Ultrasonically-actuated unit and ultrasonic processing device

A technology of working unit and processing device, applied in medical science, fluid using vibration, surgery, etc., can solve the problem of reduced processing performance at the top processing part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

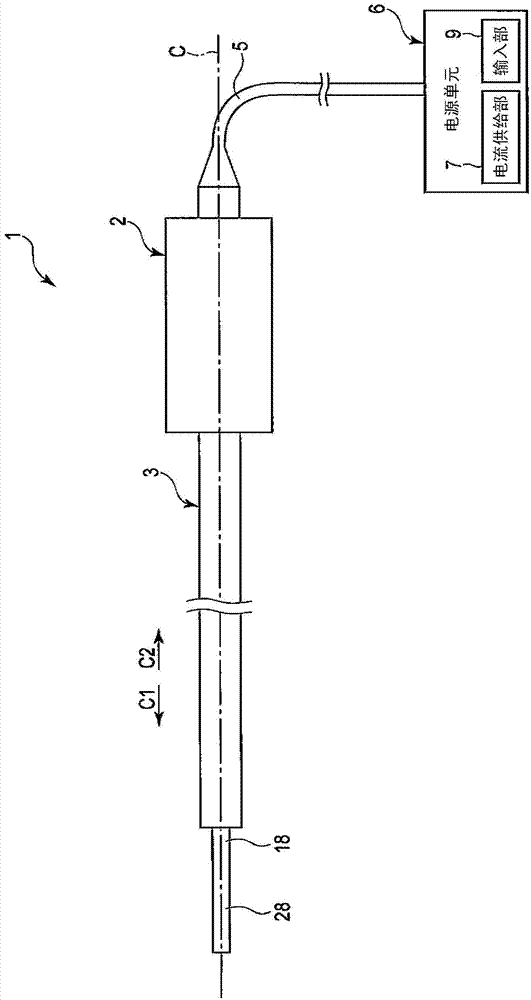

[0028] Reference Figure 1 to Figure 5 The first embodiment of the present invention will be described. figure 1 It is a figure which shows the ultrasonic processing apparatus 1 of this embodiment. Such as figure 1 As shown, the ultrasonic treatment device 1 has a longitudinal axis C. Here, one of two directions parallel to the longitudinal axis C is referred to as the tip direction ( figure 1 The direction of the arrow C1), and set the direction opposite to the tip direction as the proximal direction ( figure 1 The direction of the arrow C2). The ultrasonic processing apparatus 1 includes a vibrator housing 2 and a sheath 3 attached to the distal direction side of the vibrator housing 2. The sheath 3 extends along the length axis C. One end of the cable 5 is connected to the base end of the vibrator housing 2. The other end of the cable 5 is connected to the power supply unit 6. The power supply unit 6 includes a current supply unit 7 and an input unit 9.

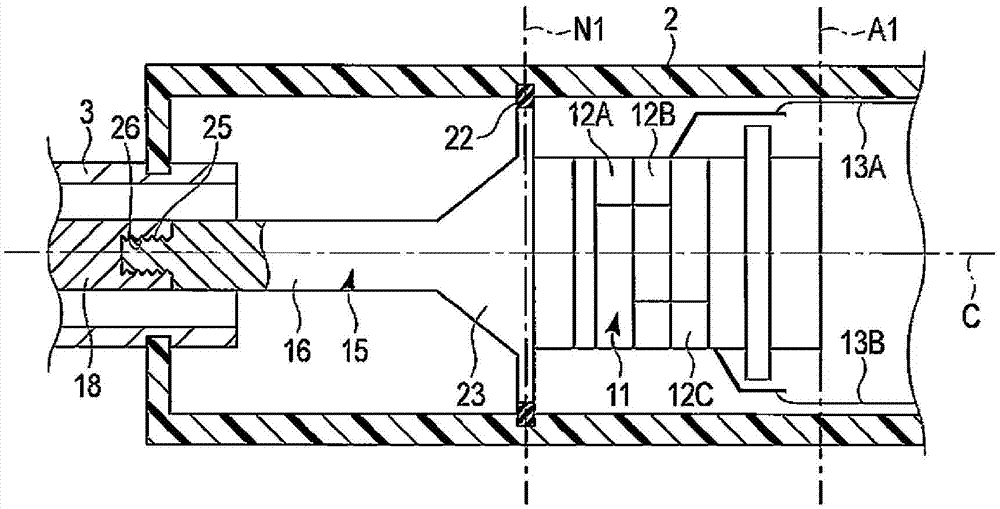

[0029] figure 2 ...

no. 2 Embodiment approach

[0056] Next, refer to Figure 8 The second embodiment of the present invention will be described. The second embodiment is formed by modifying the structure of the first embodiment as follows. In addition, the same reference numerals are given to the same parts as in the first embodiment, and the description thereof is omitted.

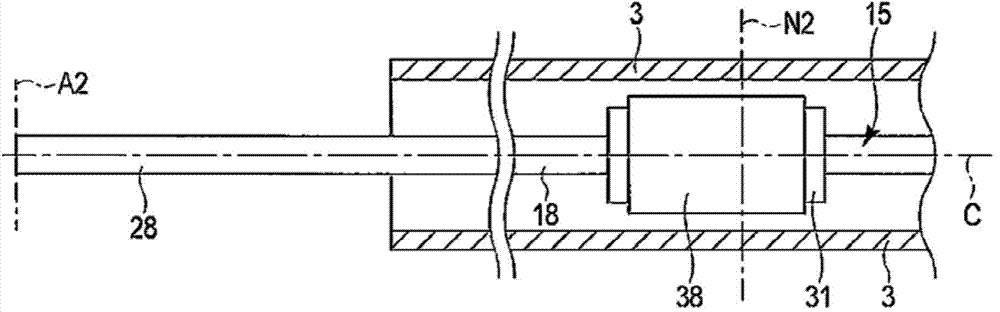

[0057] Figure 8 It is a figure which shows the internal structure of the sheath 3 of this embodiment. Such as Figure 8 As shown, in this embodiment, similar to the first embodiment, the node position N2 of the longitudinal vibration of the relay unit 32 at the reference frequency f0 is connected to the probe 18 of the ultrasonic wave transmission unit 15. Furthermore, a vibration absorbing part 38 is attached to the non-contact vibration part 31. That is, the non-contact vibration part 31 and the vibration absorption part 38 are located between the probe 18 and the sheath 3 as a distal-side transmission member in the radial direction.

[0058] However...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com