Electric compressor

A technology of electric compressors and compression mechanisms, which is applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc., can solve the problems of damage to the liquid reservoir, noise, abnormal vibration of the liquid reservoir, etc., and achieve the effect of reducing abnormal vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

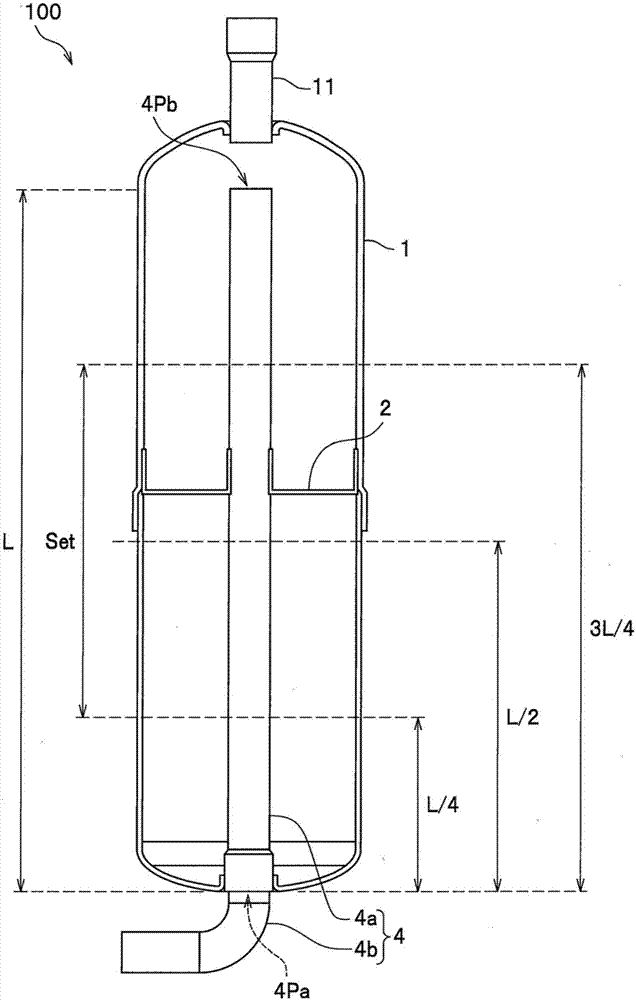

[0031] The present invention also intends to solve the following problems.

[0032] (1) Generally, the electric compressor is expected to reduce abnormal vibration and noise generated in the accumulator. However, since there are many causes of abnormal vibration and noise, it is difficult to efficiently reduce the abnormal vibration and noise generated in the accumulator.

[0033] (2) The accumulator has a dual structure of an outer shell (container body) and a suction pipe arranged inside it in terms of its function and properties. In addition, the sources of vibration that vibrate the outer shell of the accumulator (container body) and the suction pipe inside are located at two places, the motor mechanism unit and the compression mechanism unit built in the airtight container. Furthermore, the frequency band of the vibration component generated in the motor mechanism part is different from the frequency band of the vibration component generated in the compression mechanism ...

Embodiment approach 1

[0037]

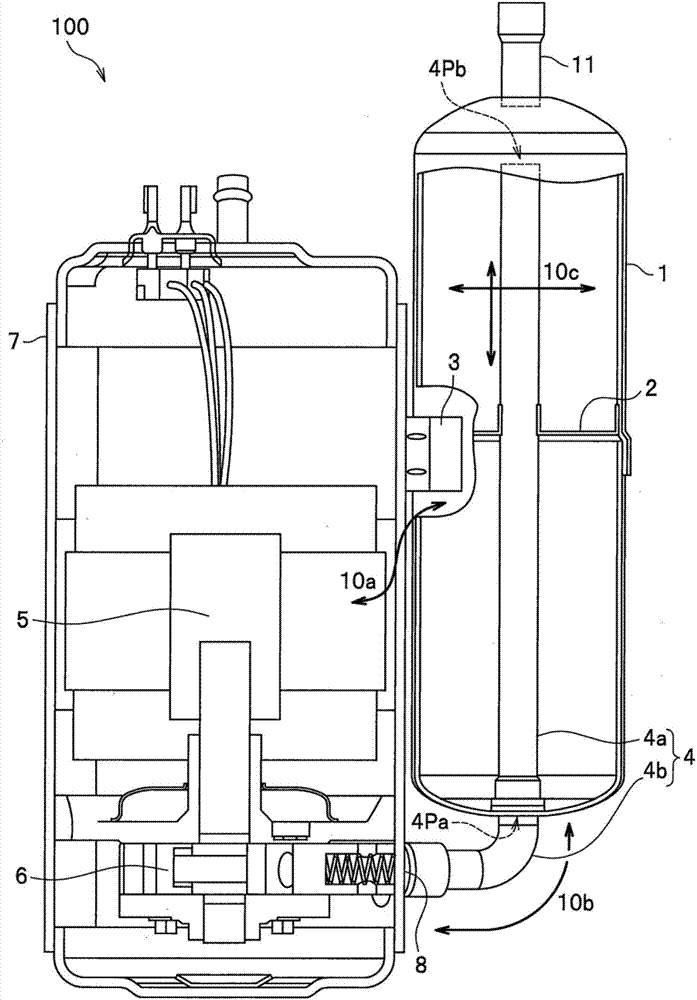

[0038] Below, refer to Figure 1 to Figure 3 , the configuration of electric compressor 100 according to Embodiment 1 will be described. Here, the electric compressor 100 will be described assuming that it is configured as a hermetic vertical rotary compressor. However, the electric compressor 100 may have a structure other than a hermetic vertical rotary compressor.

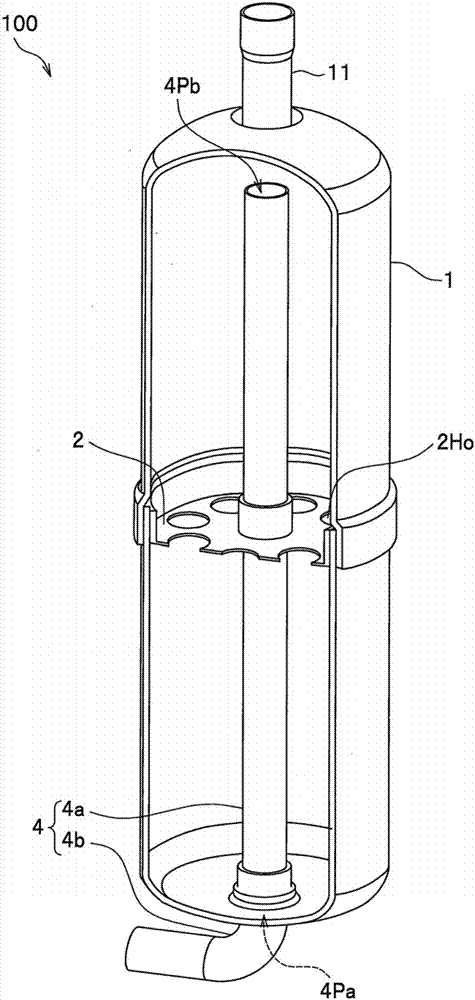

[0039] figure 1 It is a cross-sectional view showing the structure of electric compressor 100 according to Embodiment 1. figure 2 and image 3 Each is a cross-sectional view showing the structure of the accumulator 1 used in the electric compressor 100 . figure 2 The cross-sectional structure of the accumulator 1 viewed obliquely from above is shown. image 3 The cross-sectional structure of the accumulator 1 seen from the front direction is shown.

[0040] Such as figure 1 As shown, the electric compressor 100 according to Embodiment 1 includes a compression mechanism unit 6 for compressing ...

Embodiment approach 2

[0078] Below, refer to Image 6 and Figure 7 , the configuration of electric compressor 100A according to Embodiment 2 will be described. Image 6 It is a sectional view showing the structure of an electric compressor 100A according to the second embodiment. Figure 7 It is a sectional view showing the structure of the accumulator 1A used in the electric compressor 100A.

[0079] Such as Image 6 and Figure 7 As shown, it is the same as the electric compressor 100 of Embodiment 1 (refer to figure 1 and figure 2 ) compared with the electric compressor 100A of Embodiment 2 in that it has an accumulator 1A instead of the accumulator 1 . The accumulator 1A is an accumulator in which a supporting member 2 and a shielding member 9 are arranged inside. The shielding member 9 prevents liquid refrigerant (liquid refrigerant) from entering the suction pipe 4 . The liquid refrigerant is supplied to the accumulator 1A from a refrigeration cycle (not shown) through a supply pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com