rotor system of the compressor; constructing a relation curve I which corresponds to a relationship between a motion space angle of a rotor and time according to the time domain operation signal, wherein the rotor is a rotor corresponding to the rotor system; obtaining a relation curve II which corresponds to a relationship between fluctuation rotation speed of the rotor and time according to the relation curve I; obtaining a relation curve II which corresponds to a relationship between the fluctuation rotation speed of the rotor and the motion space angle of the rotor according to the relation curve II; and determining the phase of the rotor of the compressor according to the relation curve III. The determining method solves the technical problem that the compressor is easily caused to vibrate abnormally as a result of inaccurate torque compensation on the compressor if a way of obtaining the phase of the rotor of the compressor in the prior art is lower in reliability.

Owner:GREE ELECTRIC APPLIANCES INC

Industrial pipeline dynamic vibration absorber

ActiveCN105570545BReduce vibrationTo achieve the effect of vibration reductionPipe supportsNon-rotating vibration suppressionEngineeringVibration absorption

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

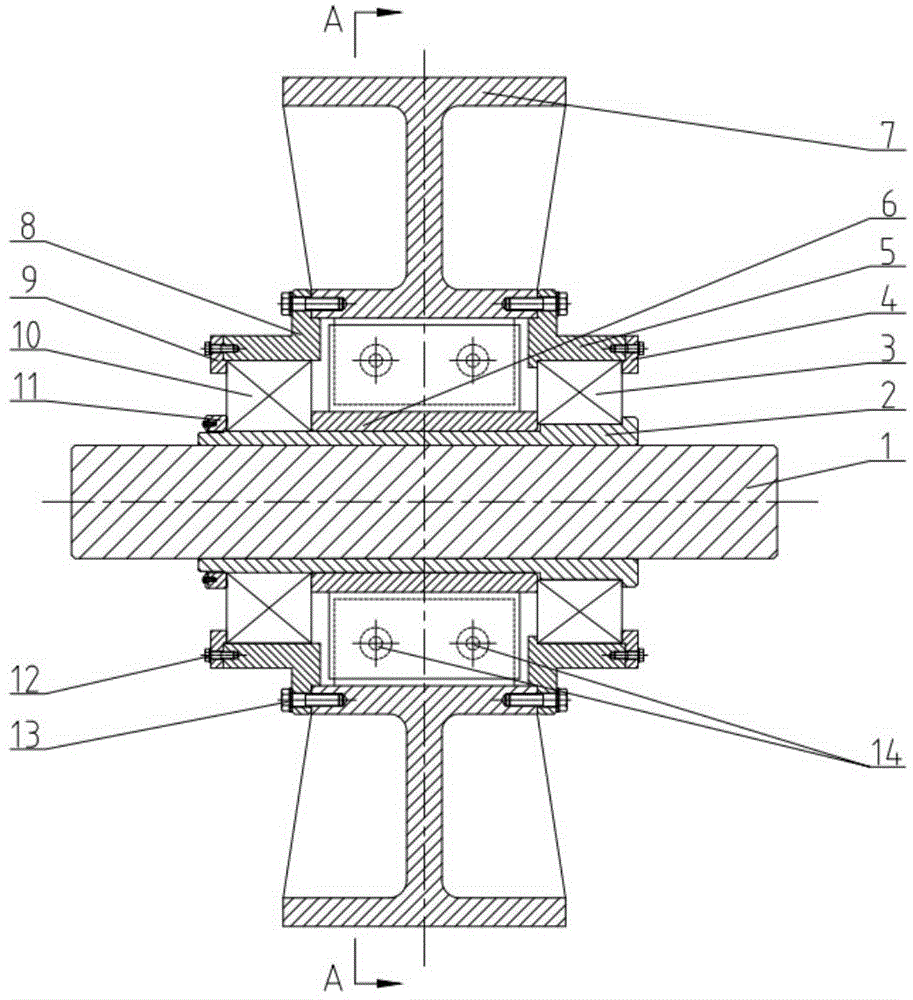

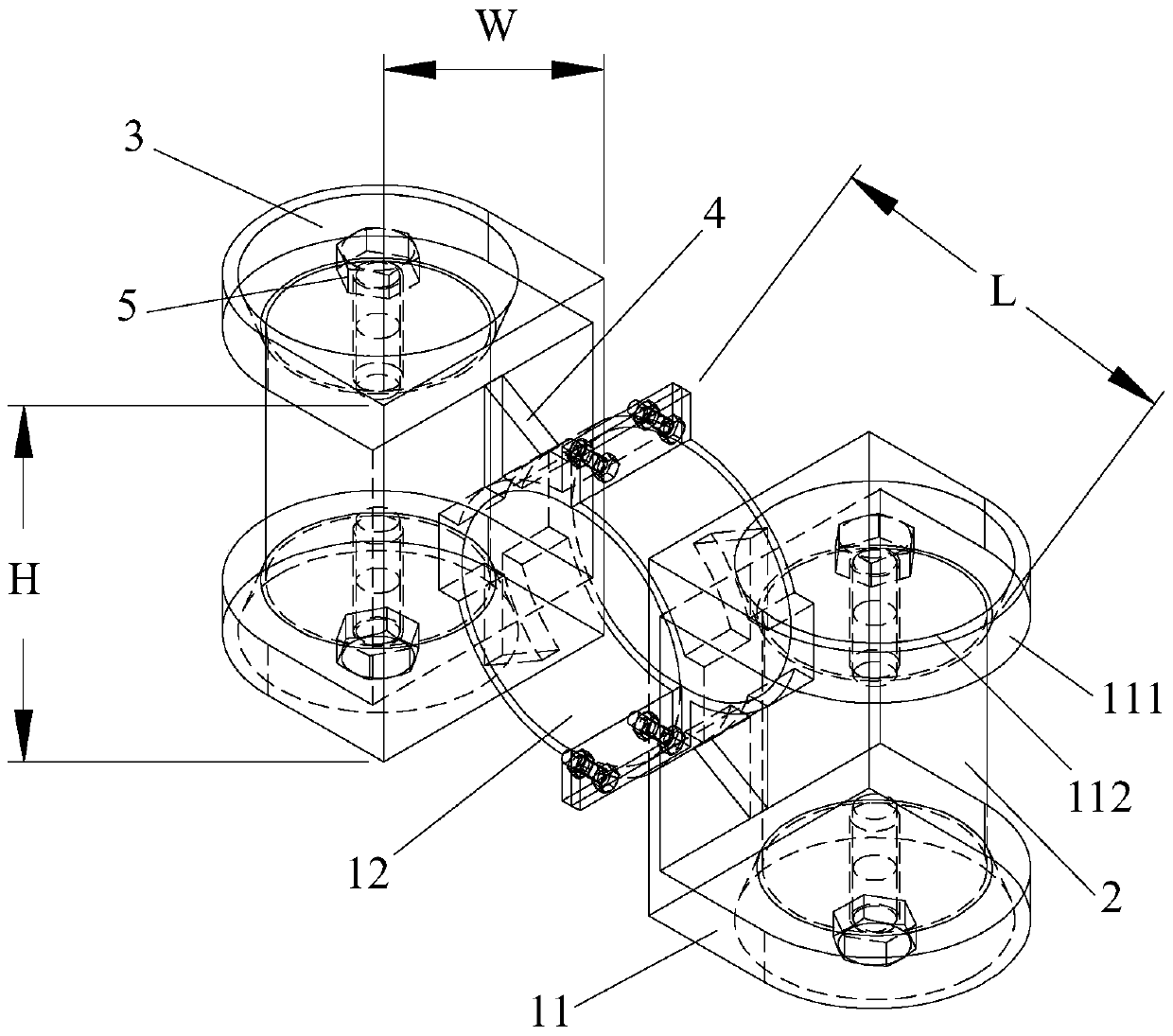

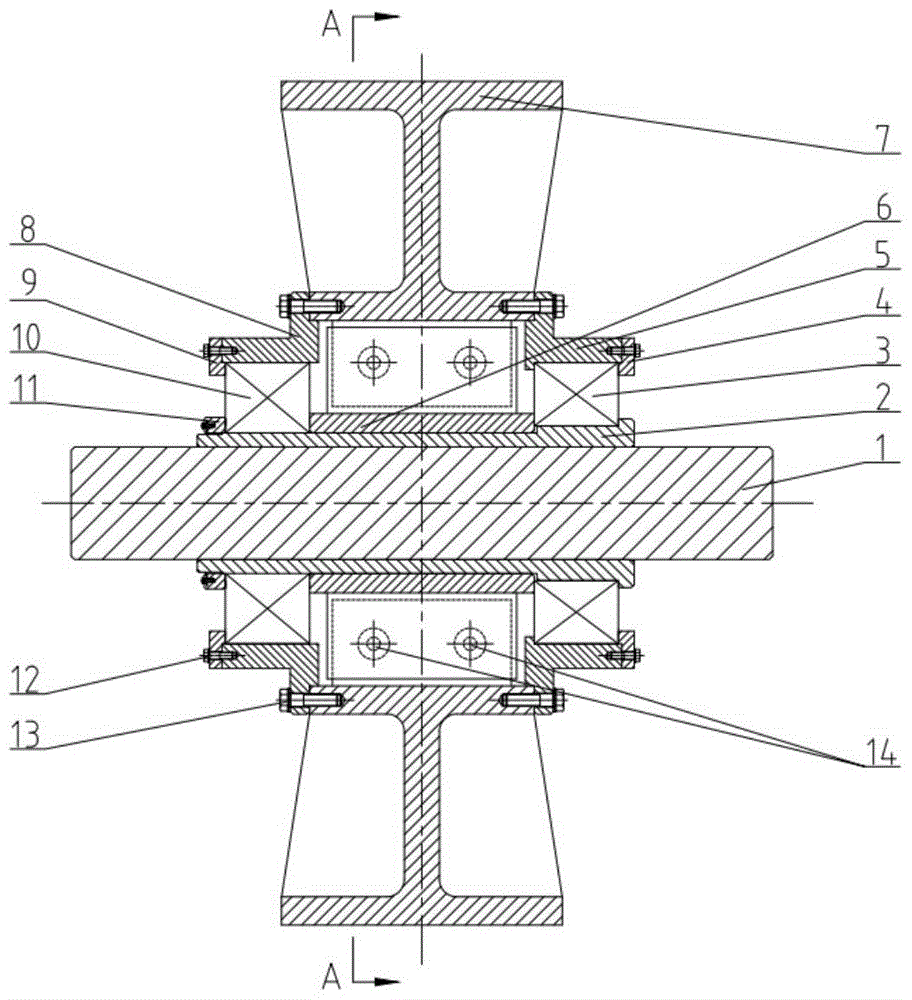

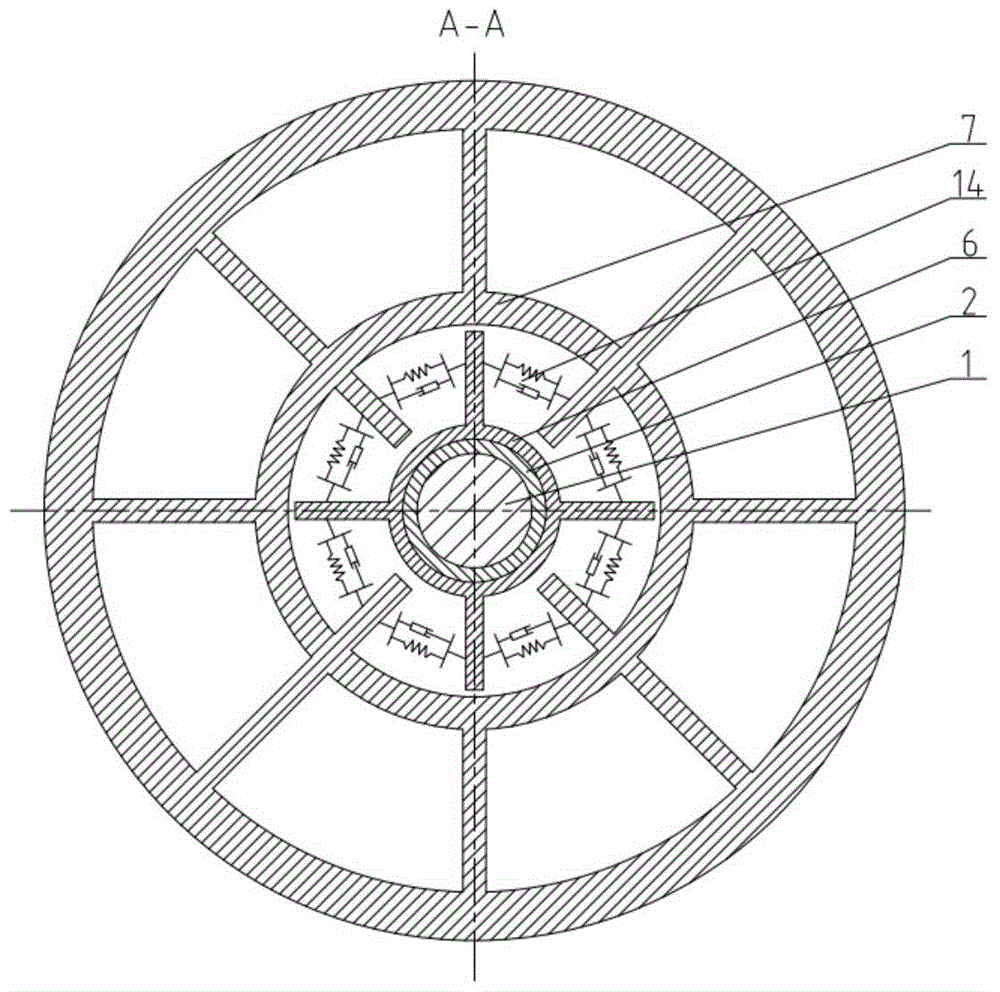

An inertial flywheel device with adjustable moment of inertia and automatic calibration

ActiveCN107741301BWith inertia automatic calibration functionReduce abnormal vibrationStatic/dynamic balance measurementFlywheelsCoil springEngineering

The invention discloses an inertial flywheel device adjustable in rotational inertia and capable of achieving automatic carlibaration. An annular bulge on a flywheel shaft is hollowly sleeved with themiddle of a flywheel disc, two lead screws which are symmetrical to each other around a center axis of the flywheel disc are radially arranged at one axial side of the flywheel disc, the inner end ofeach lead screw is provided with a small bevel gear at the inner side of the annular bulge, a mass block is assembled on each lead screw at the outer side of the annular bulge, and a bevel gear discis provided with conical teeth capable of being meshed with the two small bevel gears; the flywheel shaft is fixedly sleeved with an intermediate body, the intermediate body extends into a radial blind hole formed in the inner wall of the annular bulge through positioning columns with gaps, each positioning column is sleeved with a spiral spring, the other axial side surface of the flywheel disc is provided with two flywheel disc hinge bases, a mass adjusting block is hinged to each flywheel disc hinge base through a short connecting rod, and an intermediate body hinge base is hinged to each mass adjusting block through a long connecting rod; the magnitude of the rotational inertia can be continuously changed, and the uneven mass of a flywheel can be automatically sensed and adjusted.

Owner:江阴智产汇知识产权运营有限公司

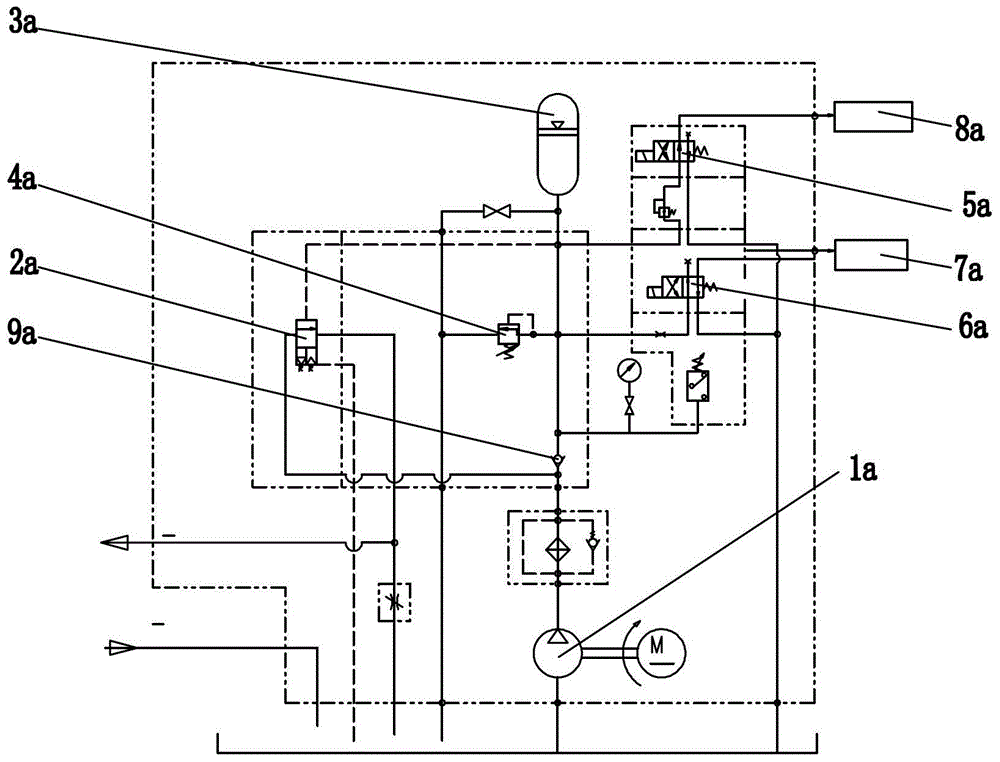

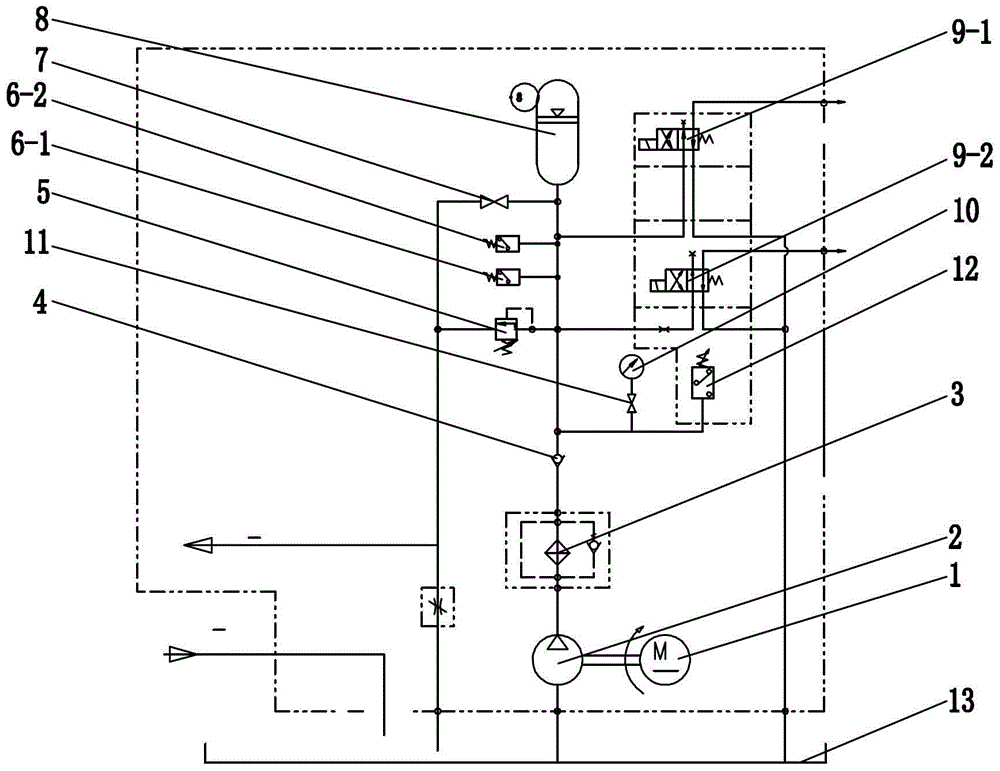

Cutting hydraulic system of cutting machine

ActiveCN103433958BReduce reactive power consumption and heat generationGuaranteed viscosity performanceMetal working apparatusFuel tankCheck valve

The invention relates to a hydraulic cutting system of a cutting machine. The hydraulic cutting system of the cutting machine comprises an oil pump, the input end of the oil pump is connected with an oil tank, the output end of the oil pump is connected with the input end of an oil filter, and the output end of the oil filter is connected with the input end of a check valve. The hydraulic cutting system of the cutting machine is characterized in that the output end of the check valve is connected with an energy accumulator, an overflow valve, a first pressure relay, a second pressure relay, a third pressure relay, a first reversing valve and a second reversing valve, and the oil outlet of the second reversing valve is connected with a hydraulic clutch of the cutting machine. A stop valve is arranged between the overflow valve and the energy accumulator. The oil return opening of the first reversing valve and the oil return opening of the second reversing valve are connected with the oil tank. The third pressure relay is connected with a pressure gage and a pressure gage switch. One end of the overflow valve is connected with the output end of the check valve, and the other end of the overflow valve is connected into the oil tank. The power input end of the oil pump is connected with a motor. According to the hydraulic cutting system of the cutting machine, idle consumption heating of the hydraulic system is reduced, the viscosity performance of oil is ensured, and the service life of the oil is prolonged.

Owner:JIANGSU GENERAL SCI TECH

A transmission system torsional vibration damping method and its application

ActiveCN104896007BReduce high frequency vibrationReduce vibration levelsVibration dampersSpringsCouplingDrive shaft

The invention provides a transmission system torsional vibration reducing method and application thereof. The method is characterized in that a torsional vibration damper, which is a tuned rotary inertia damper, is added on a transmission shaft in a parallel connection manner, and the torsional rotation movement around the transmission shaft is used for reducing the vibration level of a certain first order torsional mode frequency. The method is flexible, can effectively reduce vibration without damage to the original structure of the transmission system, and can be used for later repair of the transmission system. The method can be applied to wind energy / tidal current energy generator sets; the torsional vibration damper is installed on a shaft, connected with a generator, of a high speed shaft coupler to greatly reduce a first-order mode component in the torsional vibration, so that a transmission system can operate more stably, the reliability of the structure can be improved and the service life can be prolonged.

Owner:国能联合动力技术(保定)有限公司

Method and device for determining rotor phase of compressor, compressor

ActiveCN111237191BImprove accuracyReduce abnormal vibrationMachines/enginesTime domainClassical mechanics

The invention discloses a determining method and device for a rotor phase of a compressor and the compressor. The method comprises the following steps: acquiring an accelerated speed course response signal of a welding spot of the compressor; processing the accelerated speed course response signal to extract a time domain operation signal, at a predetermined moment, of a rotor system of the compressor; constructing a relation curve I which corresponds to a relationship between a motion space angle of a rotor and time according to the time domain operation signal, wherein the rotor is a rotor corresponding to the rotor system; obtaining a relation curve II which corresponds to a relationship between fluctuation rotation speed of the rotor and time according to the relation curve I; obtaining a relation curve II which corresponds to a relationship between the fluctuation rotation speed of the rotor and the motion space angle of the rotor according to the relation curve II; and determining the phase of the rotor of the compressor according to the relation curve III. The determining method solves the technical problem that the compressor is easily caused to vibrate abnormally as a result of inaccurate torque compensation on the compressor if a way of obtaining the phase of the rotor of the compressor in the prior art is lower in reliability.

Owner:GREE ELECTRIC APPLIANCES INC

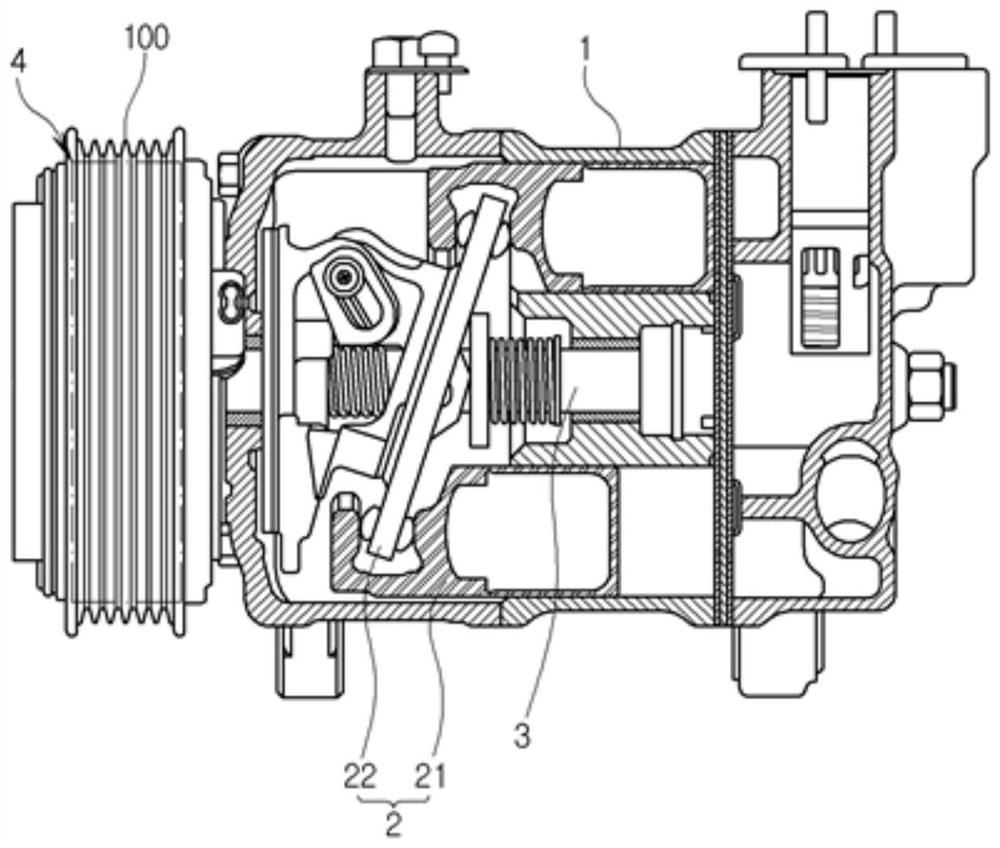

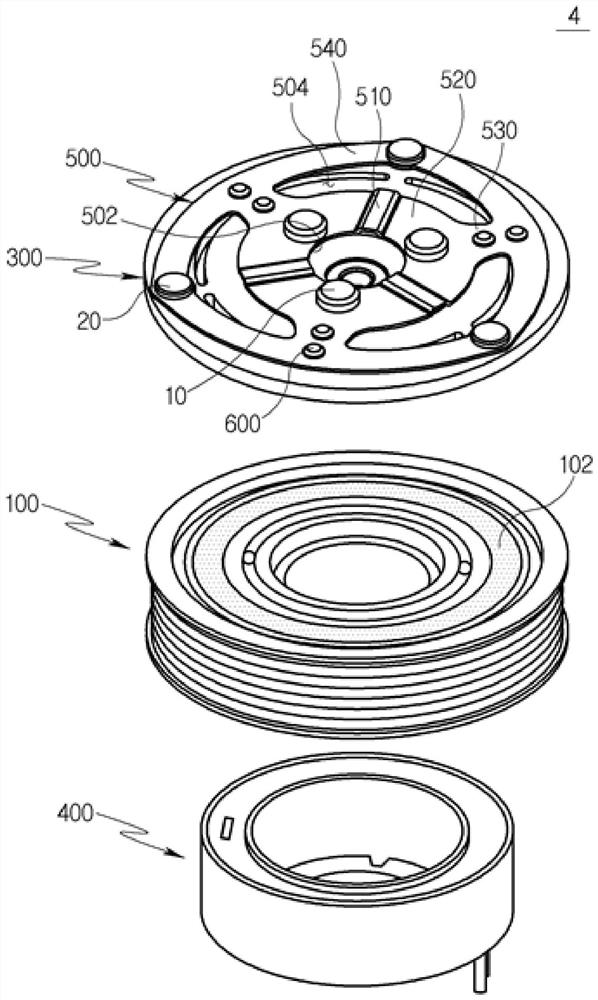

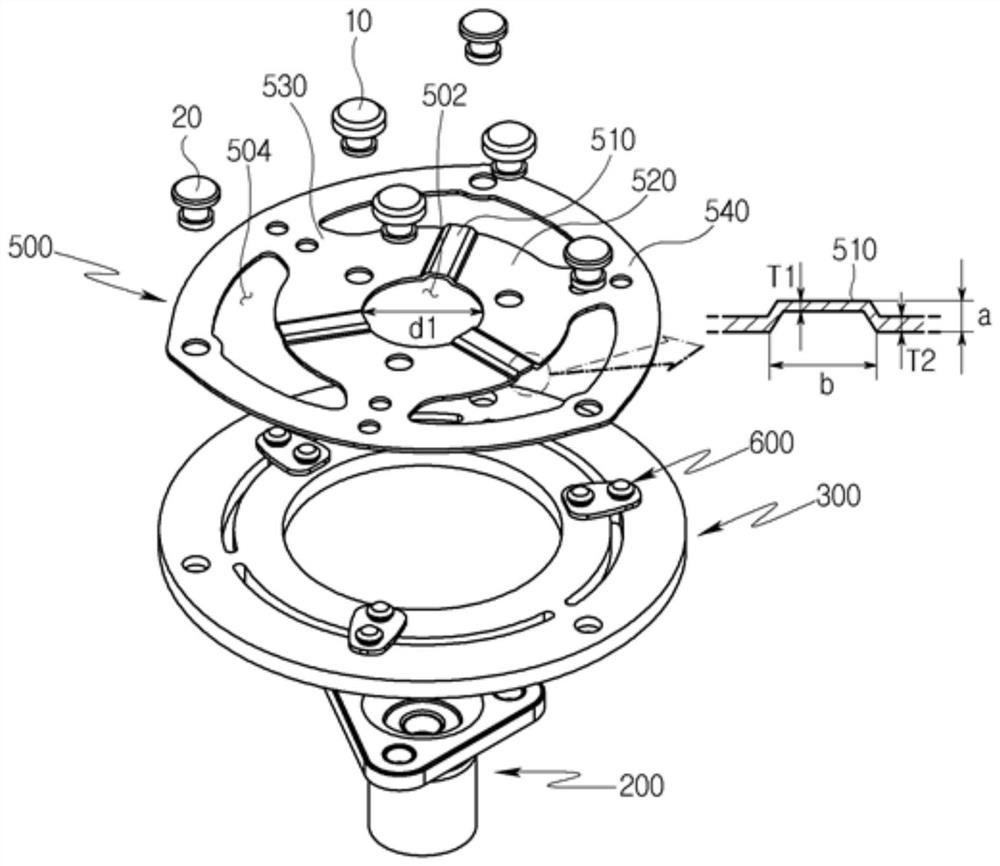

Clutch and compressor comprising same

ActiveCN112912639AReduce the amplitudeReduce vibrationMagnetically actuated clutchesVehicle heating/cooling devicesLow noiseEngineering

Owner:HANON SYST

Anti-reverse device of vortex compressor

InactiveCN100359181CImprove reliabilityPrevent reversalRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

A unit for preventing reverse rotation of vortex compressor, which has a rotary shaft with moving vortex disk, the compression unit composed of moving and static vortex disks, power generating unit, lubricating unit and reverse rotation preventer, features that it is arranged on main frame and moving vortex disk. When said moving vortex is going to rotate reverse, an elastic limiting pin moves upward and is hooked by a slot only main frame, so preventing the reverse rotation of moving vortex disk.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

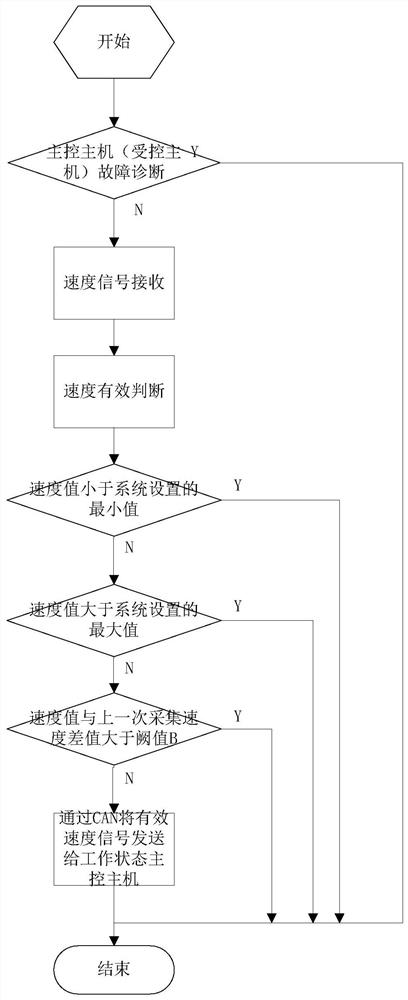

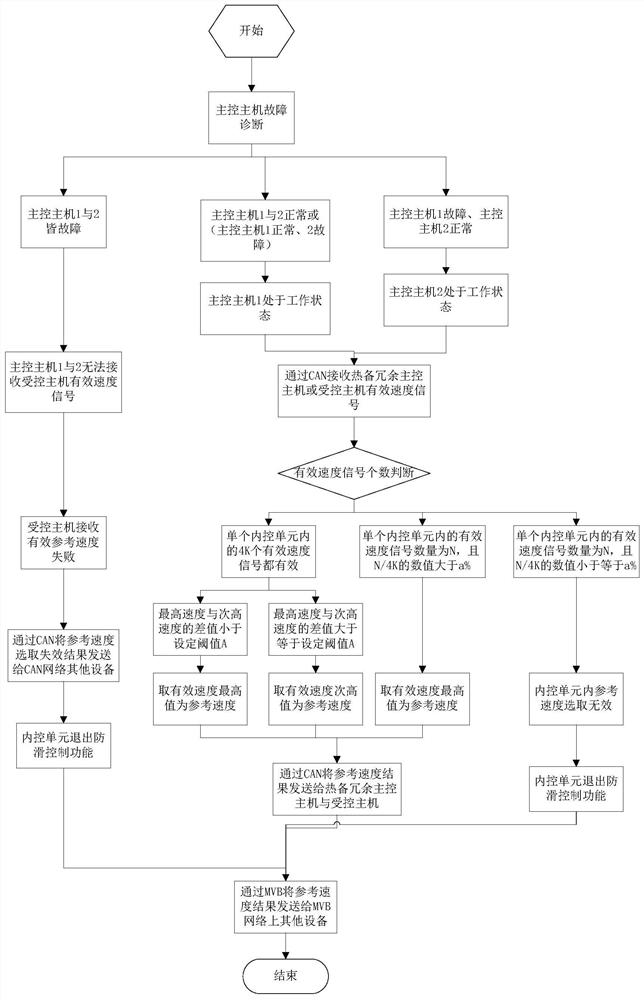

Rail transit vehicle and reference speed calculation method thereof

InactiveCN112141170AHigh precisionImprove work performanceRailway signalling and safetyEngineeringRail transit

The invention discloses a rail transit vehicle and a reference speed calculation method thereof. The method comprises the steps that the rail transit vehicle is divided into a plurality of internal control units, and each internal control unit comprises K sections of vehicles; for any internal control unit, all speed signals of the internal control unit are collected in real time within a time period, if all the speed signals are valid, whether the difference value between the maximum value and the second maximum value in all the speed signals is smaller than a set threshold value A or not isjudged, if yes, the maximum value is set as the reference speed of the internal control unit, and otherwise, the second maximum value is selected as the reference speed of the internal control unit; if the percentage of the number of the effective speed signals and the number of all the speed signals is larger than a%, the reference speed is set to be the maximum value in the effective speed signals; and if the percentage of the number of the effective speed signals and the number of all the speed signals is less than or equal to a%, the anti-skid control function of the internal control unitis closed. The precision of reference speed selection of a subway vehicle anti-skid system is greatly improved.

Owner:QINGDAO SRI TECH CO LTD

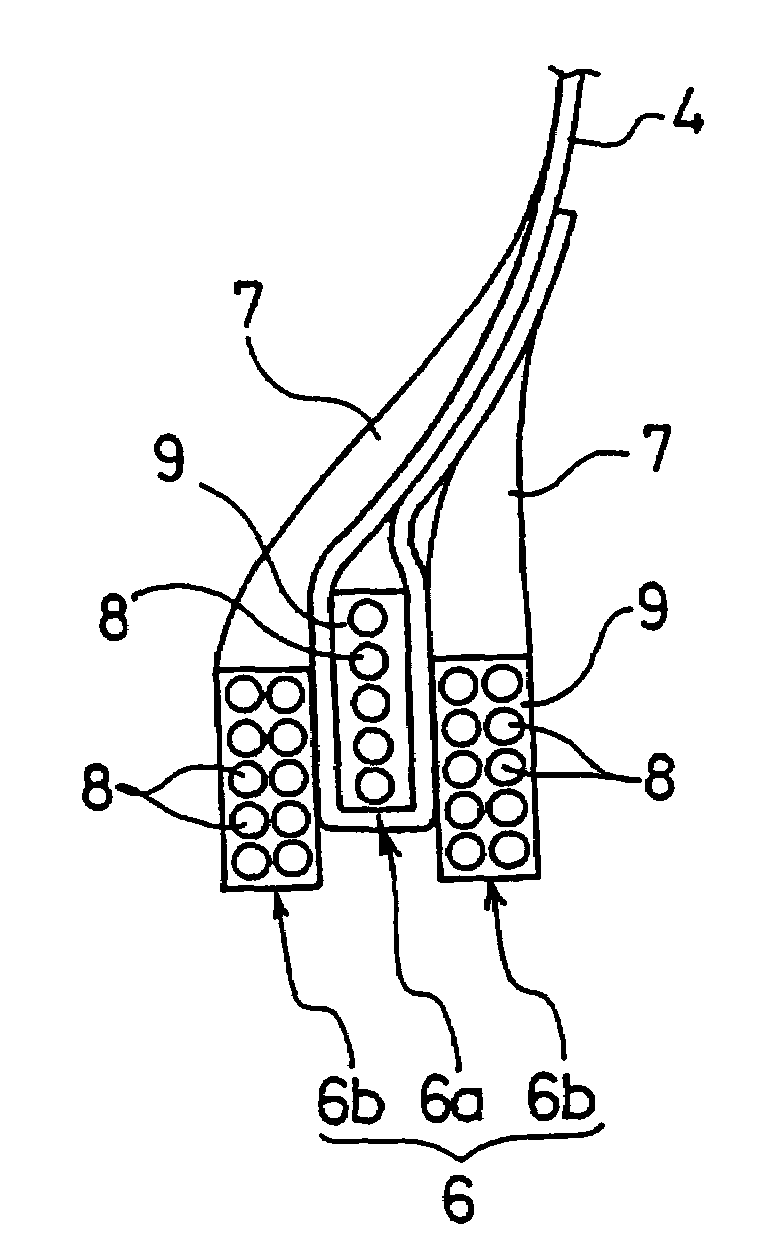

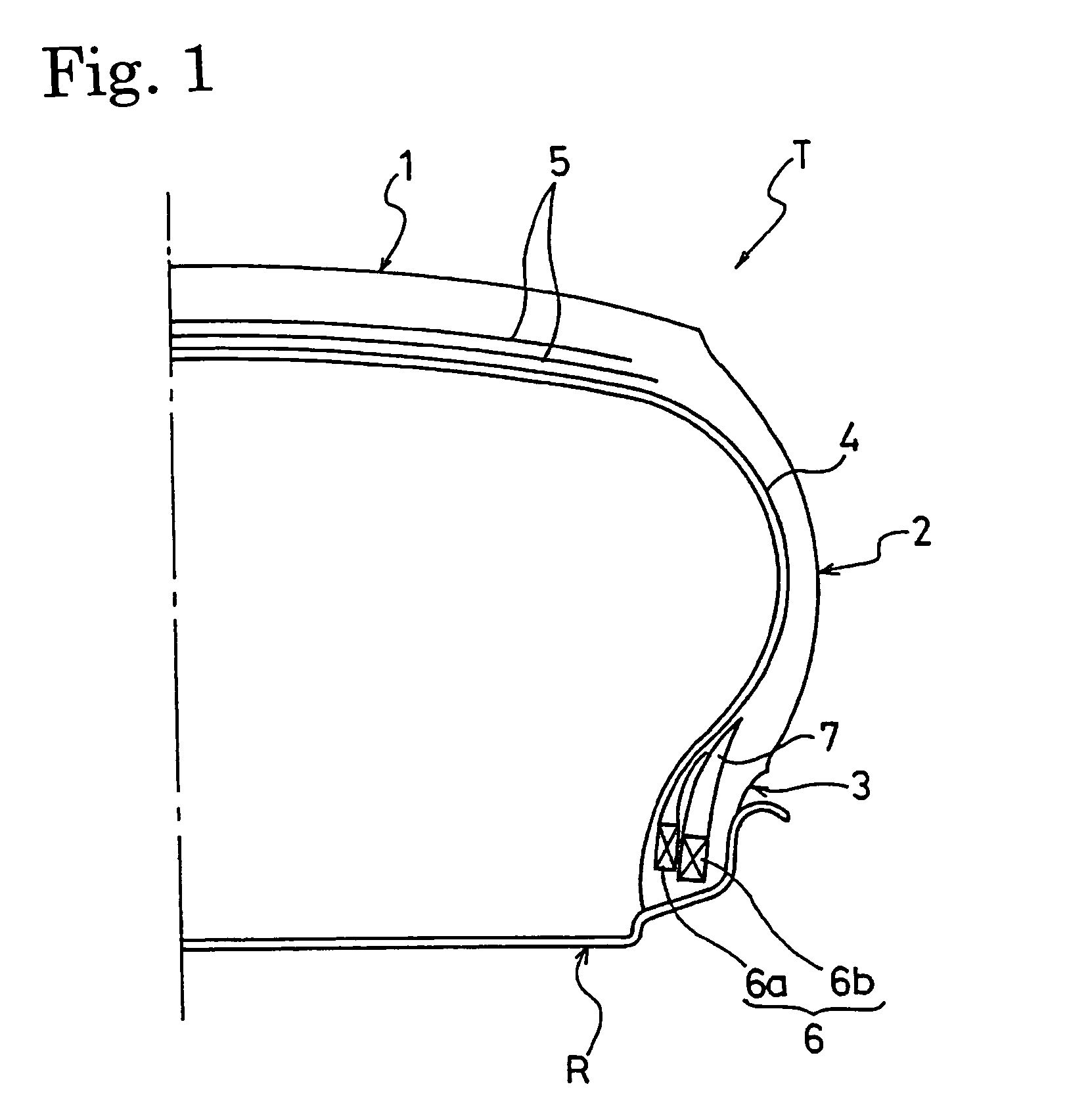

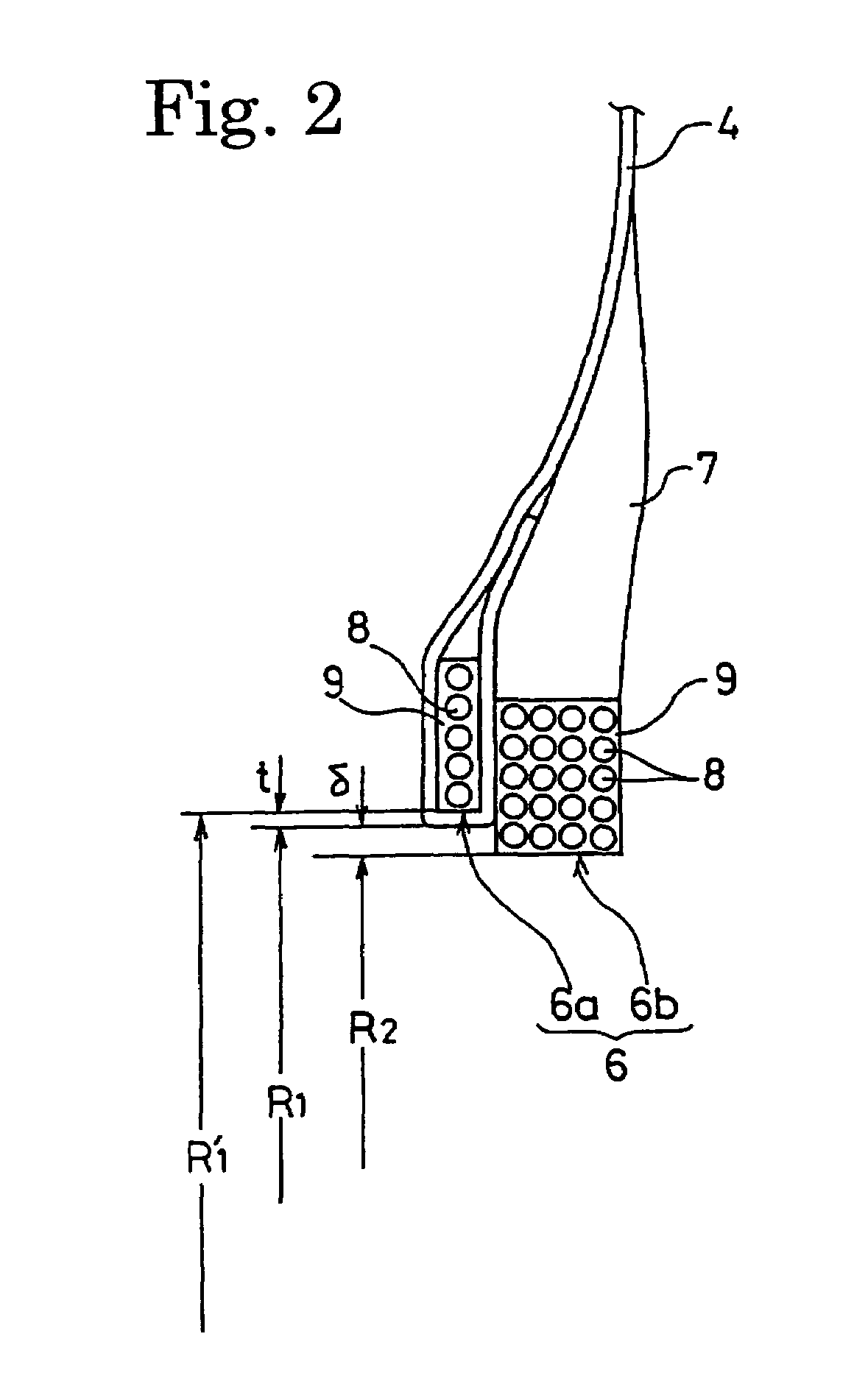

Pneumatic tire

InactiveUS7575033B2Reduce the amount requiredReduce abnormal vibrationSpecial tyresTyre beadsTire beadEngineering

In a pneumatic tire composed of a carcass layer crossing between a pair of left and right bead cores, the bead cores comprise a fastening bead core for fastening an end of the carcass layer to be turned up around the fastening bead core, and a non-fastening bead core free from the end of the carcass layer. An inner circumferential radius R2 of the non-fastening bead core is set smaller than an inner circumferential radius R1 of the end of the carcass layer to be turned up around the fastening bead core.

Owner:THE YOKOHAMA RUBBER CO LTD

Ultrasonic working unit and ultrasonic processing device

ActiveCN104334103BReduce abnormal vibrationDiagnosticsSurgical instrument detailsEngineeringLongitudinal vibration

Owner:OLYMPUS CORP

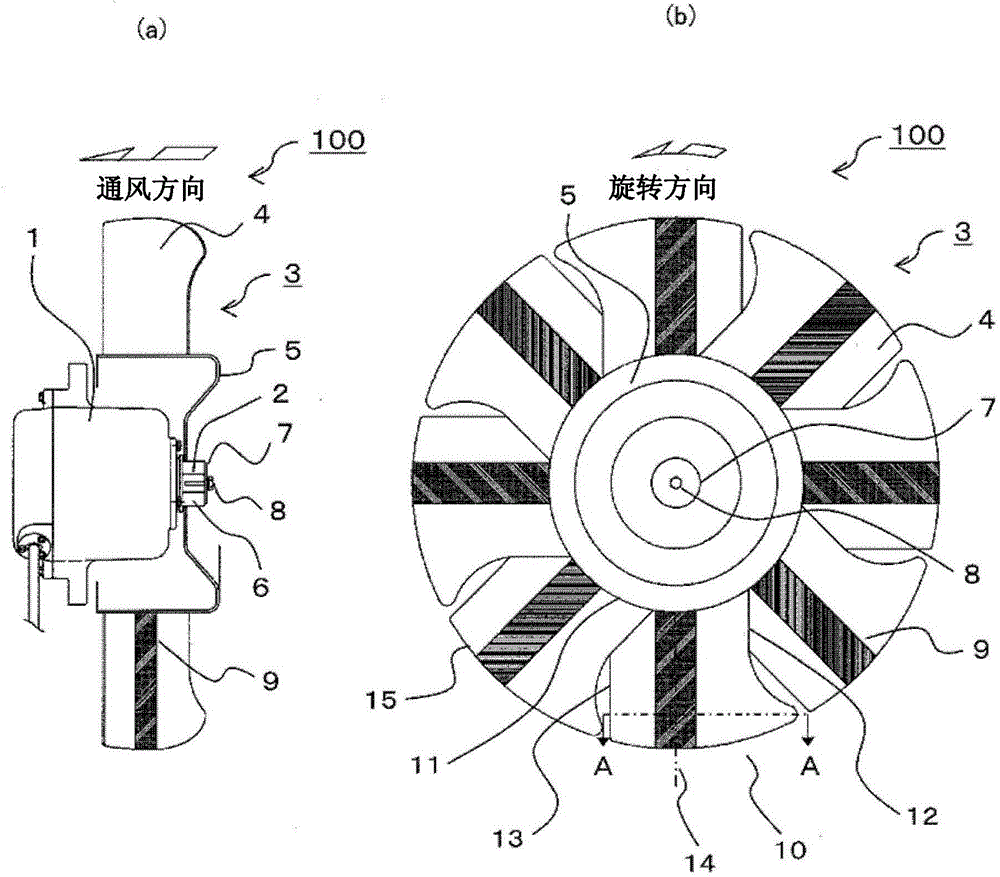

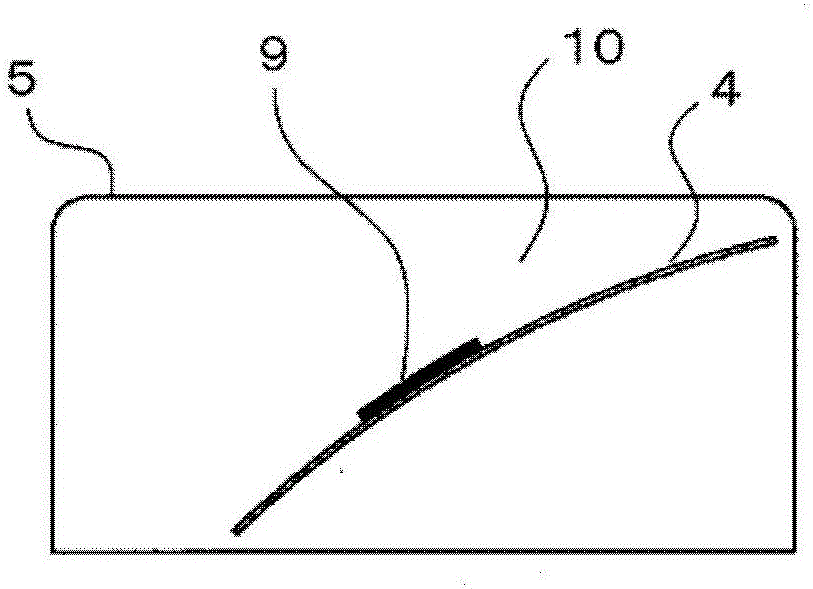

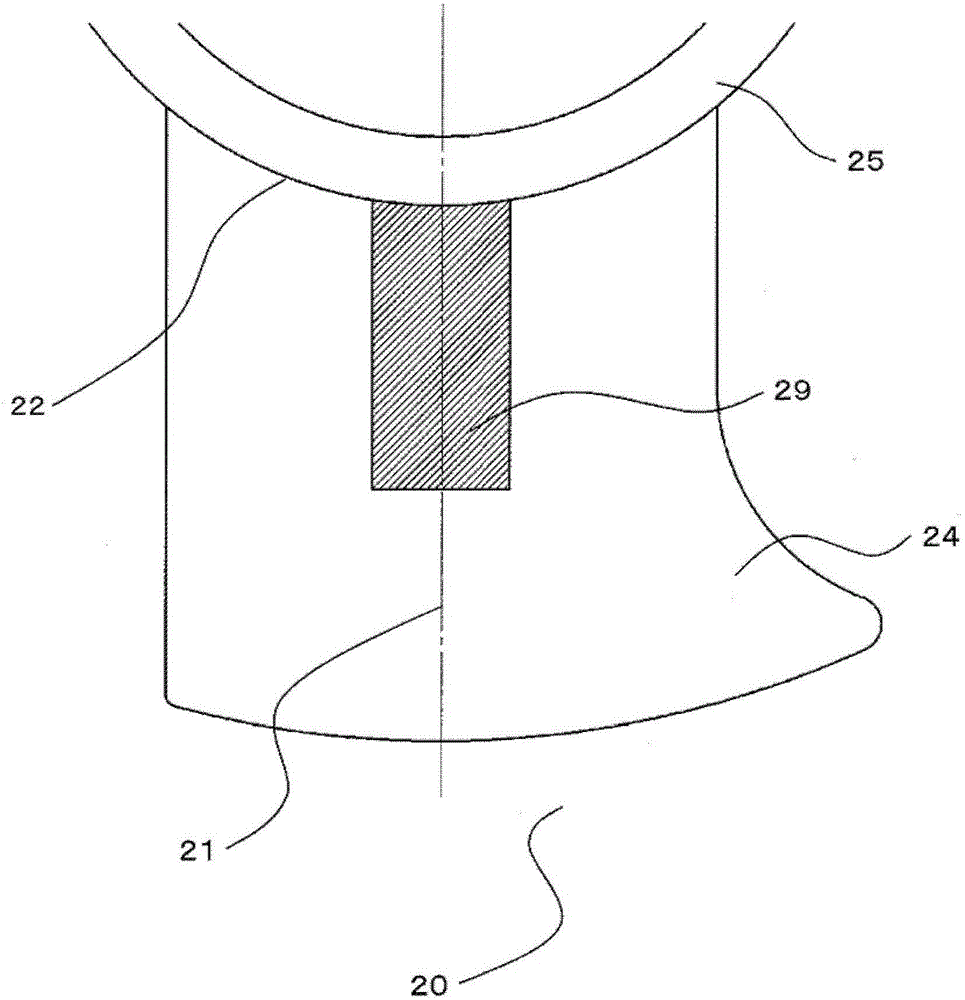

Impeller And Impeller With Axial Flow Fan

InactiveCN106481597AReduce abnormal vibrationImprove reliabilityPump componentsPumpsImpellerEngineering

The invention provides an impeller and an axial flow fan with the impeller capable of obtaining high reliability with less occurrence of abnormal vibration. The impeller comprises blades (4) which are radially provided on the outer peripheral surface of a cup-shaped boss member(5) and an aluminum plate (9) which is partially arranged on the surface of the blade (4).

Owner:HITACHI IND EQUIP SYST CO LTD

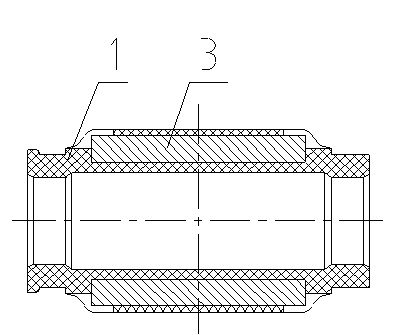

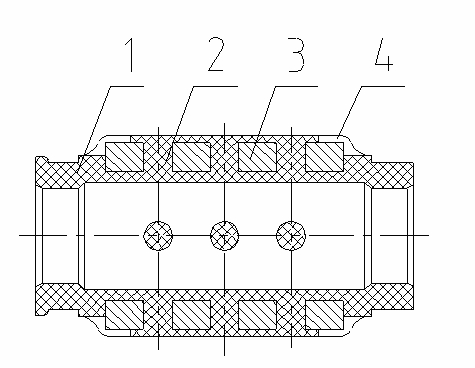

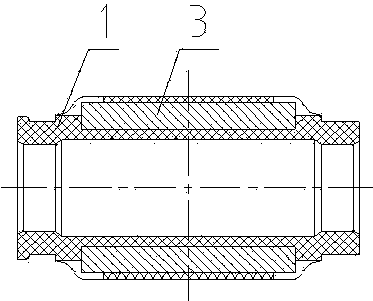

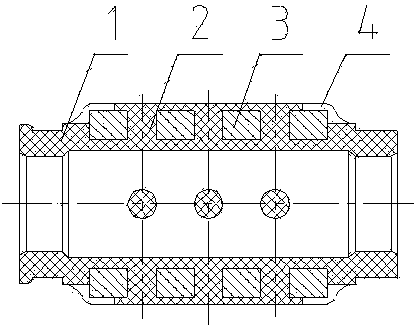

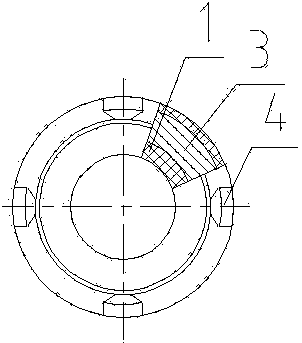

Damper for automobile transmission shafts

A damper for automobile transmission shafts comprises a damping body and an inner ring in the damping body; and the inner ring is provided with cavities in which rubber is filled. The damper ensures that the rubber is firmly integrated with the inner ring, so that the inner ring is prevented from being separated from the rubber layer due to the failure of adhesive or the unreliable adhesion of the rubber layer, and thereby the damper can effectively reduce the abnormal vibration of an automobile transmission shaft. The structure of the damper is simple and compact, integrated and standardized design and production are convenient, and the mounting space can be reduced. When the damper is produced, in the process of vulcanization, adhesive does not need to be applied, sand blasting is not needed, consequently, the production process is simplified, and the production efficiency is increased; meanwhile, since adhesive does not need to be used, the health of operators is prevented from being harmed, and environment pollution is prevented as well.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

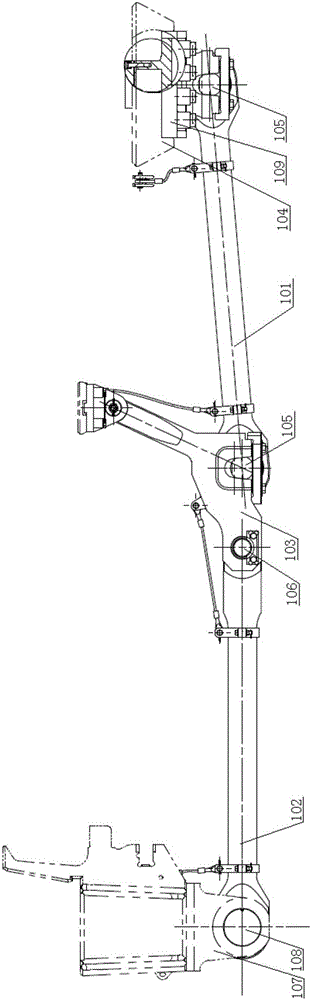

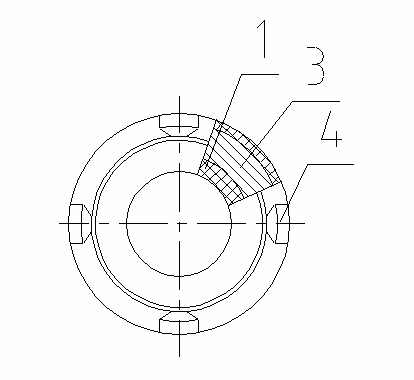

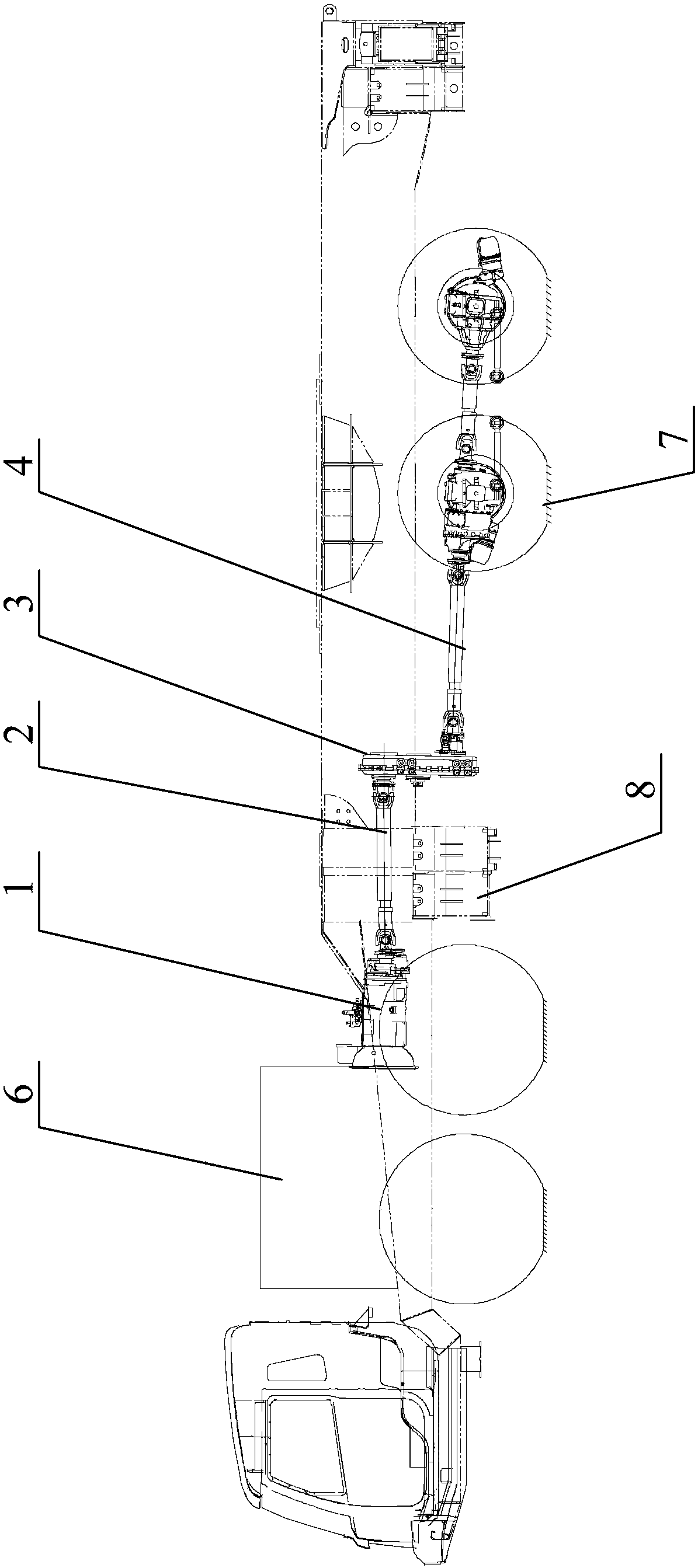

Drive system for automobile crane and automobile crane

InactiveCN108032730AExtended service lifeReduce transmission angleAuxillary drivesDrive shaftEngineering

The invention relates to the technical field of power drive, in particular to a drive system for an automobile crane and the automobile crane. The drive system comprises a gearbox, a first transmission shaft, a transmission case and a second transmission shaft; one end of the first transmission shaft is connected with the gearbox, and the other end of the first transmission shaft is connected withan input shaft of the transmission case; the first transmission shaft is parallel to an input shaft of the transmission case; one end of the second transmission shaft is connected with an output shaft of the transmission case, and the other end of the second transmission shaft is connected with a walking mechanism of the automobile crane. According to the drive system, the output shaft of the gearbox is parallel to the first transmission shaft by arranging the transmission case, and therefore the transmission angle is lowered, the transmission efficiency is improved, abnormal vibration and noise during transmission are lowered, and the service life of the first transmission shaft and the service life of the second transmission shaft are prolonged.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

A kind of shock absorber for automobile transmission shaft

A damper for automobile transmission shafts comprises a damping body and an inner ring in the damping body; and the inner ring is provided with cavities in which rubber is filled. The damper ensures that the rubber is firmly integrated with the inner ring, so that the inner ring is prevented from being separated from the rubber layer due to the failure of adhesive or the unreliable adhesion of the rubber layer, and thereby the damper can effectively reduce the abnormal vibration of an automobile transmission shaft. The structure of the damper is simple and compact, integrated and standardized design and production are convenient, and the mounting space can be reduced. When the damper is produced, in the process of vulcanization, adhesive does not need to be applied, sand blasting is not needed, consequently, the production process is simplified, and the production efficiency is increased; meanwhile, since adhesive does not need to be used, the health of operators is prevented from being harmed, and environment pollution is prevented as well.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Pumps and Washing Equipment

ActiveCN110529386BReduce the effect of concentricityEasy to controlPump componentsPump installationsDrive shaftControl theory

The present invention provides a pump and washing equipment. The pump includes a driving device. The driving device is provided with a driving shaft, a rotor assembly sleeved on the driving shaft, and a stator assembly located on the outer periphery of the rotor assembly. and a plastic connecting piece arranged between the rotor assembly and the drive shaft, the plastic connecting piece is provided with a first wall spaced between the rotor assembly and the drive shaft shaft wall, the At least one cavity extending along the axial direction of the drive shaft is provided in the first wall, one end of the cavity is sealed, and the other end of the cavity is provided with an opening. Such setting reduces the weight of the rotor assembly, reduces the moment of inertia of the rotor assembly, reduces the influence on the concentricity of the rotor assembly, and reduces the distance between the rotor assembly and the drive shaft. The generated noise and abnormal vibration enable the rotor assembly to be more precisely controlled.

Owner:SANHUA AWECO APPLIANCE SYST WUHU CO LTD

Method of regulating and controlling air volume of sintering machine by using main ventilation valve and rotating speed in combined mode

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

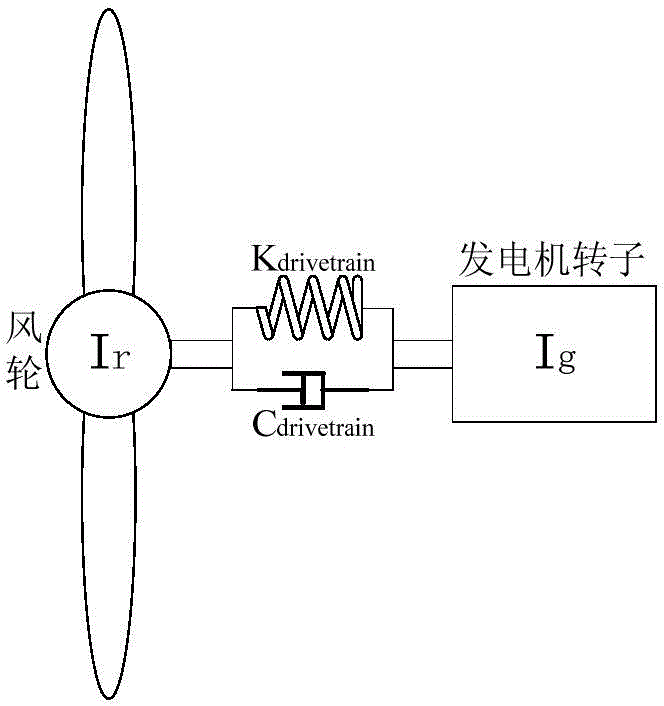

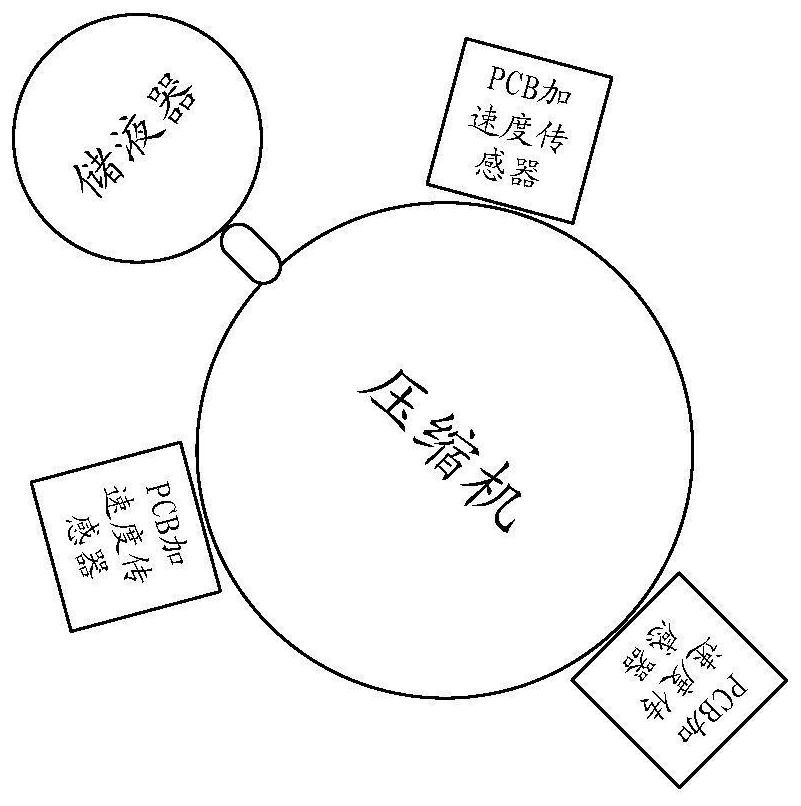

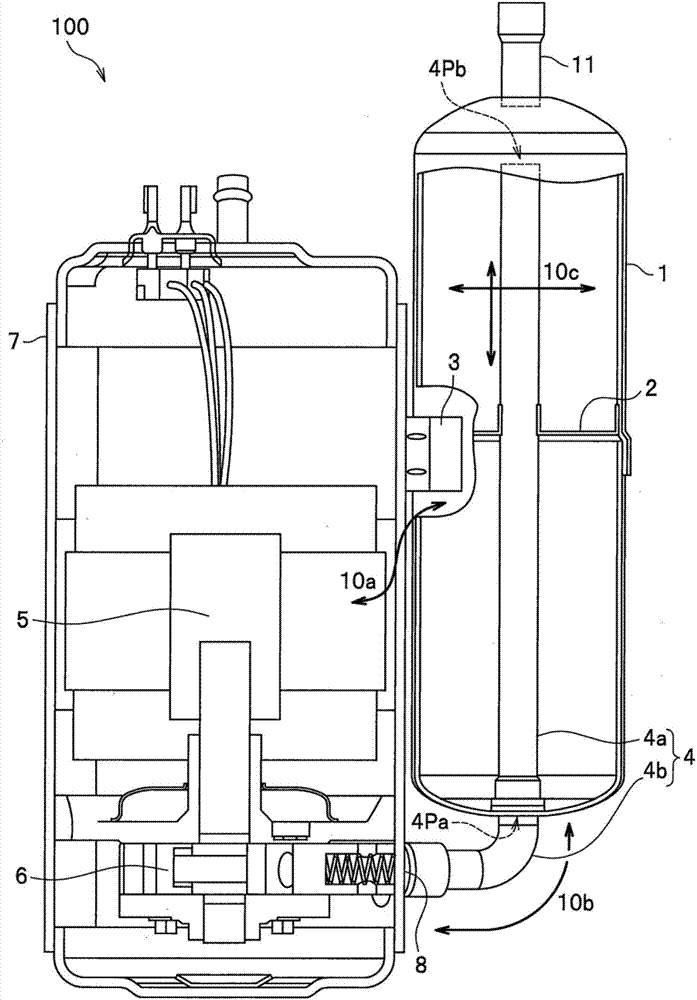

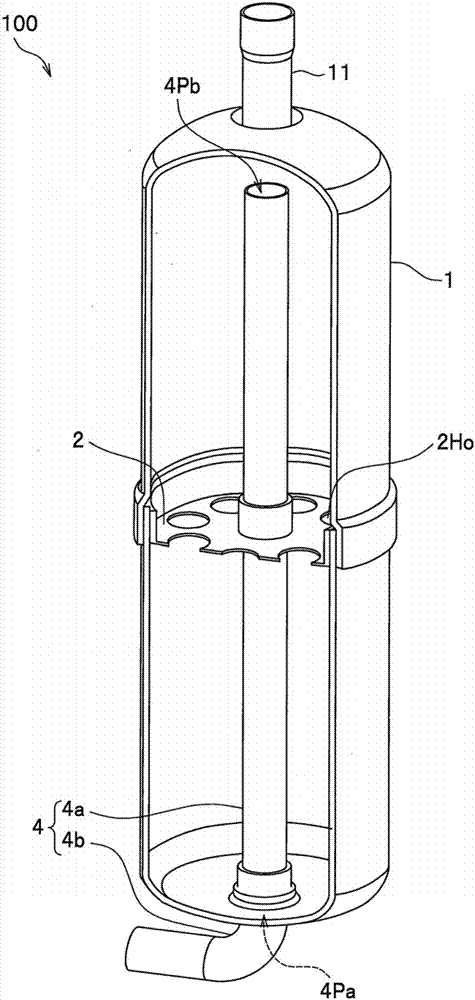

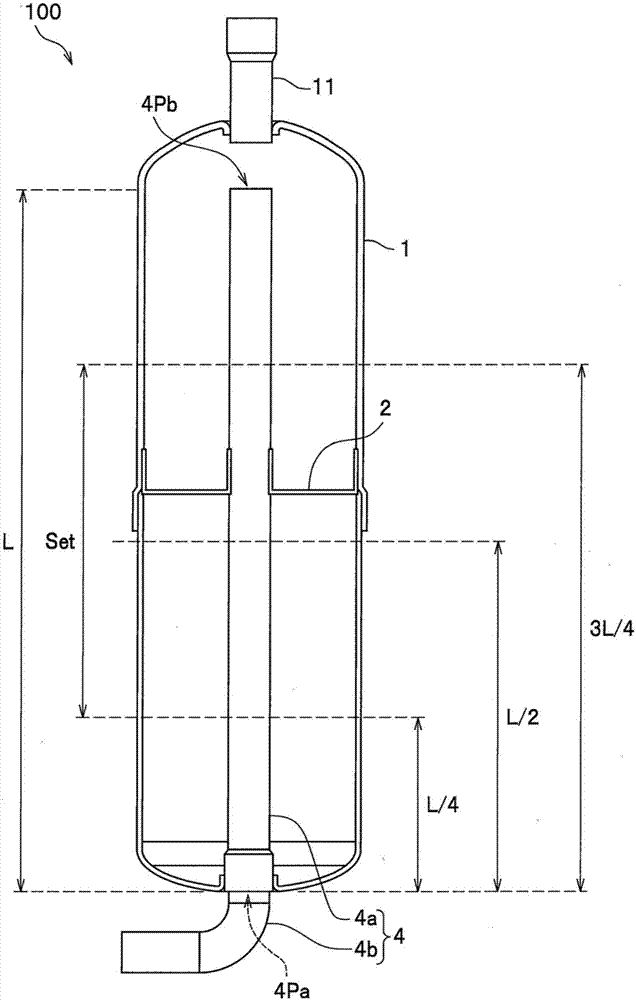

Electric compressor

InactiveCN107956694AReduce abnormal vibrationReduce noiseRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsRefrigerantEngineering

The invention provides an electric compressor which can effectively reduce vibration of a suction tube. The electric compressor is provided with a compressing mechanism part (6) for compressing a refrigerant, an electric mechanism part (5) for driving the compressing mechanism part, an enclosed container (7) where the compressing mechanism part and the electric mechanism part are arranged, a liquid storage device (1) for temporarily storing the refrigerant, a suction tube (4) which supplies the refrigerant from the to a suction inlet (8) of the compressing mechanism part arranged in the enclosed container, and a support part (2) which supports the suction tube in the liquid storage device. A straight part of the suction tube is arranged in the liquid storage device in a manner of extendingin the up-down direction. With respect to the overall length L of the straight part of the suction tube, the support part is arranged on the position away from the connecting side end (4Pa) of the enclosed container and the suction tube for more than L / 4 and less than 3L / 4.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

Pump and washing device

ActiveCN110529386AReduce the effect of concentricityEasy to controlPump componentsPump installationsDrive shaftEngineering

The invention provides a pump and a washing device. The pump comprises a driving device, and the driving device is provided with a driving shaft, a rotor assembly sleeving the driving shaft, a statorassembly located at the periphery of the rotor assembly and a plastic connecting piece arranged between the rotor assembly and the driving shaft. The plastic connecting piece is provided with a firstwall spaced between the rotor assembly and the shaft wall of the driving shaft, at least one cavity extending along the axial direction of the driving shaft is formed in the first wall, one end of thecavity is sealed, and an opening is formed at the other end of the cavity, so that the weight of the rotor assembly is reduced, the rotational inertia of the rotor assembly is reduced, the influenceon the concentricity of the rotor assembly is reduced, the noise and the abnormal vibration generated between the rotor assembly and the driving shaft are reduced, and the rotor assembly can be controlled more accurately.

Owner:SANHUA AWECO APPLIANCE SYST WUHU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com